Products and Solutions

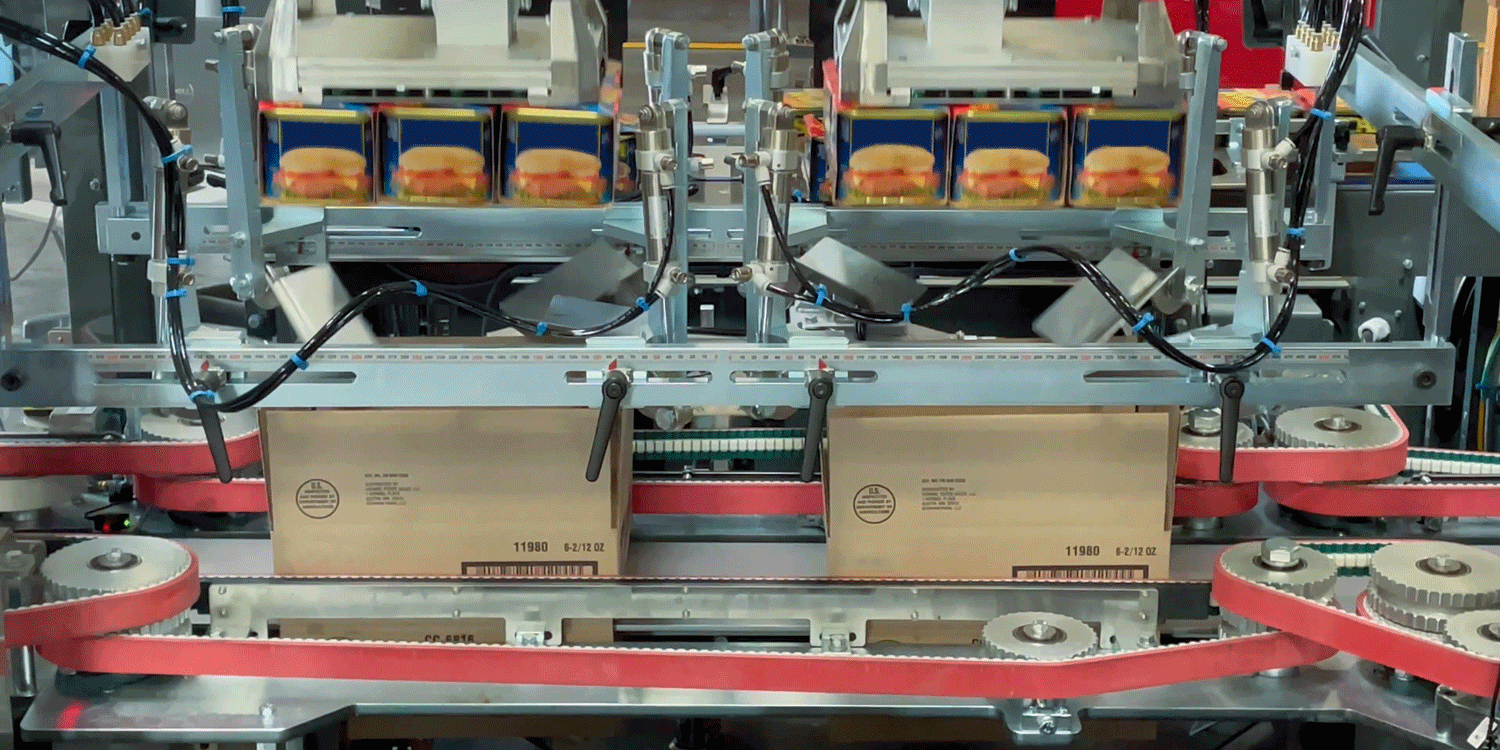

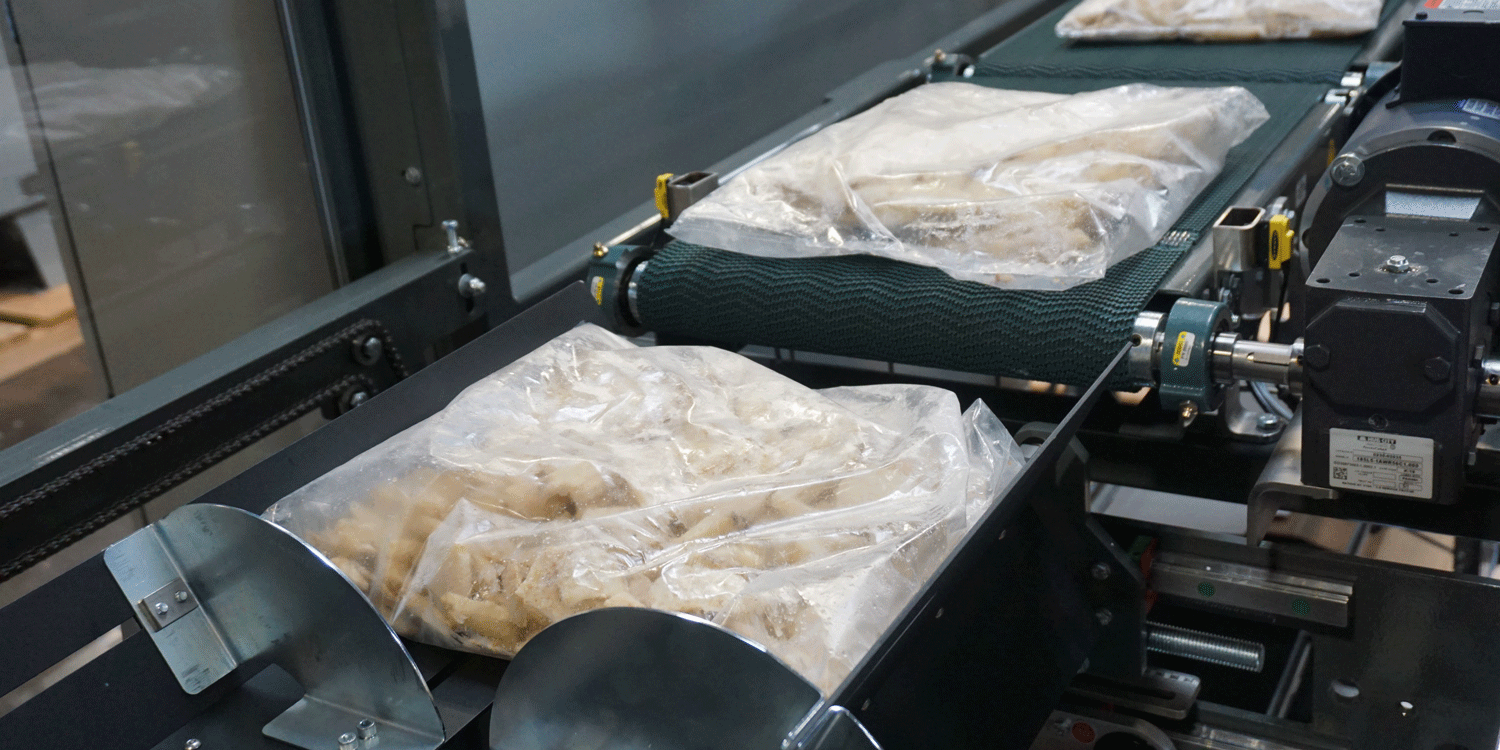

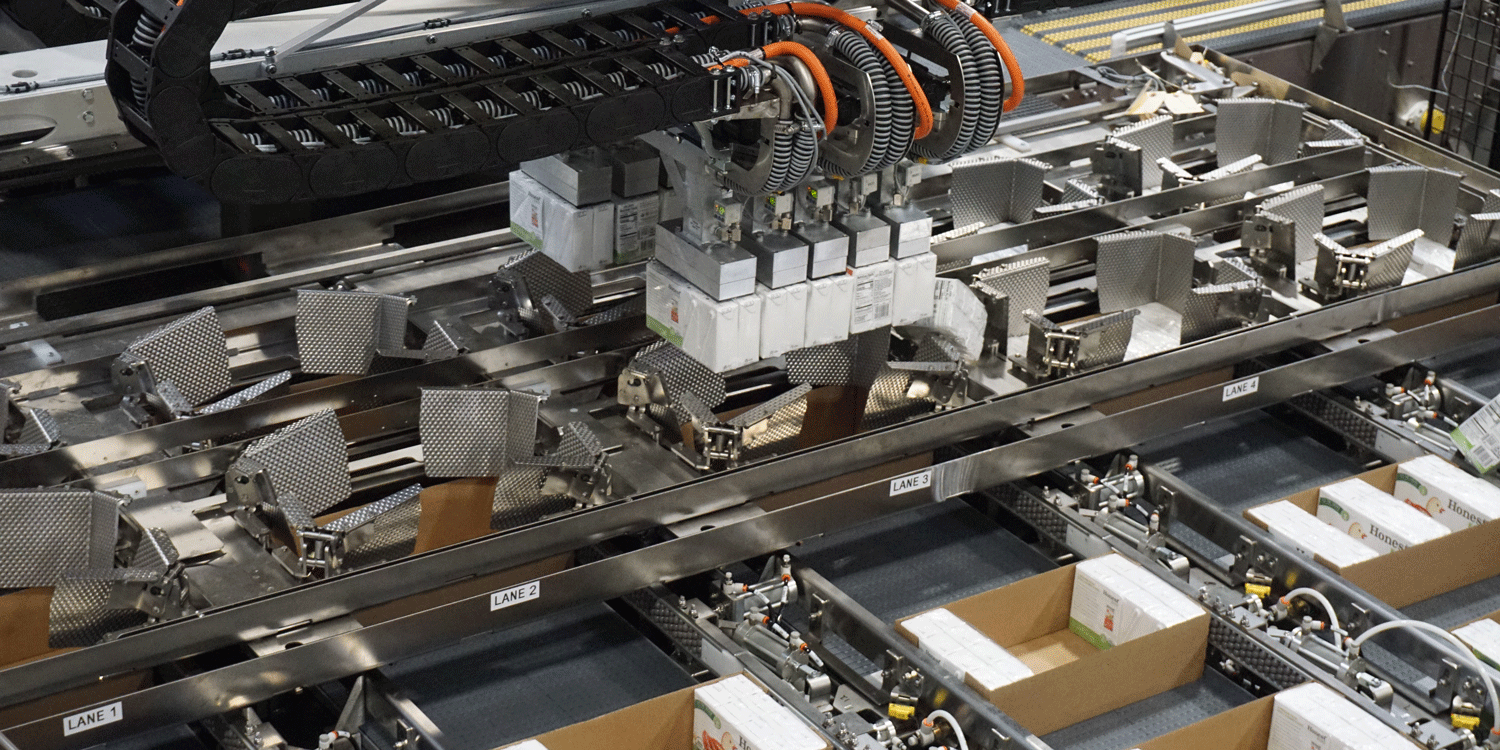

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

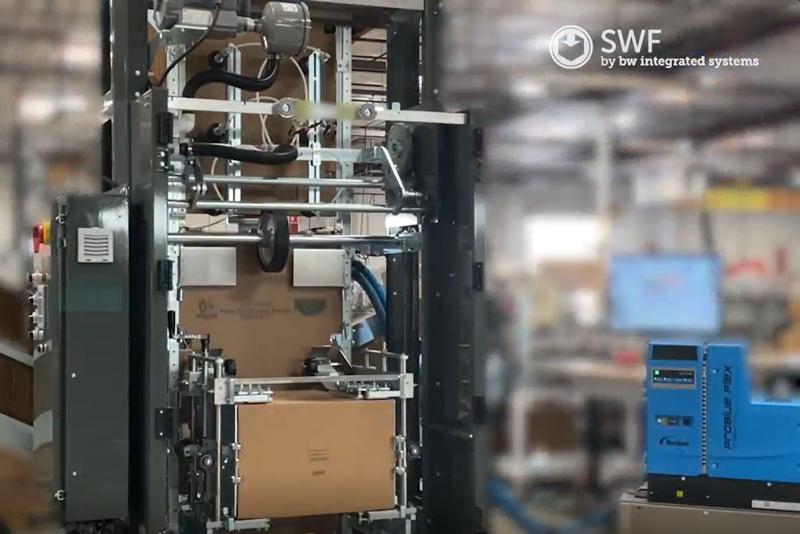

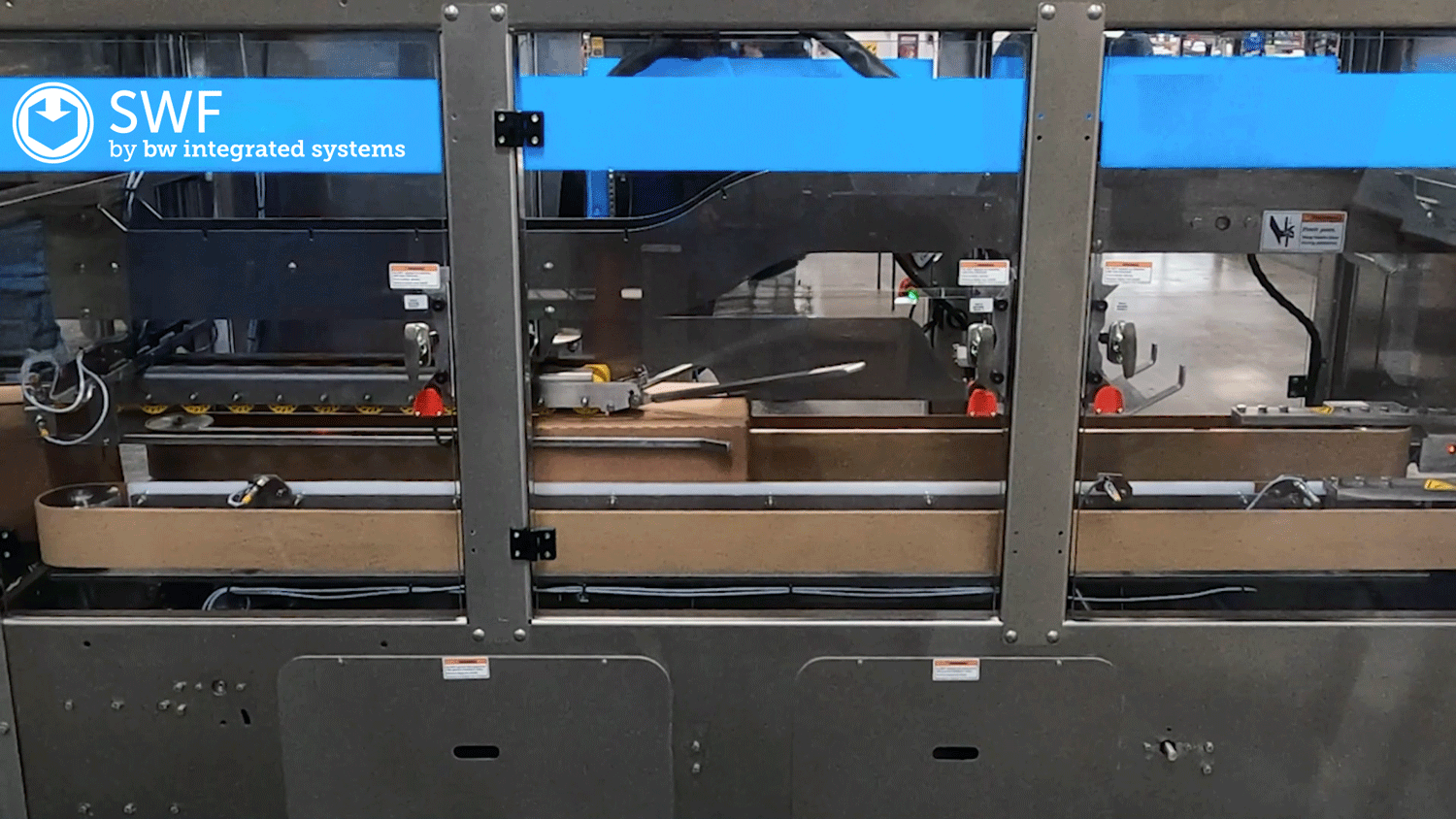

SWF BF 400V Bliss Former

The SWF brand has been a prominent name in the world of bliss and tray forming machinery since the 1940s. With a vast network comprising over 5,000 machines globally, SWF provides versatile equipment designed to efficiently create numerous styles of tray and bliss cases. Engineered with a compact footprint in mind, our robust machines occupy minimal floor space, allowing for easy relocation with casters or a forklift.

At SWF, we prioritize mechanical simplicity and durability, ensuring that our machines offer long life cycles and reliable performance for years to come. Our BF 400V model, for instance, excels in forming various bliss case styles with utmost precision.

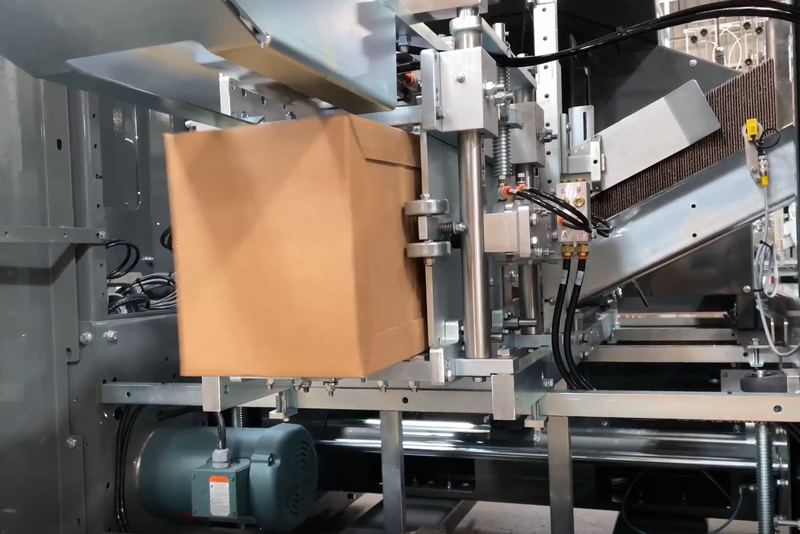

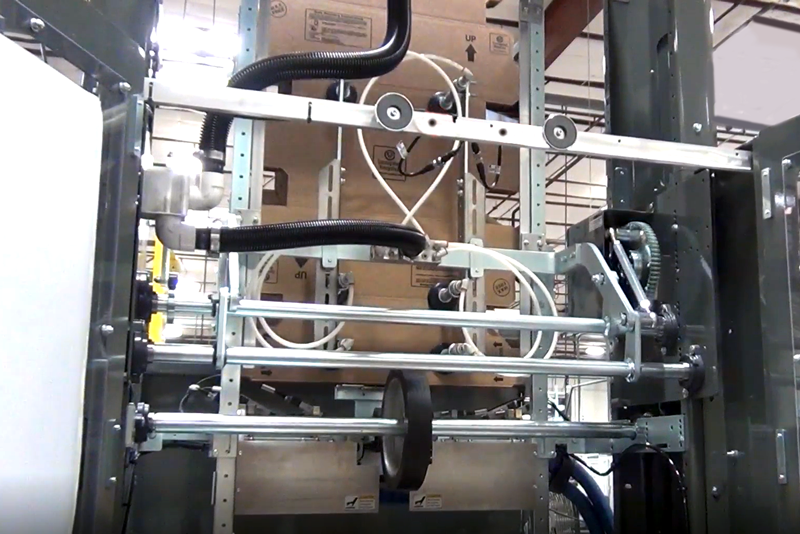

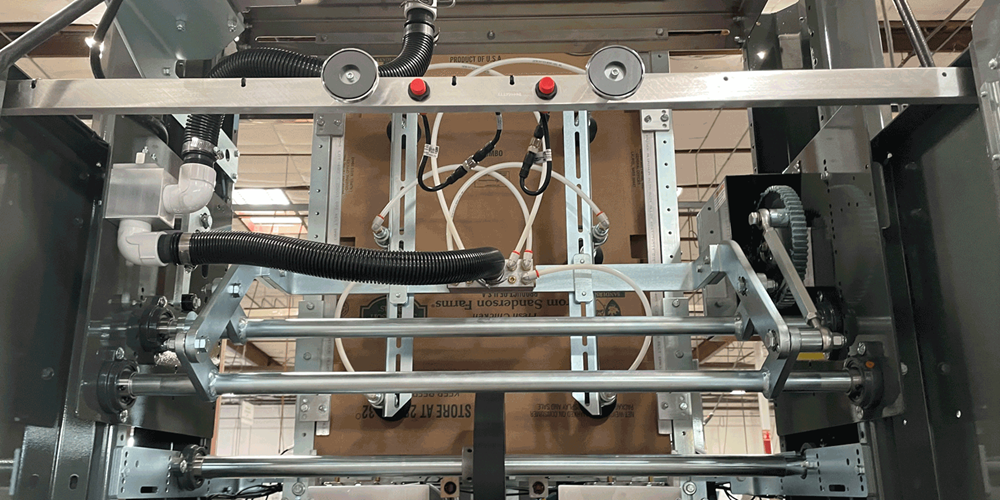

How the BF 400V Machine Works

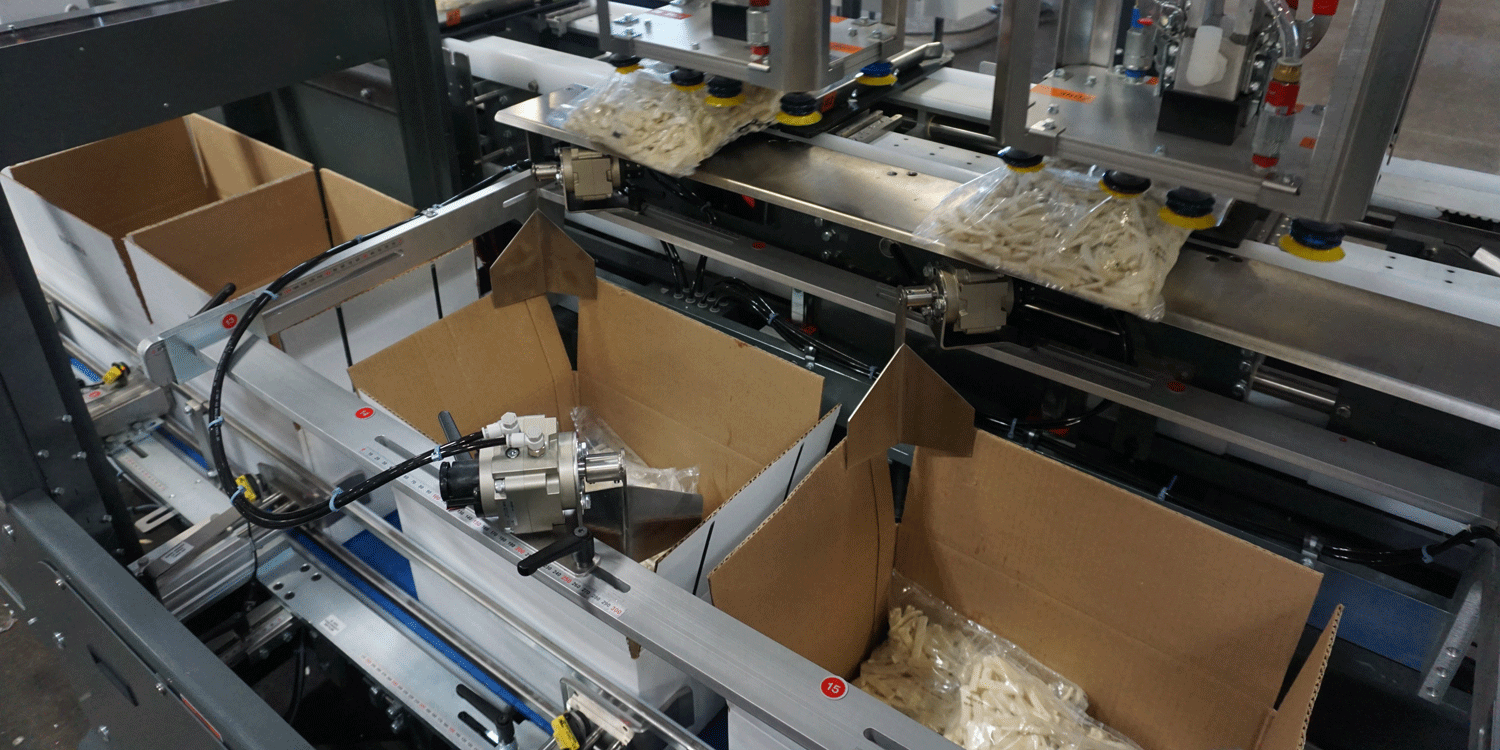

To create a bliss case, the BF 400V utilizes a corrugated blank along with two end panel blanks. The machine offers two smooth transfer options for bliss blanks: an optional powered infeed conveyor or a standard hopper. Carefully selected tray blanks are transferred from the hopper, where precise glue application occurs. As the blank is expertly formed and compressed, bliss end panels are simultaneously retrieved from the end panel hoppers. Finally, the fully formed tray is discharged onto either an optional lidding attachment or a conveyor.

Customized Solutions for Your Needs

Bliss boxes, made with various material combinations, boast a high strength-to-weight ratio, making them an excellent choice for various applications. At BW Packaging, we leverage our extensive experience to collaborate with you and your corrugated material supplier, ensuring you receive the most effective solution tailored to your needs.

Optimize your production process today with SWF's innovative forming machines, combining efficiency, reliability, and quality.

Key Features

- Up to 35 trays/min (depending on size and style)

- Small footprint

- Can be easily relocated by casters or a forklift

- Able to form hundreds of tray designs

- Rugged, 24/7 construction

- Simple operator interface

- PLC controls

- Polycarbonate interlocked guard package

- Backed by a world-class service team

Technical Data

Available Options

- Operator and material staging platform

- Corrosion-resistant packages

- Automatic stacking system for trays

- Roll-over mechanism to create display windows

- Discharge conveyors

- High-capacity hoppers fit various production needs

- Reduce changeover time with Kwik-change

- Various glue systems available - pressurized, mechanical, cold

- Large capacity glue systems to reduce filling intervals

- Automatic HSC lidding attachment inserts from tray into HSC cover

- Servo-driven mandrel allows an intermittent folding sequence

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...