Products and Solutions

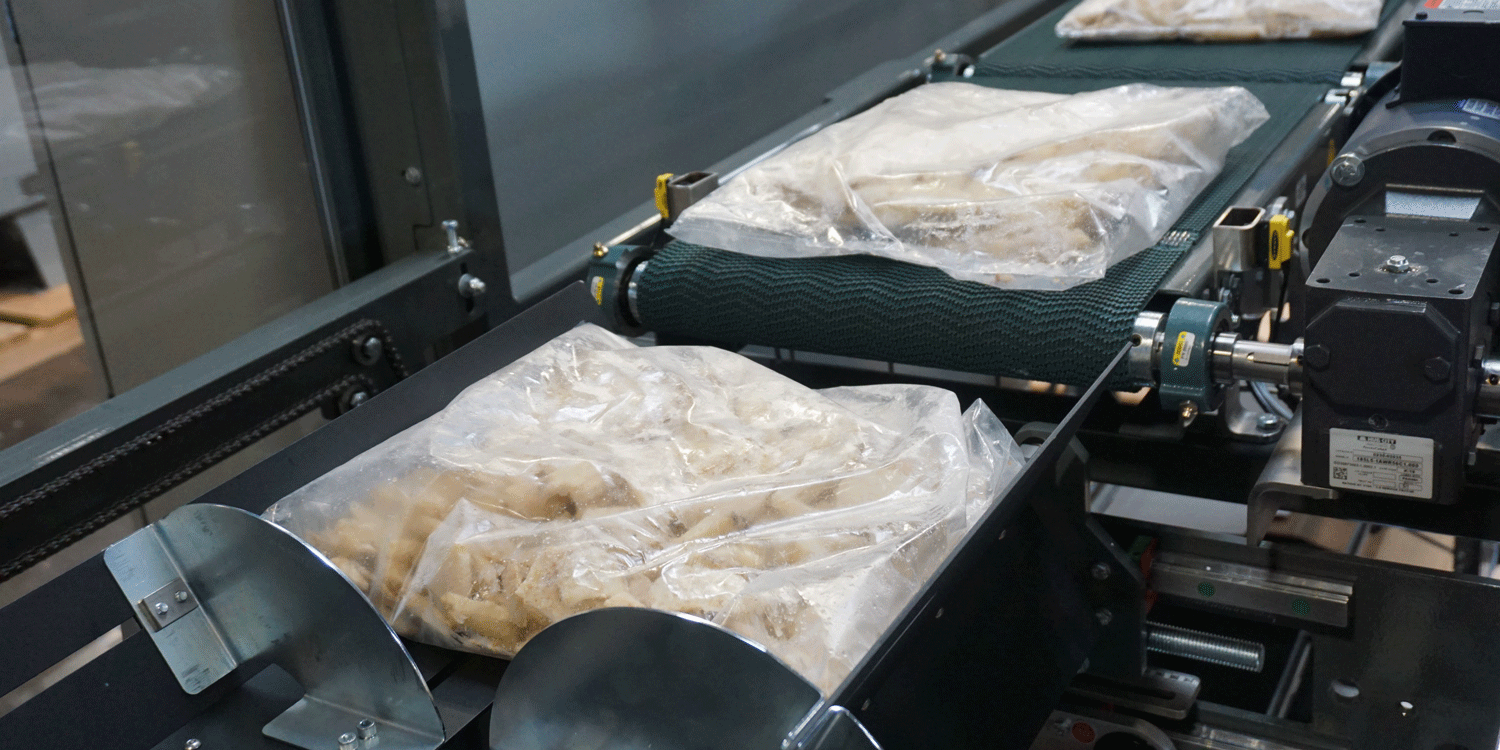

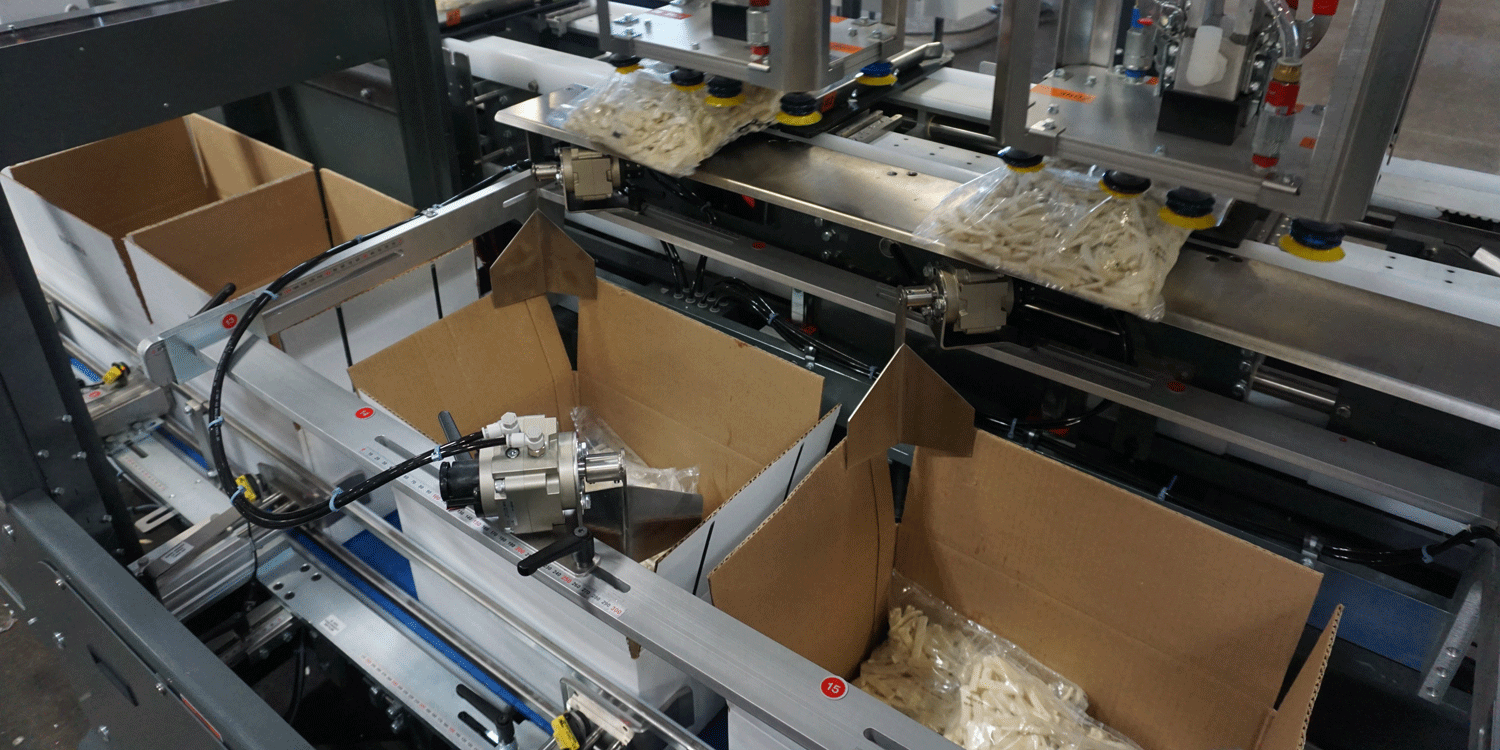

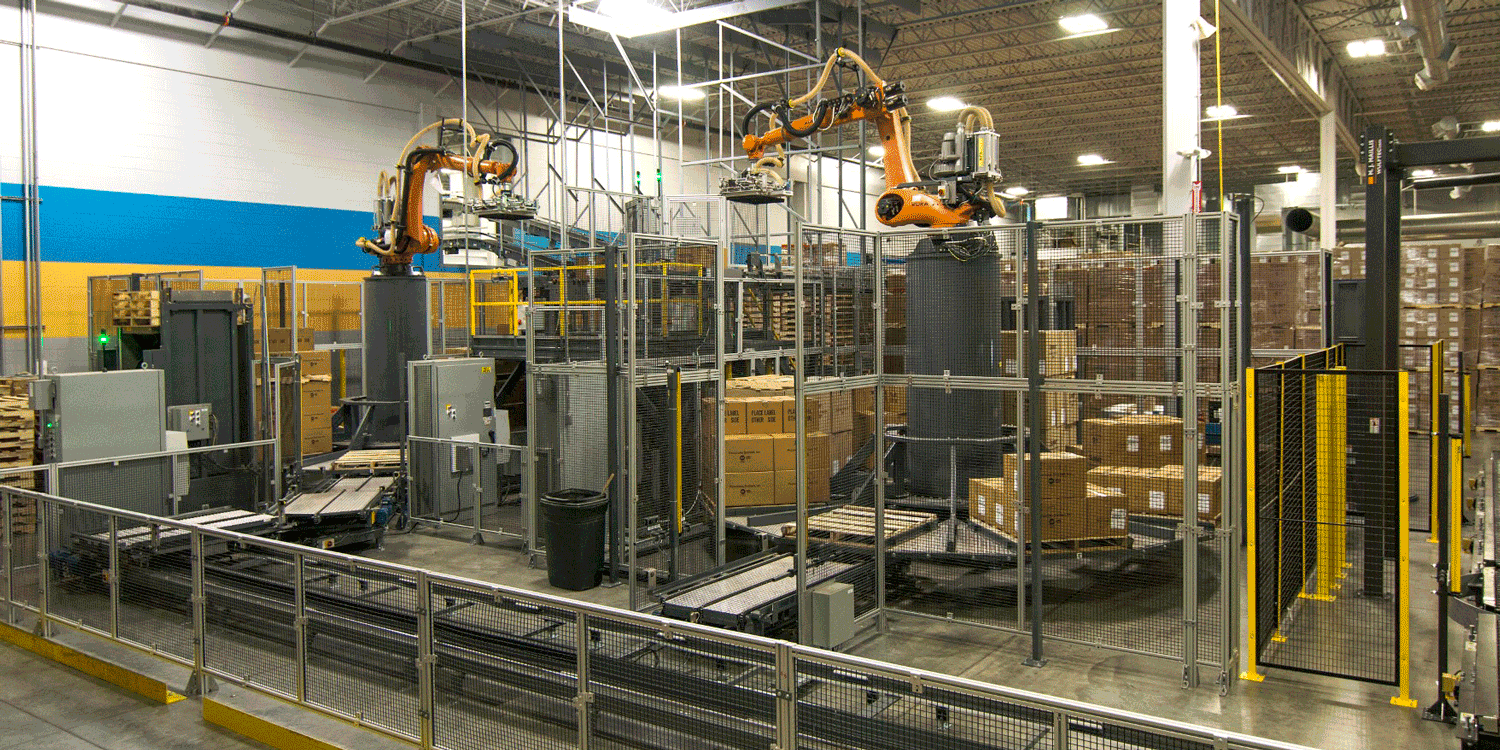

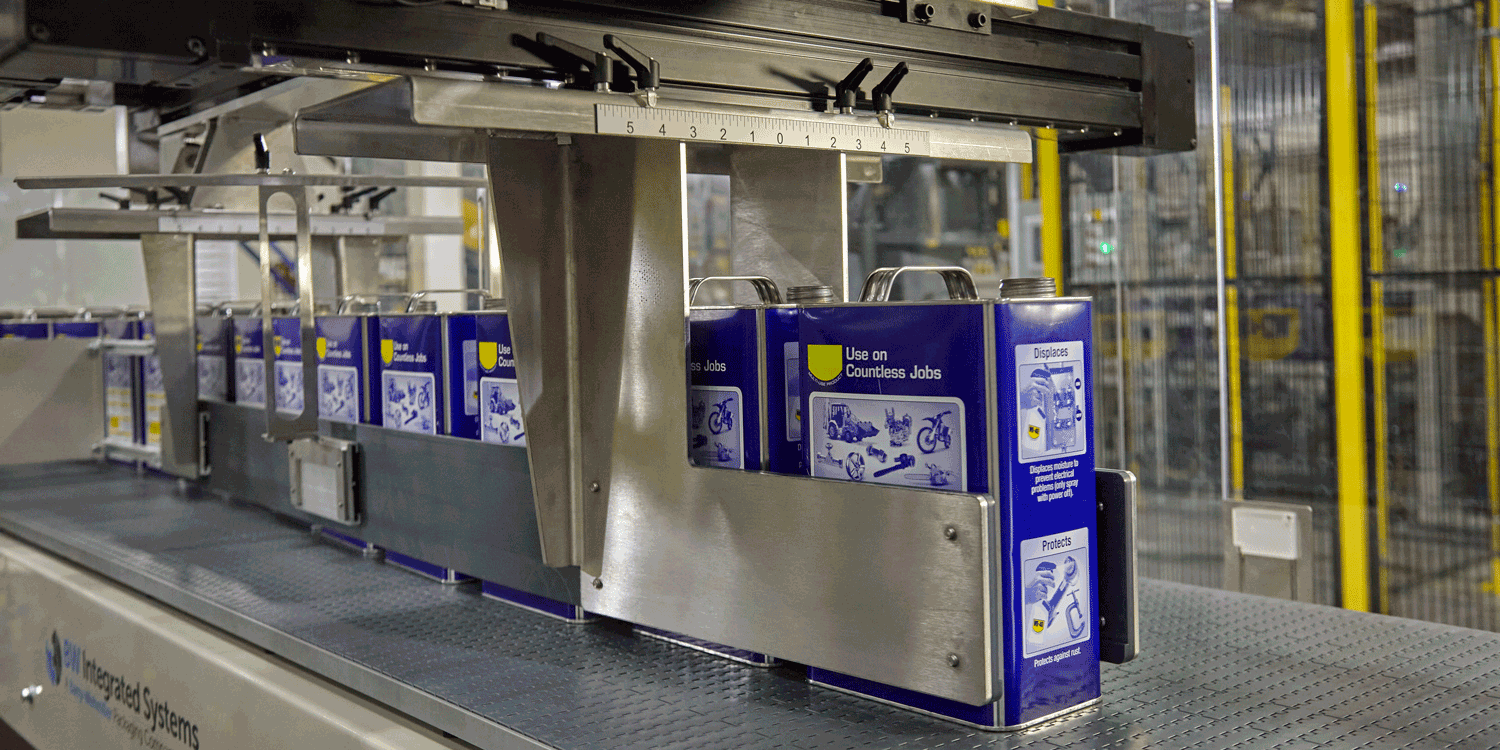

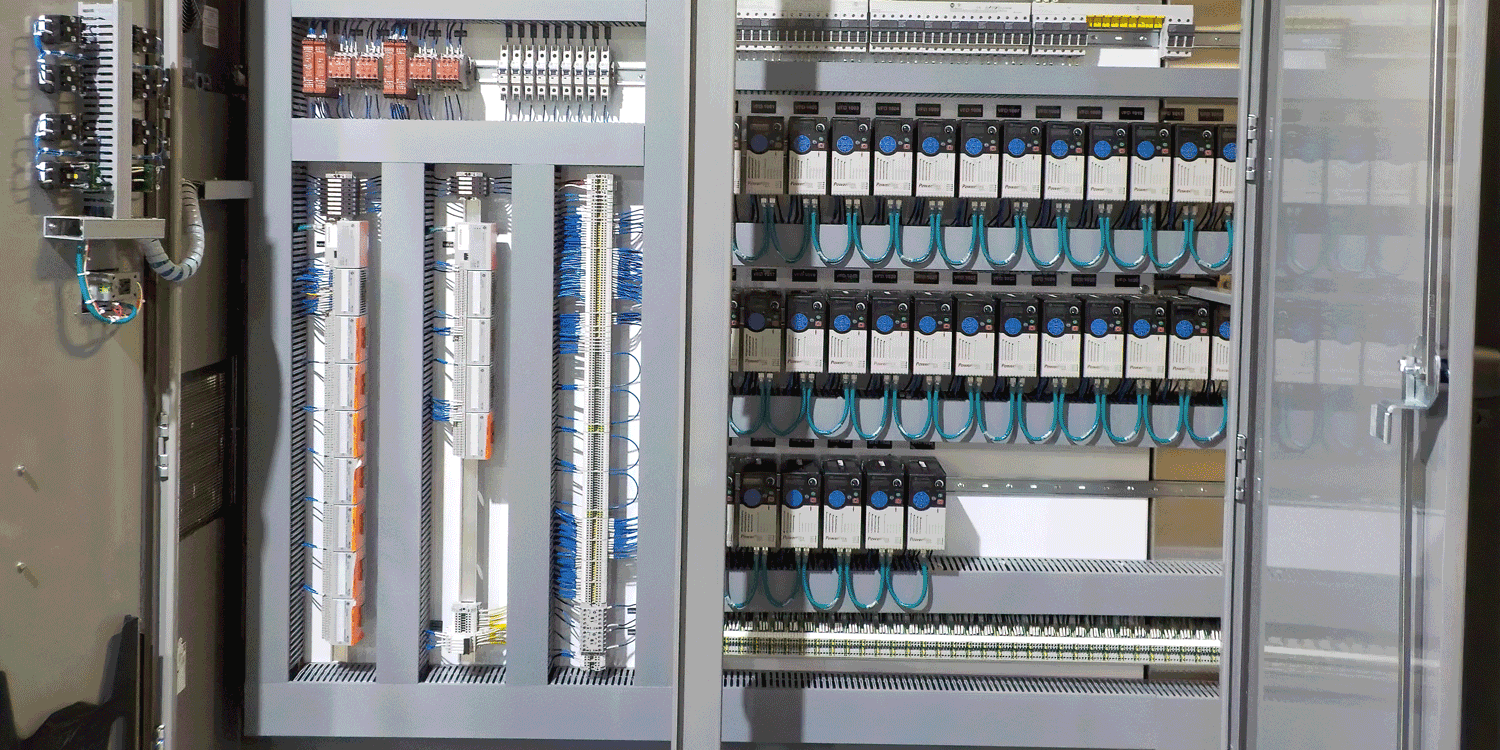

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

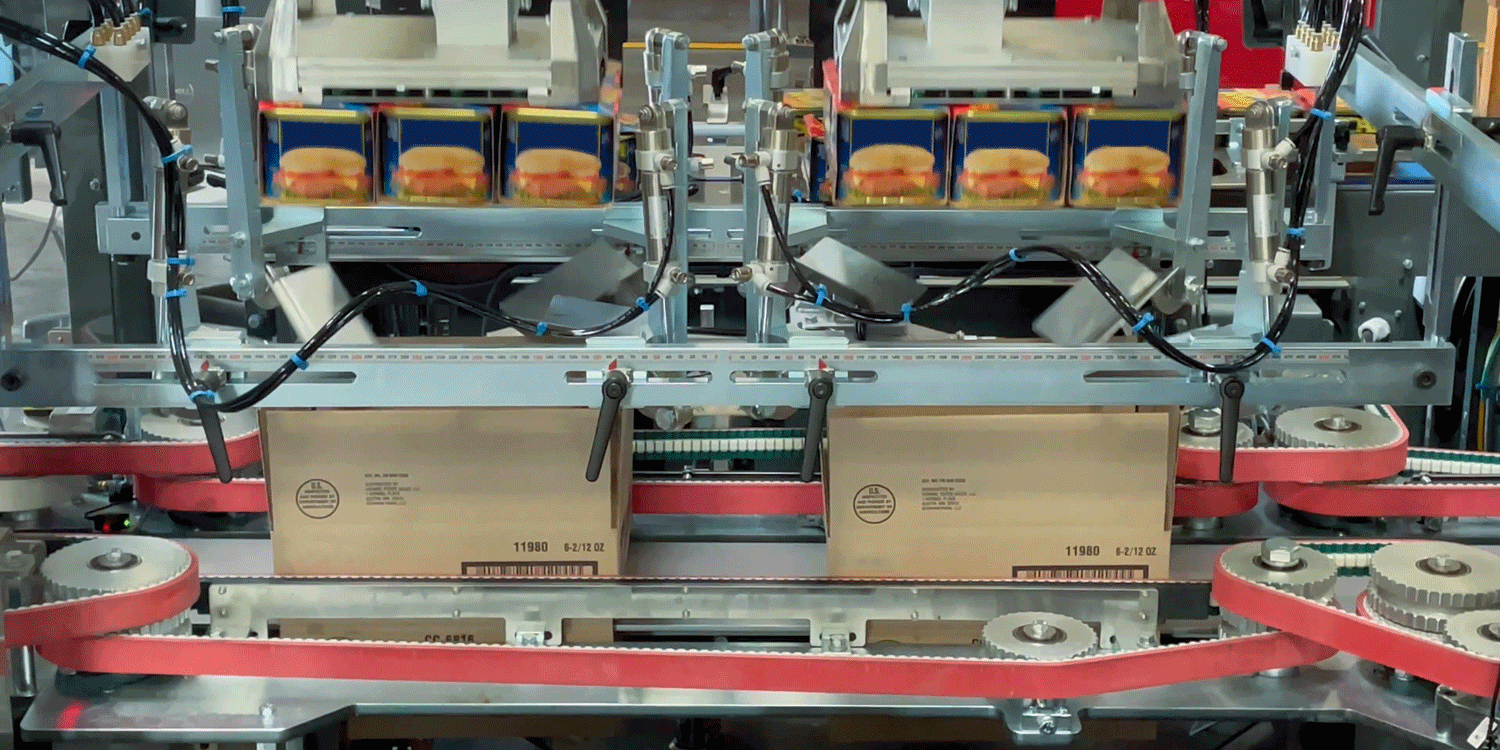

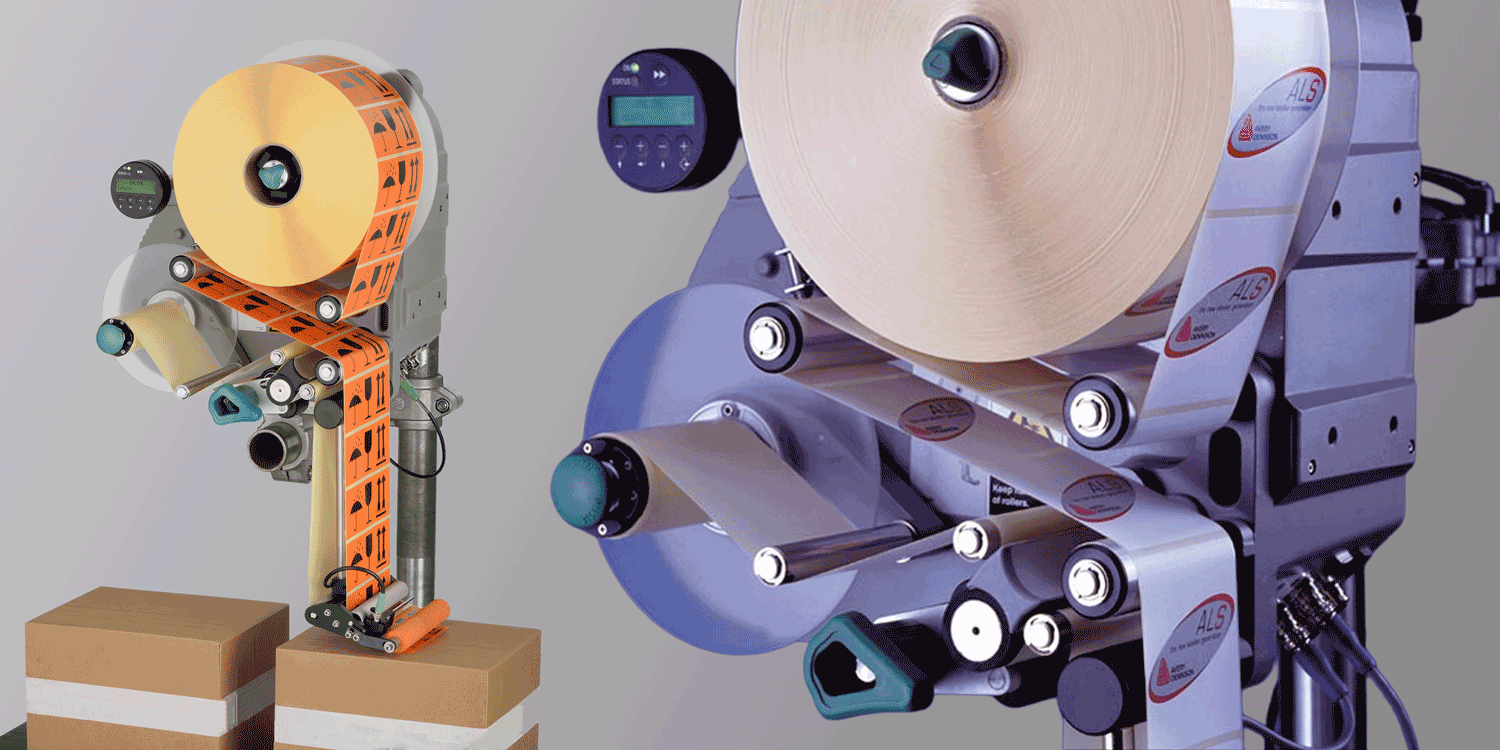

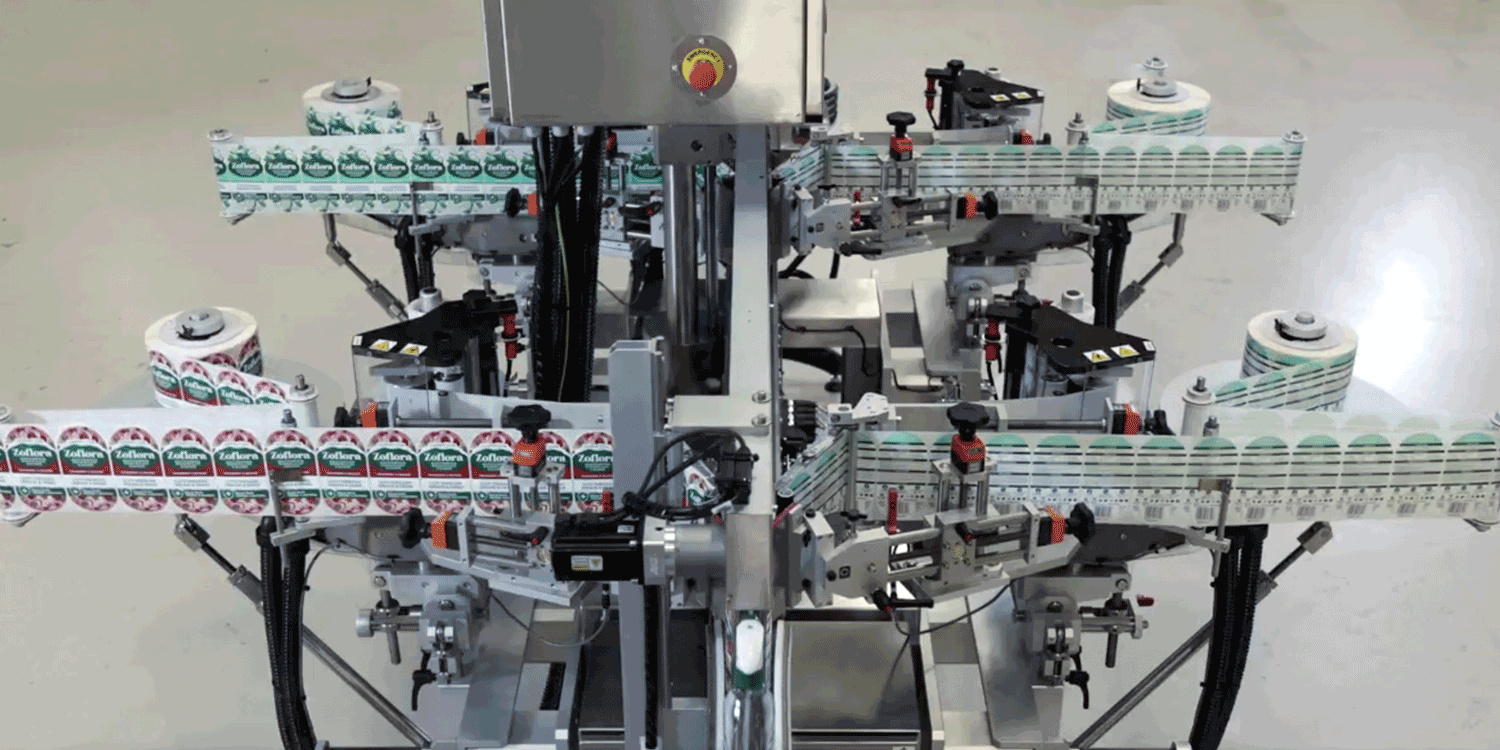

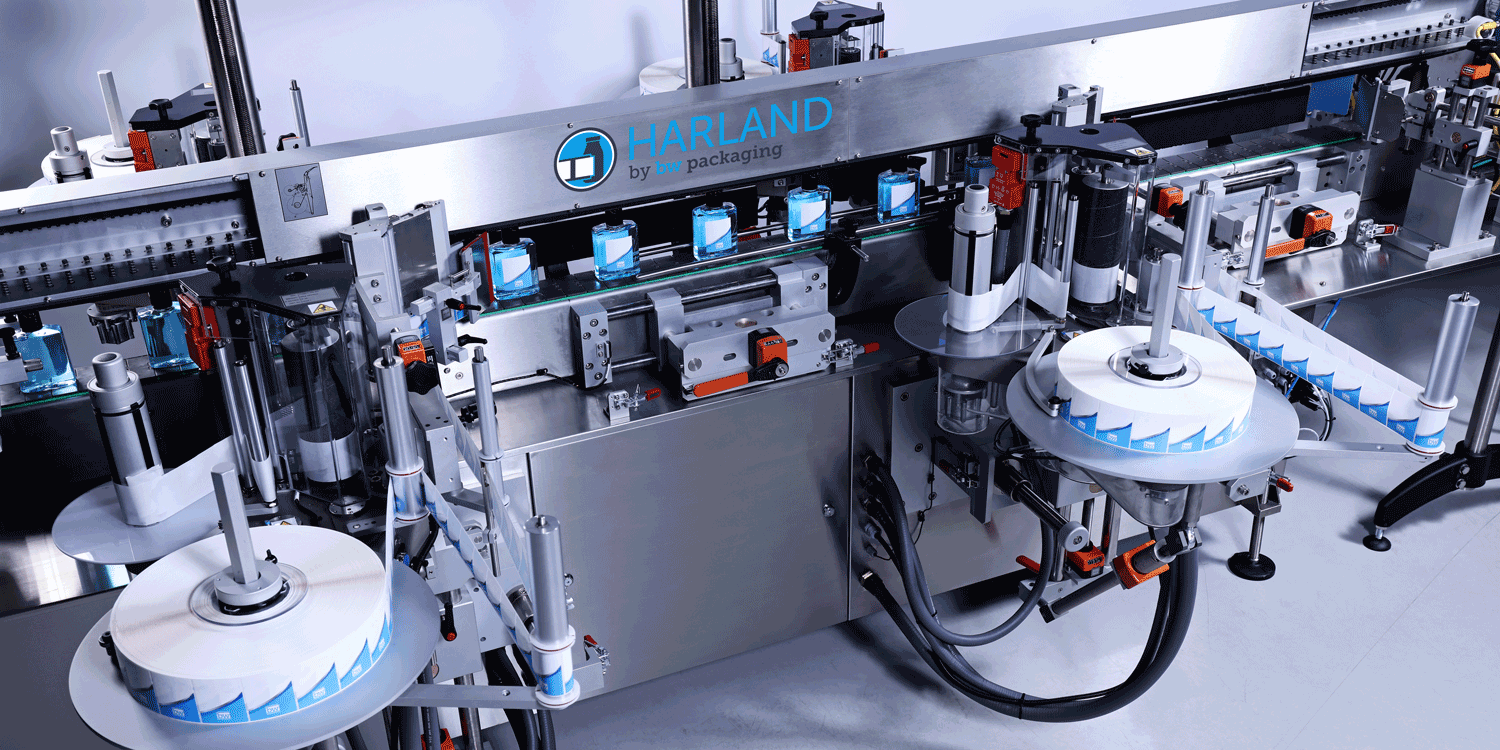

Harland PSL 35 Series Pressure Sensitive Labelers

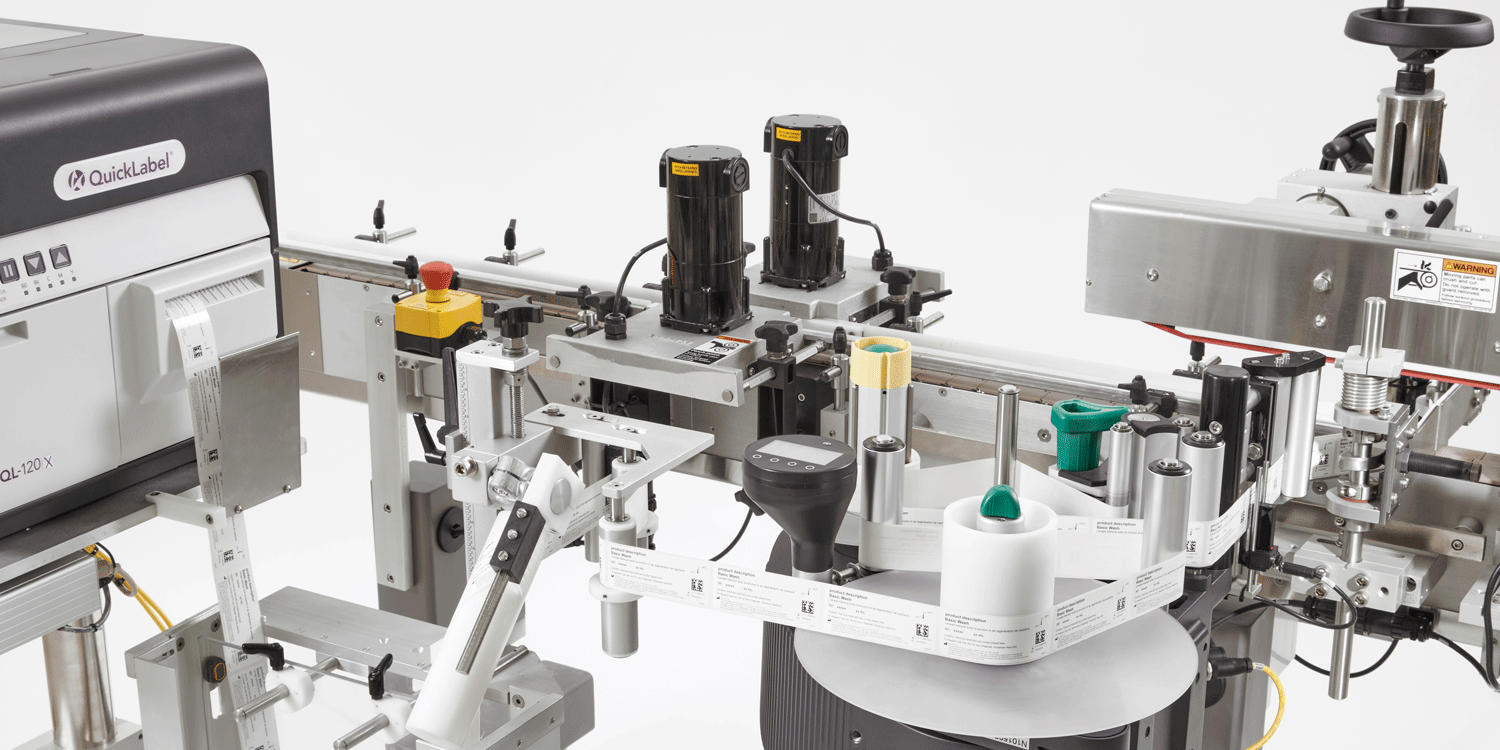

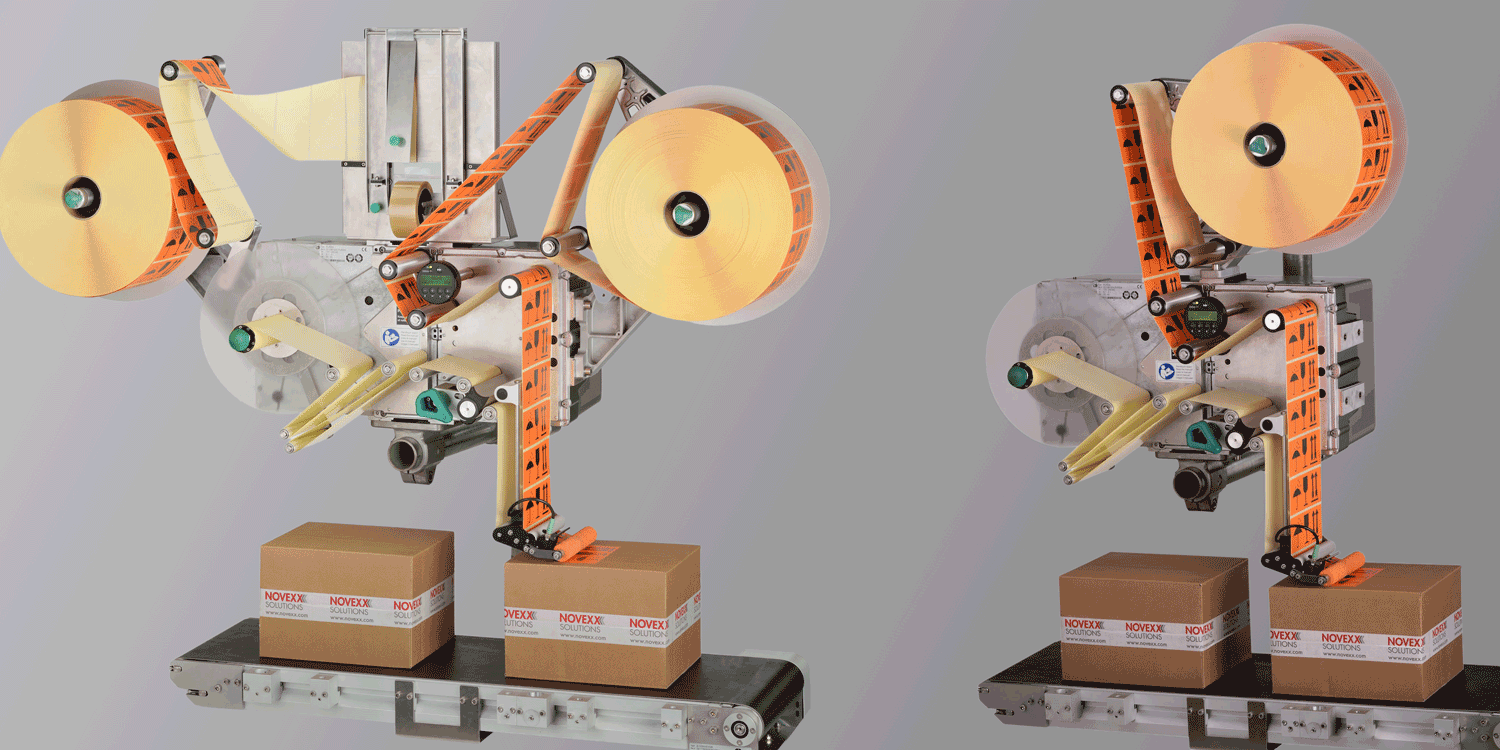

Discover the robust and versatile lineup of our Harland 35 Series Pressure Sensitive labelers, expertly designed for industries that demand high-quality labeling solutions. Built with heavy-duty materials and advanced engineering, our machines ensure years of dependable service and exceptional performance.

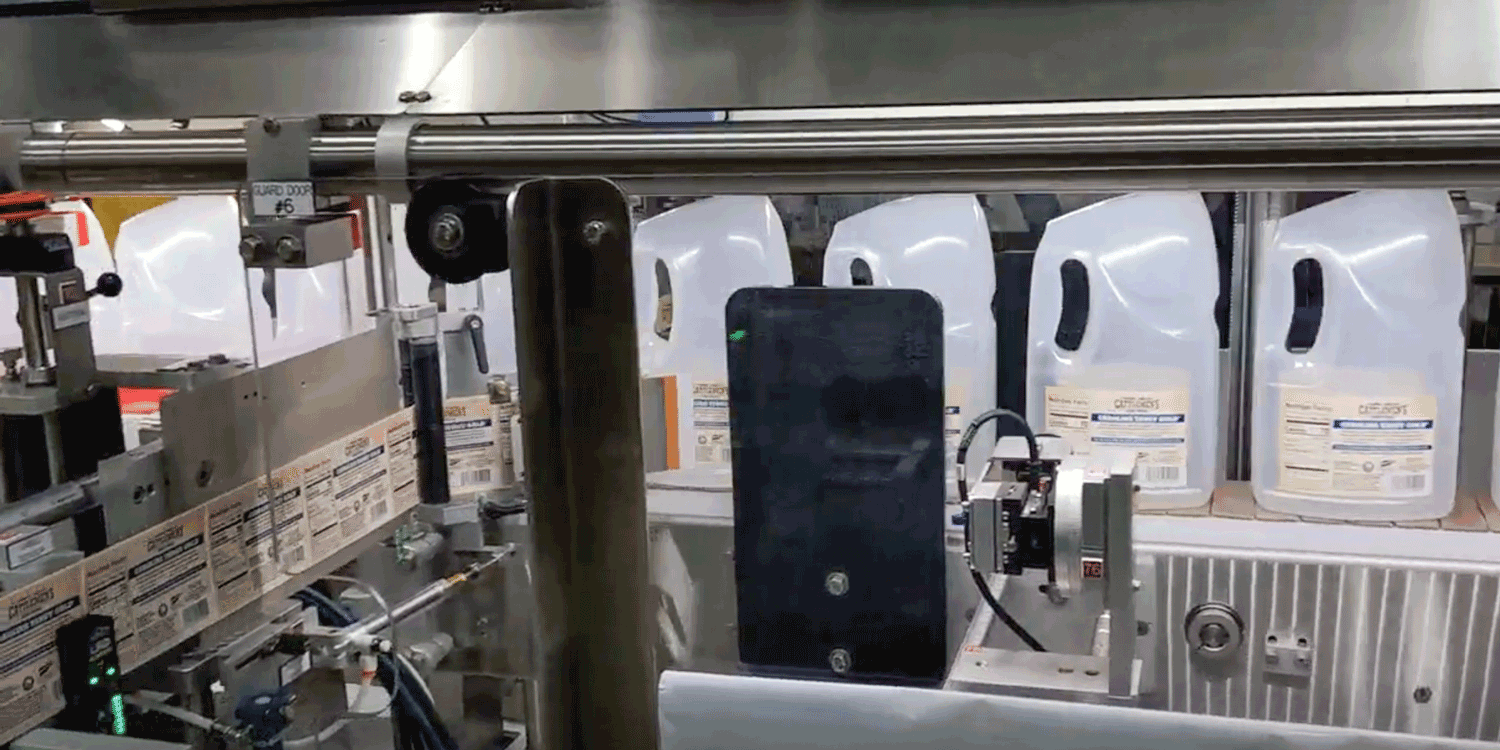

Ideal for copackers and manufacturers, our versatile labeling systems can apply both panel and wraparound labels on an extensive variety of container shapes—including square, rectangular, oval, and cylindrical products. The efficient design enables seamless transitions between applications, significantly reducing downtime without requiring tooling changes.

Key Advantages:

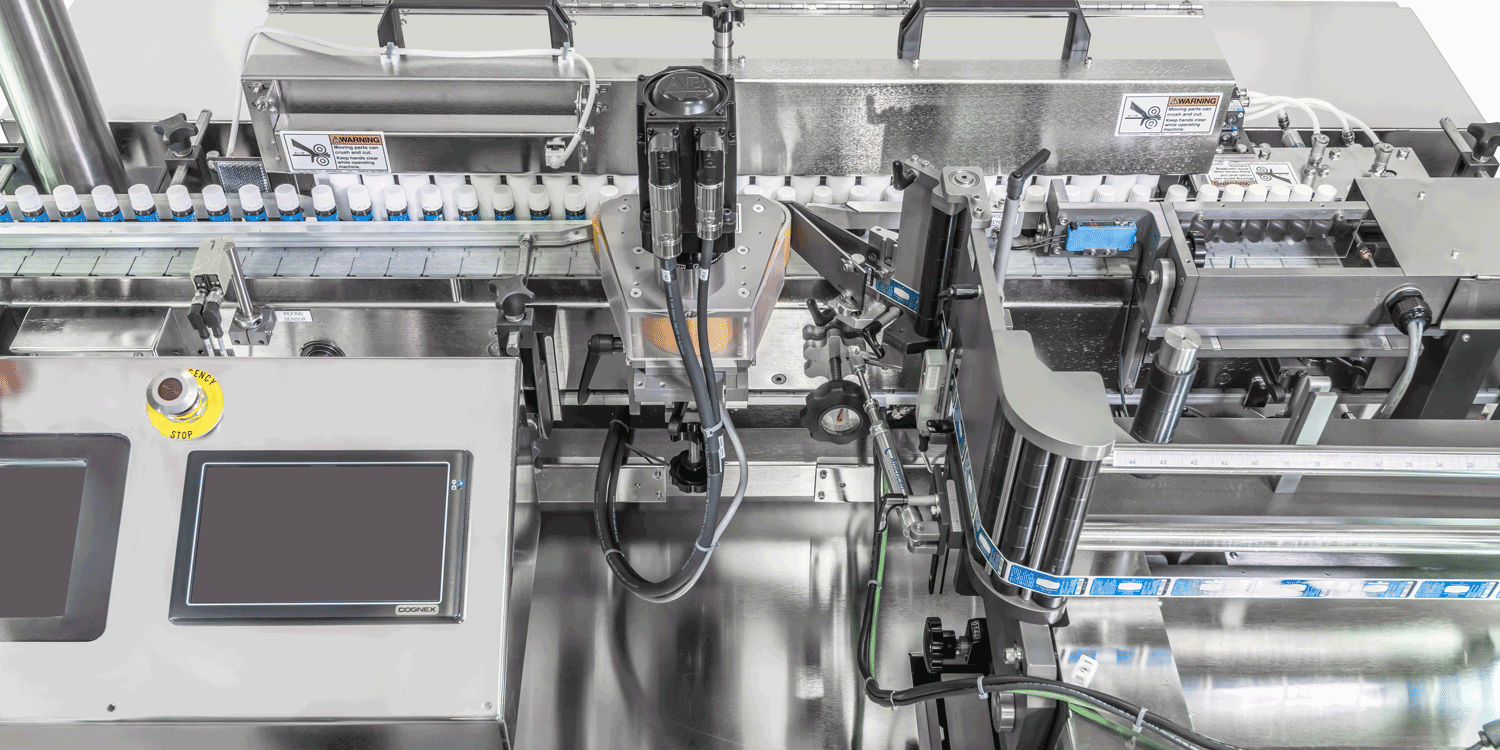

- Durable Construction: Crafted from rugged aluminum and stainless steel, these labelers are engineered for long-lasting durability and optimal performance.

- Adjustable Speed Conveyor: Customize the conveyor speed to meet varying production demands, enhancing both productivity and efficiency.

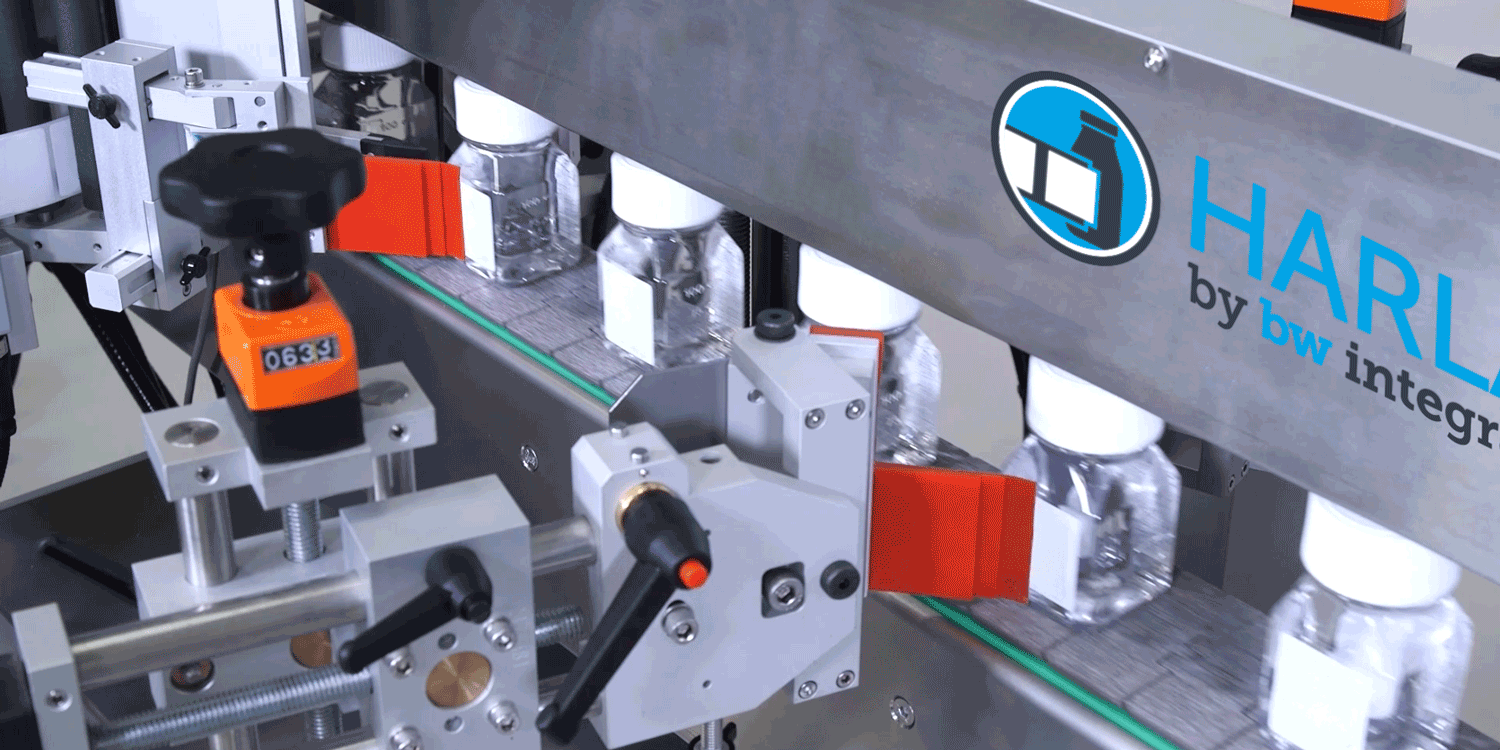

- User-Friendly Adjustments: Enjoy quick, tool-free adjustments with clear position indicators for fast and repeatable changeovers, thereby minimizing downtime.

- Precise Infeed Systems: Various infeed options enable exact product spacing, guaranteeing consistent label application across a diverse range of products.

- Centrally Driven Wrap-Belt: Benefit from constant speed synchronization for reliable wraparound labeling, accommodating different container shapes and sizes.

- Quick-Change Wrap-Belt Assemblies: Easily switch wrap-belt assemblies to label recessed areas or oversized caps, adding versatility to your operations.

- Advanced Applicator Technology: High-torque servo-driven applicators provide ratio offset and speed-following features, ensuring precise label placement on various materials.

- Easy Label Threading: The innovative drop-in labeling web path simplifies setup with a quick-release rewind reel, making maintenance hassle-free.

- Centralized Control Interface: The pivoting touch-screen control panel offers user-friendly access to product and label counters, rate meters, and intuitive operation controls.

- Versatile Product Handling: Our systems efficiently handle a wide range of cylindrical containers for precise wraparound labeling without requiring changeparts.

- Reliable Product Stability: Utilize a simultaneous “dispense and wrap” method for enhanced product stability, especially with longer wraparound labels.

- Maintenance-Friendly Design: Designed for ease of use, our labeling solutions include adjustable leveling feet and heavy-duty casters for mobility.

- Configurable Applicators: Select either stepper or servo applicators tailored to meet your specific application needs.

With rugged construction suited for continuous-duty operations and easy changeover capabilities, our labeling solutions offer exceptional value for your production line. Discover how Harland’s advanced technology can transform your labeling process!

Key Features

Technical Data

Available Options

Packaging Styles

Jump to...

Jump to...

- Automotive and Industrial

- Beverage

- Consumer Goods

- Food

- Household

- Personal Care

- Pet Food and Pet Care

- Pharmaceutical

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

3070 Mainway

Burlington ON L7M 3X1

CA -

+1 (905) 336-8880 -

+1 (905) 336-5710 (Customer Service) -

(Field Service)