Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

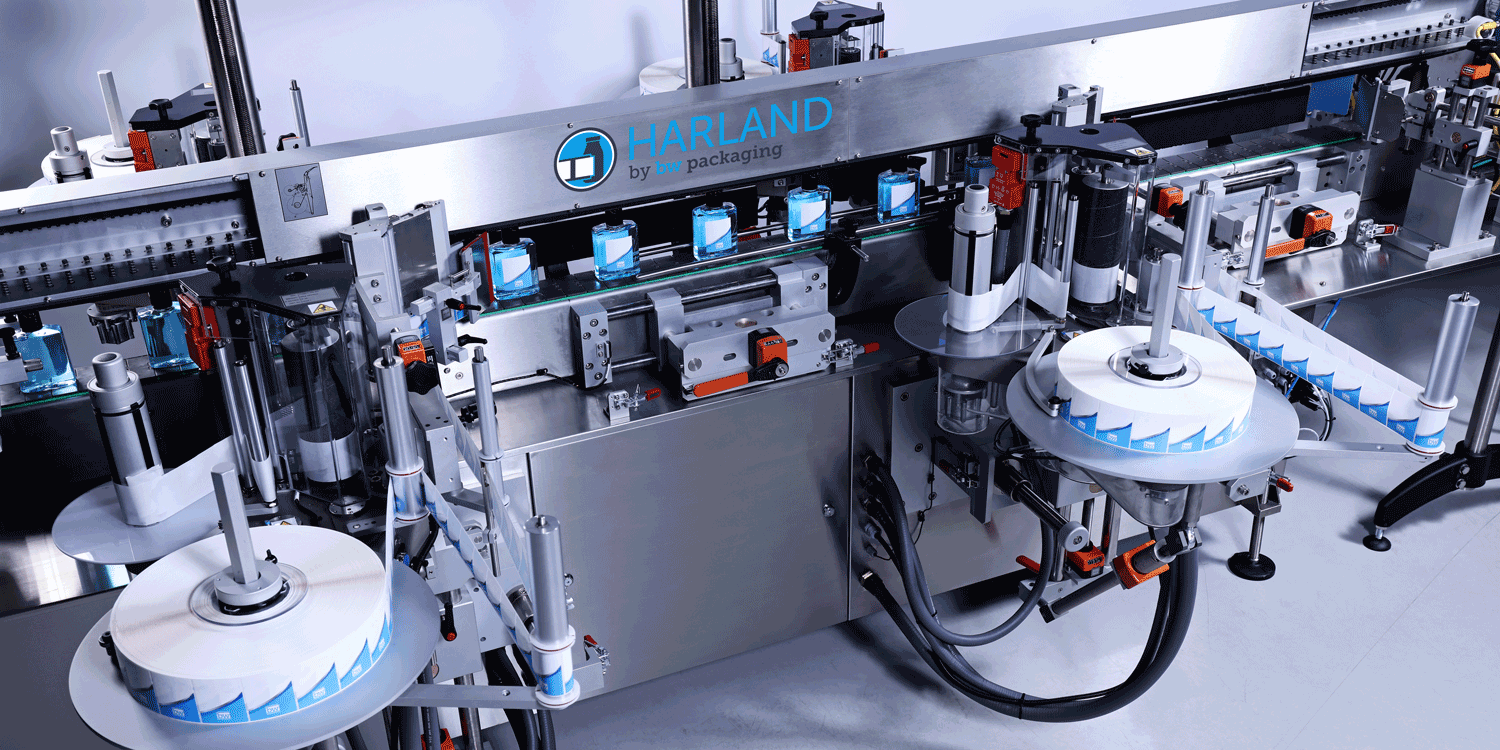

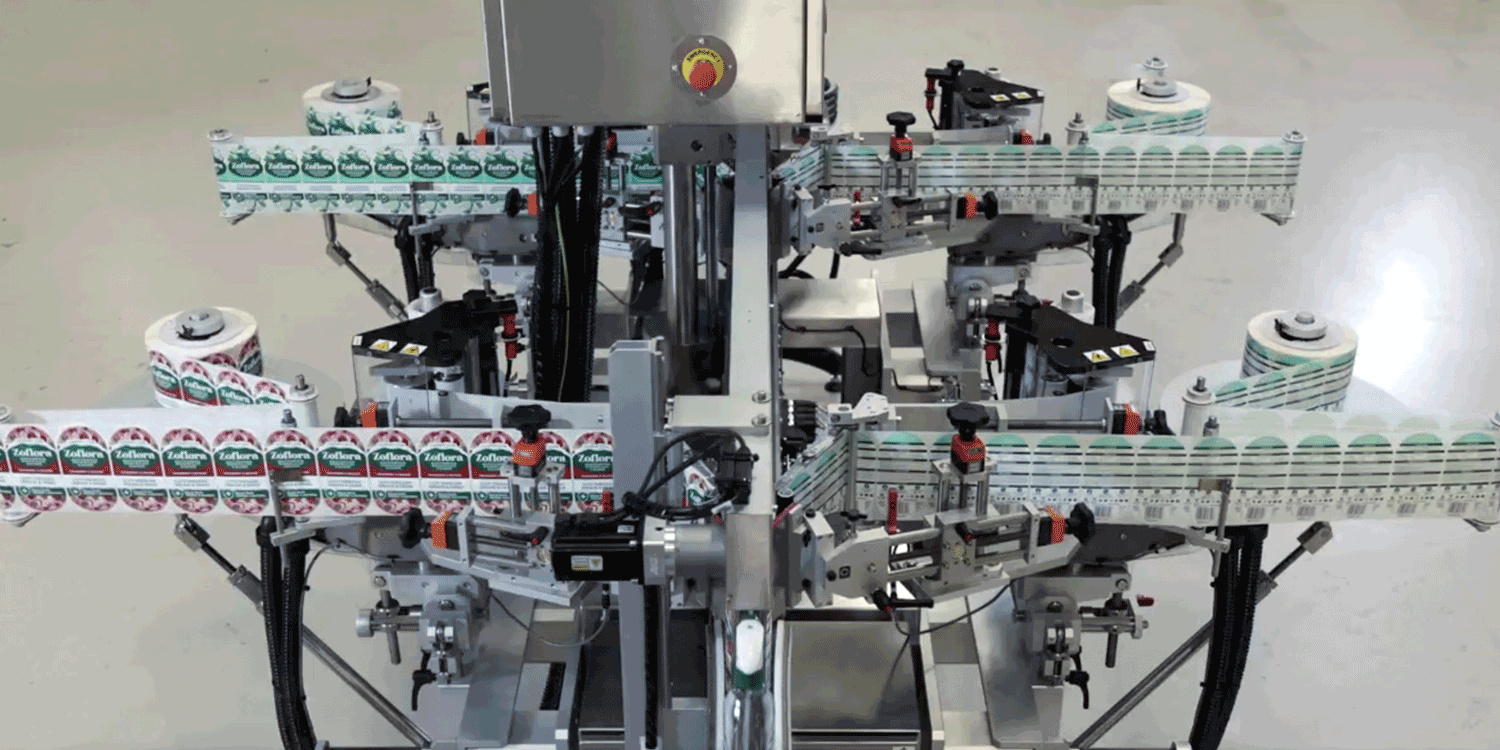

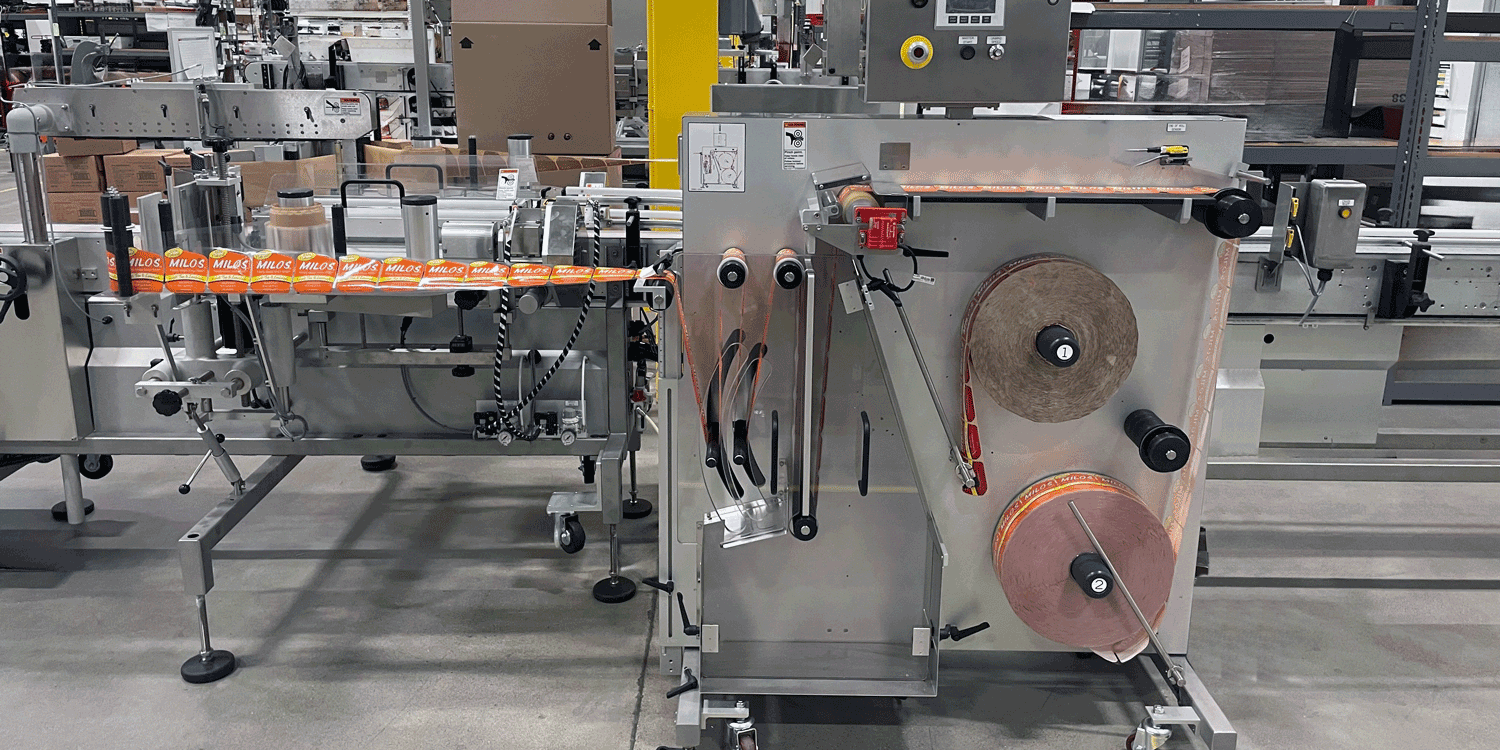

Harland PSL 9000W Pressure Sensitive Wrap Labeler

Harland’s PSL 9000W is an advanced wrap labeling machine designed for the fast and accurate labeling of cylindrical containers on a conveyor system. This state-of-the-art labeling solution is fully compatible with integrated inspection systems, ensuring high-quality output. Its user-friendly design makes setup, operation, and maintenance a breeze, providing an efficient labeling experience.

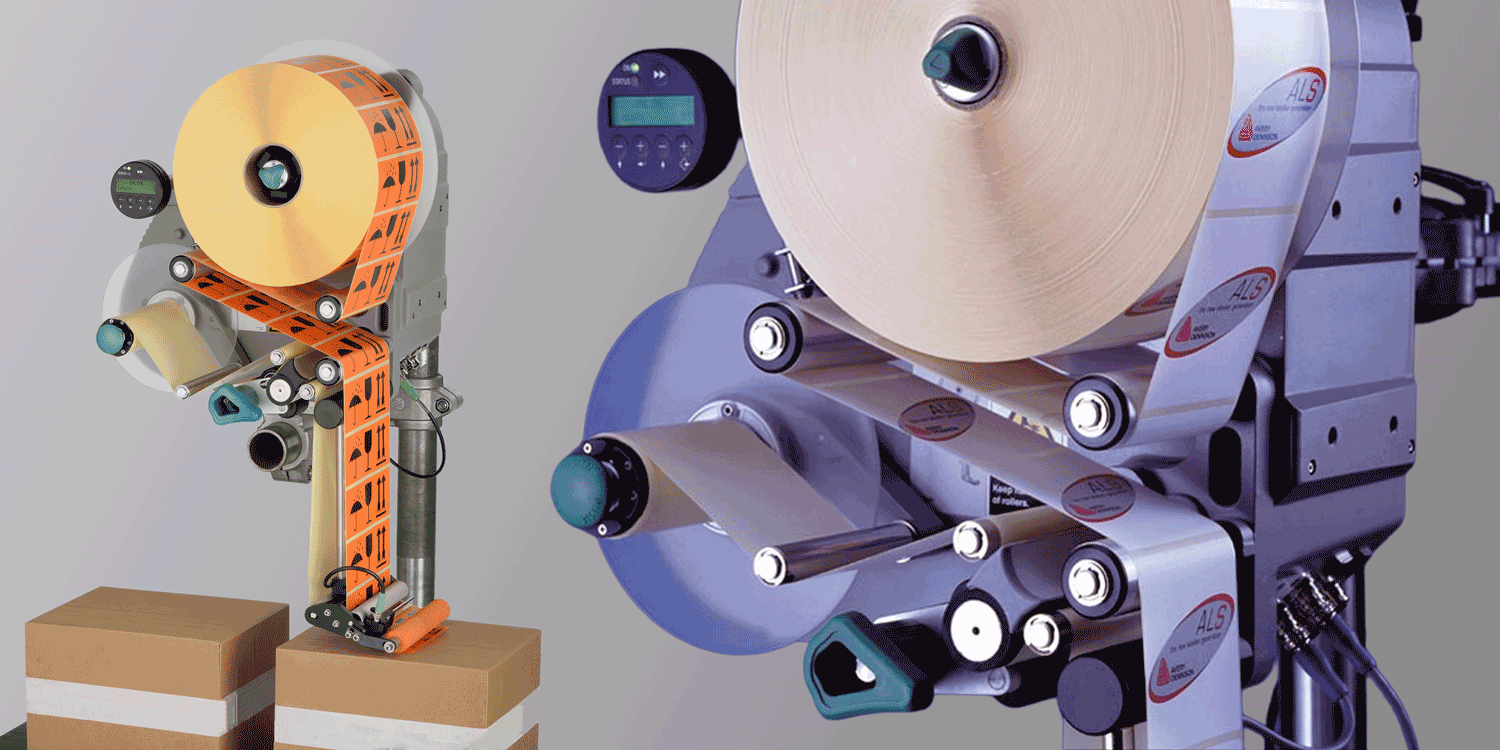

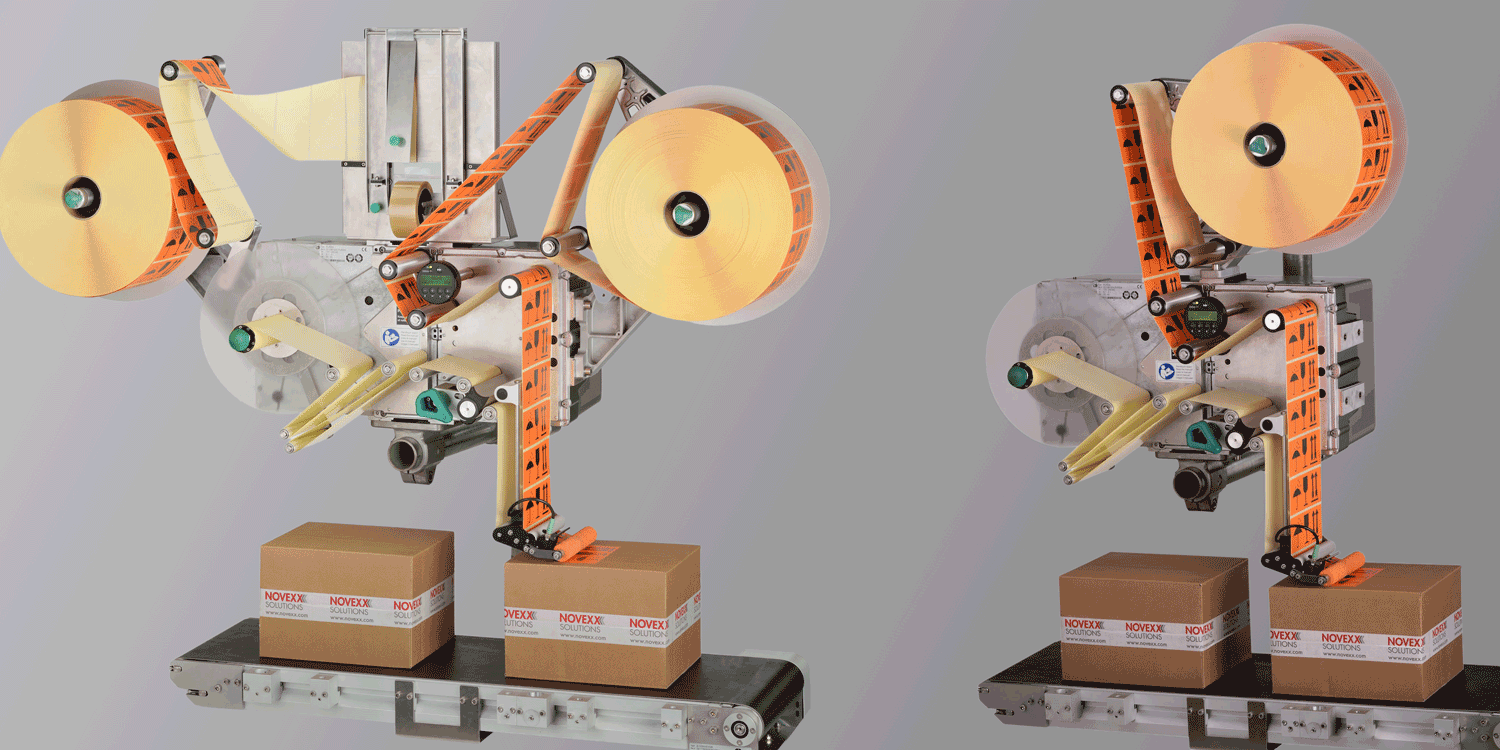

High-Performance Heavy Duty SP 20 Servo Label Applicator

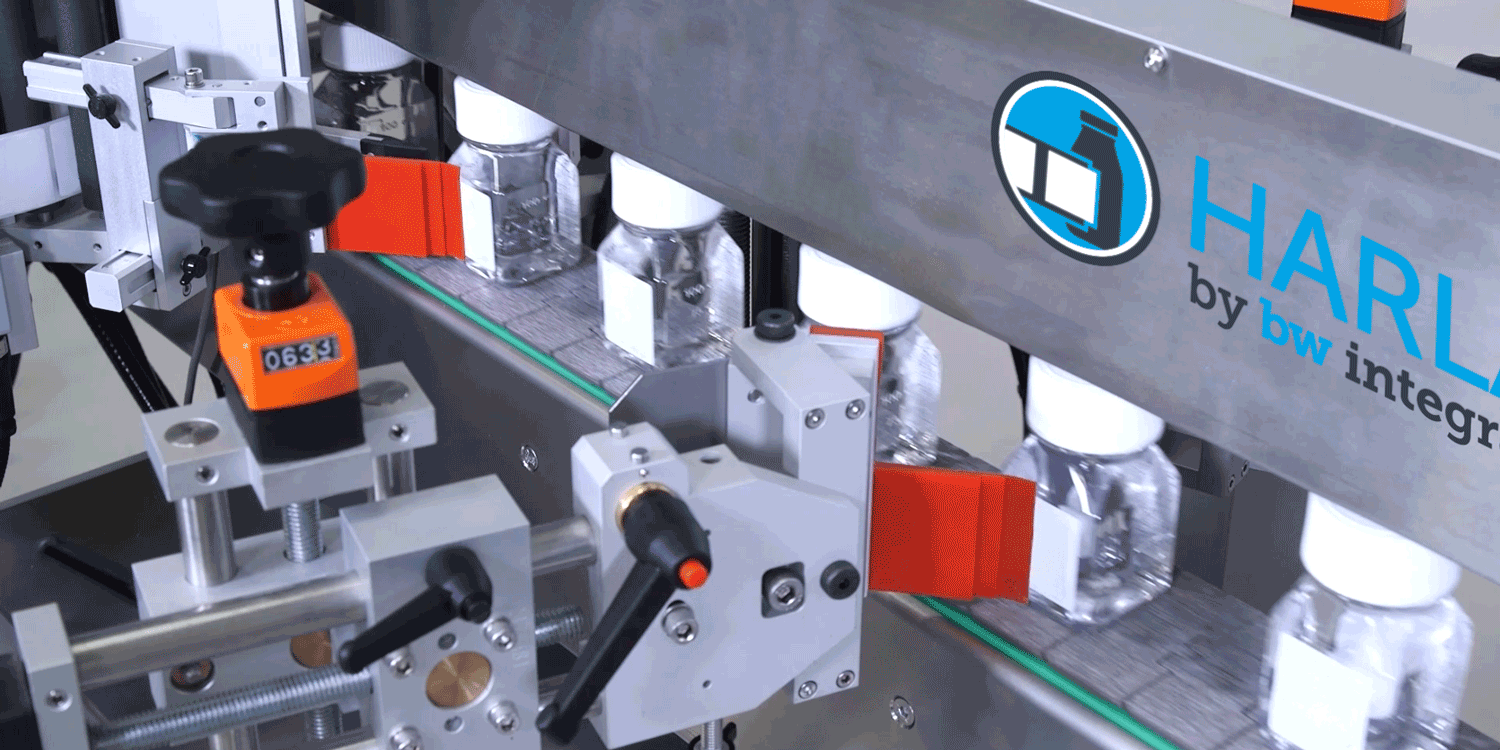

At the heart of the 9000W is the Heavy Duty SP 20 servo-driven label applicator, featuring a push/pull web drive for exceptional accuracy and repeatability in stop positions. This ensures precise lot and expiry coding, along with thorough inspection capabilities. The SP20 is engineered for superior web control, enabling accurate dispensing performance at high indexing speeds.

With the SP20 push/pull servo-driven label applicator, enjoy unparalleled web tension control and label stop accuracy. The wrap station assembly guarantees precise and consistent label application, while the variable pitch single infeed timing screw assembly ensures reliable product presentation. Experience quick, tool-free changeovers, enhancing your production efficiency.

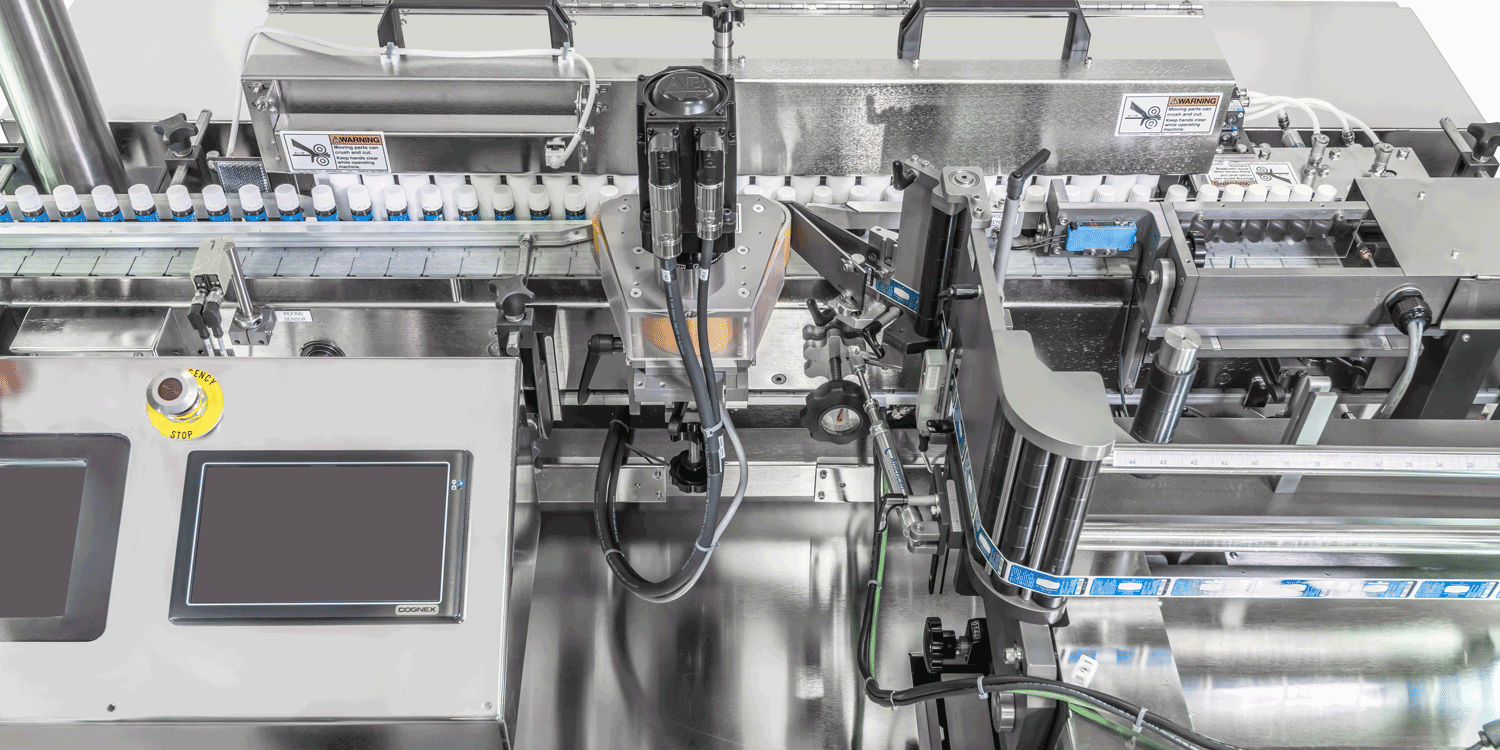

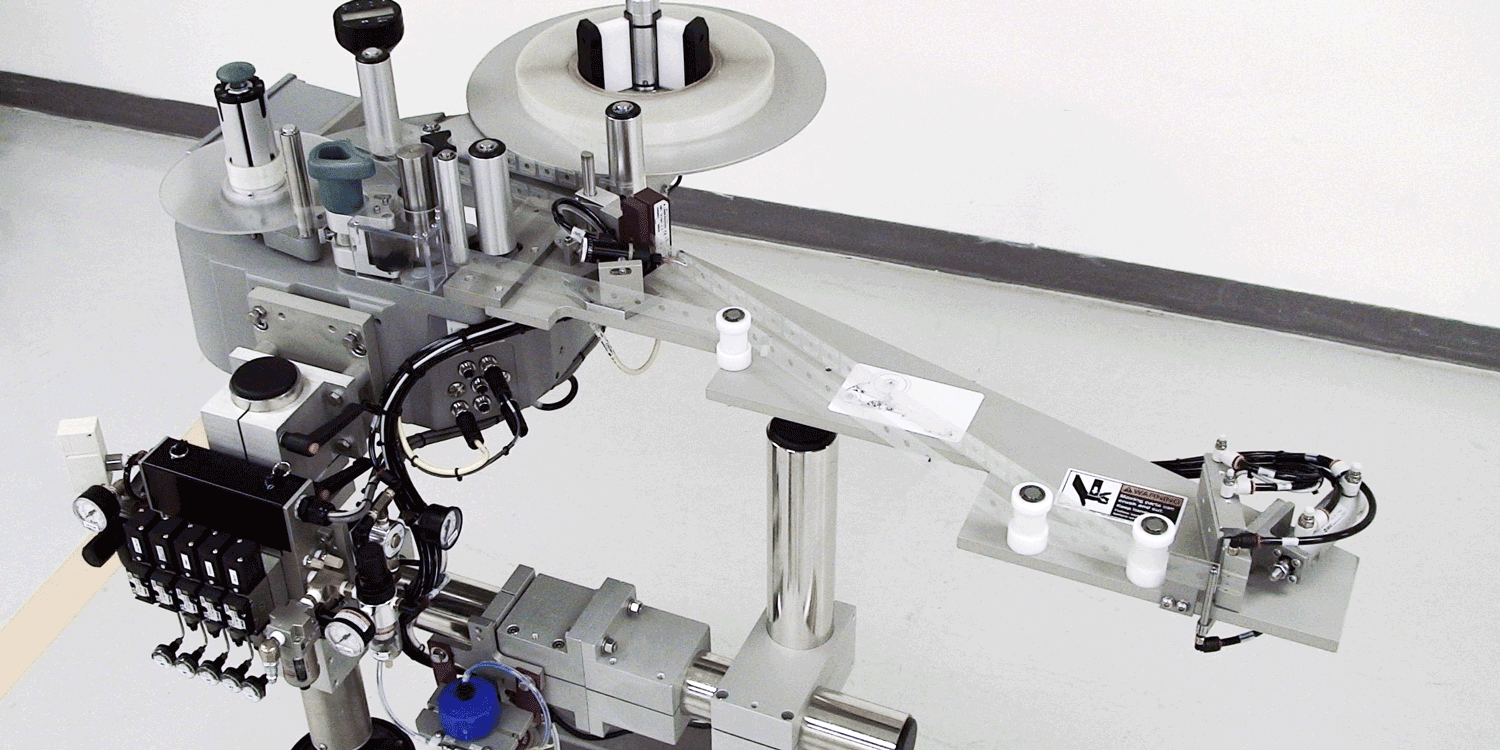

Flexible HMI for Effortless Control

The flexible Human-Machine Interface (HMI) allows for intuitive control of various labeling applications. Users can easily manage setup recipes, counters, and graphical fault displays, making the labeling process more efficient. Product changeovers are straightforward and quick, thanks to no-tools guides, an infeed timing screw, and wraparound assemblies.

Sturdy and Sanitary Design

This top-tier labeling system boasts a heavy-duty stainless steel base frame, capable of supporting numerous printing, verification, and inspection systems. The raised bed stainless steel conveyor is designed for easy cleaning, ensuring hygienic operations. Additionally, the touch-screen operator interface delivers cutting-edge controls, promoting effortless functionality across the entire system.

Upgrade your labeling processes with Harland’s 9000W Pressure Sensitive Wrap Labeling Machine and experience the perfect blend of speed, accuracy, and ease of use.

Key Features

Technical Data

Available Options

- Tooling for oversized caps and recessed label panels

- Laser, thermal transfer, ink jet & hot stamp printer

- Integration of a wide range of inspection systems

- Product, label, and eject counters

- Complete system alarm packages with any combination of audio alarm, visual alarm, and conveyor stop

- Free-standing dual label unwinds with splice station

- Waste cutter to eliminate the need to stop and remove waste rolls

- Splice detector

- Clear label sensor - non-contact

- Product or label eject stations

- Label pick-off assembly

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

3070 Mainway

Burlington ON L7M 3X1

CA -

+1 (905) 336-8880 -

+1 (905) 336-5710 (Customer Service) -

(Field Service)