Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

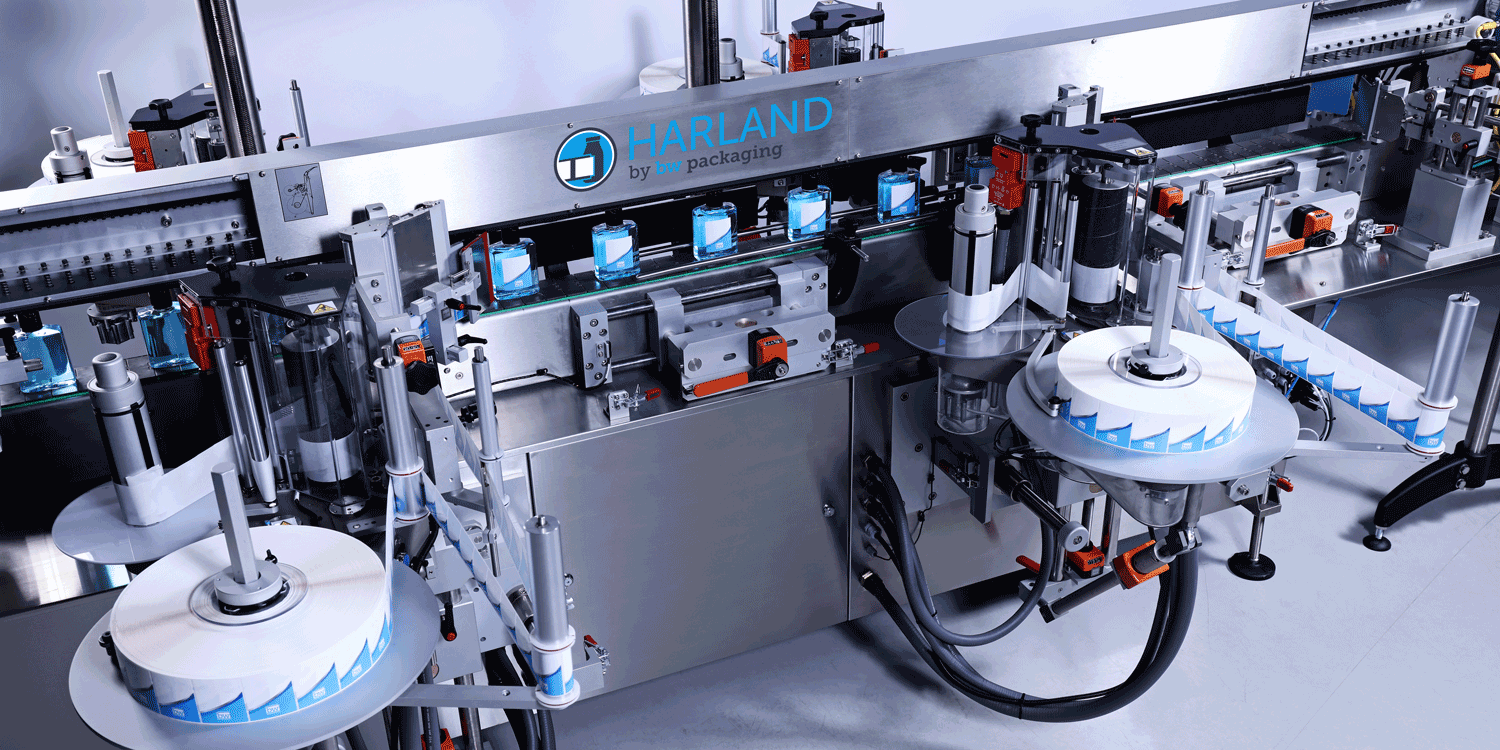

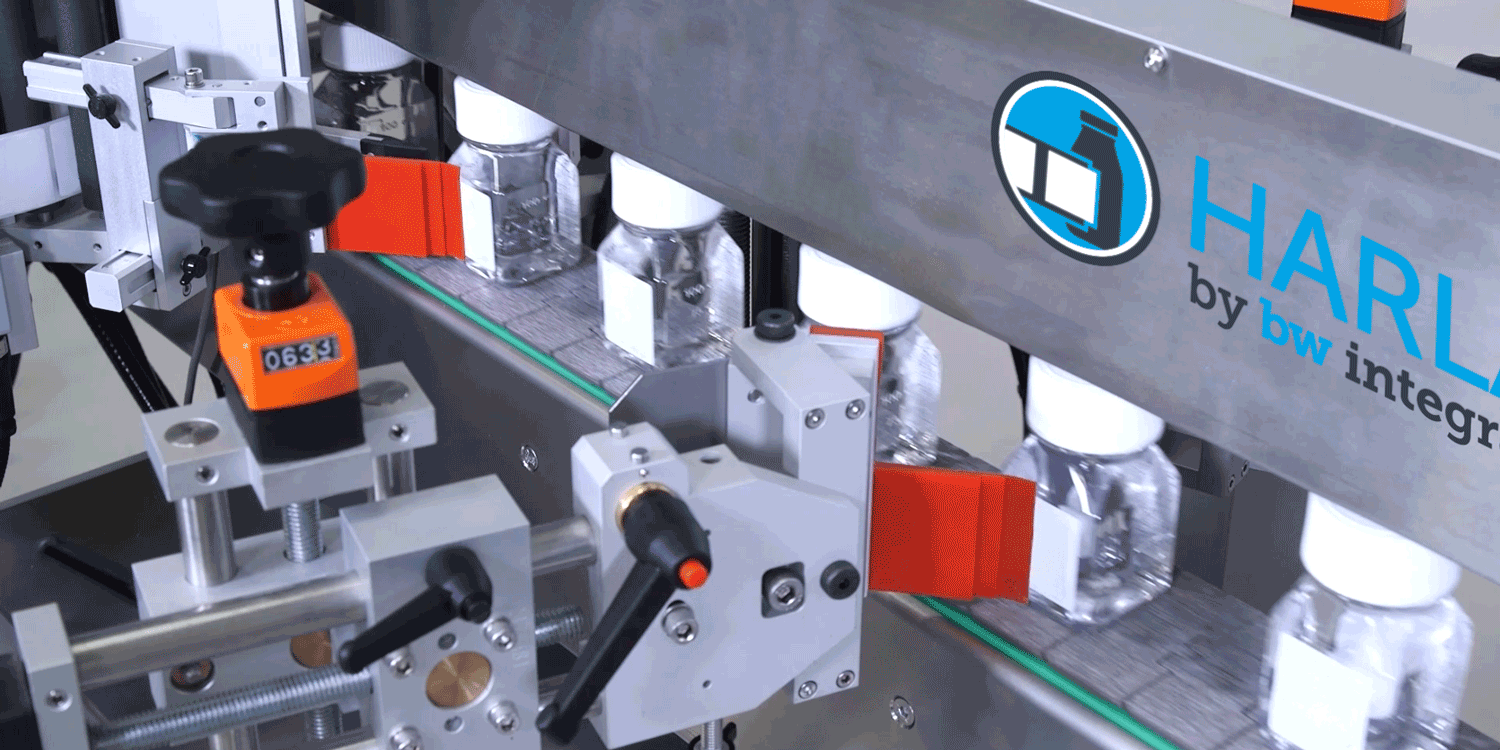

Harland Top and Bottom (TBL 200 Series) Pressure Sensitive Labelers

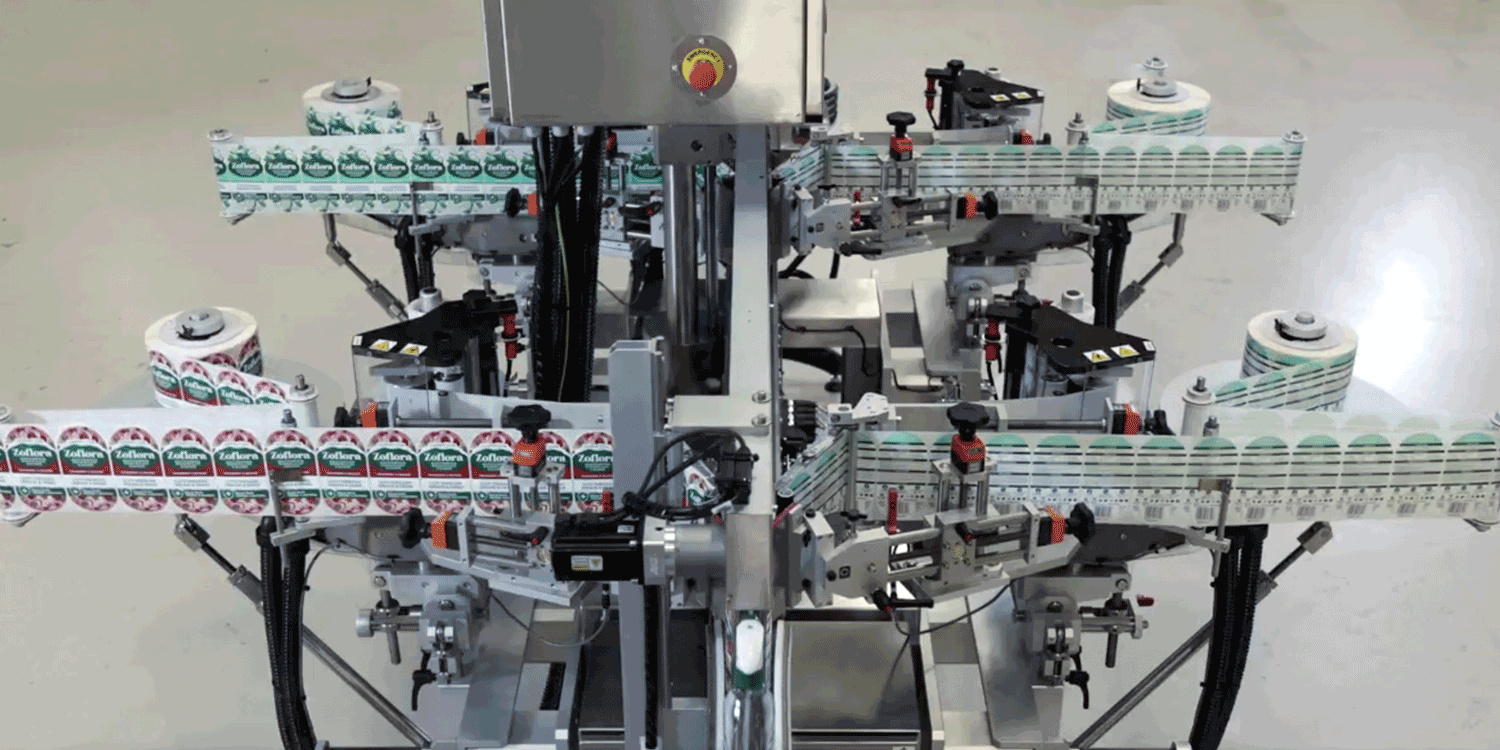

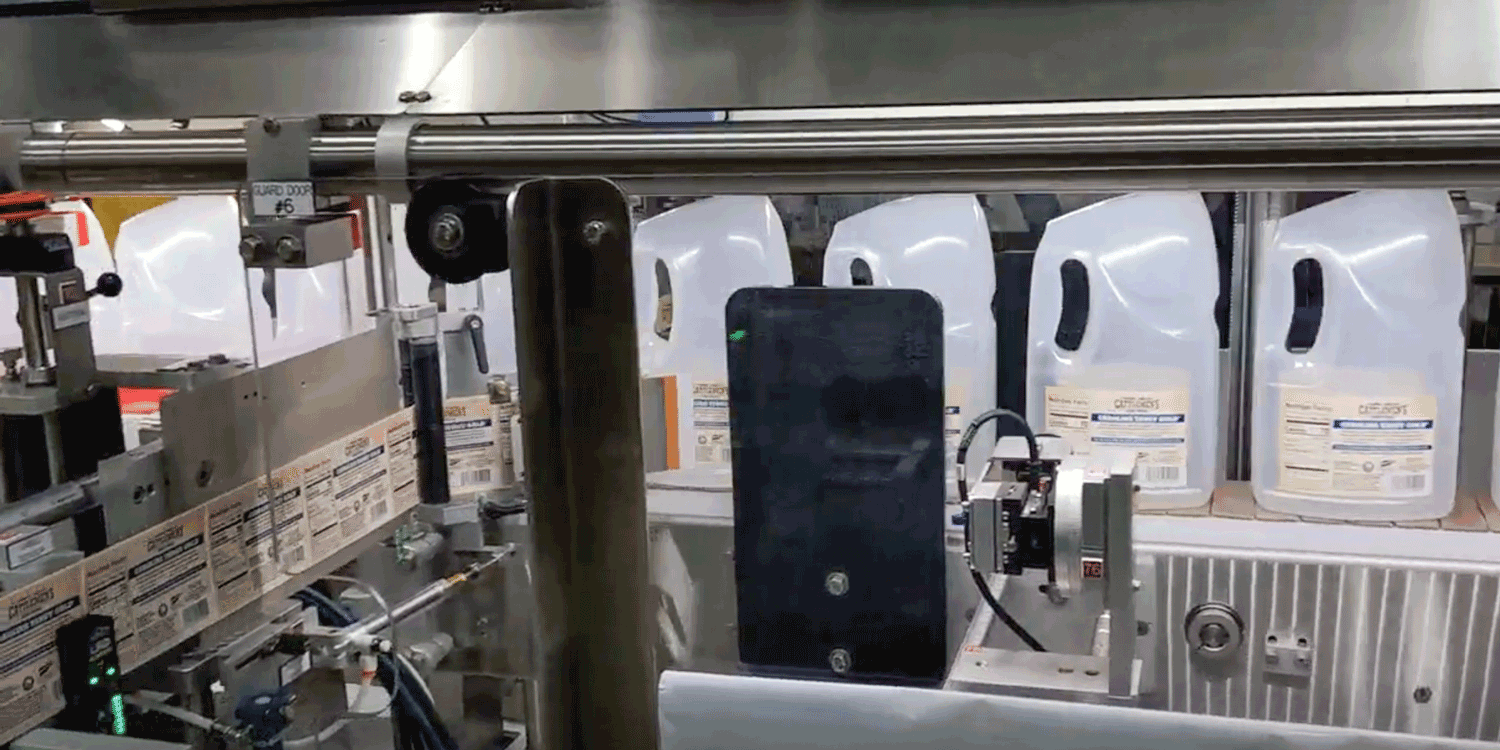

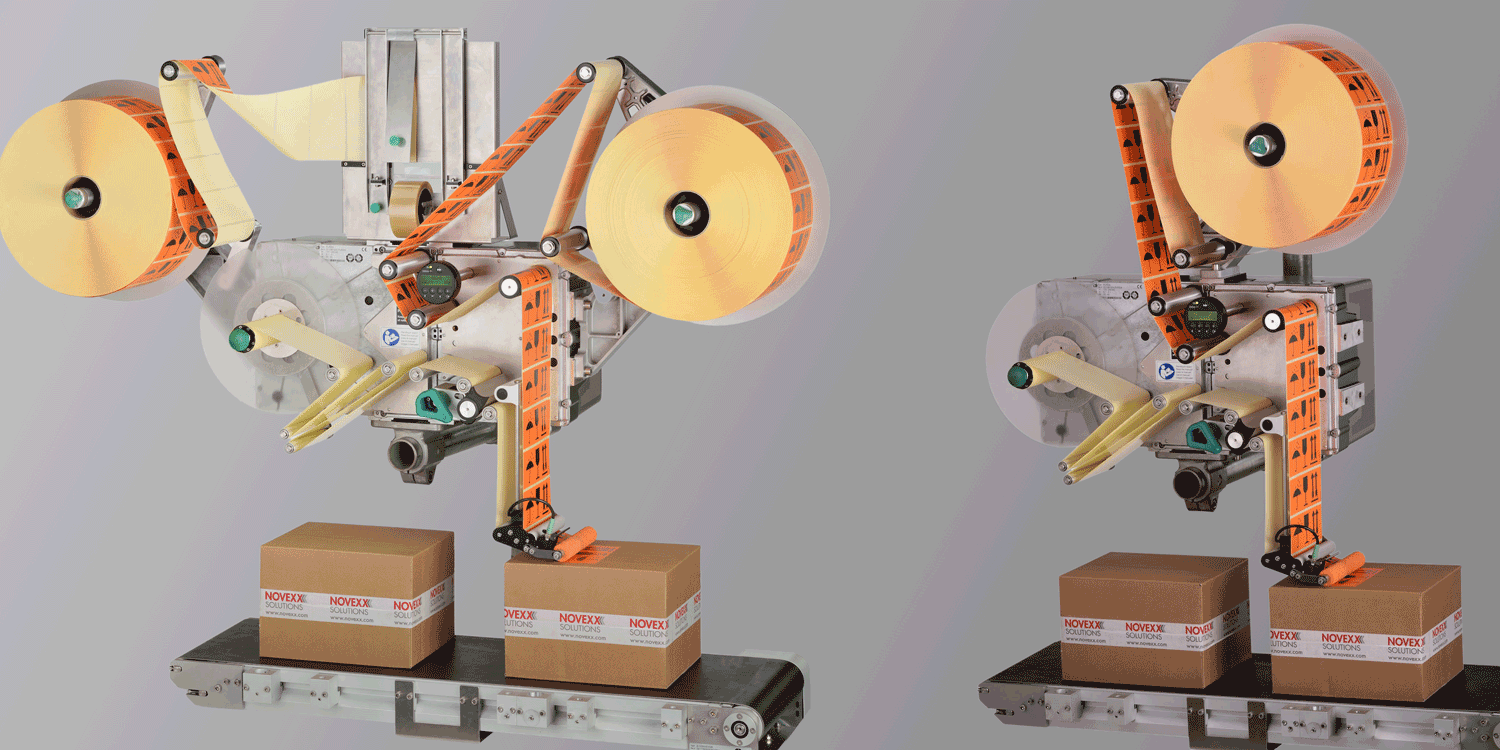

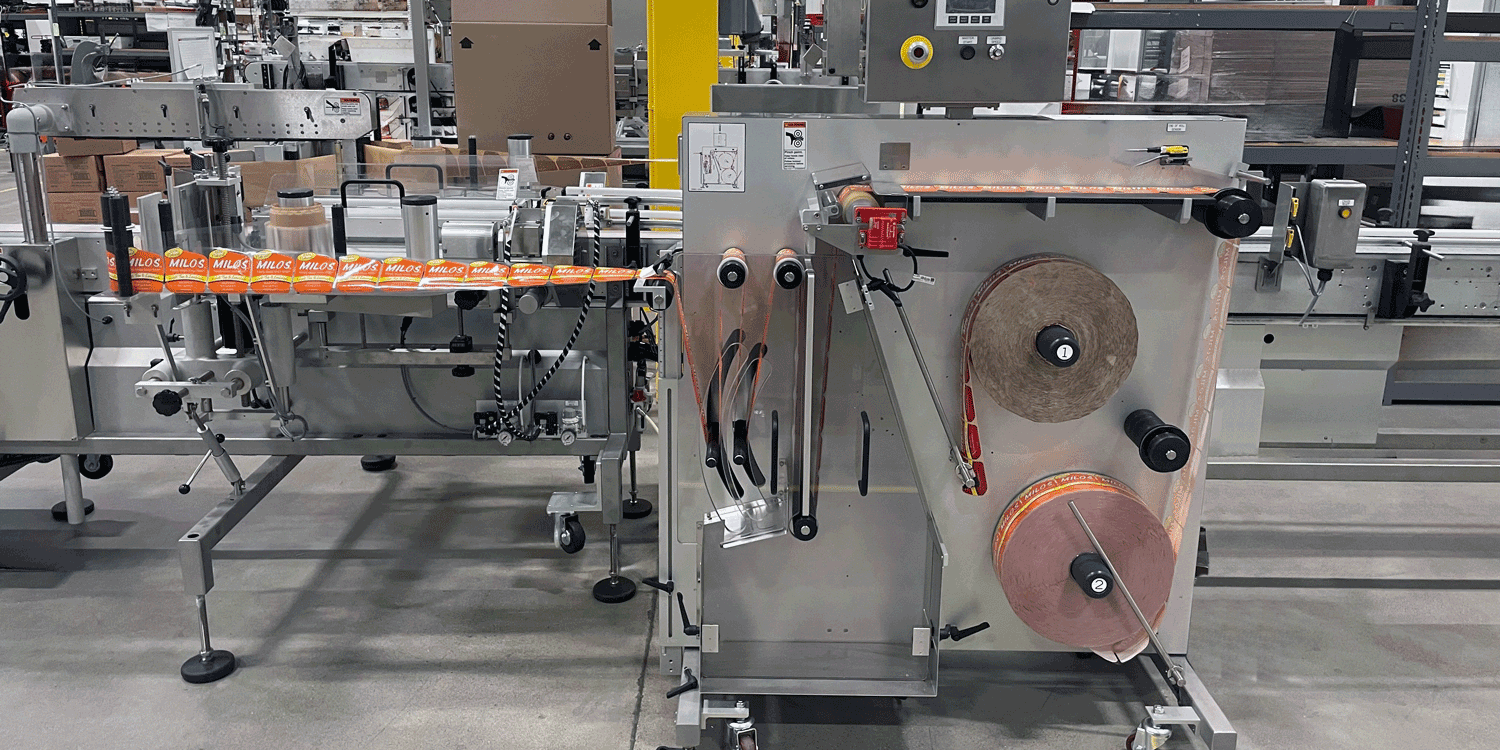

Experience the power and durability of Harland’s top and bottom labelers, which provide an efficient solution for labeling the tops, sides, or bottoms of products. Designed as wipe-on applicators, these labelers can also perform corner wraps and side stamps. They can easily integrate with your existing packaging line or be supplied with custom-designed product handling systems from Harland. These high-performance labelers feature a rugged construction combined with advanced electronics and drives, ensuring seamless operation.

Versatile Labeling Solutions

Our Top and Bottom Labelers are engineered to accommodate a wide range of pressure-sensitive labels, including thin films, clear films, hang-tabs, Sensormatic/Checkpoint tags, coupons, and booklet-style labels. Their universal design allows for easy integration into existing packaging lines, and they can be paired with tailored product handling systems to meet your unique production needs.

Key Advantages of Top and Bottom Labelers

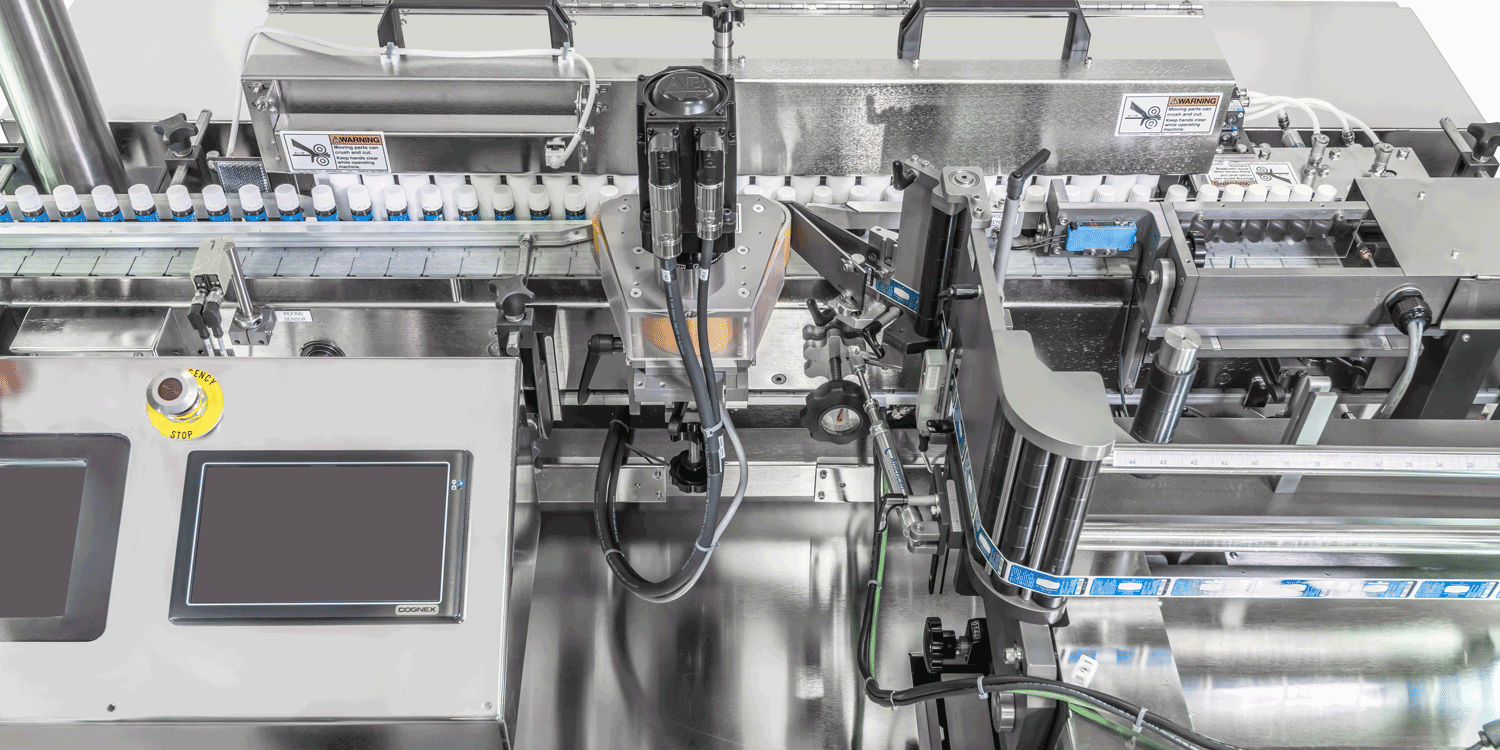

- High Productivity: The TBL 200 Series is designed for optimal performance in high-demand environments, featuring intuitive menu navigation via a large display for easy operation.

- Compact and Flexible: Its space-saving design ensures compatibility with various packaging equipment, allowing for quick adjustments and seamless transitions between different labeling tasks.

- User-Friendly Design: With fast and reliable labeling capabilities, these machines are perfect for 24/7 operations while requiring minimal maintenance thanks to their robust industrial frame and components.

- Exceptional Support: Backed by Harland’s “Gold Standard of Service,” our customers receive unparalleled support to maximize machine uptime and efficiency.

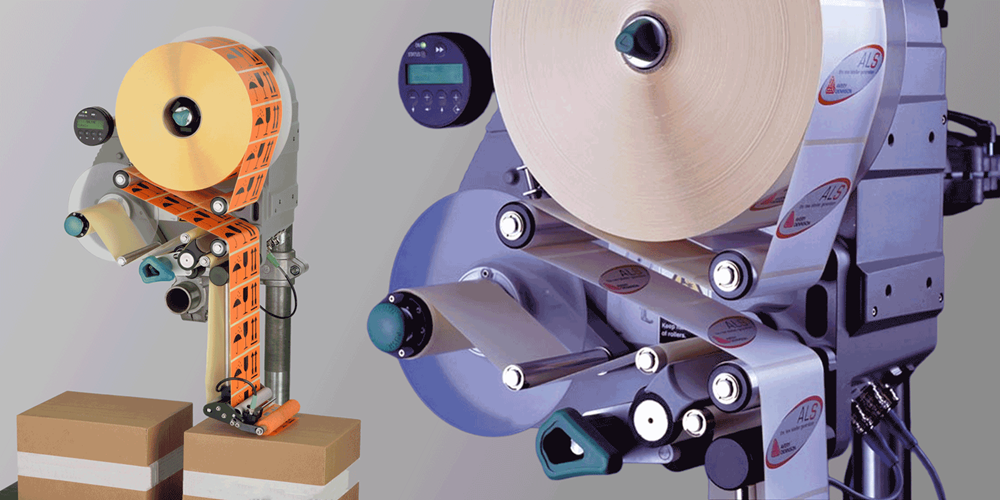

TBL 200 Series Advanced Features

- 300mm/12” Diameter Label Roll: Handle larger label rolls efficiently for extended operation without frequent replacements.

- Dual Nip Rollers: Ensure smooth and accurate label application with a stepper drive system.

- Integrated Redundant Control: Experience added reliability with advanced label applicator controls.

- Remote Connectivity: An Ethernet connection enables remote monitoring, troubleshooting, and setup, while a USB port allows easy backup of setup parameters to a flash drive.

Elevate your labeling processes with Harland’s Top and Bottom Labelers from the TBL 200 Series—where performance meets innovation. Contact us today to learn more about how our solutions can enhance your packaging operations!

Key Features

- Wide range of label width & length adjustment

- Collapsible rewind for quick, easy removal of the waste liner

- Microprocessor with built-in applicator controls, auto diagnosis and auto set-up of the label sensor and label pitch

- General error signal to indicate end of labels, missing label on web & no gap found

- Integrated redundant label applicator control for non-stop label roll changes

- Automatic product speed following (available with optional shaft encoder)

Technical Data

Available Options

- Blow-on, Tamp-Blow, Swing-Arm, and Corner-Wrap applicators

- Shaft encoder for automatic speed following

- Remote operator interface

- Label coders such as SmartDate or DataFlex thermal transfer printers

- Ultrasonic label sensor for clear labels

- Alarm package with three-color light stack

- Kits to run Hang-Tabs, Checkpoint, or Sensormatic tags

- IP65 rating for wet or dusty environments

- Custom-engineered product handing solutions

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

3070 Mainway

Burlington ON L7M 3X1

CA -

+1 (905) 336-8880 -

+1 (905) 336-5710 (Customer Service) -

(Field Service)

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

Jump to...

Jump to...