Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

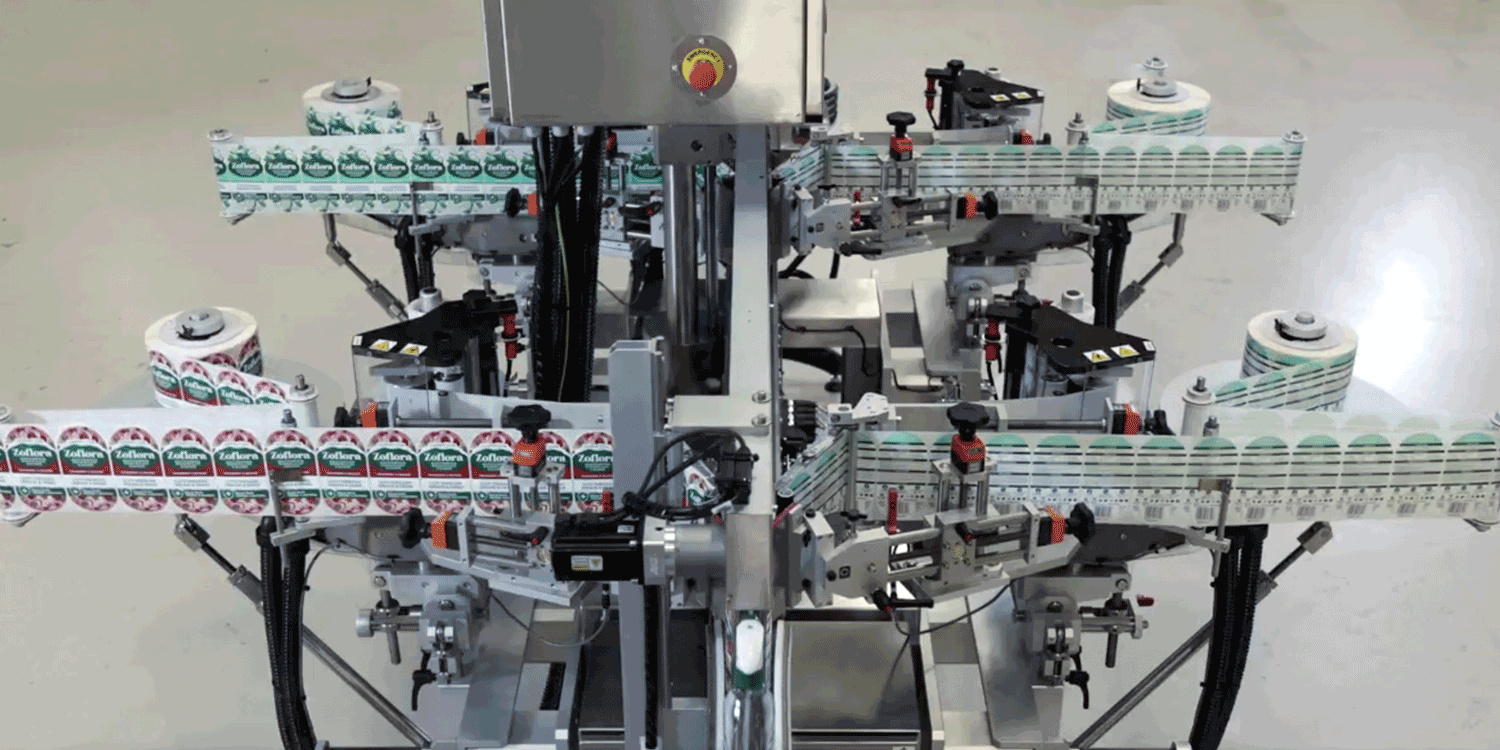

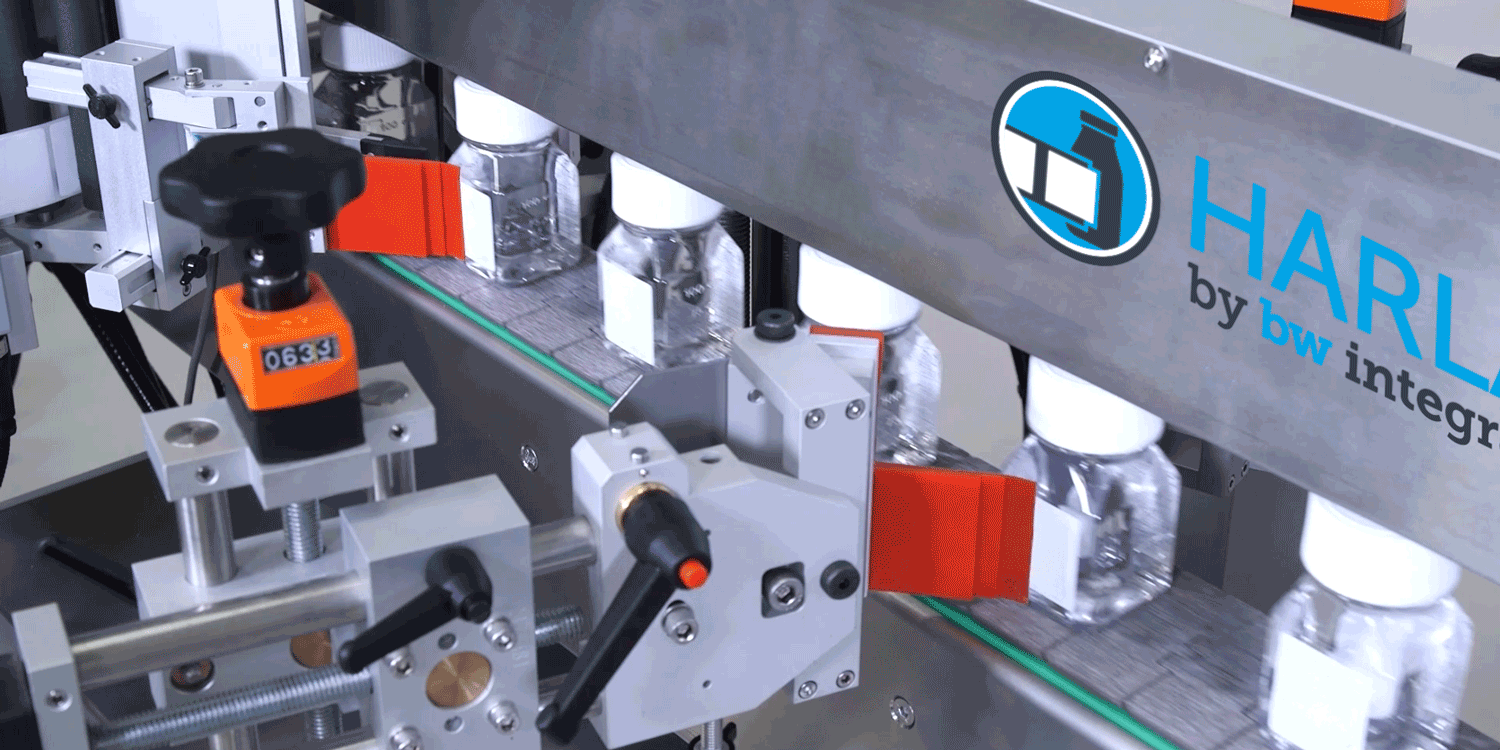

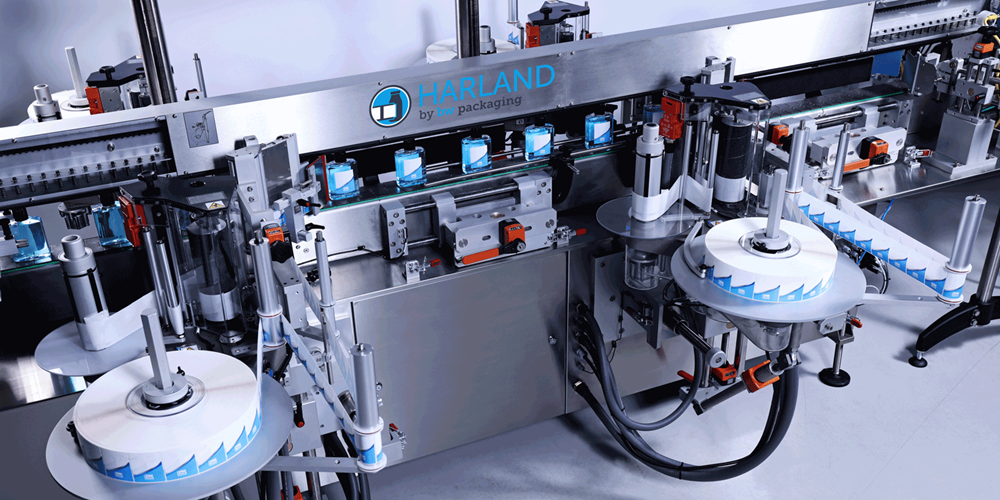

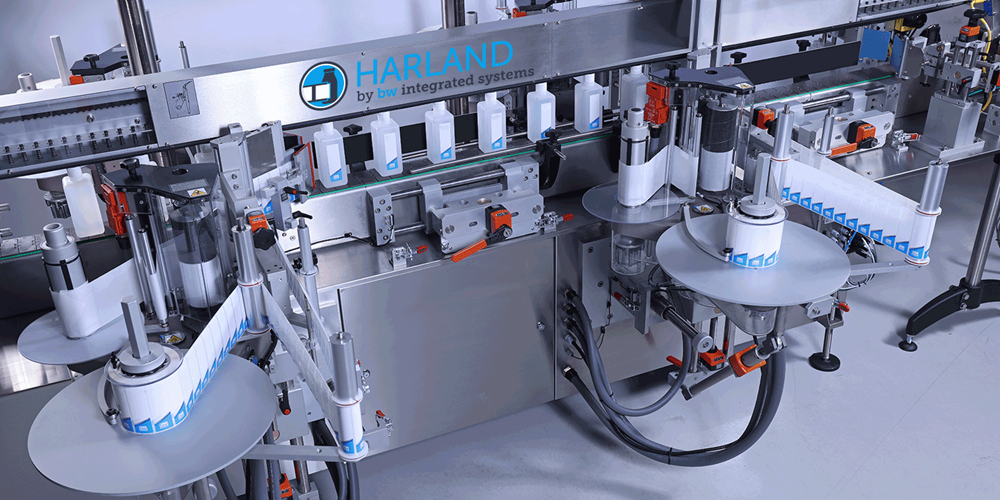

Harland Mercury Pressure Sensitive Labeler

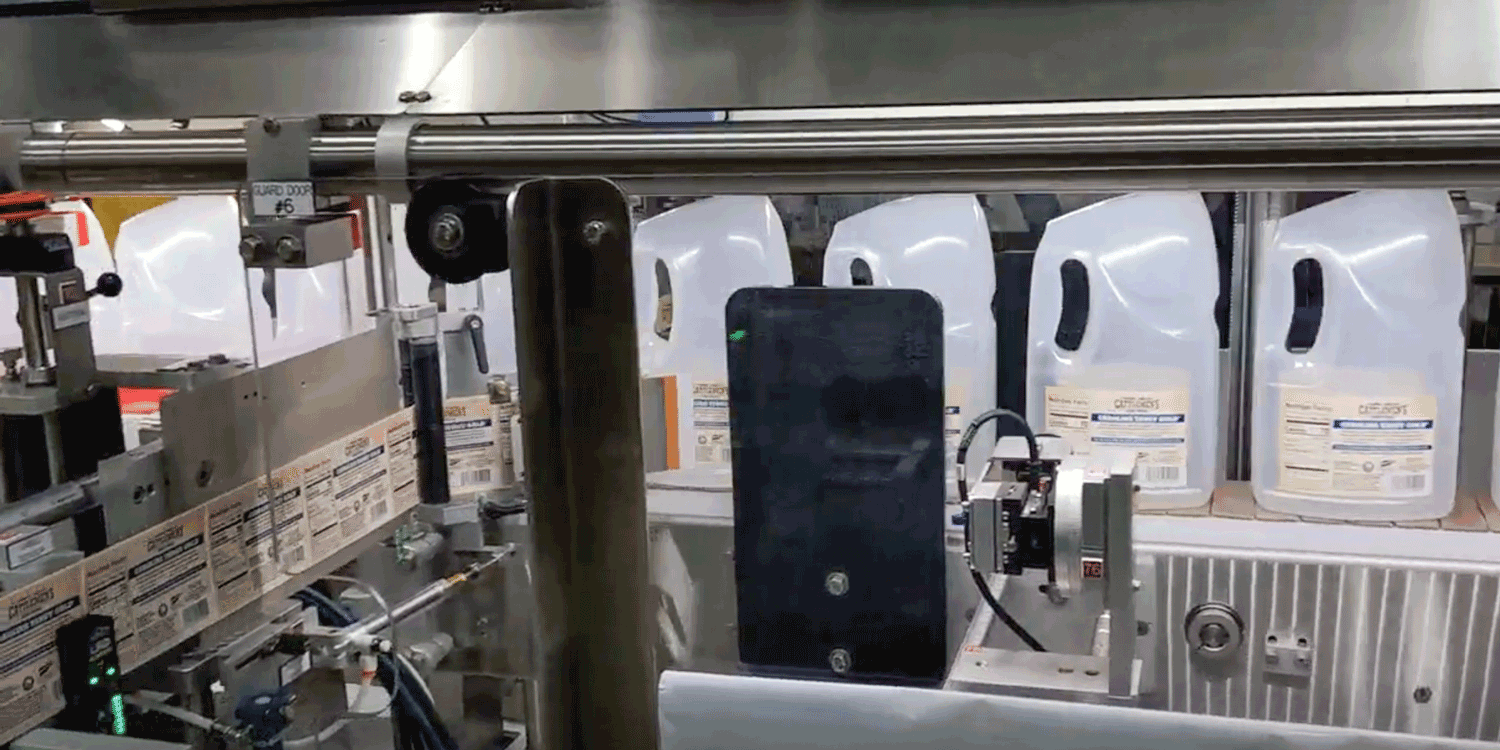

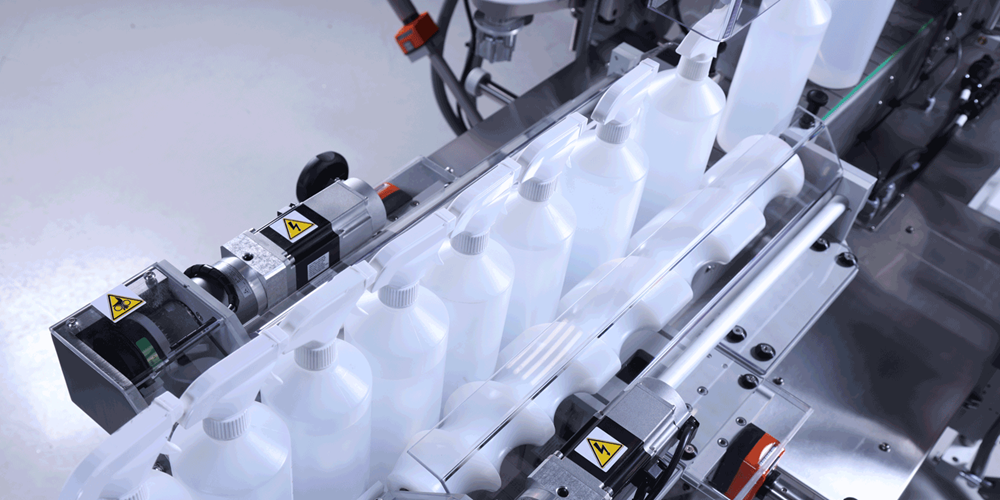

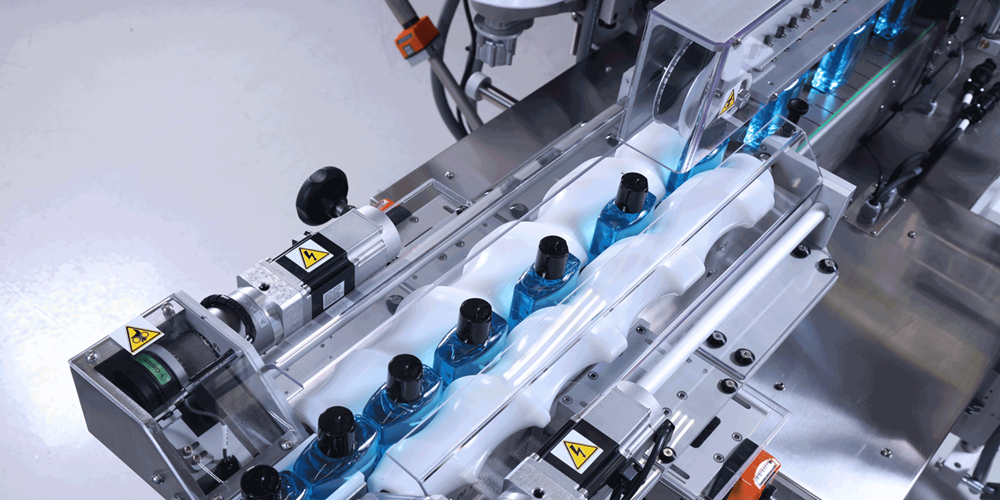

Harland’s Mercury Linear Labeling System is engineered for high-speed production environments where zero downtime is crucial. This innovative labeling solution accommodates up to four labeling heads, complete with advanced label wipe-down modules that ensure precise application and smoothing on a variety of container shapes—all at an impressive speed of up to 250 labels per minute.

Advantages of the Mercury Linear Labeling System:

- Modular Design for Continuous Operation: The flexible setup allows for independent operation of Labeling heads or pairs in auto-redundancy mode, ensuring uninterrupted production even as label reels run low.

- Streamlined Changeovers: Designed for efficiency, the Mercury system allows for quick and easy changeovers between products. Retractable labeling heads and color-coded change part scrolls minimize line downtime, maximizing productivity.

- Durable and Easy Integration: Built with heavy-duty modular construction, this Labeling system not only reduces maintenance and changeover costs but also seamlessly integrates into existing production lines.

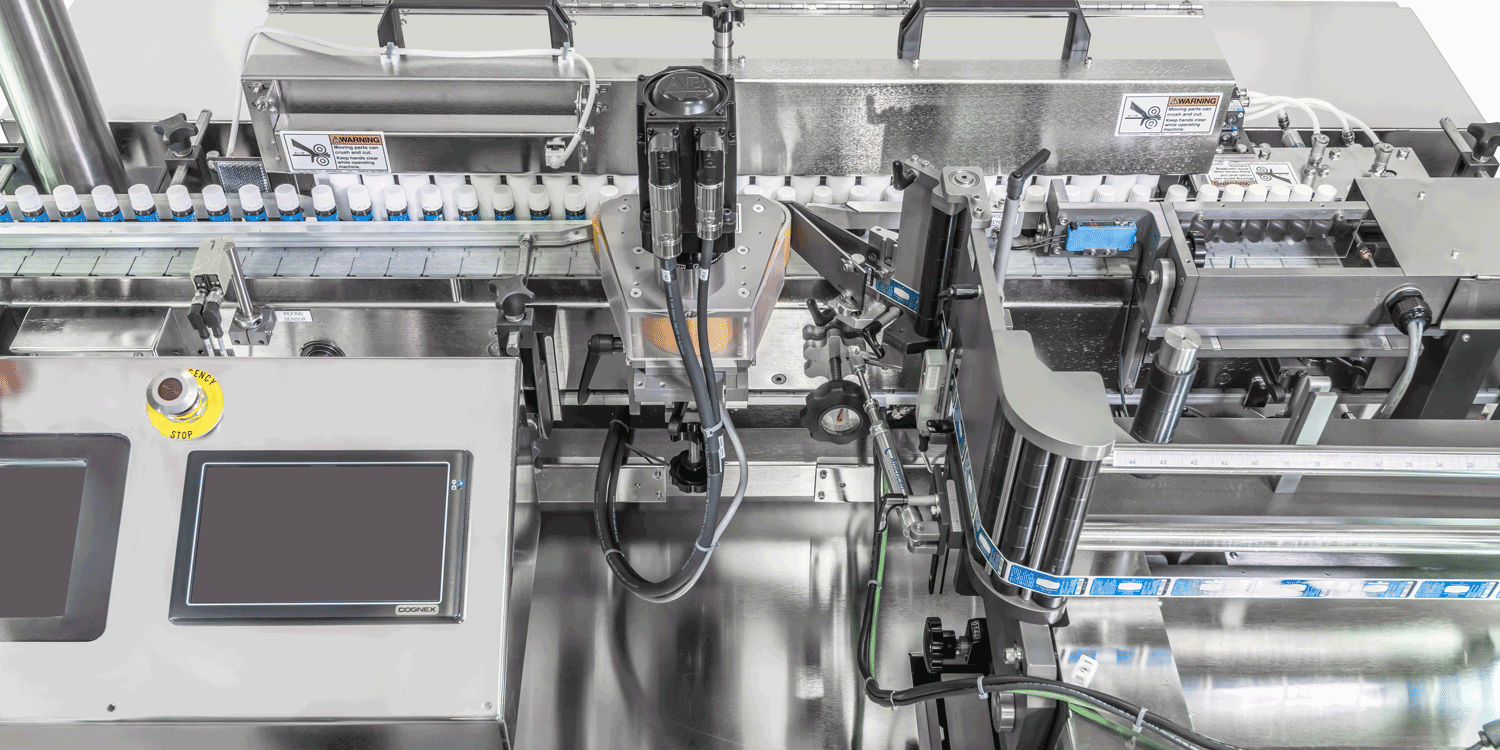

- User-Friendly Control System: Experience superior diagnostics through an enhanced control system featuring a single touch-screen interface, designed for intuitive operation.

- Precision Label Application: Our unique wipedown module guarantees that labels adhere smoothly and accurately to even the most irregularly shaped containers and bottles.

- Comprehensive Inspection Systems: The Mercury Linear Labeling System is equipped with fully integrated inspection and vision systems that verify label presence, accuracy, position, and alignment, along with advanced barcode reading functionality.

At Harland, we go beyond providing labeling solutions; we empower your business to thrive. Experience seamless repeatability, minimal downtime, and reduced waste with our cutting-edge Mercury Linear Labeling System. Transform your labeling processes today and ensure your production lines operate at peak efficiency.

Key Features

- Up to 4 labeling heads

- Fully synchronized servo-driven axis

- Toolless changeovers

- Digital position indicators

- User-friendly next-generation smart HMI interface

- Rugged robust design

- Reliable 24 / 7 operation

- Designed for easy operator and maintenance access

- Global certification – UKCA, CE, UL, (others available)

Technical Data

Available Options

- PackML

- Safety PLC’s

- Industry 4.0

- Pharmaceutical: 21 CFR part 11 & validation packages

- Siemens or Allen-Bradley/Rockwell controls

- Label overprint by TTO, CIJ, laser or hot foil

- Vision inspection system - sensor, scanner or camera

- Fail safe, track-and-reject systems with verification

- Queue control

- Fallen bottle detection

- Front, back, top & wrap labeling options

- Infeed & outfeed container transfer via side belts, conveyor flush sides

- Product pitching via servo scroll, gapping wheel, or gatting unit

- Product orientation via chain aligners, centering units, or tri-roller

- Label wipe down via heavy-duty wipes, foam rollers, or walking beam module for complex container and label profile

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)