Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

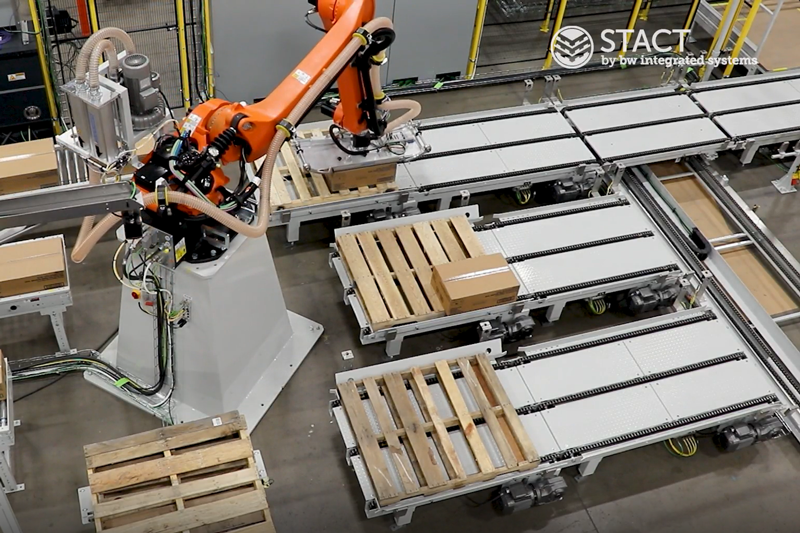

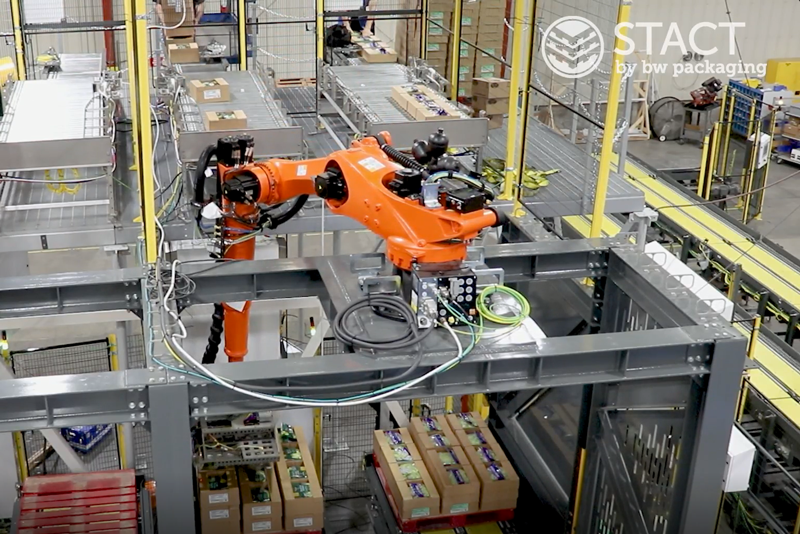

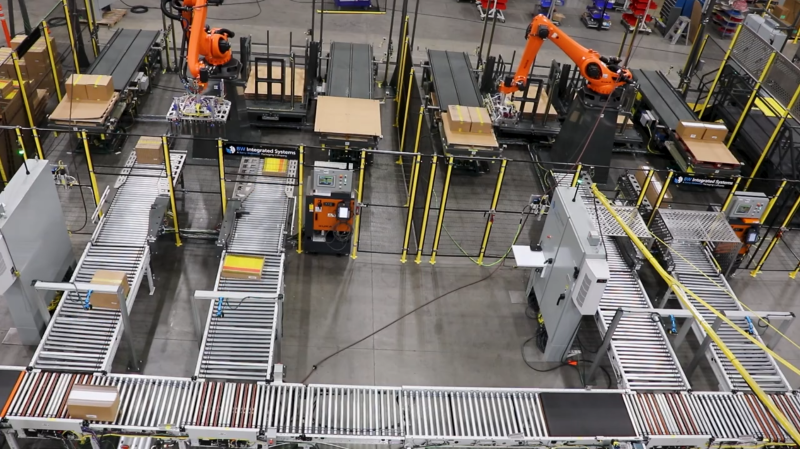

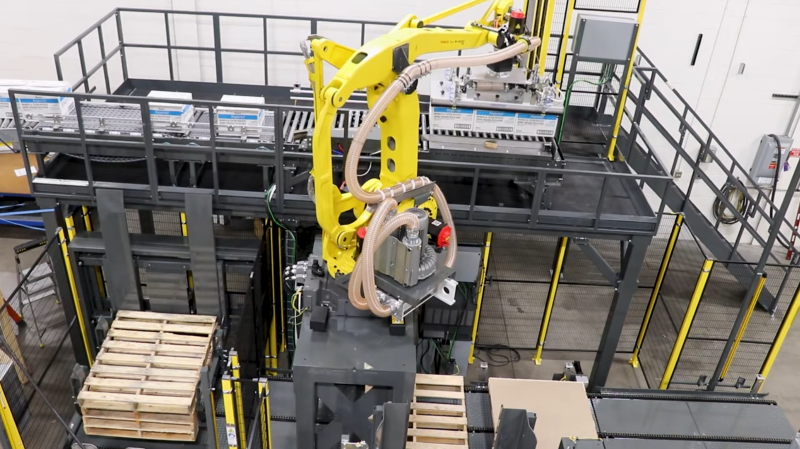

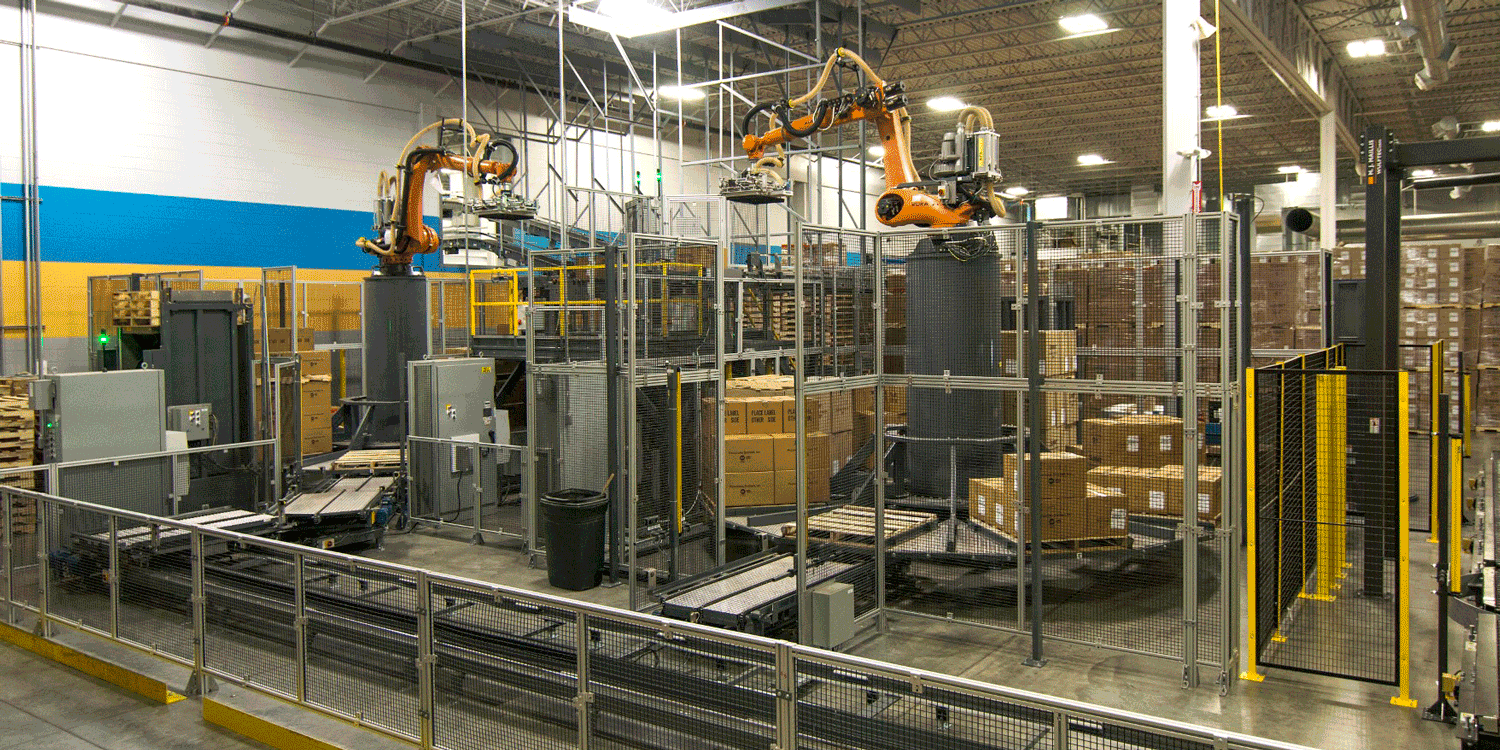

Stact Robotic Case Palletizer

As a premier global leader in the design and implementation of robotic case palletizers, we have successfully delivered hundreds of innovative systems tailored to diverse market segments. Our deep-rooted expertise in the packaging industry distinguishes us from competitors, making us the go-to choice for businesses looking to enhance their operational efficiency and productivity.

Custom Solutions for Every Environment

Whether your operations are in a frozen environment or ambient conditions, our state-of-the-art robotic solutions are meticulously engineered to meet your unique requirements. Our advanced technology supports both intermittent and continuous motion capabilities, allowing our systems to seamlessly adapt to varying speed requirements. This versatility ensures that you can scale your operations without compromising on performance.

Proven End-of-Arm Tooling Designs

To provide you with the ultimate flexibility, we offer an extensive range of proven end-of-arm tooling designs and patterns. Each tooling solution is tailored specifically to ensure a perfect fit for your application, enhancing the efficiency of your packaging processes. We pride ourselves on our ability to customize tools that work in harmony with our robotic systems, offering both reliability and precision.

Space-Saving, Compact Designs

Our robotic case palletizers feature compact designs that optimize valuable floor space. By enabling the handling of multiple products within a single cell, we help streamline your operations and maximize productivity. Our solutions are engineered to offer efficient handling, reducing the complexity of your packaging lines and ultimately lowering operational costs.

Cutting-Edge Technology for Superior Performance

Equipped with state-of-the-art electro servo-driven technology, our robotic systems are designed for minimal maintenance while delivering superior performance compared to conventional equipment. This innovative technology ensures long-lasting durability, allowing your business to run smoothly and efficiently over the years. Investing in our robotic palletizers means that you are investing in a solution that is built to stand the test of time.

Why Choose Us?

Choosing our robotic case palletizers means choosing a partner dedicated to quality, innovation, and customer satisfaction. With our extensive experience and commitment to excellence, we are here to help you navigate the complexities of modern packaging solutions. Trust us to elevate your operations with our advanced robotic systems designed to optimize efficiency and drive growth.

Explore to learn more about how our robotic case palletizers can transform your packaging operations and increase your competitive edge in the market!

Key Features

- Our three-strand chain pallet conveyor design ensures an even distribution of loads during pallet transport, maximizing efficiency

- Centrally located and easily accessible pneumatics feature a unique plug-and-play design, simplifying maintenance and operation, enhancing productivity

- Operator interface can be mounted in a number of locations to provide the best view of machine function

- Our pallet dispenser stands out as the most versatile unit in the market, thanks to its open architecture that accommodates multiple configurations, pallet sizes, and even forgives bad pallet quality - Choose between fork truck or conveyor loading options

- Light curtains are strategically placed at empty pallet loading and full pallet discharge with personnel access points conveniently located through interlocked gates

- Hassle-free programming access with a standard PLC port and electrical receptacle on the panel door, eliminating the need to open the door for quick adjustments

Technical Data

Available Options

- Enhance efficiency with multiple infeed and discharges for palletizing multiple packaging lines

- Benefits of all electric operation

- Ensure optimal performance in frozen environments with our freezer environment package

- Customize and tailor your solutions with our Product Builder software

- Choose from a selection of robot manufacturers to meet your specific needs

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

5605 Goldco Dr

Loveland CO 80538

US -

+1 (970) 663-4770 -

+1 (800) 248-0605 (Customer Service) -

+1 (800) 248-0605 (Field Service)

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...