Products and Solutions

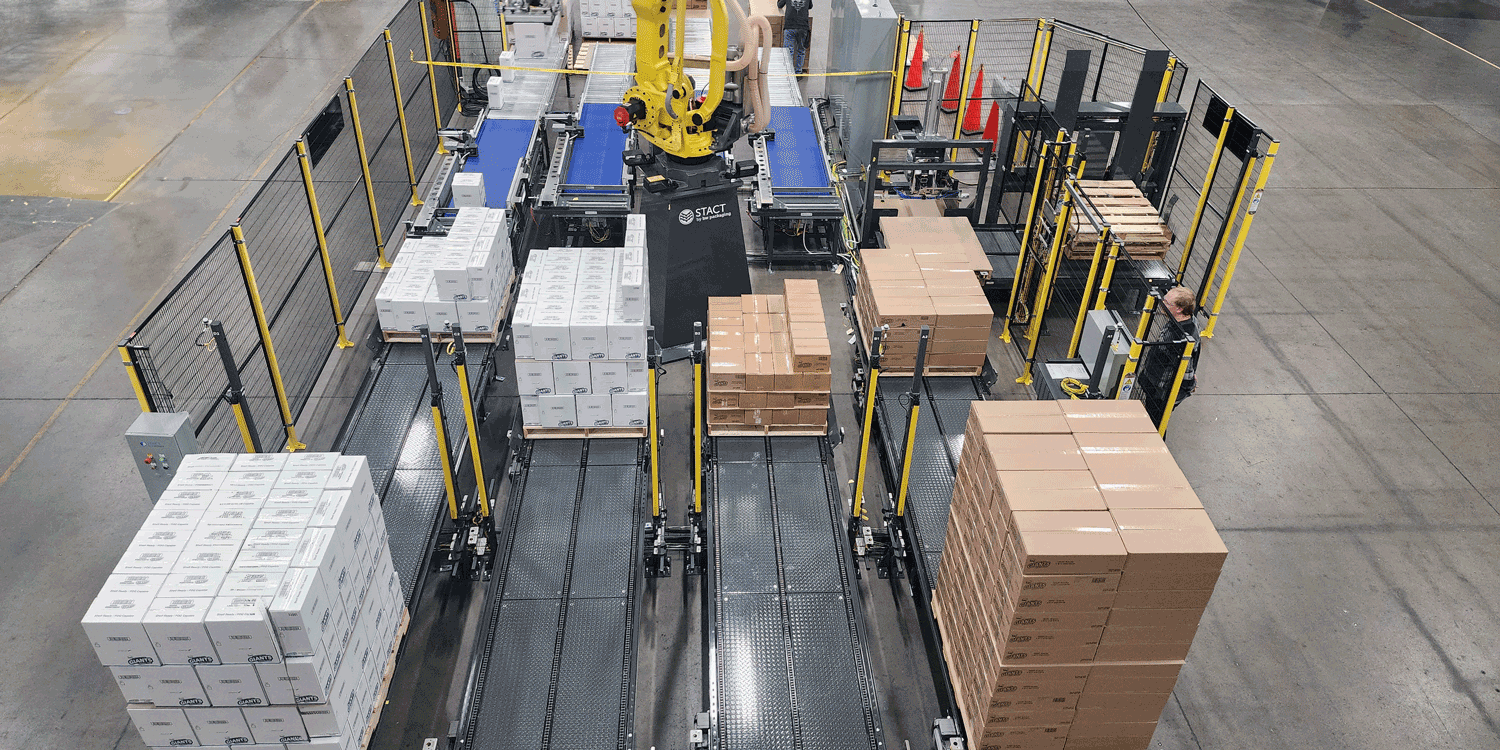

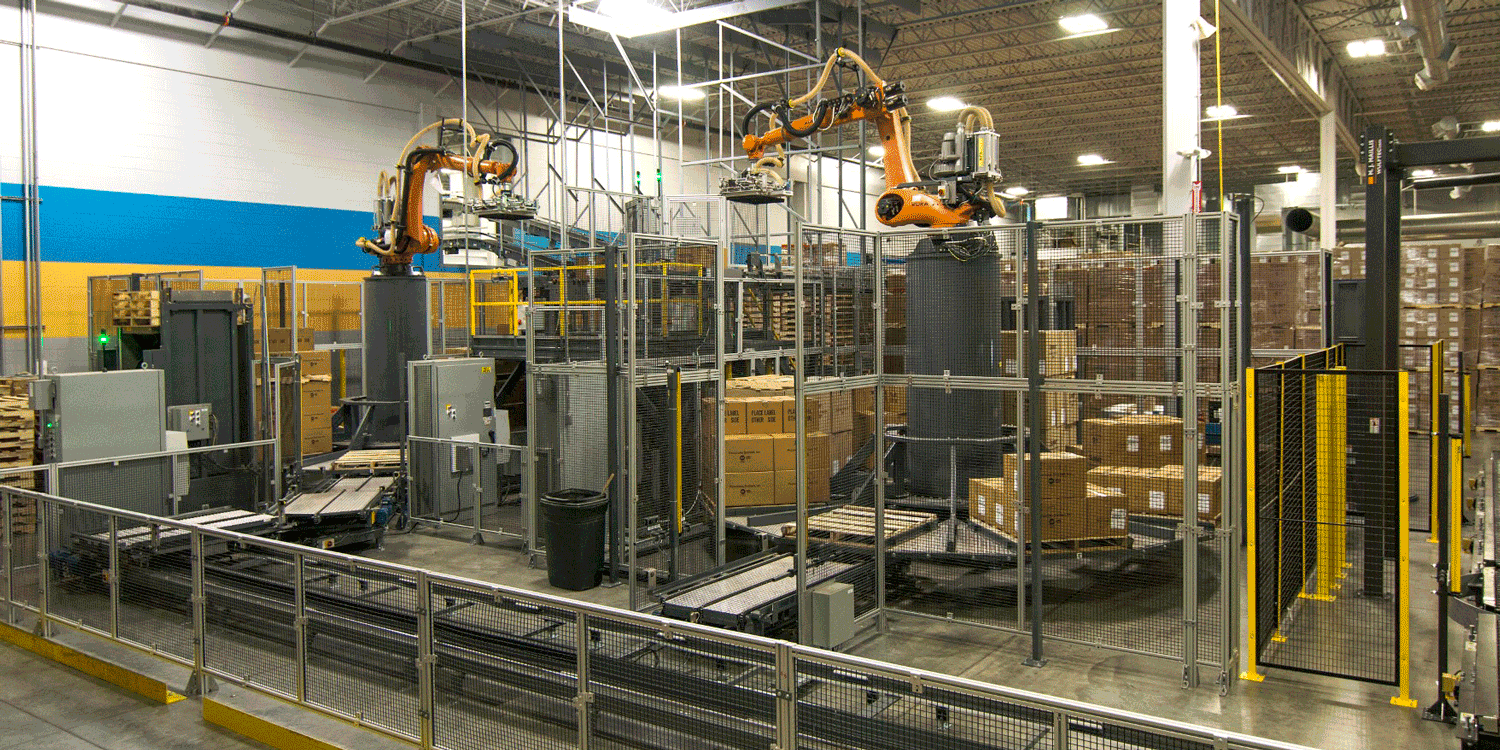

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

Nigrelli WrapAround Case Packers

Discover the innovative Nigrelli WrapAround Case Packers, designed with the food, beverage, and consumer products industries in mind. With a focus on packaging efficiency and space conservation, our range of WP 20, WP 25, and WP 35 models are expertly engineered to meet your high-volume packaging needs.

Why Choose Nigrelli WrapAround Case Packers?

- Compact and Flexible Design: All models bring an efficient footprint, perfect for facilities with limited space without sacrificing functionality.

- Fully Automatic Operation: Experience exceptional productivity with speeds ranging from 20 to 35 cases per minute, optimizing your packaging workflow.

- Versatile Infeed Options: Support for various infeed configurations—including in-line, reverse, and right-angle flow systems—ensures seamless integration with your existing production lines.

Explore Our Models:

WP 20 WrapAround Case Packer

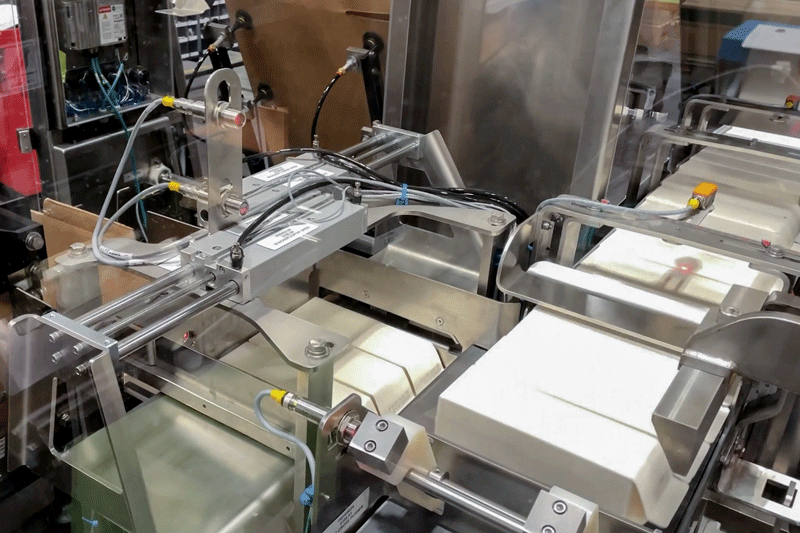

The WP 20 is your solution for diverse product formats, adeptly handling cartons, tubs, cans, and jars. The four-station processing setup includes:

- Tray Blank Feed: Vacuum cups efficiently position tray blanks for product loading

- Product Infeed: Using a patented design for seamless indexing

- Flap Folding and Gluing: Ensures maximum protection for your products

- Compression Sealing: Completed with a precise hot-melt glue system

WP 25 WrapAround Case Packer

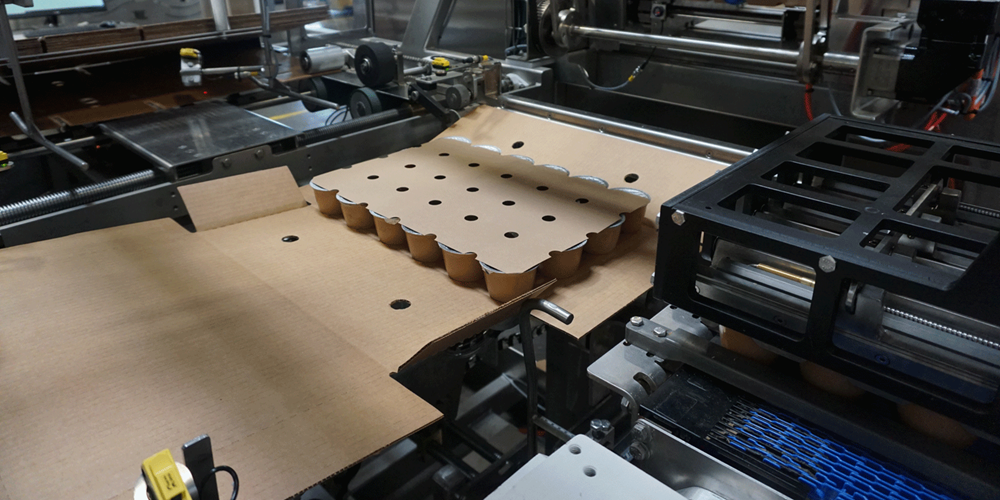

The WP 25 is designed for flexibility, accommodating tubs, cups, bottles, and cartons. Key features include:

- Advanced Infeed Options: With lane dividers and repositioning devices for efficient operation

- Servo-Operated Pick Head: Ensures precise handling and transfer of products

- Compression Stage: Secures products while ensuring packaging integrity

WP 35 WrapAround Case Packer

The pinnacle of our packaging technology, the WP 35 utilizes servo drive and intermittent motion for high-output efficiency:

- High Speed: Processes up to 35 cases per minute, ideal for high-demand environments

- Modular Design: Easily configurable to fit various packaged product styles, accommodating both inside and outside manufacturer flaps

Transform Your Packaging Operations Today!

Nigrelli WrapAround Case Packers combine cutting-edge technology with operational ease to deliver a reliable and efficient packaging solution tailored to your business needs. Streamline your packaging process and enhance productivity while ensuring the integrity of your products.

Contact us today to learn more about how Nigrelli can revolutionize your packaging line with our state-of-the-art solutions!

Key Features

WP 20

- Infeed systems designed for your specific requirements

- Allen-Bradley Logix Series PLC and PanelView HMI

- Nordson hot-melt glue system

- Servo-indexing case flight system

- Self-contained vacuum generator system

WP 25

- Heavy-duty construction

- Compact footprint and modular design

- Servo-drive motion

- Groups, packs, and wraps

- Quick changeovers

- Multiple infeed configurations

- Cluster point lubrication system

- Fully automatic interlocked safety doors

- Allen-Bradley programmable controller

- HMI Display with full diagnostic capabilities

WP 35

- Up to 300 corrugated case blanks storage capacity

- All servo driven for optimal performance

- Nordson hot-melt glue system

- Capable of both inside or outside manufacturer’s joint closure

- Convenient 4’ low profile magazine with a floor load height of 24”

- 39” load and discharge height

- Allen-Bradley PanelView HMI & Logix Series PLC

- Full perimeter guard package

- Low level case detection

- Open flap detection

Technical Data

Available Options

WP 20

- Digital read-out adjustment package

- Horizontal case magazine

- Low case blank detection

- Stainless steel frame construction

- NEMA 4X washdown electrical construction

- Self-contained vacuum system reduces air consumption

- UL listed electrical enclosures

- Plug-in jog cord

- Three-color beacon+

WP 25

- Washdown construction

- Infeed options

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...