Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

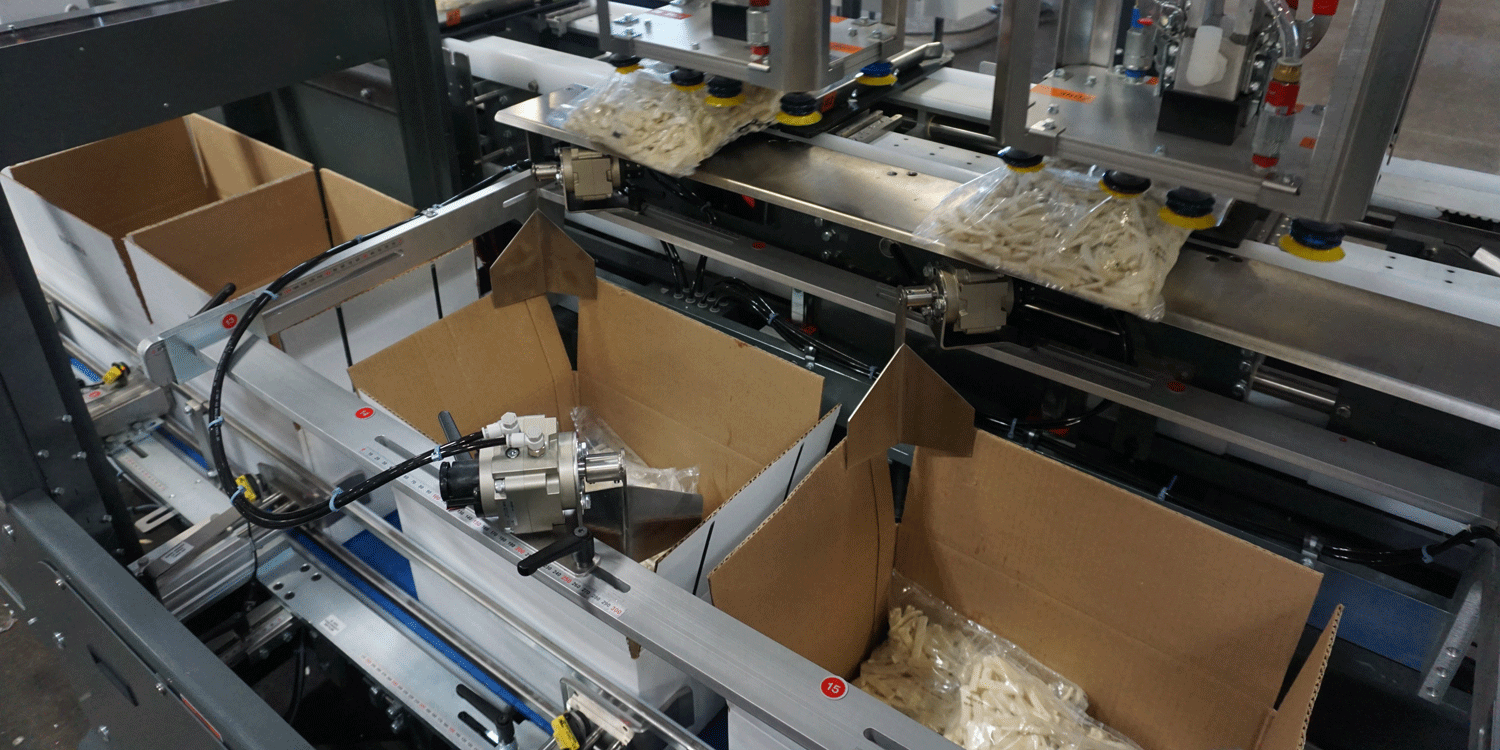

Nigrelli DL 25 Case Packer

Elevate your production efficiency with Nigrelli’s DL 25 Direct Loader Case Packers, designed specifically for the seamless loading of flexible products into a horizontal case pattern. This innovative equipment is ideal for individual quick frozen (IQF) products and various flexible items, combining versatility with precision for your packaging line.

DL 25 Direct Loader Advantages

- Advanced Infeed Conveyors: Our state-of-the-art infeed conveyors offer unmatched flexibility, allowing you to space bags individually or employ an optional shingling mechanism. This feature enables the creation of perfectly organized and nested groups of bags for each case layer, significantly enhancing efficiency and reducing handling time.

- Gentle Handling and Maximum Capacity: As layers of products build on the rotating impellers, the DL 25 meticulously places bags directly into cases or onto lower product catchers and case flap openers. To ensure optimal case capacity, the optional case vibration feature facilitates perfect settling of the bags, maximizing your packaging output.

- Flexible Layout Design: Designed for layout versatility, the DL 25 Direct Loader allows for cases to enter and exit from any direction. This ease of integration makes it compatible with both new and existing case formers and sealers when connected via straightforward conveyors.

- Hygiene Compliance: The DL 25 features wash-down construction options, making it ideal for installation in your processing area while ensuring full compliance with hygiene and safety standards.

Enhance Your Production Line Today

Invest in Nigrelli’s DL 25 Direct Loader Case Packers to streamline your packaging processes and boost operational efficiency. Our commitment to quality and innovation ensures that you receive the best in flexible packaging solutions. Contact us today to learn more about how the DL 25 can be tailored to meet your specific production needs!

Key Features

- Up to 240 bags per minute

- Easy changeover

- Minimal air requirement, electro-mechanical operation

- Touchscreen control

- Flexible pack patterns

- Small footprint

- Servo-driven, patented, rotary impeller system

- Packs various RSC, HSC, and display-style cases and trays

- Gentle product handling

- Simple integration with our line of Tray/Case Erectors and Sealers

- Automatic case positioner

- Product catcher/flap opener

- Rugged, reliable, low-maintenance construction

- Polycarbonate interlocked safety guarding

Technical Data

Available Options

- Bag shingling

- Broken bag detector

- Product settling conveyor

- Inline or right-angle product infeed

- Stainless steel construction

- Case load station settler

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...