Products and Solutions

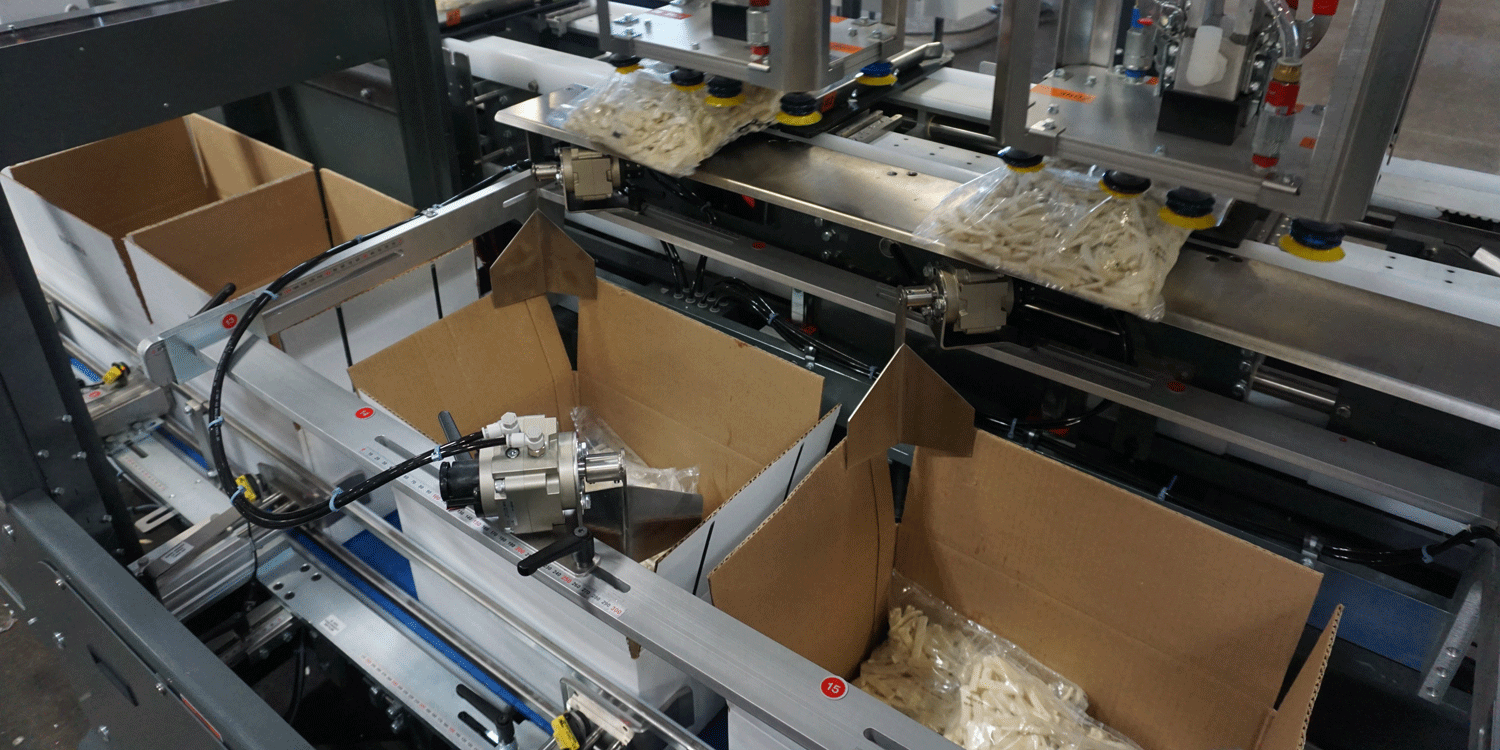

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

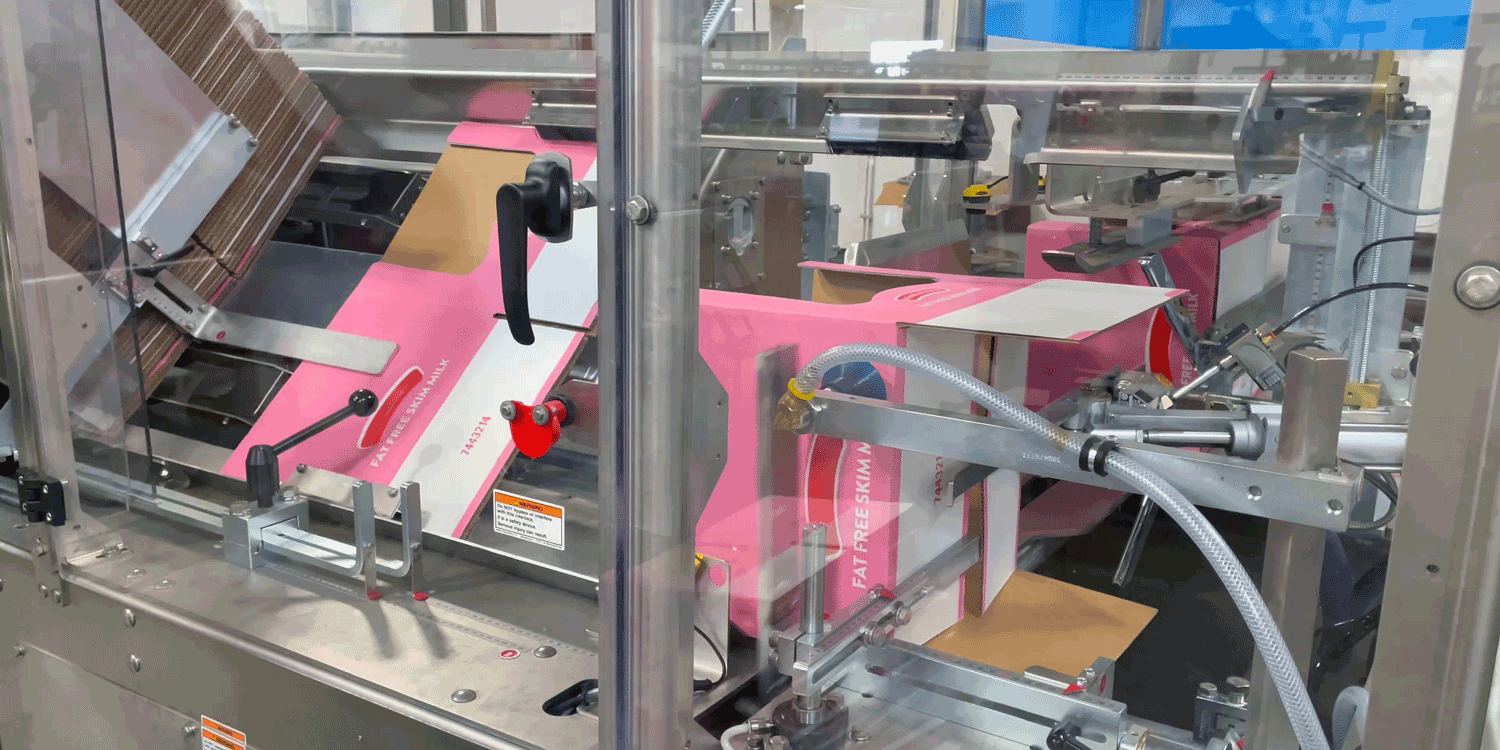

SWF CS Series Case Sealers

Streamline your packaging operations with SWF’s innovative side belt-driven Case Sealers, designed to efficiently close and seal both top and bottom case flaps. The base model expertly seals top flaps, while the optional feature ensures bottom flaps are securely sealed as well. Our cutting-edge side belt design enhances case stability and guarantees reliable case transfer throughout the sealing process.

User-Friendly Adjustments for Maximum Efficiency

Achieving the perfect fit for your cases is easy with our tool-less case size adjustments and intuitive hand cranks. Experience hassle-free operation and adaptability to various case sizes, all while maintaining safety with our durable, laser-cut frame and complete polycarbonate guard package.

Important Guidelines for Case Presentation

For optimal sealing results, ensure that cases are presented to the machine with bottom flaps closed, and the top major flaps either vertical or slightly tucked inward. Cases should be transported to the sealer via conveyor, maintaining a minimum distance of 15 inches (380 mm) apart, unless you’re utilizing the optional infeed indexer.

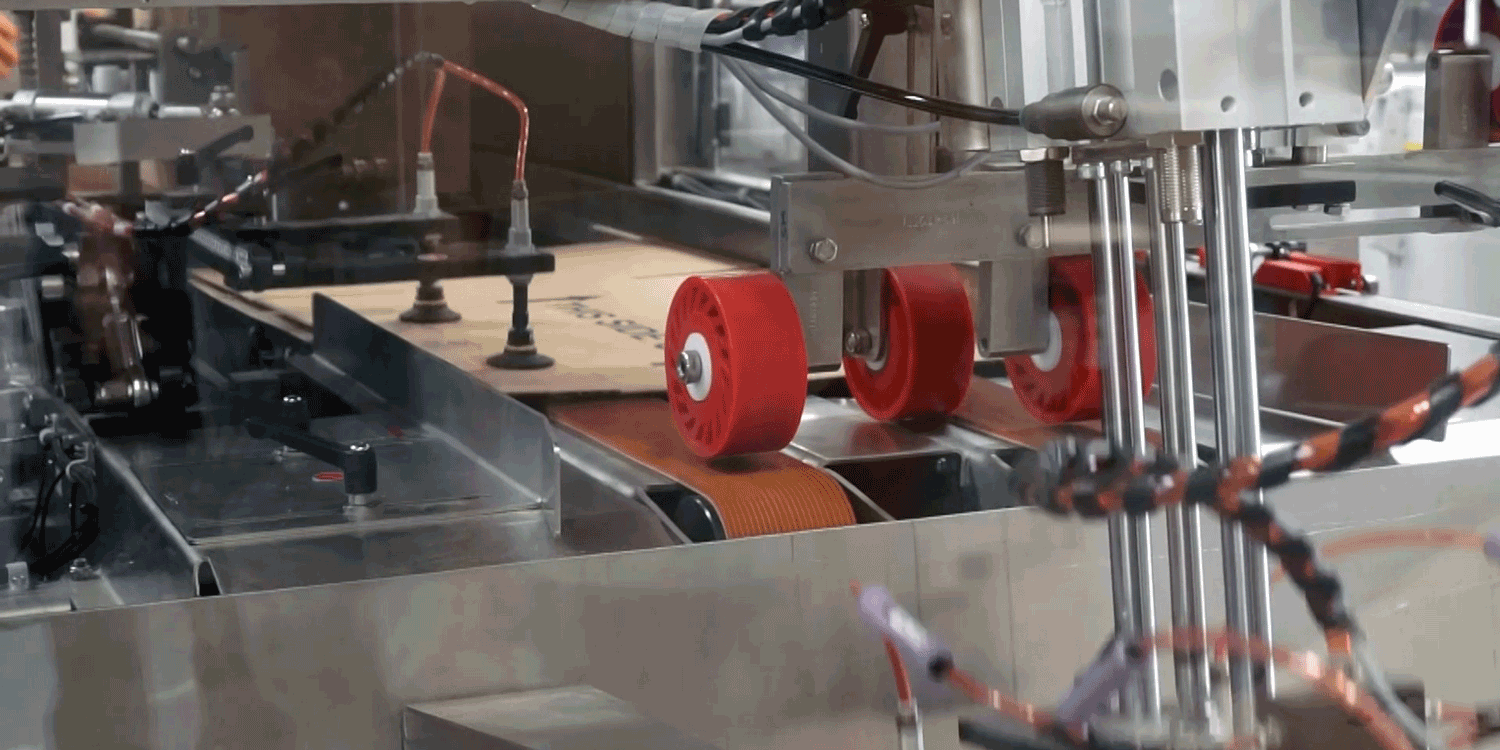

Sealing Process Overview

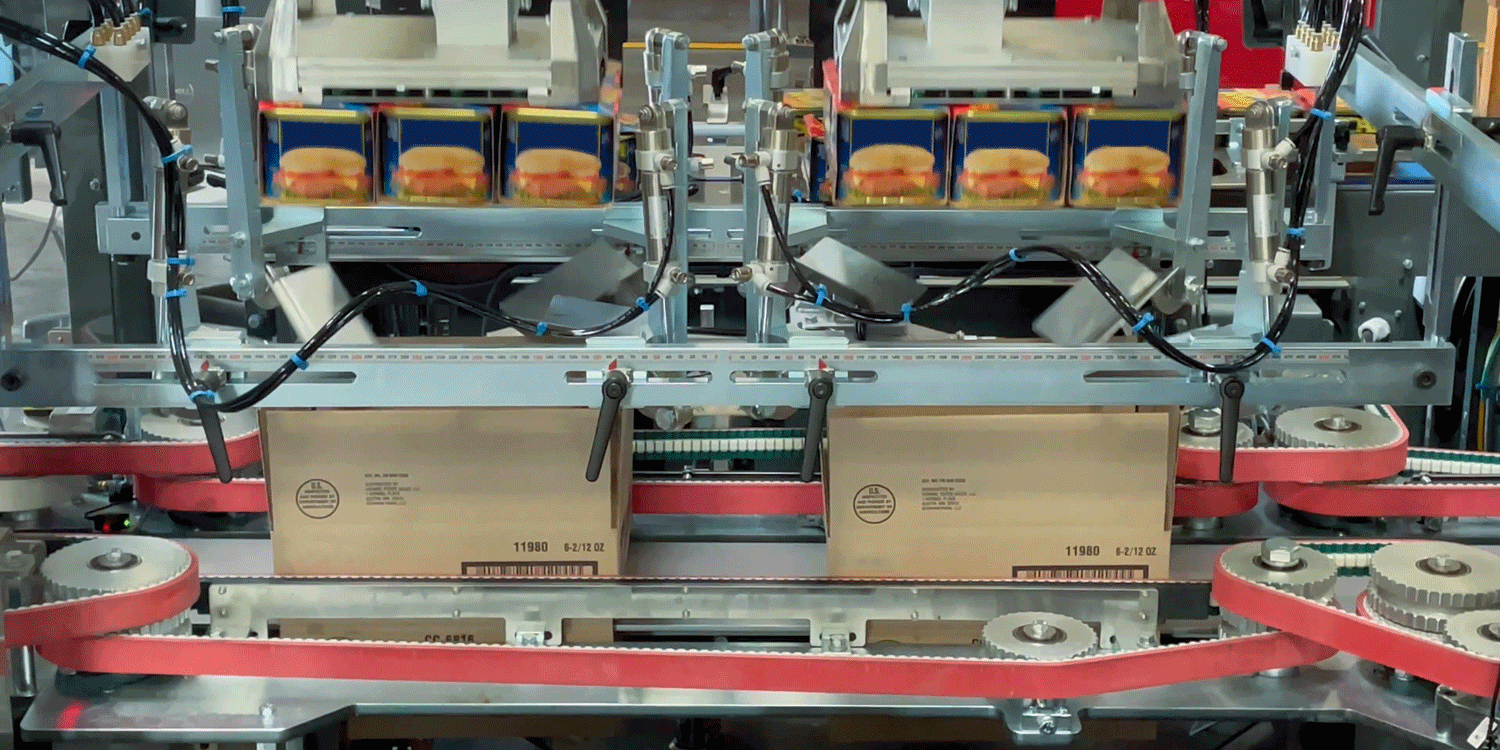

As each case moves through the CS 25T, the top flaps are expertly tucked and securely closed. The upper and lower taping heads then apply tape centrally to the leading and trailing panels, with approximately 2 inches (51 mm) of tape on the top and bottom end panels for robust sealing.

For the CS 25G model, the sealing process allows for tucking the top minor flaps while keeping the major flaps open to accommodate the low-profile glue applicator. Hot-melt adhesive is then applied to the upper minor and lower major flaps, with the case progressing through the compression section to ensure that the upper and lower major flaps are tightly closed and sealed.

Enhance Your Packing Operations Today!

Discover the efficiency and reliability of SWF’s advanced case sealers for your packaging needs. Boost productivity, ensure safety, and achieve perfect case sealing every time.

Key Features

- Fully automatic - no operator required

- Closes and seals top flaps (base) and seals bottom flaps (optional)

- Easy, hand-crank adjustment for case size changes - no tools required

- Rugged, laser-cut steel construction for long life

- Side-belt design provides maximum stability and positive transfer

- Full polycarbonate guarding package

- Overload protection for the electrical system

Technical Data

Available Options

- Infeed indexer maintains a minimum spacing between cases

- Discharge conveyor-roller conveyor 23” (584 mm) long for off-loading convenience

- Leg extensions - from 2” to 8” (51 mm to 203 mm)

- Locking type casters (require leg extensions for mounting)

- Side pressure rollers control the gap between the top major flaps

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...