Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

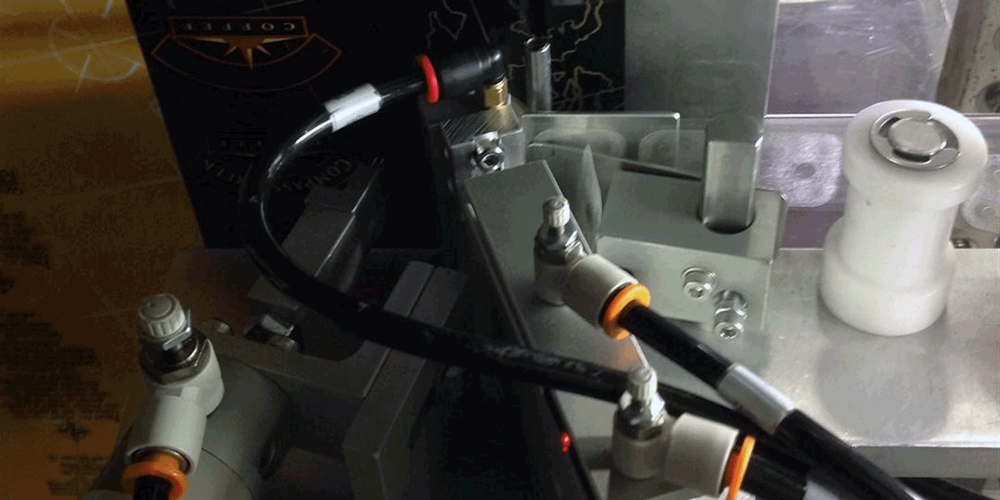

Harland PRV 204 Series Degassing Valve Applicators

At Harland, we specialize in advanced pressure relief valve (PRV) machines designed for packaging a range of products from coffee to pet food. Our PRV 204 Series machines effectively manage the precise application of pressure relief valves, which are essential for safely releasing built-up gas pressure in airtight containers and flexible packaging. By utilizing our advanced application system, you can preserve the quality and freshness of your products while protecting them from contaminants.

Seamless Integration with FFS Machines

Our versatile PRV machines seamlessly integrate with various form fill seal (FFS) and bag pouch making machines, including both intermittent (PRV-i) and continuous (PRV-c) models. This adaptability allows for easy configuration with different types of pressure-sensitive release valves, enhancing your packaging efficiency.

Effortless Valve Application

Many consumers overlook the importance of degassing valves, yet they play a crucial role in maintaining coffee freshness. Our Harland PRV 204 Series simplifies the application process by placing degassing valves on the outside of coffee bags, eliminating the need for extra steps that involve internal valve application. The entire valve application process is controlled by an integrated microprocessor, streamlining tasks such as oil insertion, hole punching, and valve placement.

High-Speed Performance

Our continuous operation models can apply up to 300 valves per minute, making Harland machinery a leader in speed and consistency. For those needing intermittent motion, our 204PRV-I model efficiently applies 110 valves per minute, while our 204PRV-C model offers continuous motion designed for large-scale operations.

Customizable and Efficient Solutions

All of Harland's PRV machines are equipped with advanced features that enhance adaptability and efficiency. These machines not only preserve the aroma and quality of oxygen-sensitive products but are also perfect for packaging coffee right after grinding. Our systems include oil injection modules that accommodate both pre-oiled and standard valves, providing unmatched flexibility.

Experience faster and more effective coffee packaging with Harland's industry-best PRV machines—your trusted partner for ready-to-ship, shelf-stable products.

Key Features

- Advanced web control for accurate valve placement

- Stepper drive with custom nip rollers for precise and consistent feed

- Independently driven collapsible rewind for quick, easy removal of the waste liner

- Microprocessor with built-in applicator controls, auto diagnosis and status messages

- 405mm [16”] diameter label roll unwind with advanced valve liner tension control

- Intermittent model includes an integrated converging hole punch & applicator

- Continuous model includes an integrated servo hole punch and wipe-on applicator with automatic product speed following

- User-friendly, rotatable operator interface and feature rich micropressor controls

- Integrated module for oil injection

- Compact, flexible, and high adaptable with an industrial design suitable for 24/7 operation

Technical Data

Available Options

- Applicator extensions designed to access existing packaging equipment

- Web cage for diverting the film path in vertical form, fill & seal machines

- Web brake to ensure film stability on intermittent form, fill & seal machines

- Non-stop supply roll change kit (dual unwind & splice table)

- Non-stop waste roll removal kit (waste cutter or vacuum nozzle)

- Inspection options for missing oil, valves, or vent holes

- Alarm package with three color light stack

- IP65 rating for wet or dusty environments

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

3070 Mainway

Burlington ON L7M 3X1

CA -

+1 (905) 336-8880 -

+1 (905) 336-5710 (Customer Service) -

(Field Service)

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)