Products and Solutions

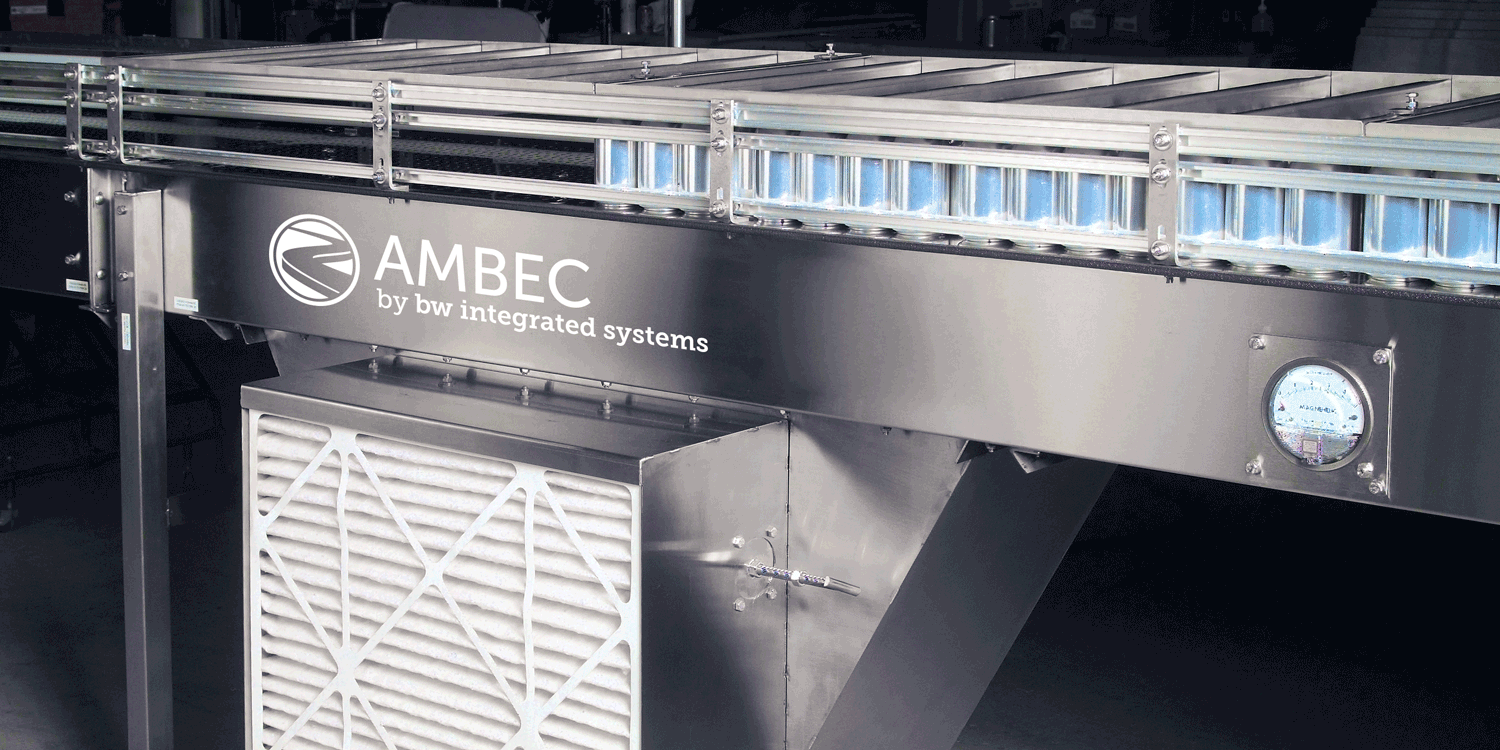

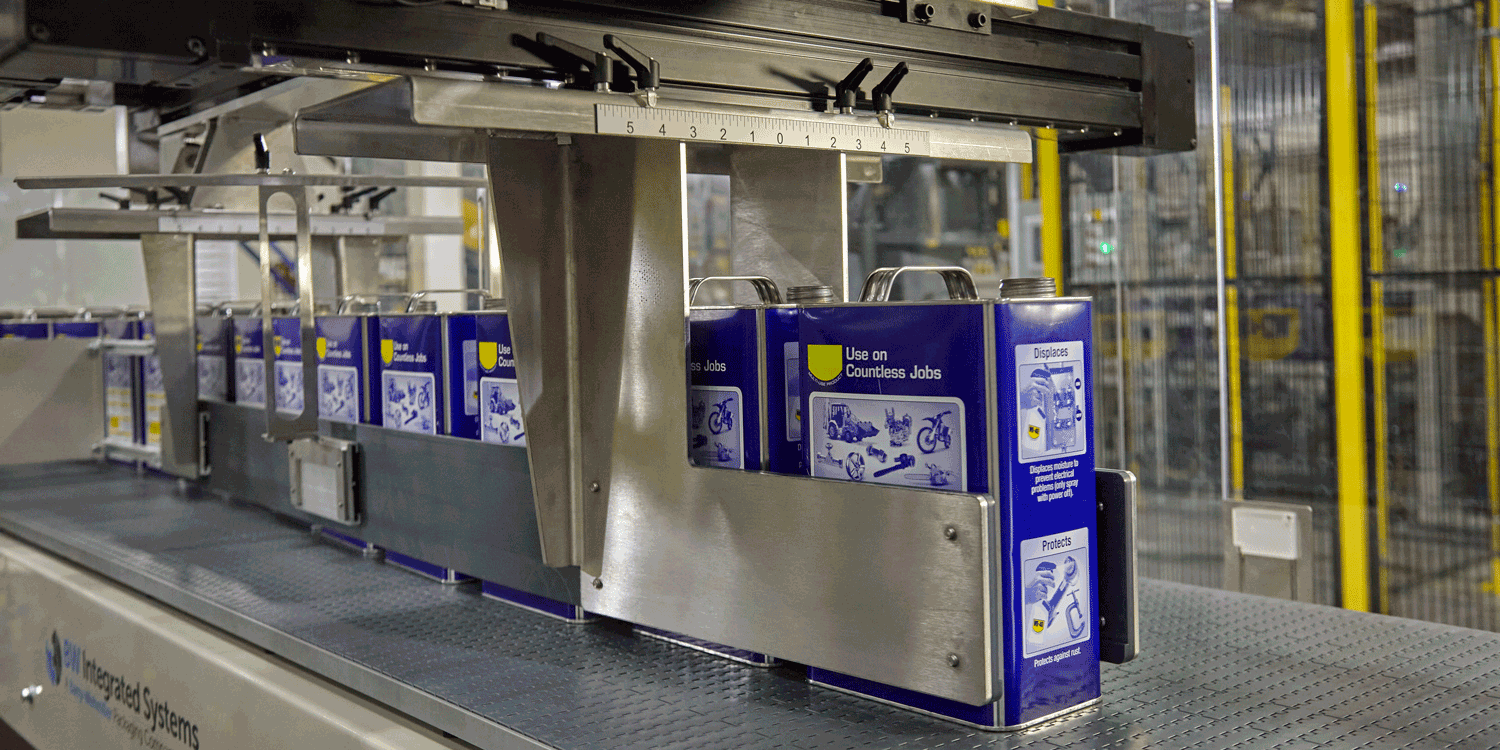

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

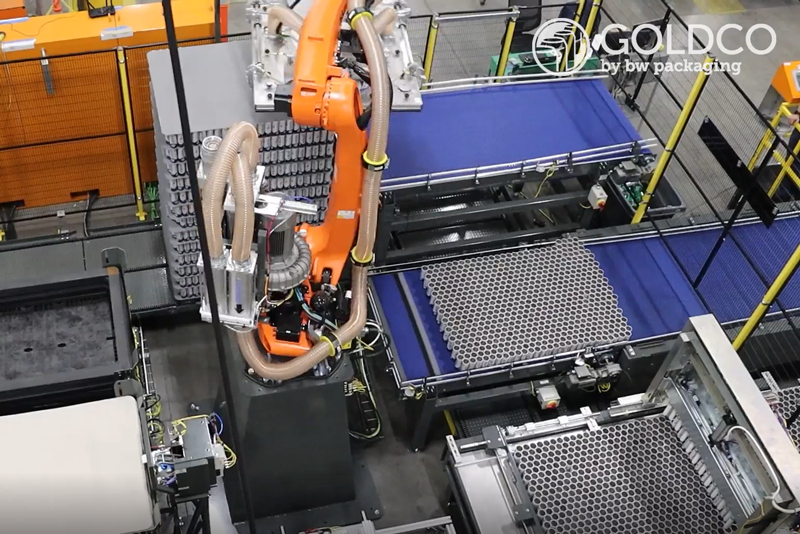

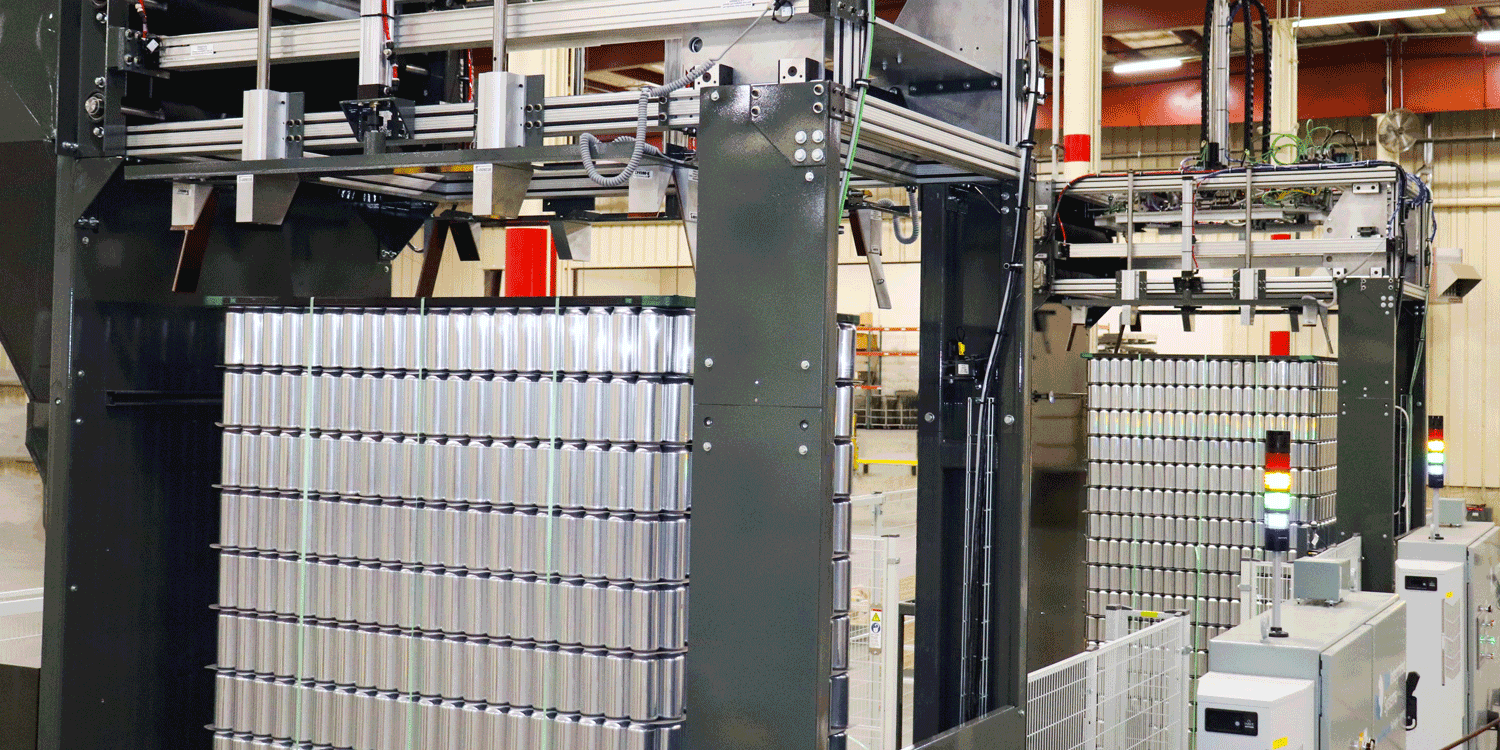

Goldco Robotic Bulk Depalletizer

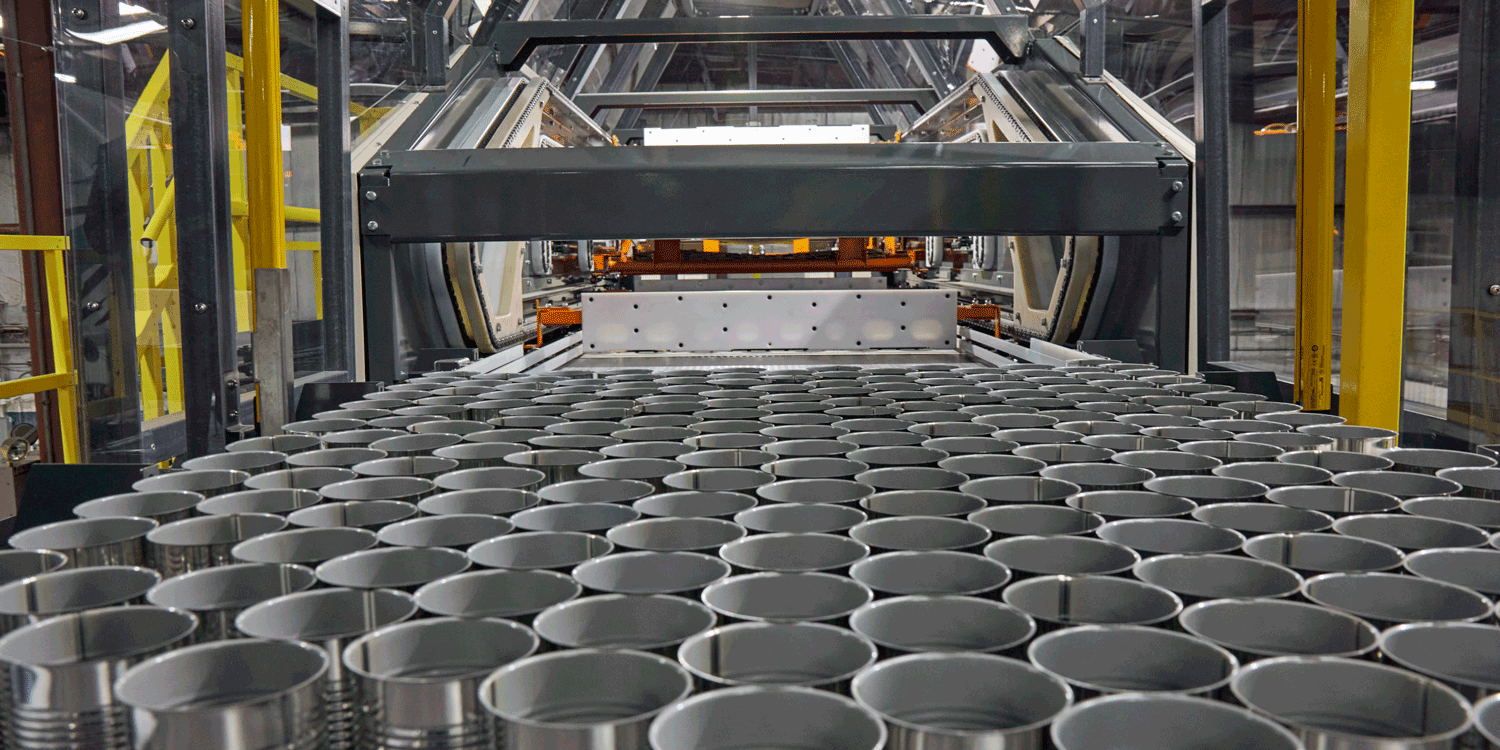

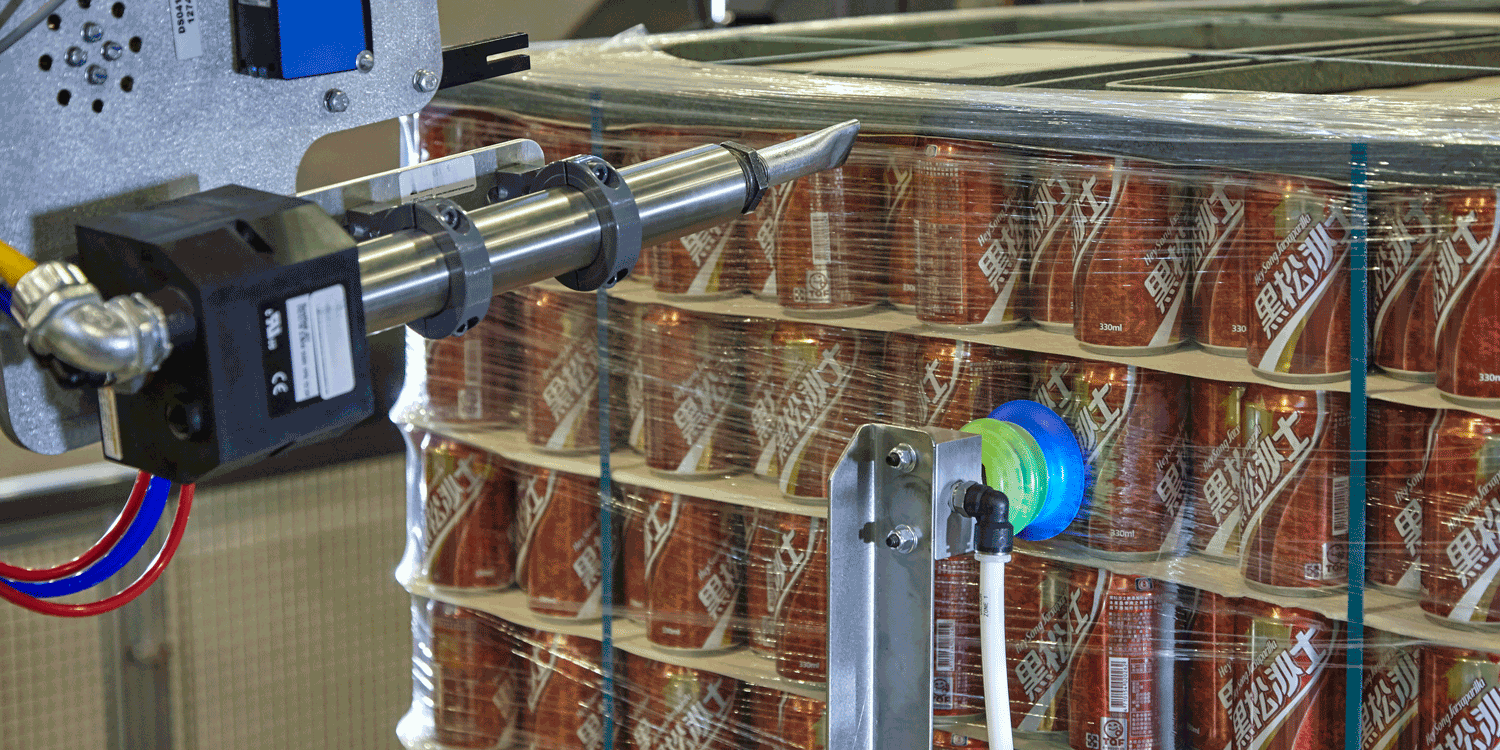

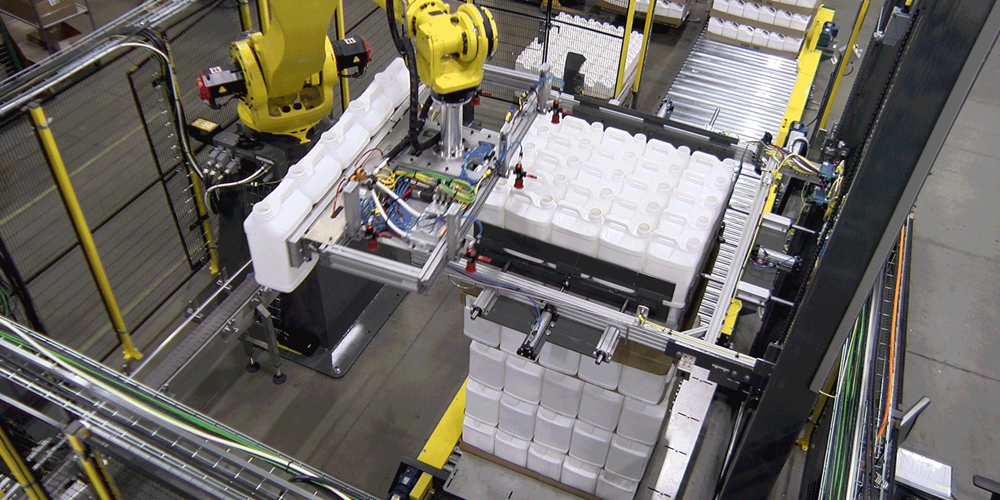

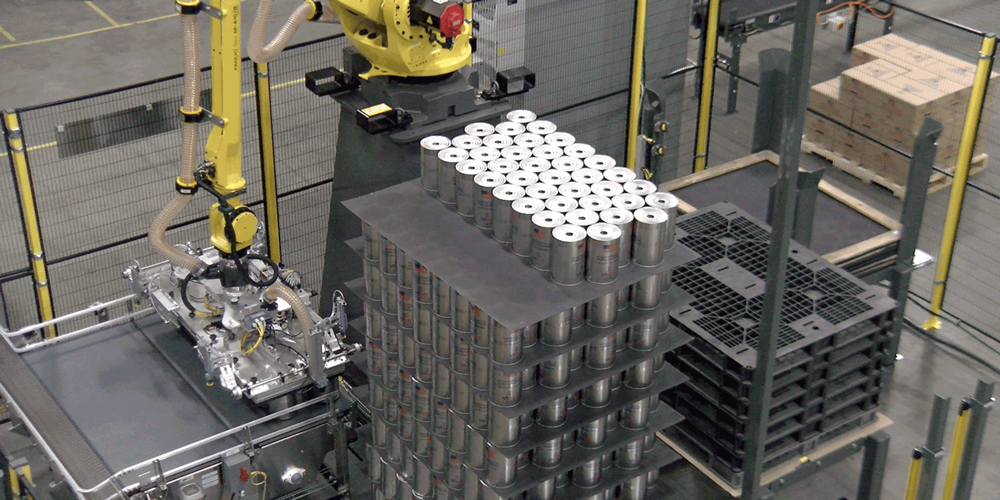

Goldco’s cutting-edge Robotic Bulk Depalletizers are engineered to optimize the handling of various product sizes from multiple incoming production lines. Designed for seamless integration, our depalletizers efficiently deliver goods to numerous distribution lines. With versatile end-of-arm tooling options, our systems can easily manage the depalletization of empty and filled cans—whether aluminum or steel—as well as plastic containers and cases.

Streamlined Depalletization Process

The operation begins when a new load is received. Our robotic system is equipped with an ultrasonic sensor integrated into the end-of-arm tooling to precisely detect the load’s position. This sensor enables accurate assessments, ensuring effective handling from a full load onward. The robot methodically removes the top layer pad and, when necessary, the top frame, gently placing both components onto a designated dunnage stack. The depalletization process continues smoothly until the final layer is removed.

Once the load is fully depalletized, the robot efficiently positions the empty pallet onto a waiting dunnage stack. To maintain optimal pallet management, advanced proximity sensors ensure that the empty pallet is securely placed within the stack. For added flexibility, pallets can also be stacked using a conventional pallet magazine as per your operational needs.

Why Choose Goldco?

- Versatility: Handle various product types, including cans, containers, and cases

- Efficiency: Streamlined processes reduce labor costs and boost productivity

- Customization: Different end-of-arm tooling options to fit your specific needs

Invest in Goldco's Robotic Bulk Depalletizers today for a more efficient and reliable solution for your depalletizing needs!

Key Features

- Flexible footprint design for flexibility

- Accurate package placement for optimal efficiency

- Gentle product handling to protect your products

- Highly adaptable to product changes in your operation

- Simultaneously handles varying product sizes with ease

- Using a single depalletizer, other traditional designs are not capable of handling multiple product lines without extensive changeover

- Eliminates the need for multiple conventional depalletizers, due to its high flexibility

- Multiple options for dunnage handling

- State-of-the-industry safety and monitoring systems package

- Lower maintenance requirements when compared to conventional depalletizers

Technical Data

Available Options

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

5605 Goldco Dr

Loveland CO 80538

US -

+1 (970) 663-4770 -

+1 (800) 248-0605 (Customer Service) -

+1 (800) 248-0605 (Field Service)

Jump to...

Jump to...