Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

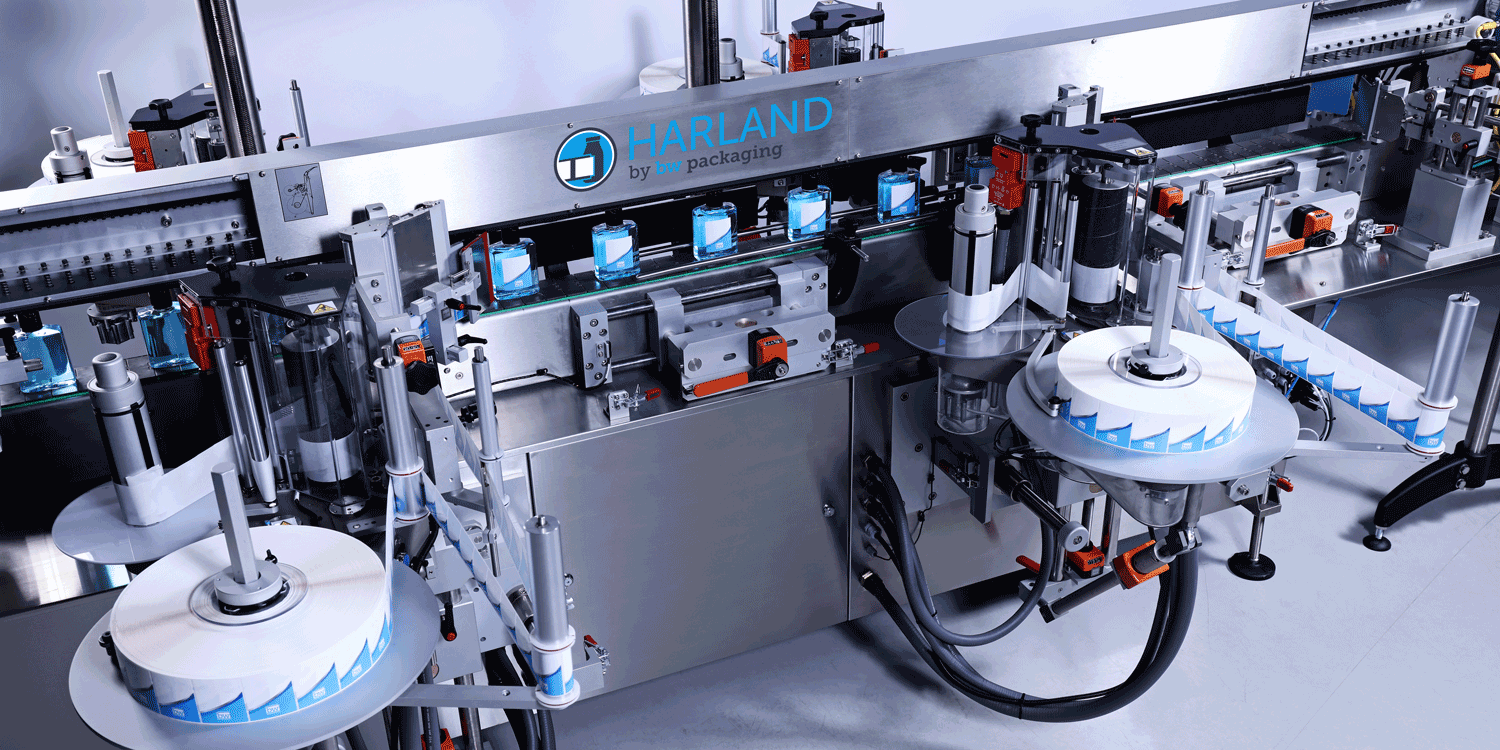

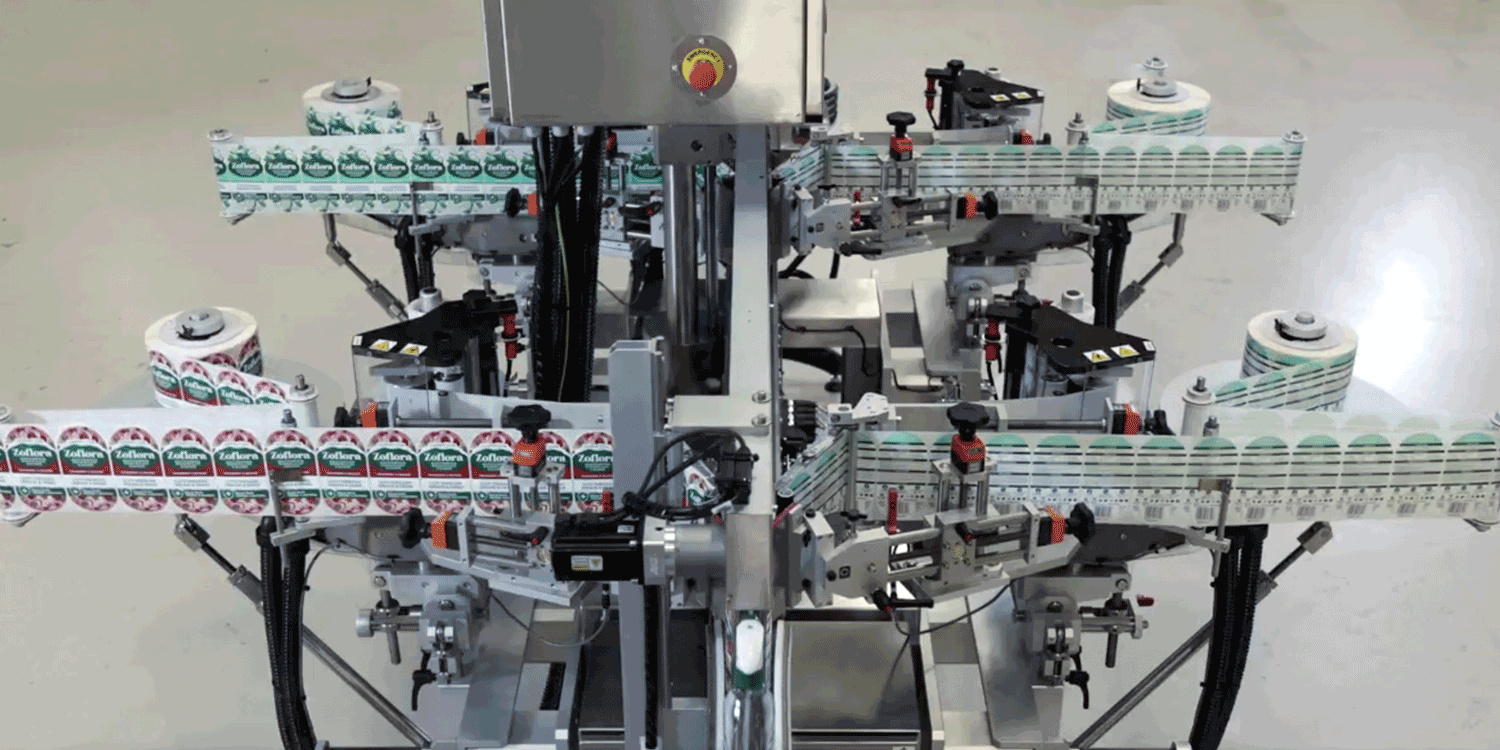

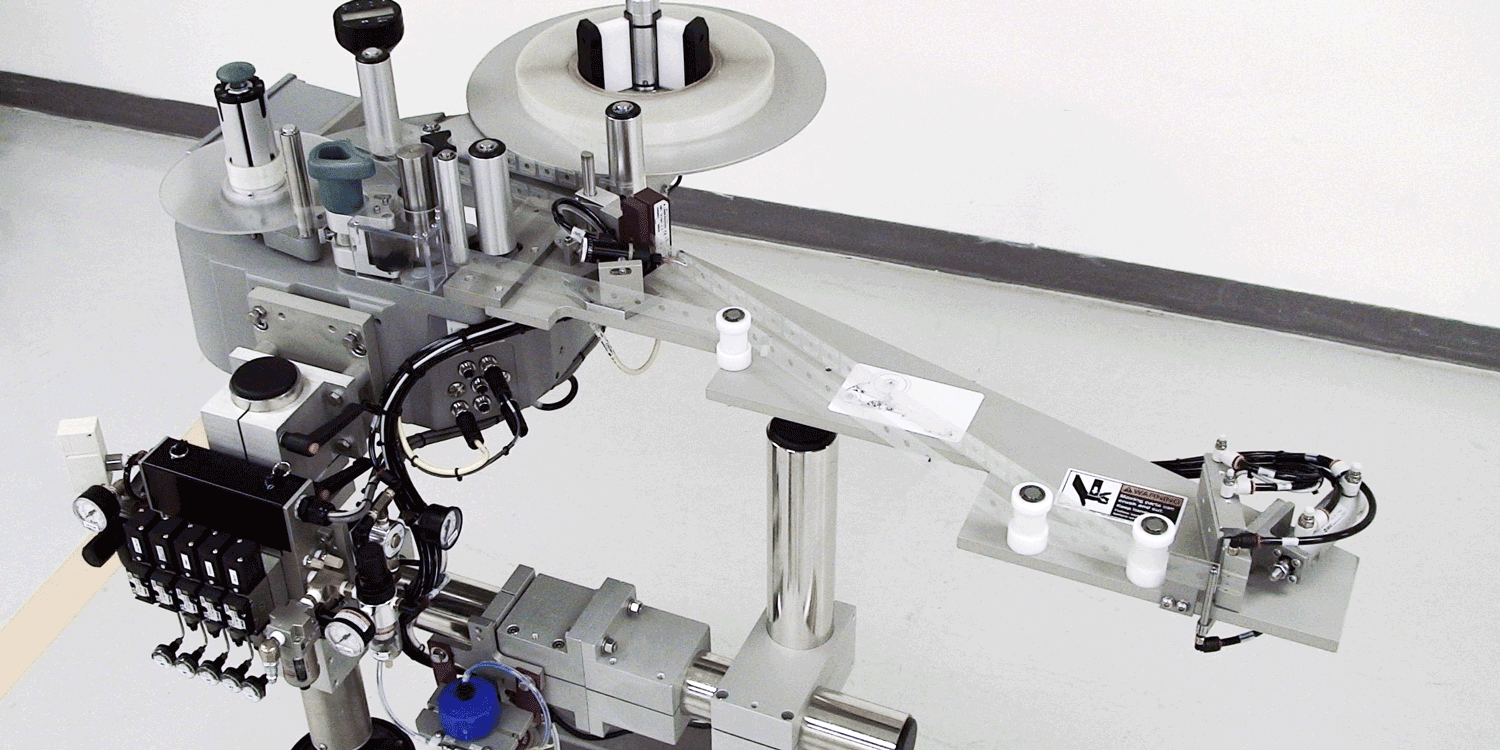

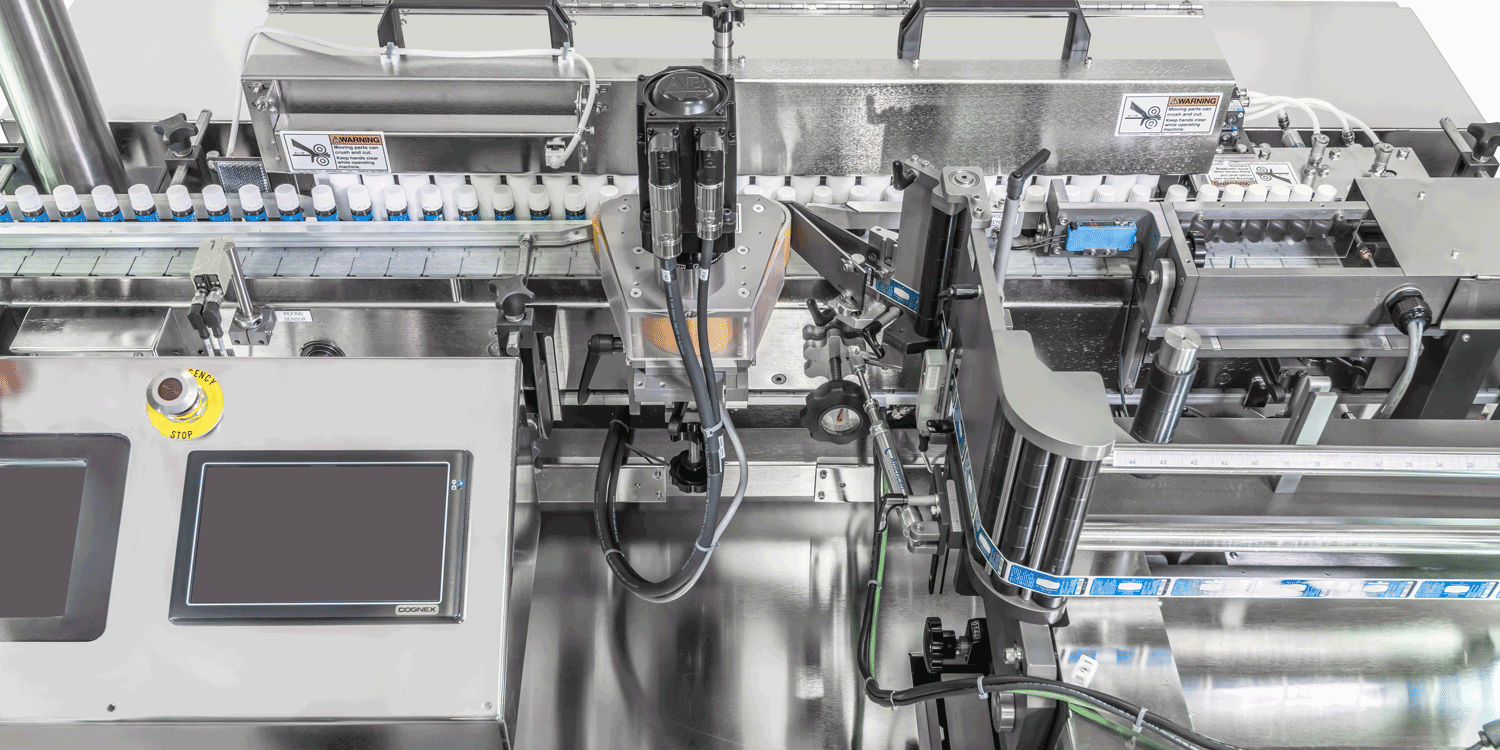

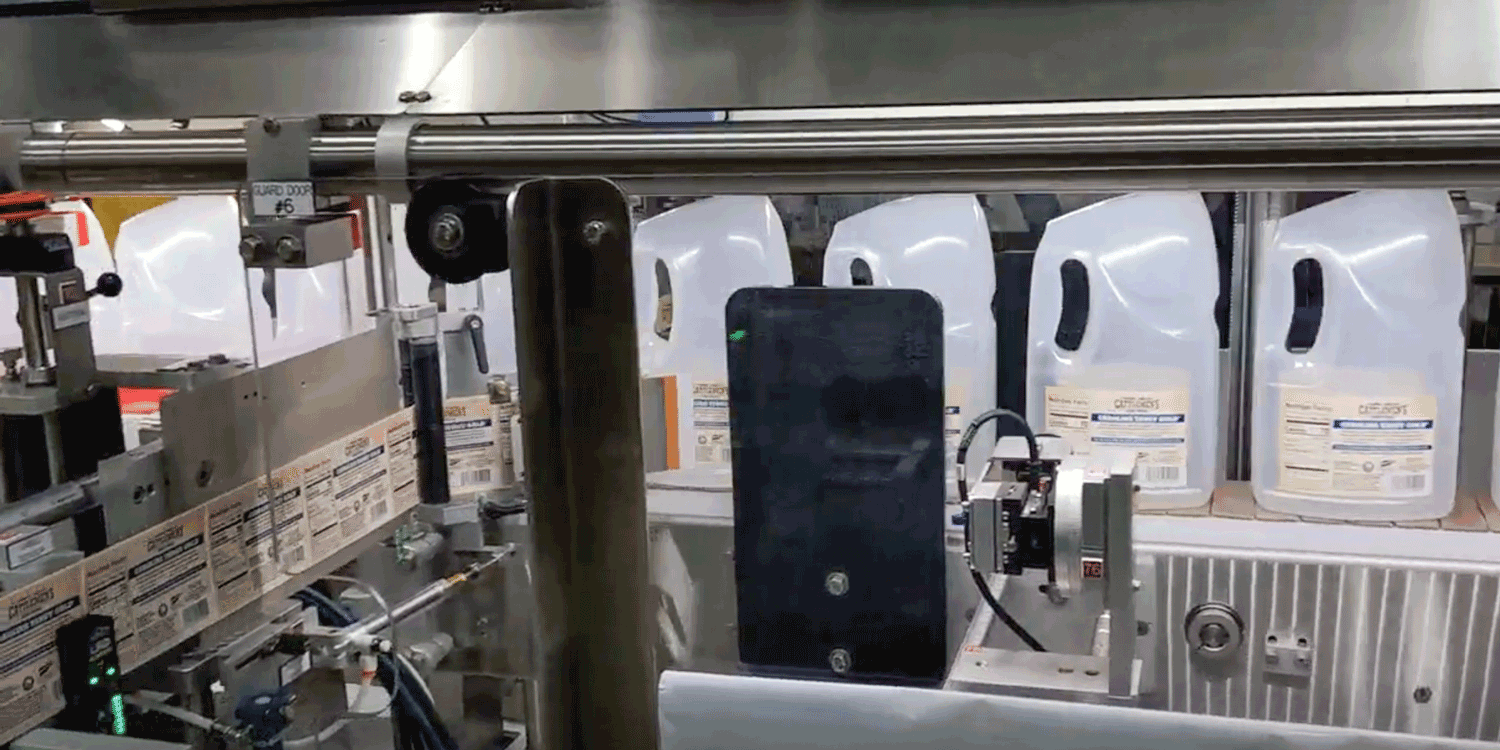

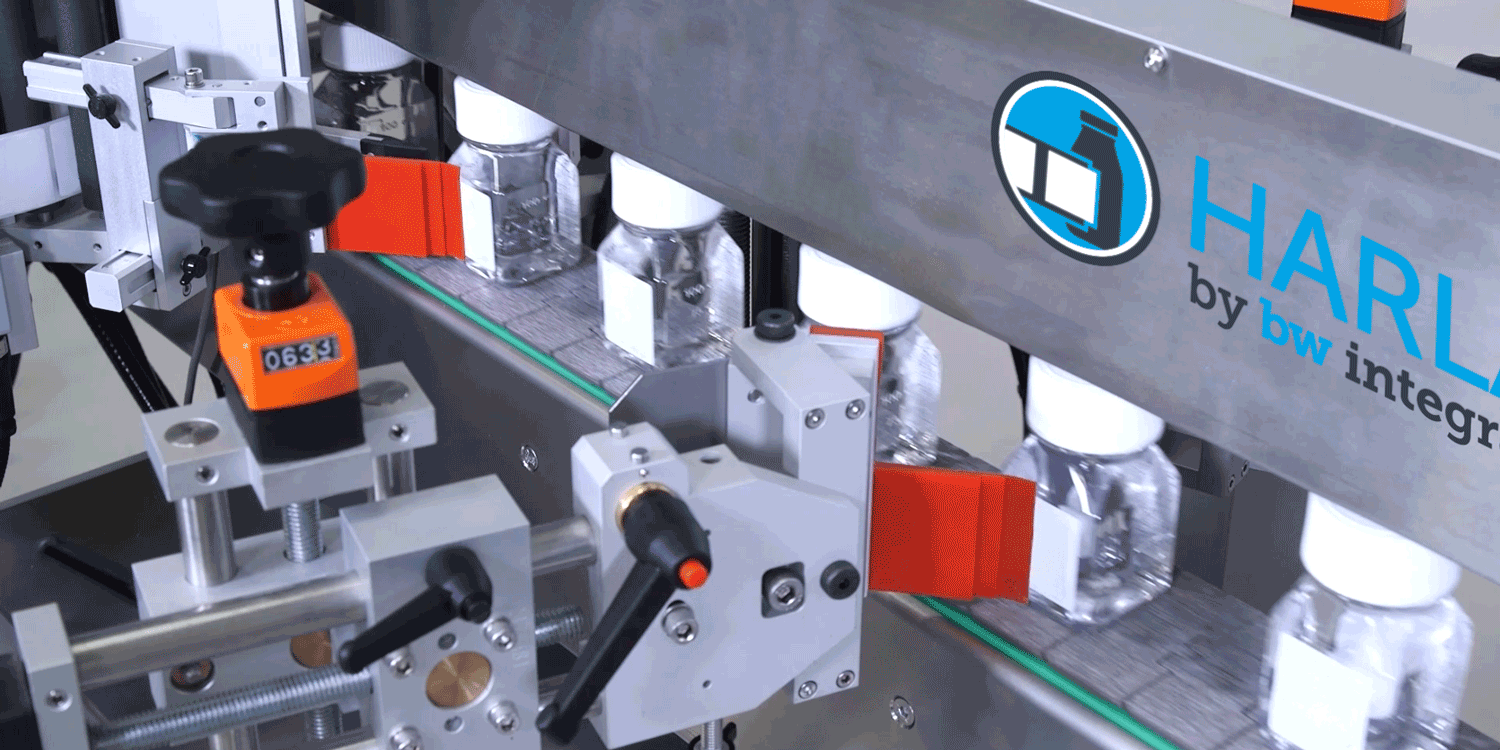

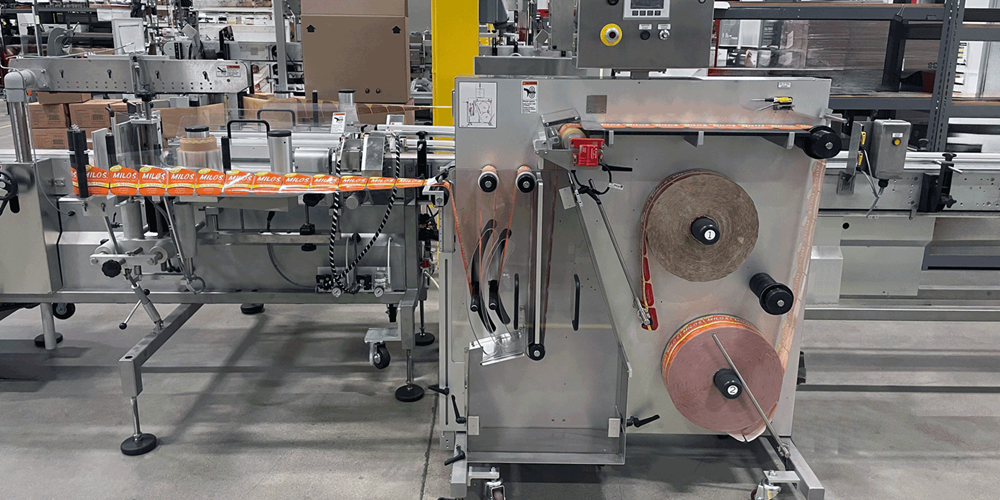

Harland UNW 924 Unwinder

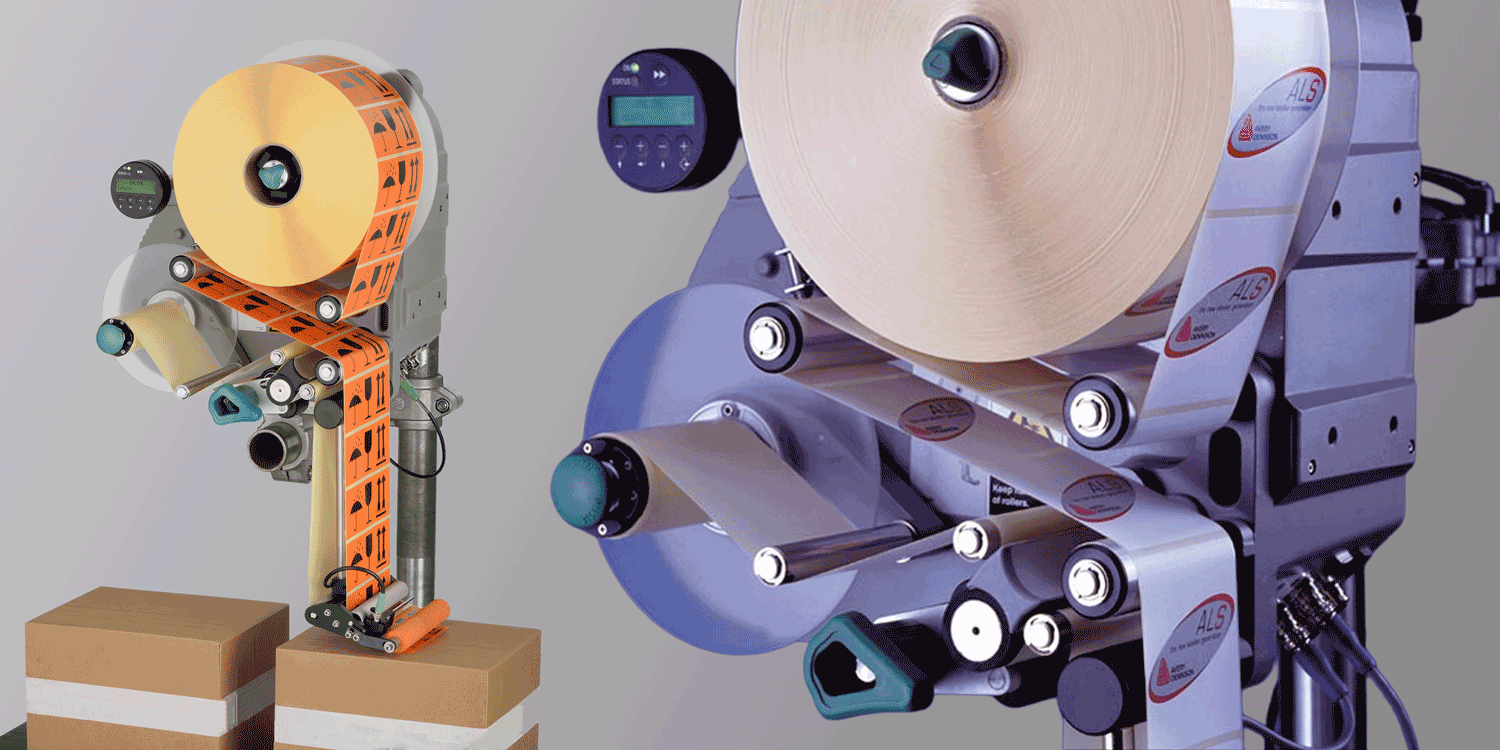

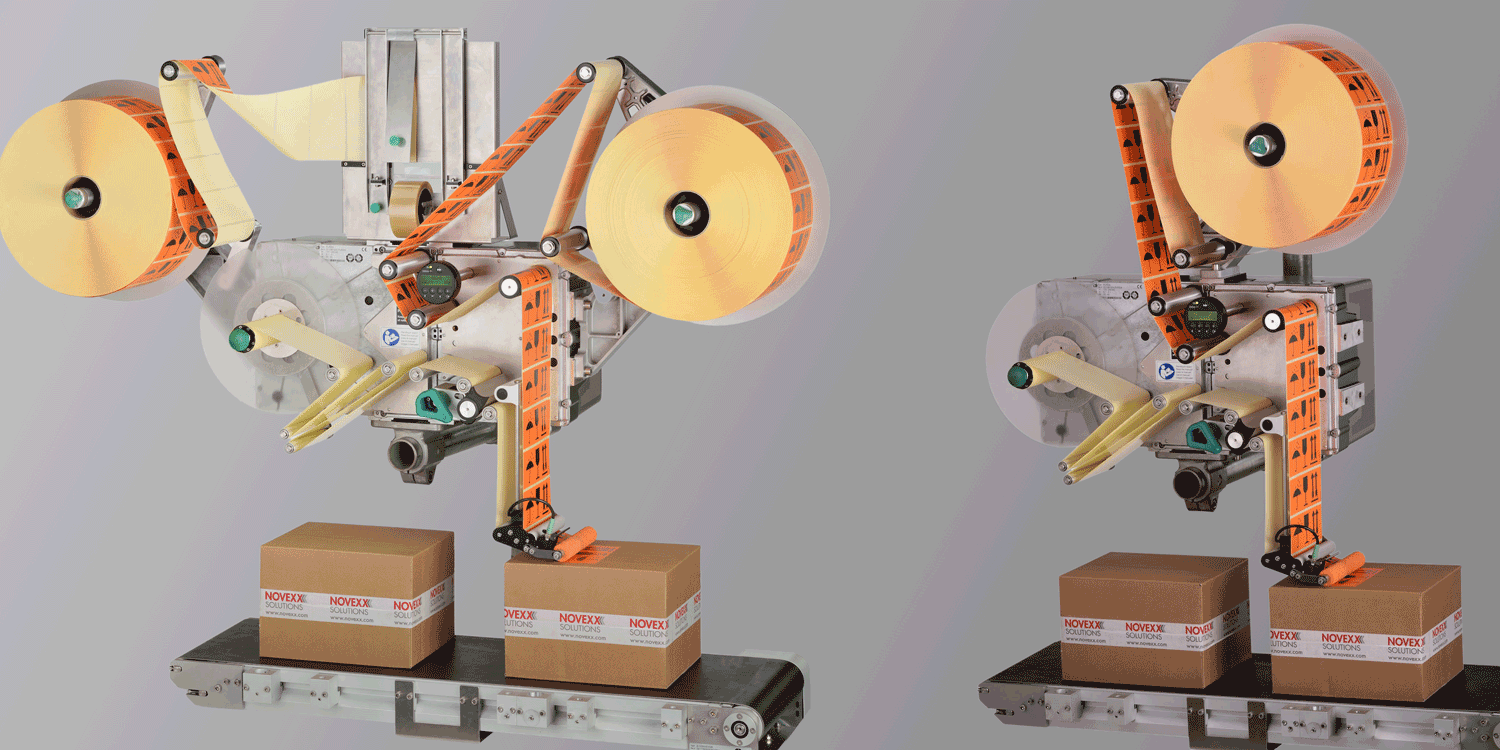

Enhance your production efficiency with the innovative Harland UNW 924 Unwind System. This advanced labeling solution significantly boosts your production capacity while minimizing downtime associated with label roll changes. By accommodating larger label rolls, the Unwind System reduces the frequency of roll replacements, enhancing your operational flow.

Key features include a built-in low-label roll alarm that promptly alerts operators when the label roll is nearing its end. This gives them ample time to transfer the remaining labels to a holding bin without disrupting the production line. The jog function automatically stops when the end of the roll reaches the worktable, allowing experienced operators to splice in new rolls swiftly and seamlessly.

Our labeling machine is specifically designed for continuous operation, even during supply roll transitions. With a spacious label accumulation bin and table, it facilitates the splicing of labels without interruption. The low-label roll detection system enhances efficiency by signaling operators through an alarm and indicator light when a change is necessary. Additionally, the end-of-roll detection function activates an alarm, visual alert, and applicator inhibit feature to prevent production halts.

To maintain optimal performance, the machine is equipped with analog unwind-loop controls that ensure consistent web tension and smooth operation. Constructed from heavy-duty aluminum and stainless steel, this robust labeling machine is designed for durability, and its electrical enclosure is rated NEMA 12 for added safety.

Upgrade your labeling process with the UNW 924 Unwind System and experience uninterrupted production flow, improved efficiency, and reduced downtime.

Key Features

Technical Data

Available Options

- Waste cutter

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

3070 Mainway

Burlington ON L7M 3X1

CA -

+1 (905) 336-8880 -

+1 (905) 336-5710 (Customer Service) -

(Field Service)

Jump to...

Jump to...