Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

Apply the filters to refine your selection

Efficient Dunnage Handling

Discover the transformative capabilities of Fortis with its state-of-the-art dunnage handling solutions. Our advanced robotic system is specifically engineered to streamline the process of managing dunnage, making it easy to bring consolidated materials down to floor level for seamless robotic separation.

Fortis's robotic dunnage handling system is tailored to meet the demands of suppliers by effectively separating essential components such as layer pads, top frames, and pallets. Our innovative approach ensures that dunnage materials are handled efficiently, reducing operational time and increasing productivity. By implementing Fortis's robotic dunnage handling system, you can enhance workflow efficiency, minimize manual labor, and ensure a safer working environment.

Built for Performance, Backed for Life

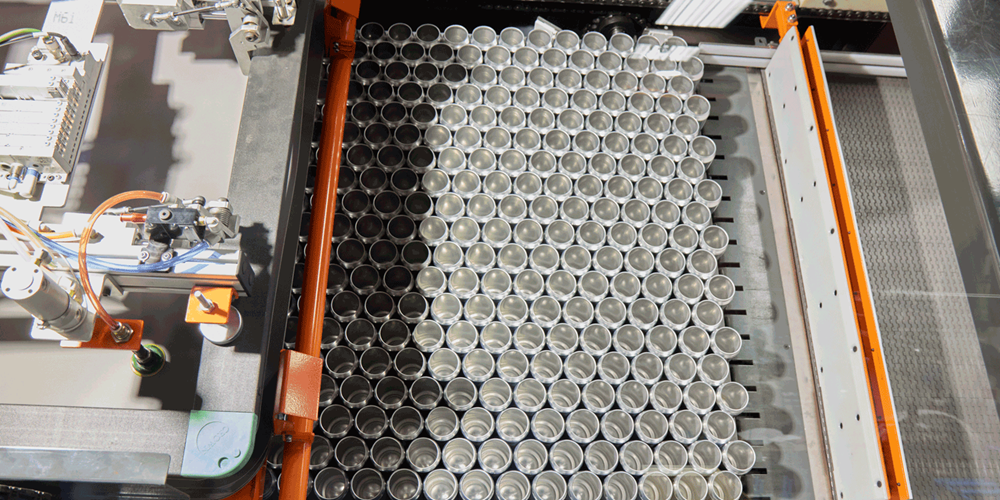

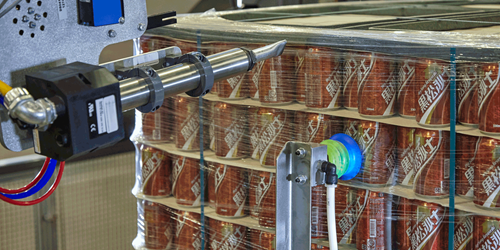

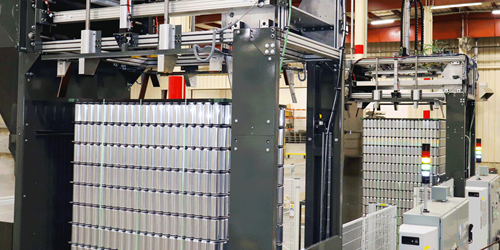

At BW Packaging, we recognize that your depalletizing solution must perform reliably, day in and day out. Our equipment is designed with key features that matter to operations leaders, including fast and flexible changeovers, high safety ratings, and seamless integration with upstream and downstream systems. Whether handling steel, aluminum, or PET containers—both round and non-round—our machines are engineered to keep your production line running smoothly.

For operations seeking advanced automation, our robotic depalletizers are capable of handling various product sizes from multiple incoming lines, efficiently directing products to several distribution paths. Additionally, our destrappers and Super Sorter systems enhance efficiency and safety, streamlining material handling and quality control at the front end of your line.

Every solution is supported by our industry-leading lifetime support commitment because we believe your investment should provide long-lasting value. Explore our comprehensive range of depalletizing solutions and supporting equipment, or contact our expert team today to discover the perfect fit for your operational needs.

Transform your operations with Goldco's reliable and innovative depalletizing solutions today!

What is a depalletizer?

A depalletizer is a machine designed to automate the process of removing items from pallets, which is a critical step in many manufacturing and distribution operations. These machines provide significant advantages over manual depalletizing, such as increased speed, reduced risk of injury, and improved overall efficiency.

What is dunnage in the depalletizing process?

Dunnage refers to the materials used to protect and stabilize products on a pallet during transportation and storage. In the depalletizing process, common types of dunnage include layer pads (also known as tier sheets) and top frames. These materials are crucial for preventing product shifting and damage, as well as maintaining the integrity of the stack.

When goods are removed from the pallet in the depalletizing process, it is important to also manage the dunnage appropriately. This may involve handling or removing it to ensure a smooth transition of products from the pallet to their next destination. Proper management of dunnage helps prevent potential damage and enhances operational efficiency.