Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

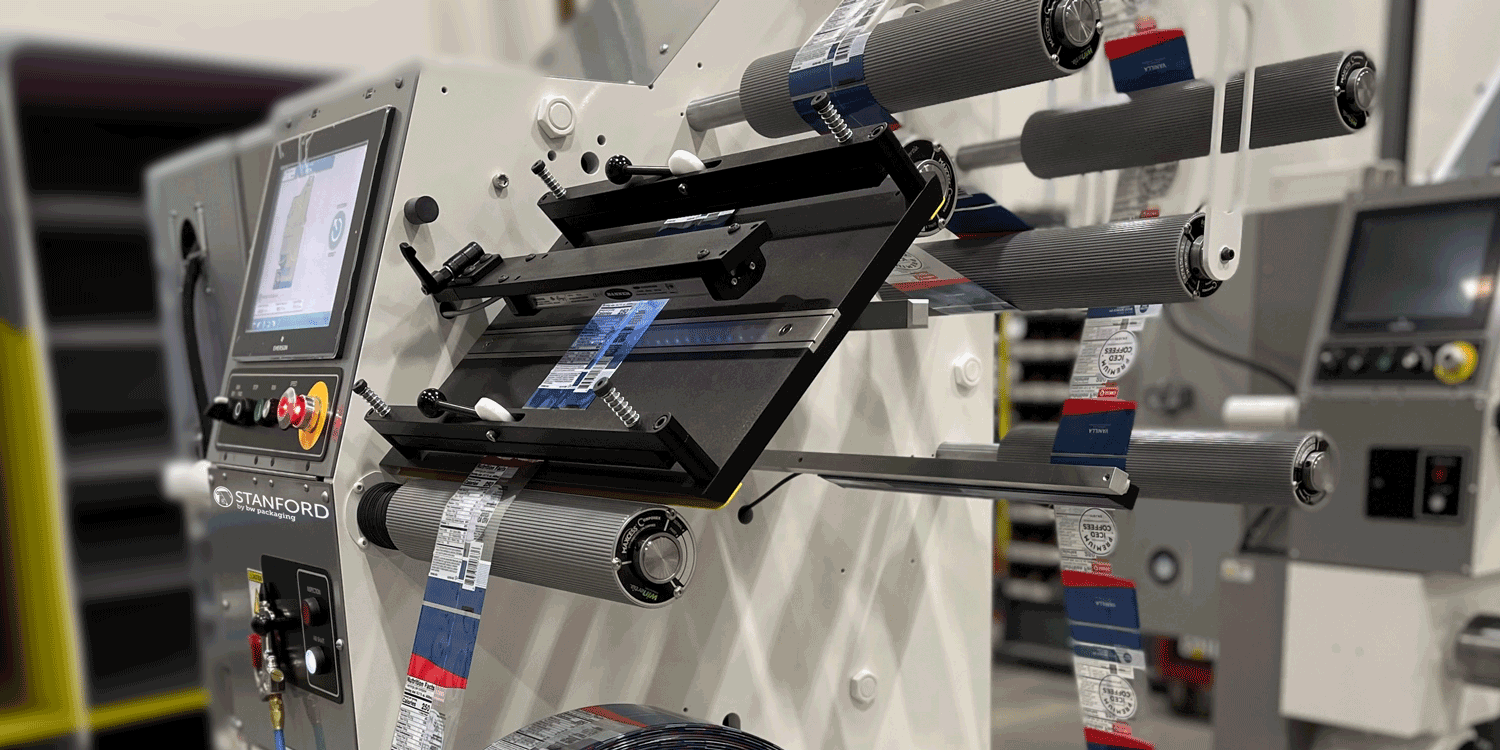

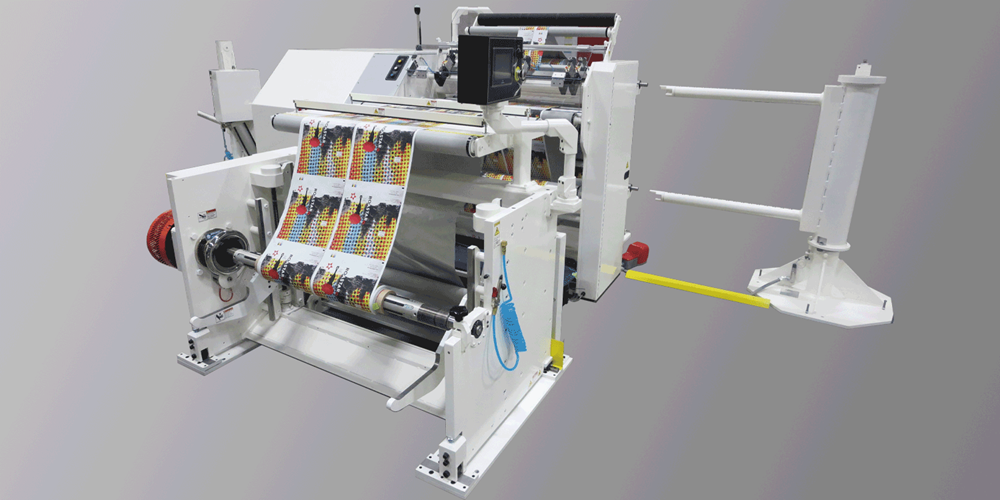

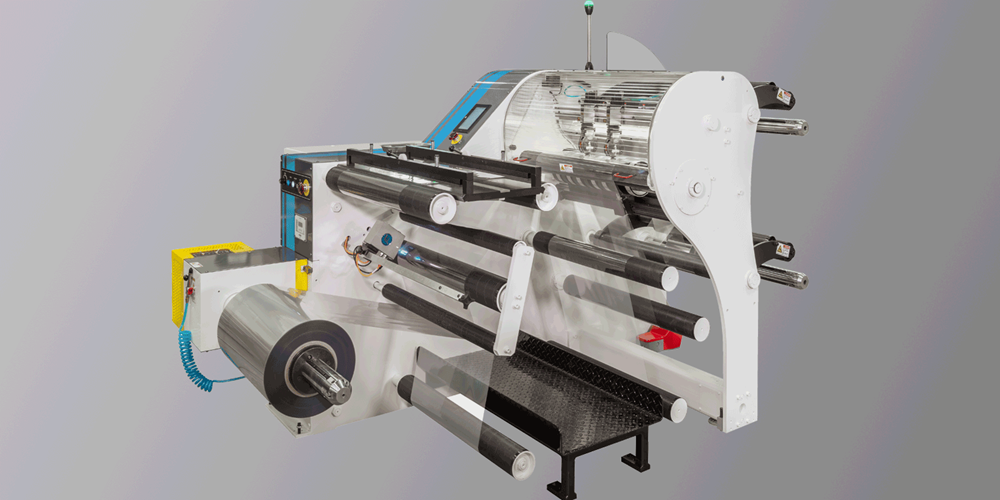

Stanford SR Series Slitter Rewinders

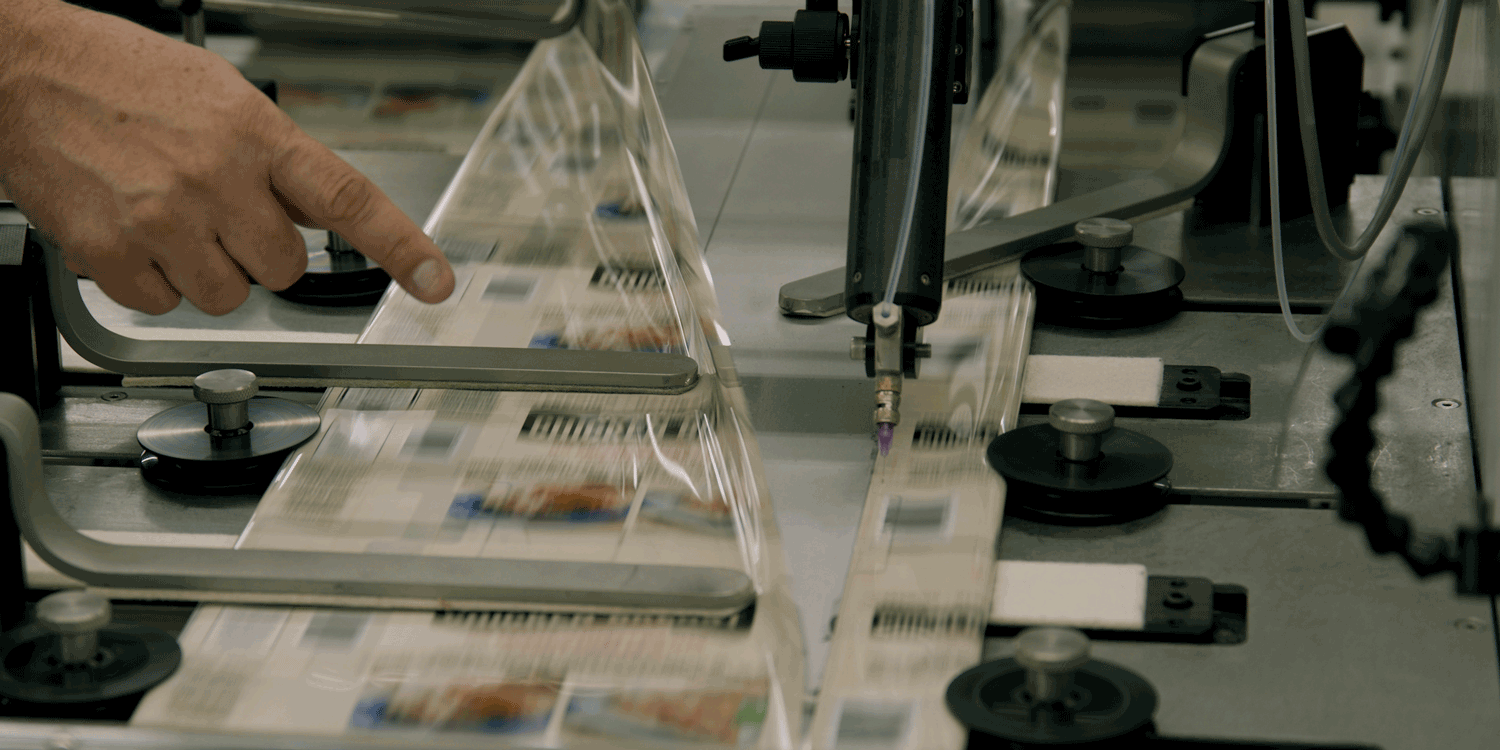

Enhance the versatility of your flexible packaging system with a reliable slitter rewinder. At Stanford, we provide trusted slitter rewinders designed to lower costs and boost the efficiency of your production line. Since 1943, we've been delivering high-quality slitter rewinders that cater to demanding production environments and a variety of product lines.

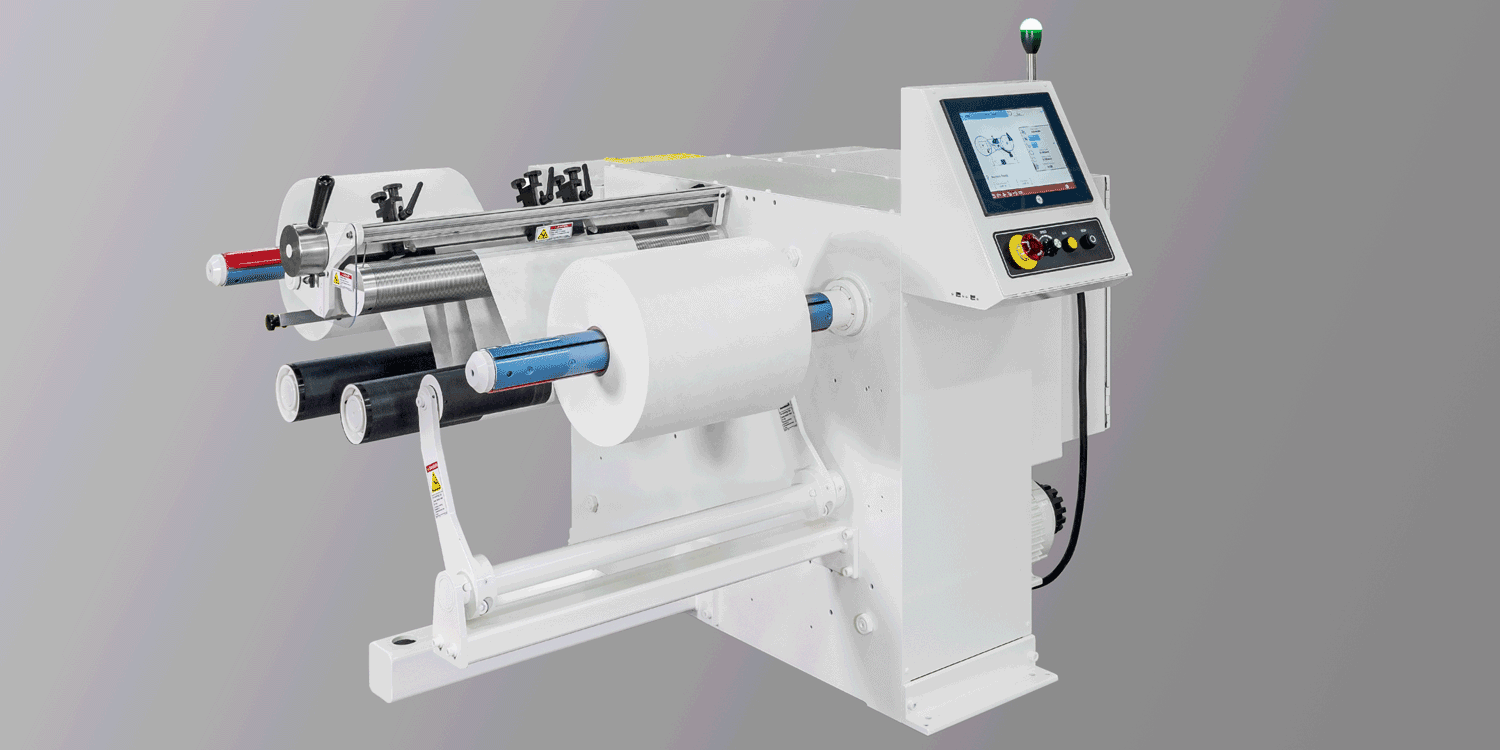

The Stanford SR 438 Slitter Rewinder is a standout choice for converters looking for an innovative and cost-effective solution tailored to diverse slitting needs. Featuring a cantilevered duplex differential center winder, the SR 438 is user-friendly and space-efficient.

With advanced features such as constant tension rewind through load cells and constant torque rewind, the SR 438 showcases the core attributes of Stanford slitters. Its ultrasonic unwind measurement, adaptive tension control, and dual shaft winding capabilities enhance precision and reliability during operation. Plus, the intuitive 12-inch touchscreen interface and on-board drive processor make it the most sophisticated slitter in its class.

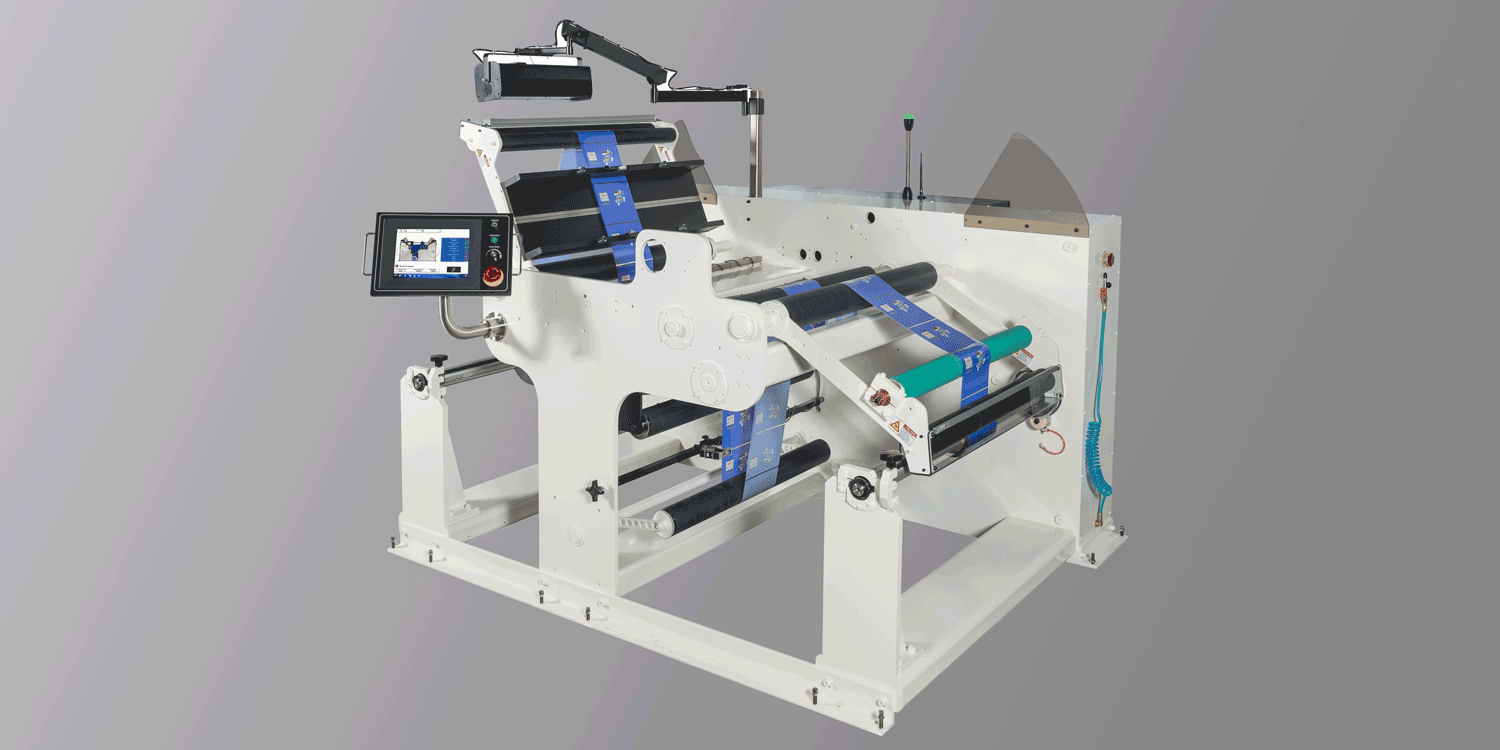

For narrow web converters managing a wider range of materials, consider the SR 738 HC and SR 738 XC Slitter Rewinders. Specifically engineered to handle varying thicknesses, these models feature a step-in platform for seamless knife setup. Their AC Vector drive system, CompactLogix-based controls with touchscreens, and unlimited recipe storage ensure exceptional versatility.

Both the SR 438 and SR 738 Series are adept at processing numerous materials, including polyethylene, polypropylene, polyester, film laminates, self-adhesive label stock, paper, and other flexible substrates.

Advantages of the Stanford SR 438 Slitter Rewinder

- Dual differential rewind shafts for enhanced functionality

- Cantilevered rewind shafts for optimized operation

- Automatic web guide and tension control for precision

- Load cell tension control for consistent performance

- Constant tension or constant torque winding capabilities

- On-board drive processor for advanced control

- Low power consumption for energy efficiency

- Ergonomic walk-in knife setup for user convenience

- Single and dual shaft rewinding options

- Internet-based remote diagnostics and Wi-Fi capabilities for modern connectivity

Advantages of SR 738 HC and XC Models

- Splice table with pneumatic clamps for secure material holding

- Pneumatically inert rider rolls for material density regulation

- Integrated web guide and tension control system for accuracy

- Two-motor smart AC vector drive system for superior performance

- CompactLogix PAC control for enhanced operational efficiency

- Over/under winding capability for added flexibility

- Internet-based remote diagnostics with WiFi for convenience

Explore how the Stanford SR 438 and SR 738 Slitter Rewinders can elevate your converting operations with cutting-edge technology and unmatched reliability. Contact us today to learn more or to schedule a demonstration!

Key Features

Technical Data

Available Options

Shaft Options:

- DXF shafts

- Cam-Lock shafts

Trimming Options:

- Shear (Tangential)

- Shear (Wrap)

- Razor

- Score

Machine Options:

- Gap winding

- Line/Edge guide

- Roll unloading

- Laser core positioner

- Digital knife readout

- Independent rider rolls

738 HC and XC Additional Options:

- Roll lift

- Roll pusher

- Automatic knife readout

- Trim removal

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...