Products and Solutions

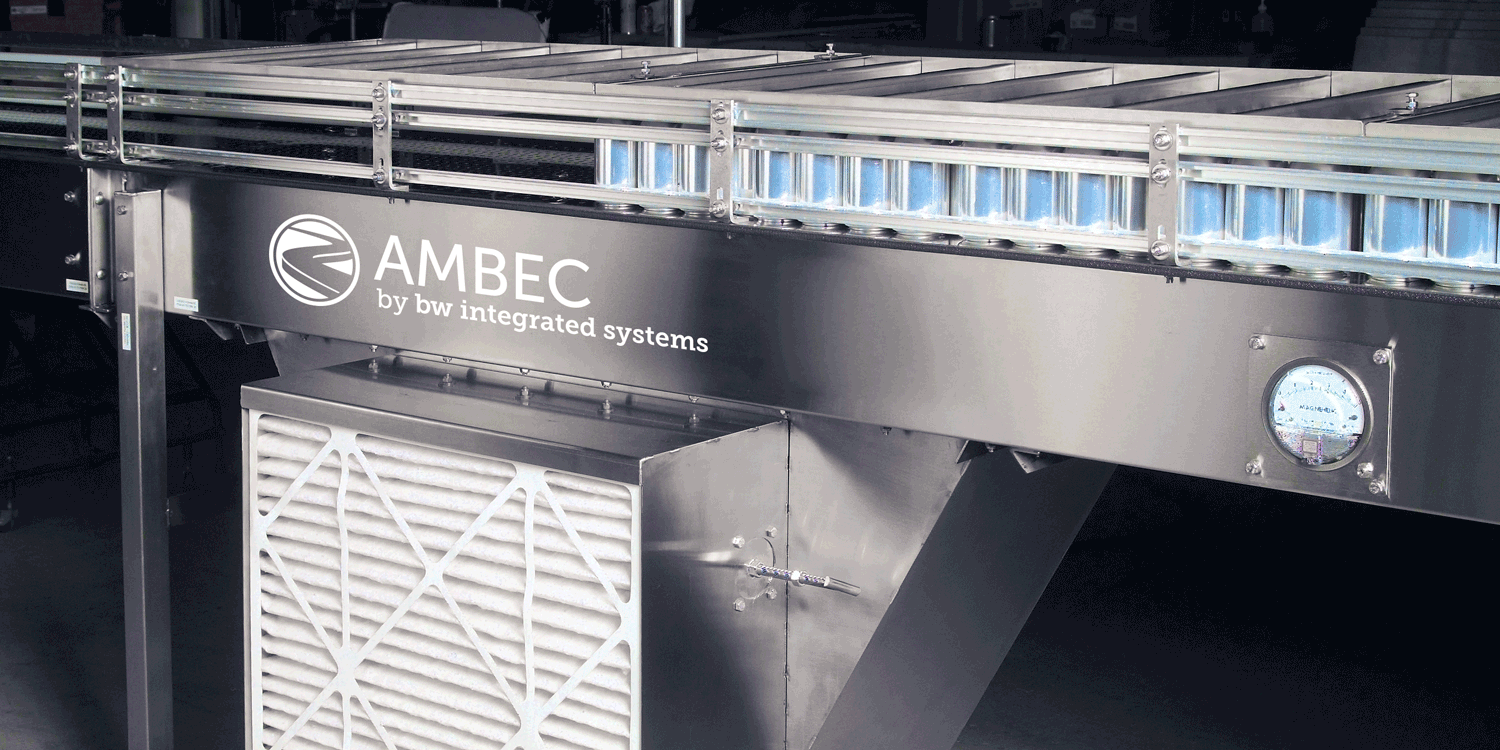

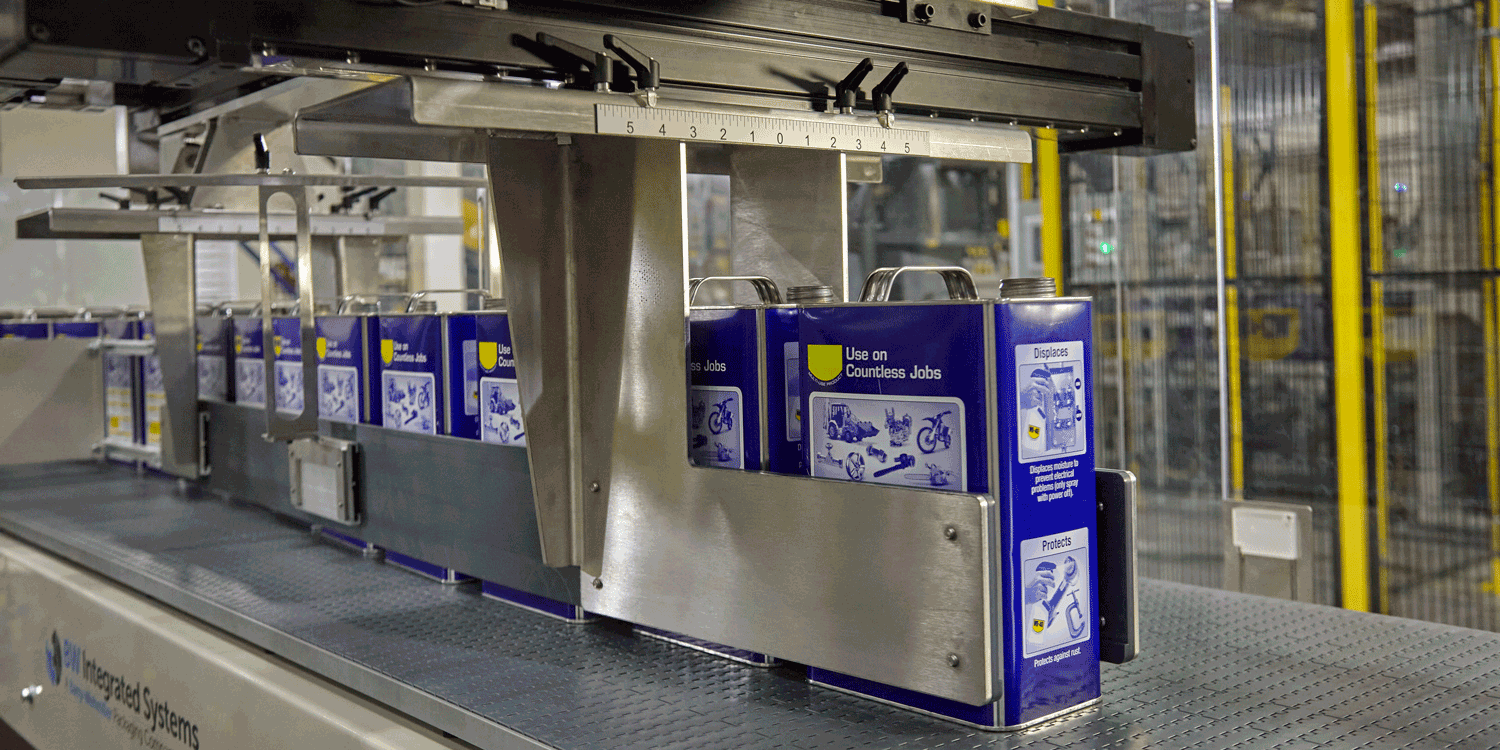

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

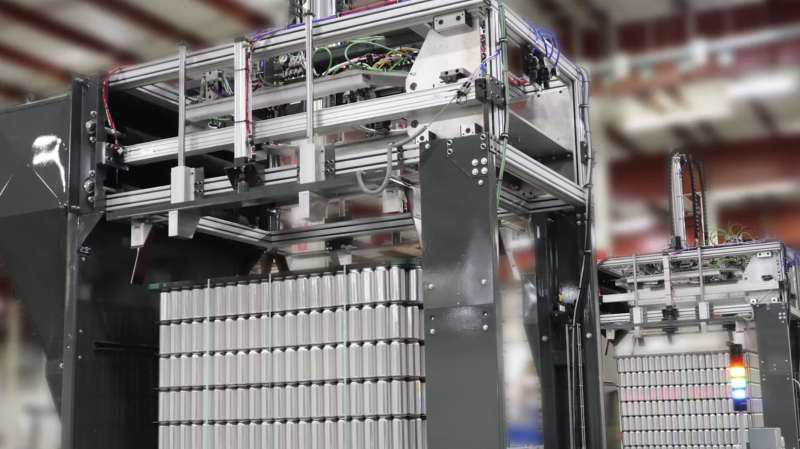

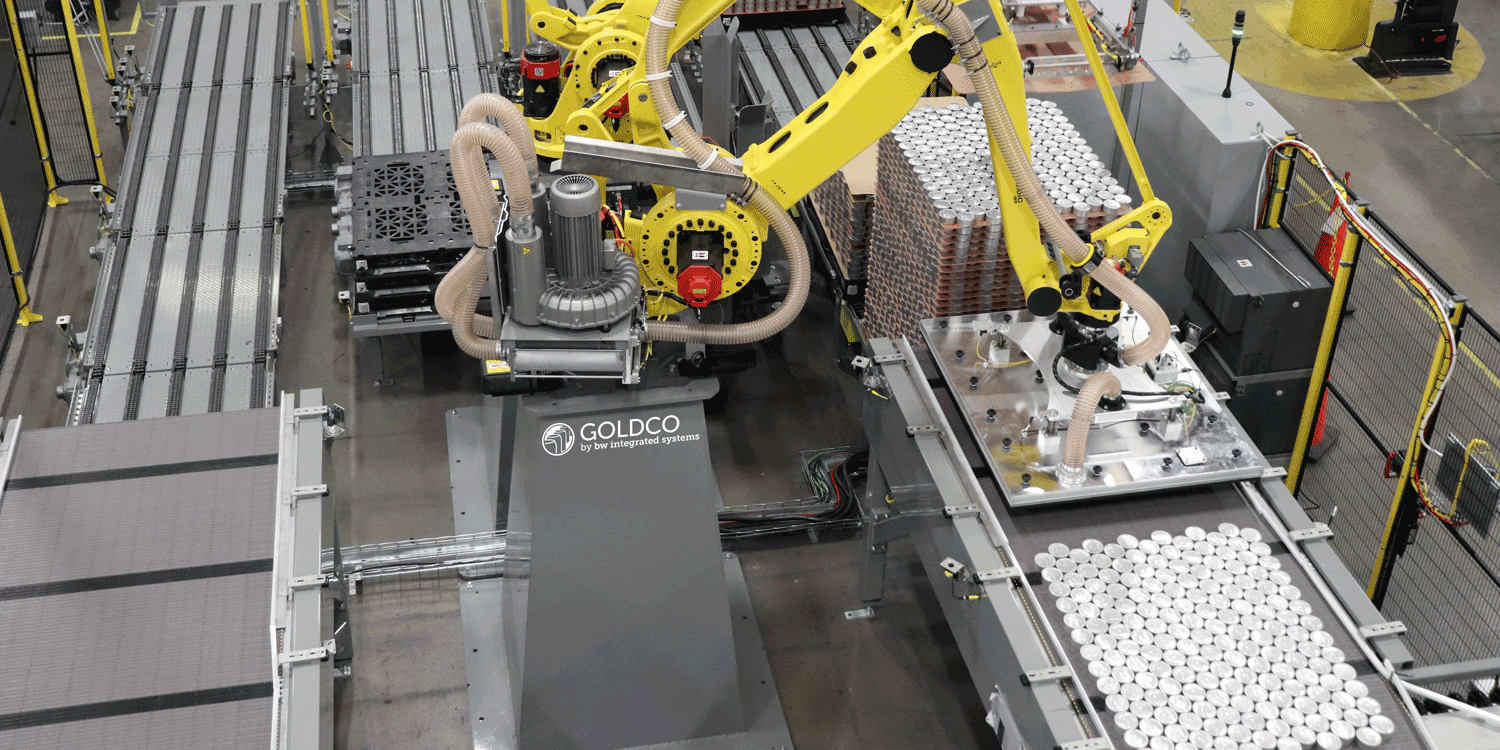

Goldco Destrapper

Say goodbye to the tedious and time-consuming process of removing plastic holding straps with Goldco Destrappers. Designed for optimal efficiency, our state-of-the-art destrapping systems automate the removal of plastic straps from your pallets, ensuring a seamless operation that saves you time and labor costs.

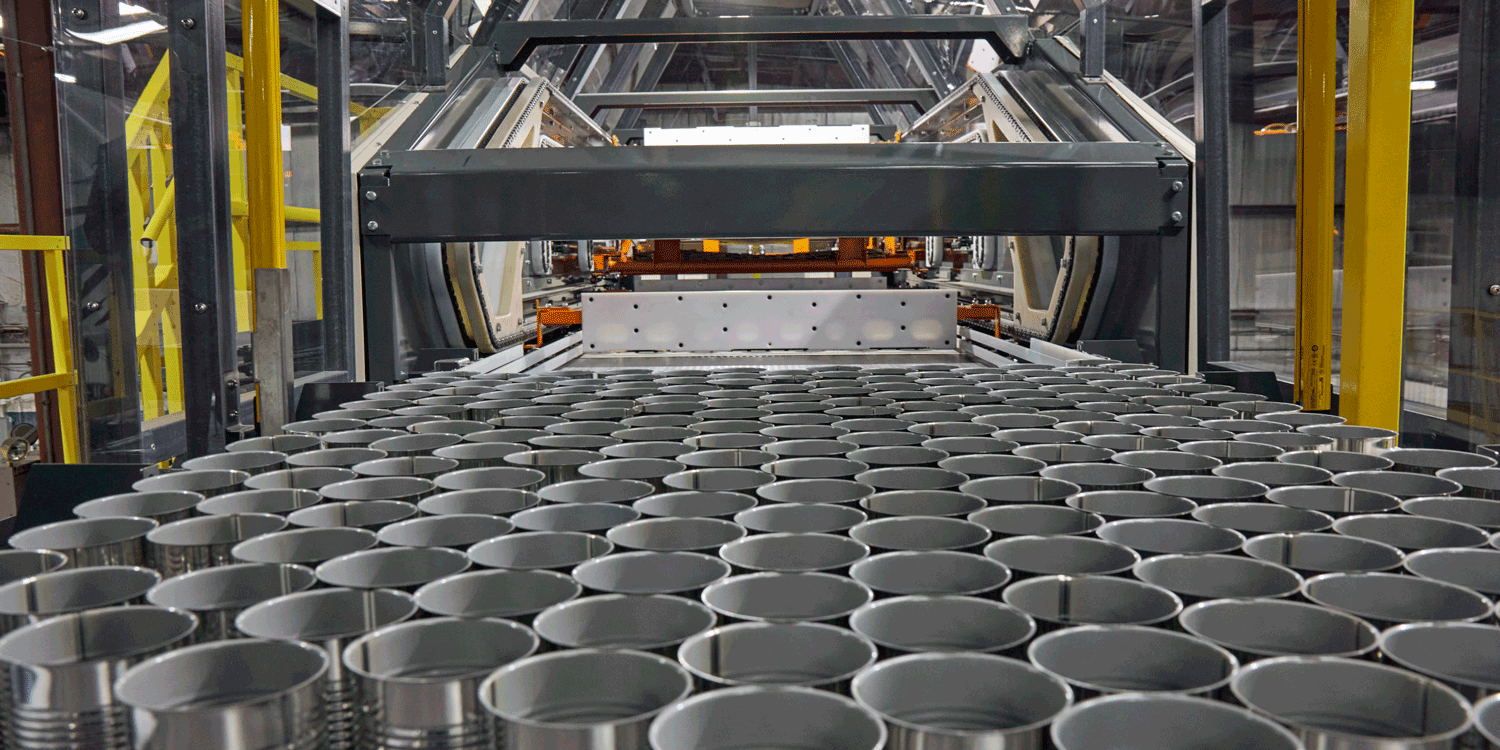

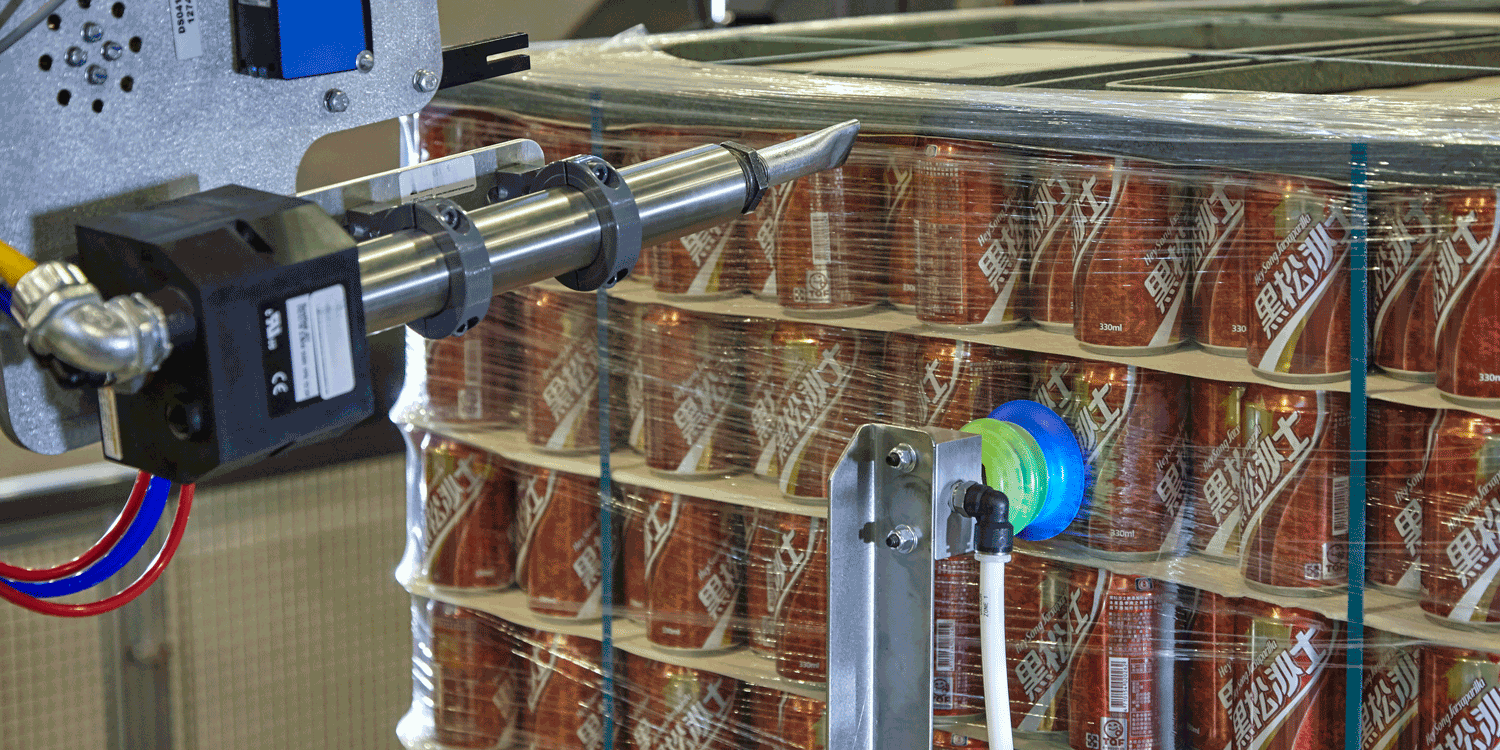

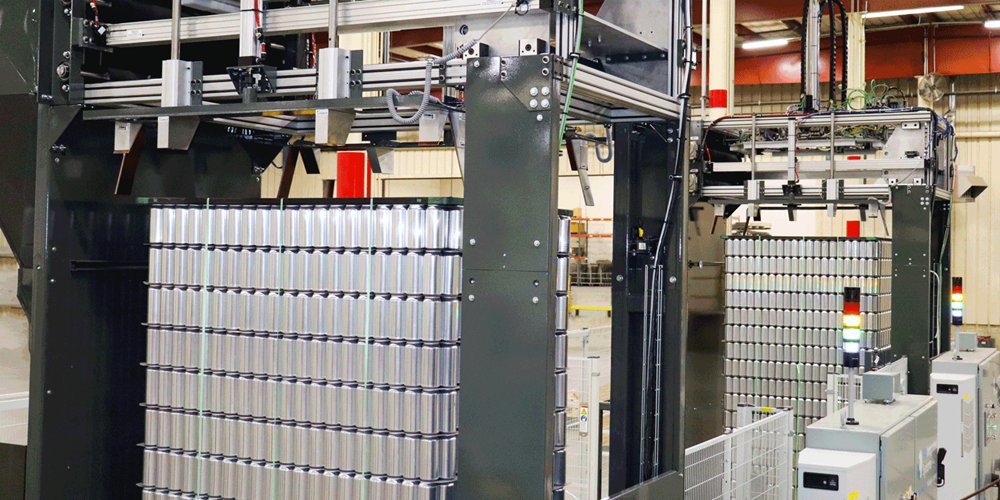

Whether you’re working with cans, glass, PET bottles, or other materials, our innovative Destrappers are equipped to handle various pallet loads effortlessly. As each pallet enters the Destrapper, durable load stabilizers descend to secure the pallet in position. Next, our advanced cutting heads activate, quickly identifying and slicing through the straps for swift removal.

Once the straps are cut, they are expertly lifted into position by a gathering roller, which engages them against a pinch roller. These components work in perfect synergy, efficiently feeding the straps into a granulator. This process not only minimizes waste but also maximizes productivity by depositing the processed straps directly into the client's designated container.

With the completion of this operation, the pallet stabilizers rise back to their starting position, allowing the gathering roller to return smoothly to its original spot. The entire process ensures that the pallet is quickly shifted to the next stage for frame removal or depalletizing, streamlining your workflow.

Choose Goldco Destrappers for a reliable, automated solution that enhances efficiency and productivity in your operations. Experience the future of pallet strap removal today!

Key Features

- Strap detection technology

- Convenient, quick disconnect sensors

- User-friendly PanelView touch screen with diagnostics

- A strap granulator offering two disposal options: effortless gravity unloading into a recycle box or easy removal via a vacuum/blower to a relocated recycle box

- Reduced labor costs - Our machine eliminates the need for an operator to manually remove and feed straps into a chopper before infeeding to the Depalletizer

- Simple controls that allow an operator to set the machine and leave it unattended for extended periods of operation

- Our pneumatic and electrical operating system is not only efficient but also consumes very little power

- Razor-sharp knives effortlessly cut straps into fine, 1/4” or smaller, granules for effortless disposal and recycling

- Pallet load heights can vary as much as 24” and still be accommodated

- Easy access to the cutting head assembly and other areas of the machine for hassle-free cleaning and maintenance

- Flexibility is key with variations available for 4, 5, 6, and 8-strap configurations

- Prioritize safety by eliminating the hazardous process of cutting tensioned straps with a knife or shears, keeping human hands out of harm’s way

Technical Data

Available Options

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

5605 Goldco Dr

Loveland CO 80538

US -

+1 (970) 663-4770 -

+1 (800) 248-0605 (Customer Service) -

+1 (800) 248-0605 (Field Service)

Jump to...

Jump to...