Products and Solutions

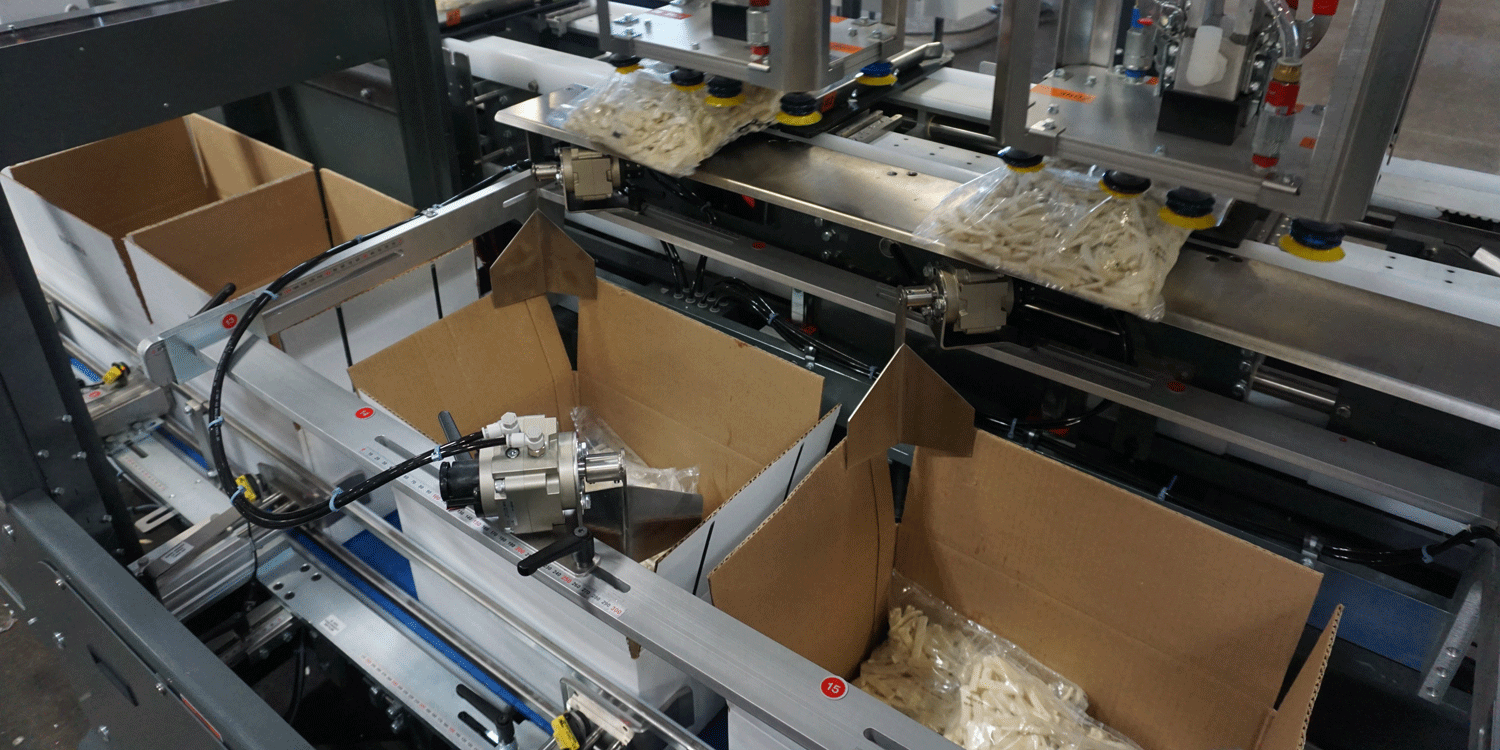

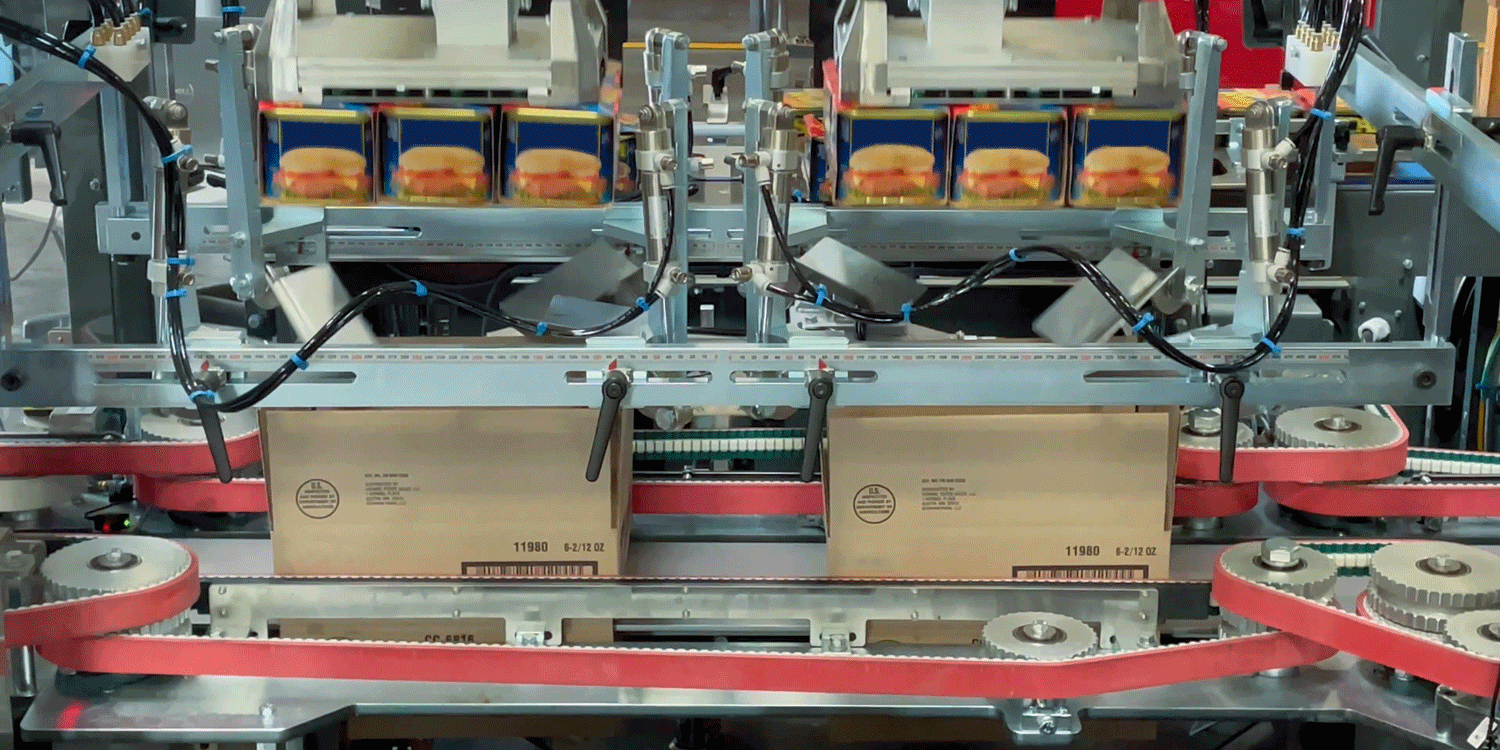

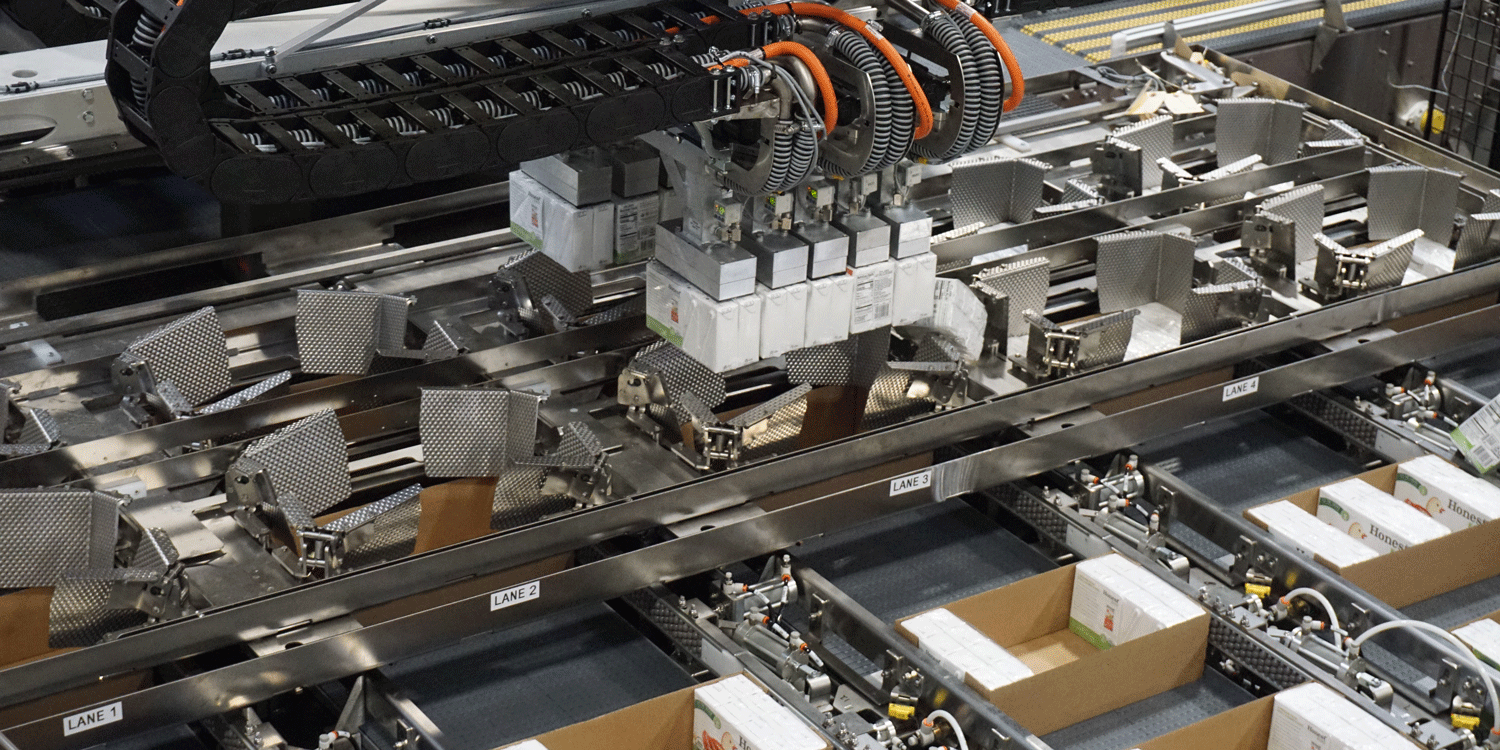

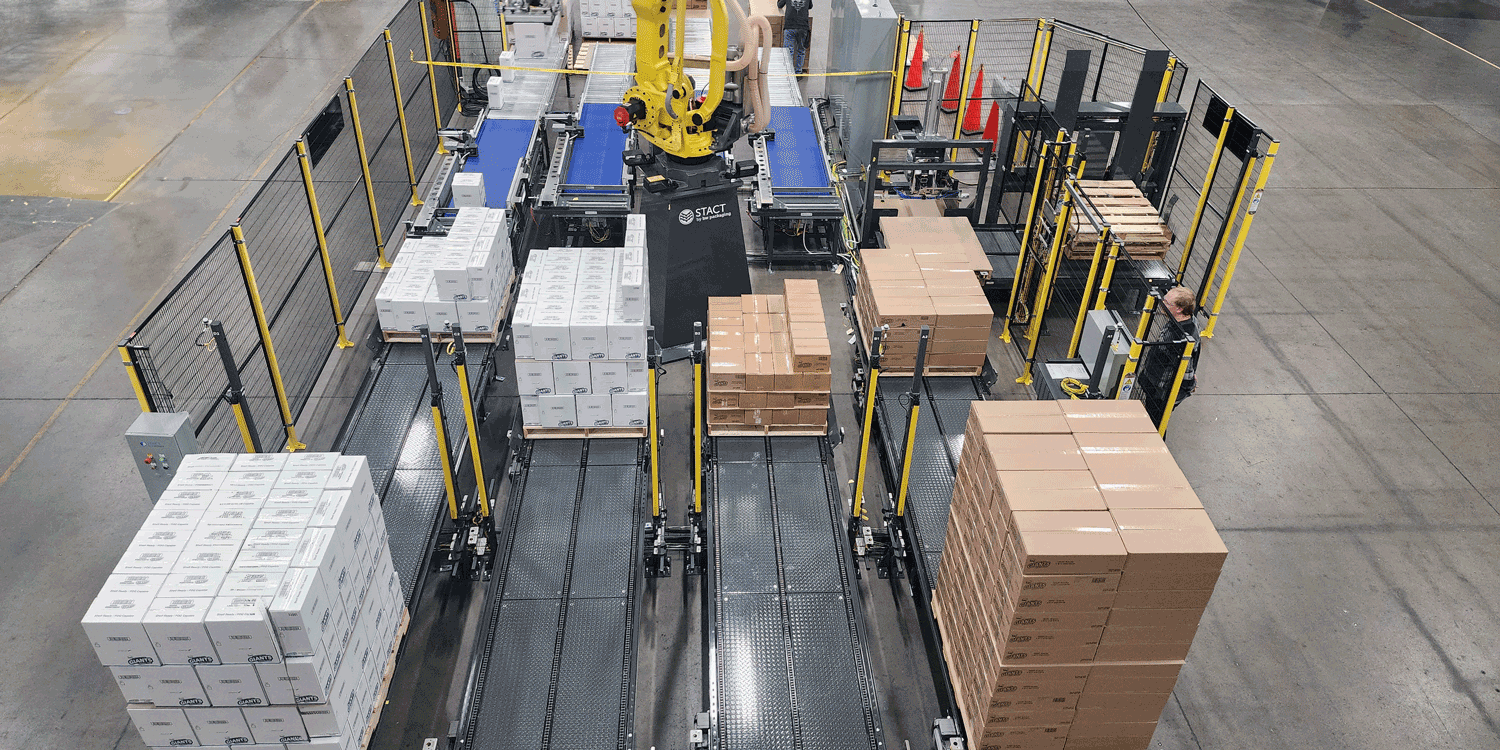

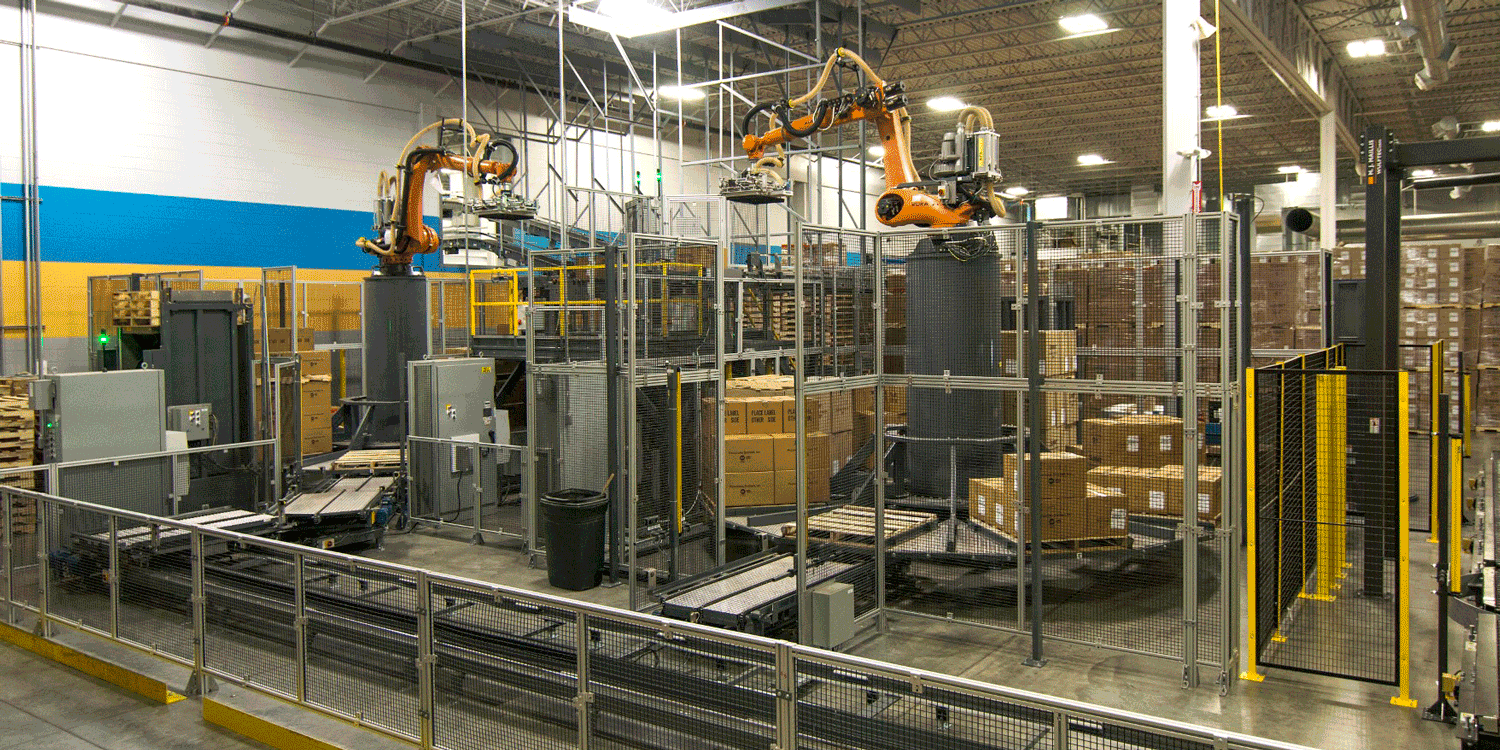

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

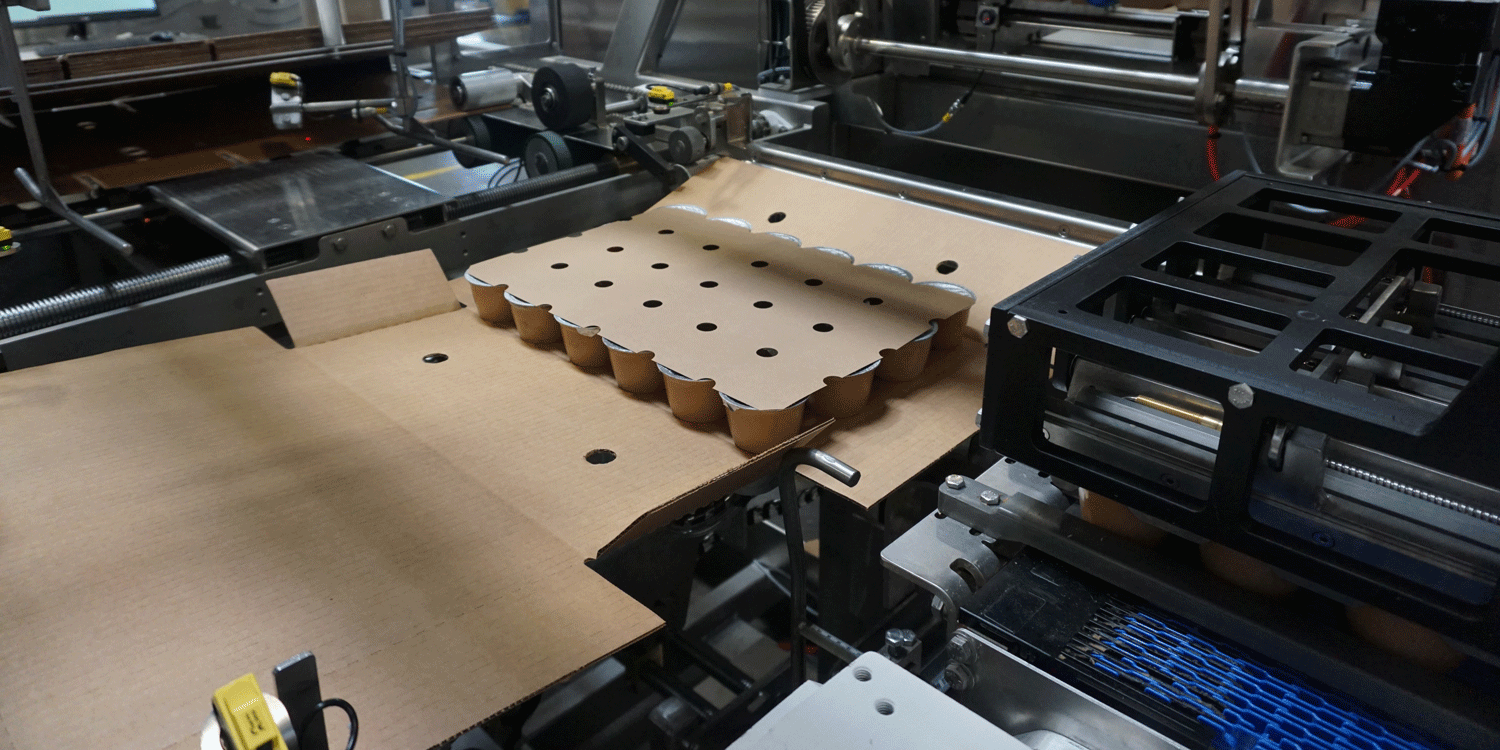

Nigrelli Wrapstar Multiwrap Sleever

At Nigrelli, we specialize in cutting-edge sleeving solutions designed for efficiently packaging cups, tubs, and bowls of individual food products. Whether you need single or dual-tier cup applications, our top, bottom, and side-sealed sleeves can elevate your packaging process. Our sleeves are engineered to seamlessly integrate with complete secondary packaging lines, including advanced case packing and palletizing systems.

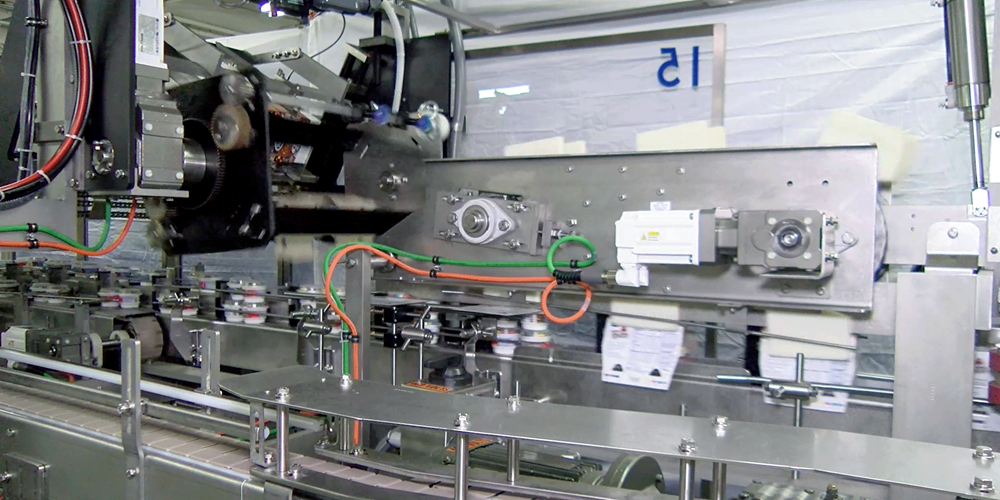

Introducing the Nigrelli WrapStar Sleever

Setting a new standard for sleeve packaging productivity, the Nigrelli WrapStar Sleever boasts robust construction and multi-axis servo technology. Our innovative starwheel metering system ensures precise product feeding into the infeed transfer section. Combining this with our legendary rotary placer guarantees accurate sleeve placement based on product presence. The unitized sleeve squaring and gluing system ensures your products are consistently squared and ready for the market.

Elevate your packaging efficiency with Nigrelli's state-of-the-art sleeving solutions. Reach out to us today to learn more!

Key Features

- Capable of handling single or double tier wraps with configurations accommodating one to sixteen packs

- Versatile enough to handle a wide variety of product shapes

- Achieve speeds of up to 250 sleeves per minute based on your specific configuration

- Advanced multi-axis servo drive system for enhanced efficiency

- User-friendly Allen-Bradley PanelView HMI for intuitive operation

- Full perimeter polycarbonate guarding with radio frequency style guard door switches (category 4) for maximum safety

- Low profile design suitable for various setups

- Efficient Nordson glue system ensuring secure adhesion

- Reliable Allen-Bradley Logix Series PLC for seamless machine integration

- Unique unitized sleeve squaring feature that eliminates chain stretch issues

- Durable non-corrosive surfaces for product contact to maintain hygiene standards

Technical Data

Available Options

- Choose between intermittent motion and continuous motion functionality tailored to your production needs

- Optional Allen-Bradley Logix Series PLC and multi-axis servo drive systems for enhanced control

- Quick-change assemblies for easy product changeover

- Digital readout package for monitoring performance and low sleeve detection in the hopper

- Stainless steel frame for enhanced durability

- NEMA 4X washdown electrical construction for hygienic processing

- Placer options for adding divider boards between product layers

- Pneumatically activated top hold-down rails for secure loading

- Minimal moving parts designed for efficient product loading

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...