Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

Apply the filters to refine your selection

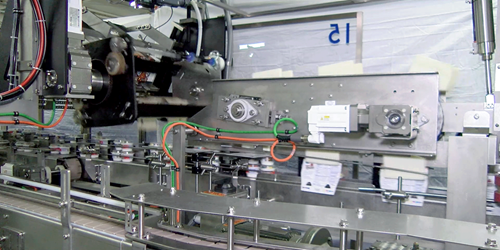

Advanced Features for Superior Performance

We take pride in equipping our cartoning machines with advanced features that enhance their functionality. Among these features are cycle stop flap closing, rotary carton capabilities, and adjustable carton plows, all of which contribute to superior flexibility and high-performance applications. These innovative functionalities ensure that our machines can adapt to the unique packaging needs of your business, delivering consistent and reliable performance time and again.

Reliable Packaging Operations

In today's fast-paced market, reliable packaging operations are crucial for maintaining productivity and meeting customer demands. Our machines are engineered for efficiency, particularly in managing foil rolls and eye drops, ensuring that your packaging processes remain seamless and uninterrupted. With Nigrelli, you can trust that our high-performance cartoners will elevate your operational efficiency, allowing you to focus on what you do best—growing your business.

Partner with Nigrelli Today

Join countless satisfied customers who have transformed their packaging operations with Nigrelli's state-of-the-art cartoning solutions. Discover how our commitment to quality, innovation, and customer service can help you achieve your packaging goals. Explore our expansive range of cartoning machines today and see how Nigrelli can support your business in navigating the complexities of modern packaging demands.

What are the advantages of automated cartoning?

Automated cartoning enhances operational efficiency by boosting accuracy and productivity while significantly reducing labor costs. It offers scalability, allowing businesses to adapt to varying production needs, and is capable of handling multiple product types and carton designs.

Which products are appropriate for automated cartoning?

Automated cartoning systems are versatile and can accommodate a broad range of products across various industries, including food, pharmaceuticals, personal care, and automotive sectors. They are also effective with different carton types, particularly folding cartons, suitable for packaging food, pharmaceutical, and cosmetics.

What should I consider when selecting a cartoner?

When choosing a cartoner, take into account factors such as the types of products you'll be packaging, carton sizes, production speeds, and the desired changeover times. It's also essential to evaluate the level of automation needed and the quality of the carton materials to ensure compatibility with your products.

How can I effectively design a cartoning line?

For an efficient cartoning line, evaluate your production volume, the types of products being packaged, and the necessary speed and accuracy. Ensure that your line is adaptable to numerous carton sizes and product types, and prioritize quick and seamless changeovers for enhanced operational efficiency.