Products and Solutions

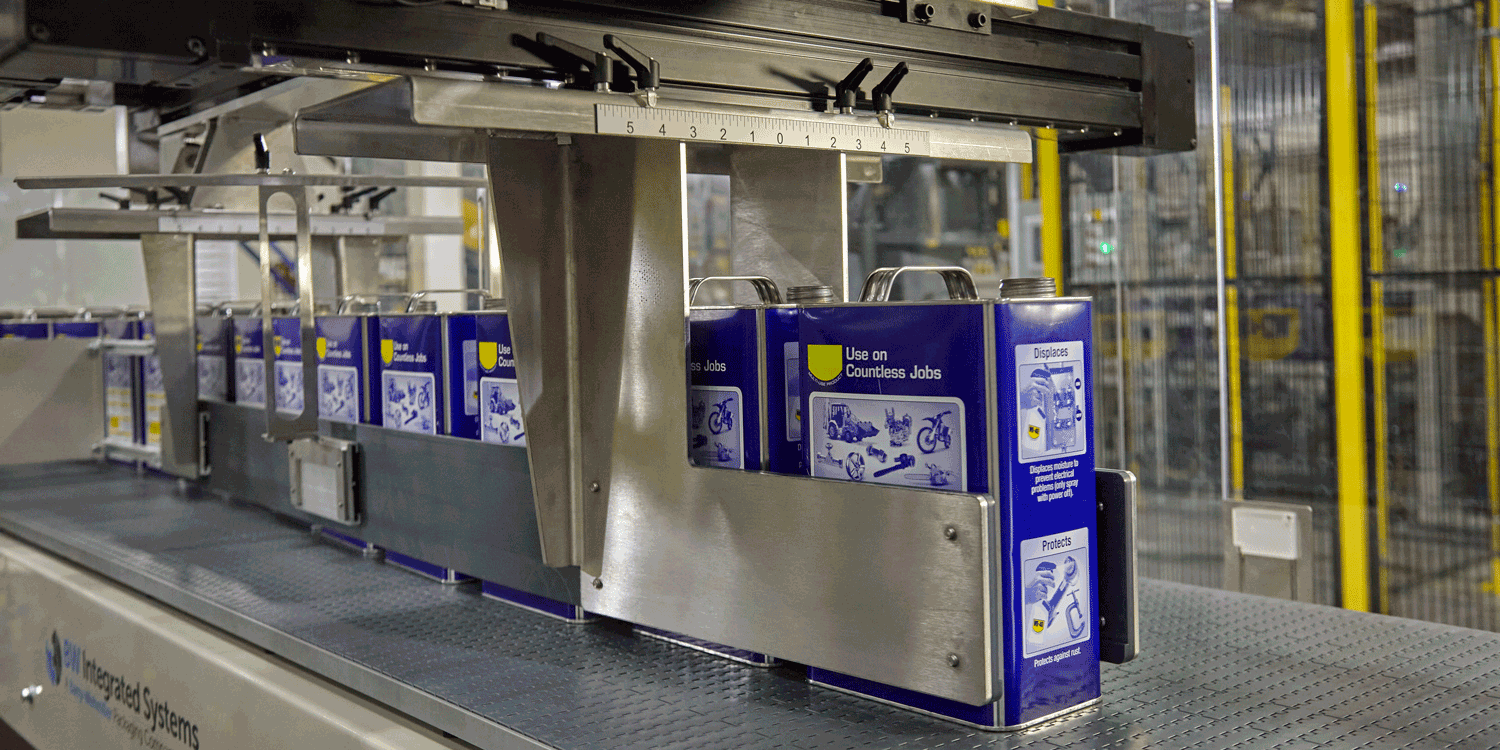

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

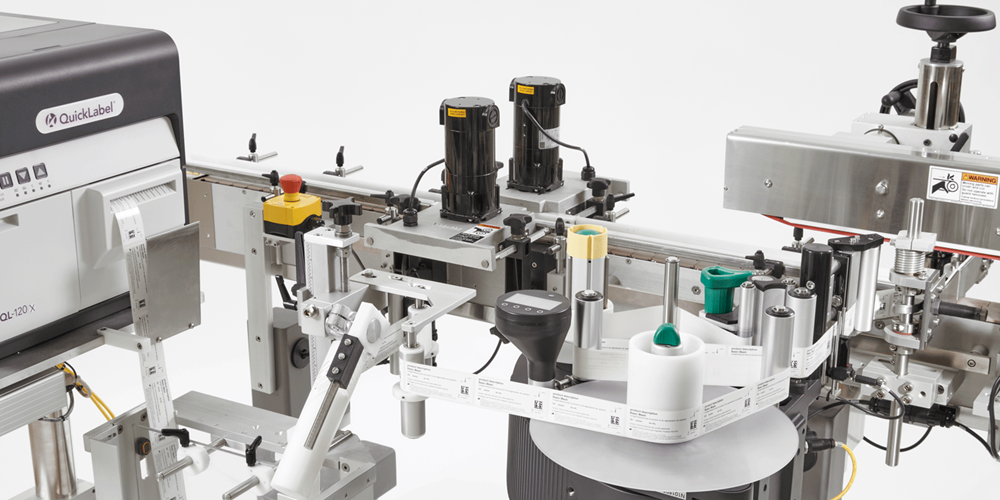

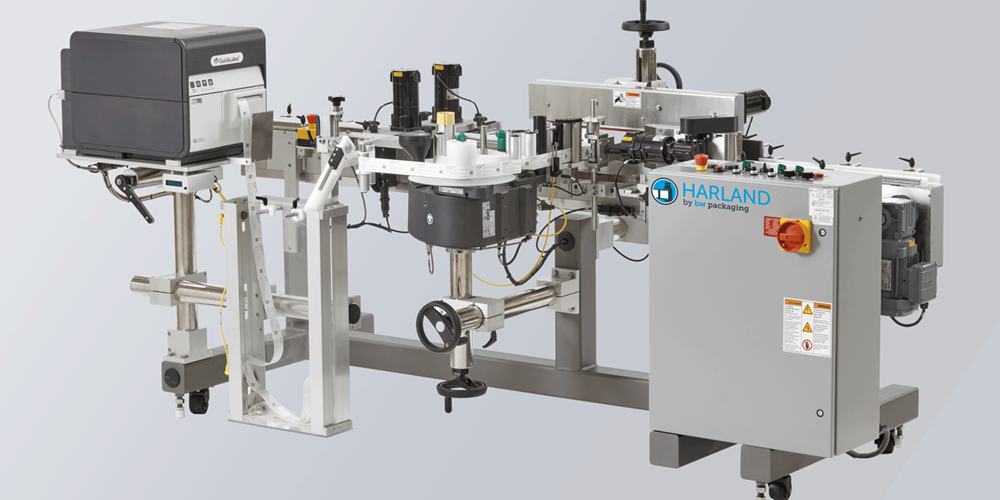

Harland Print and Apply Labeling Machines

Experience unparalleled efficiency and precision with Harland's Print and Apply Label Machines, meticulously designed for high-volume production lines. Our compact labeling solutions ensure your products stand out with clear, readable barcodes and visually striking graphics.

Why Choose Harland's Print and Apply Labeling Solutions?

Formerly known as Accraply, Harland’s print and apply machines utilize advanced microprocessor controls and an intuitive operator interface, ensuring a smooth operational experience that boosts your production efficiency. Explore our cutting-edge labeling solutions below.

The Advantages of Print and Apply Labeling

- High-Quality Output: Achieve crisp, easy-to-read barcodes and labels, thanks to the latest Zebra and SATO print engines seamlessly integrated into our PAL 200 and PAL 1000 models. Experience exceptional labeling quality with minimal upkeep.

- In-House Labeling: Streamline your operations by bringing your labeling processes in-house, saving both time and costs. Our print and apply machines support on-demand label creation, providing you with unparalleled flexibility on the production line.

- Versatility Across Industries: Harland's innovative print and apply technology is capable of automatically applying labels to a diverse array of products, including consumer goods, food items, pharmaceuticals, and beyond.

Explore Harland’s Print and Apply Labeling Systems

PAL 200 Series Print and Apply Labelers

Designed for high performance, the PAL 200 series excels in demanding production environments, delivering clear, legible text and graphics through microprocessor-controlled operation for optimal flexibility. Compact and easily integrated, the PAL 200 series fits seamlessly with any existing packaging equipment.

PAL 900 Series Labelers

The PAL 900 models are premium printer applicators featuring a compact design that integrates seamlessly into your production flow. Offering 100% tool-free cleaning and component replacement, these machines dramatically reduce maintenance time and enhance operational efficiency. Built with robust metal housing and multiple mounting options, the PAL 900 series is engineered for durability in any industrial setting.

PAL 1000 Series Labelers

The PAL 1000 Series is renowned for delivering exceptional output, ensuring 100% readable barcodes and superior graphics. Equipped with an easy-to-use operator interface, this series guarantees effortless machine operation. Ideal for high-volume production, it features multiple label application methods, including Wipe-On and Tamp/Wipe, making it suitable for various applications.

Types of Print and Apply Label Applications

Harland’s print and apply systems offer versatile labeling methods to accommodate various product shapes and fragility levels, including:

- Wipe-On

- Tamp/Wipe

- Tamp/Blow

- Corner-Wrap

- Swing-Arm

Custom Labeling Solutions

Looking for a tailored labeling solution? With over 50 years of industry experience, Harland can design and manufacture a custom print and apply label machine tailored to meet your specific needs.

Explore our range of high-performing print and apply labelers today. For more information or to discuss a custom solution, please contact a Harland representative. Elevate your labeling operations with Harland’s superior technology and expertise!

Key Features

PAL 200 Series

- Supports label sizes up to 6” wide by 16” long for versatile application

- Easy Wipe-On Label Application for quick and user-friendly operation

- Equipped with Integrated Microprocessor Control for precise label management

- High-Speed Batch Printing and Application for efficient processing

- Capable of applying pre-printed labels seamlessly for added convenience

- Features Automatic Product Speed Following to ensure consistent operation

PAL 900 Series

- Intuitive, multi-colored, high contrast display with icon-guided navigation

- Rotatable display is readable even when installed for bottom labeling

- Corner-edge technology for high quality printing

- No-fan design keeps dust out of the enclosure

- Robust metal frame with high quality components

- Wipe-on, tamp-blow, leading-side panel and corner-wrap applicators

- 300mm/ 12” label roll capacity

- Advanced web tension control

- Collapsible waste rewind mandrel

- Digital interface and real-time data to support Industry 4.0

PAL 1000 Series

- Accommodates label sizes up to 7.2” wide x 14” long

- Dual functionality with 1:1 tamp or tamp/blow print and apply options

- Configurable for right or left-hand operation

- Versatile label application from the top, side, or bottom

- Equipped with Allen Bradley controls for reliable performance

- Features an “Easy-Access” swing-away tamp mount for quick maintenance

- Adjustable for a wide range of label widths and lengths

- Supports 12”/300 mm diameter label rolls with dancer arm web tension control

- Efficient rewind system allows for quick removal of the waste liner

- Machine control via AB Micrologix 1000 PLC and intuitive PanelView touchscreen

- Durable construction with a 3/8” (9.5 mm) thick aluminum plate

- Swing-away applicator mount for effortless access to the print head and dispense edge

- Quick-change vacuum pad design that requires no tools for easy adjustments

Technical Data

Available Options

PAL 200 Series

- Tamp / Blow

- Corner-Wrap

- Dual-Label

- Leading / Trailing Panel

- Label design software

- Vision systems and alarm packages

- Portable mounting stands

- 16” powered unwind with extended rewind capacity

PAL 900 Series

- Wipe-on, tamp-blow, dual label and corner-wrap applicators

Alarm package with flashing beacon - I/O cable for status signals

- Deviation roller for inside wind label rolls

- Remote operation via 7” Panel PC

- BarTender label software

- Vision systems with product eject stations

- Product handling conveyors

PAL 1000 Series

- Corner-Wrap and Adjacent Panel Applicators

- Direct dispense, wipe-on label application

- PanelView 600 HMI colour touchscreen

- AB Micrologix 1100 PLC with Ethernet Ports

- Alarm package with light stack and discrete outputs for specific alarms

- 16”/400 mm diameter label roll unwinds with extended waste rewind

- Label inspection systems: vision, barcode & 2D code scanners/verifiers

- Product eject with eject verification

- Product handling systems

Packaging Styles

Jump to...

Jump to...

- Automotive and Industrial

- Beverage

- Consumer Goods

- Food

- Household

- Personal Care

- Pet Food and Pet Care

- Pharmaceutical

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

3070 Mainway

Burlington ON L7M 3X1

CA -

+1 (905) 336-8880 -

+1 (905) 336-5710 (Customer Service) -

(Field Service)