Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

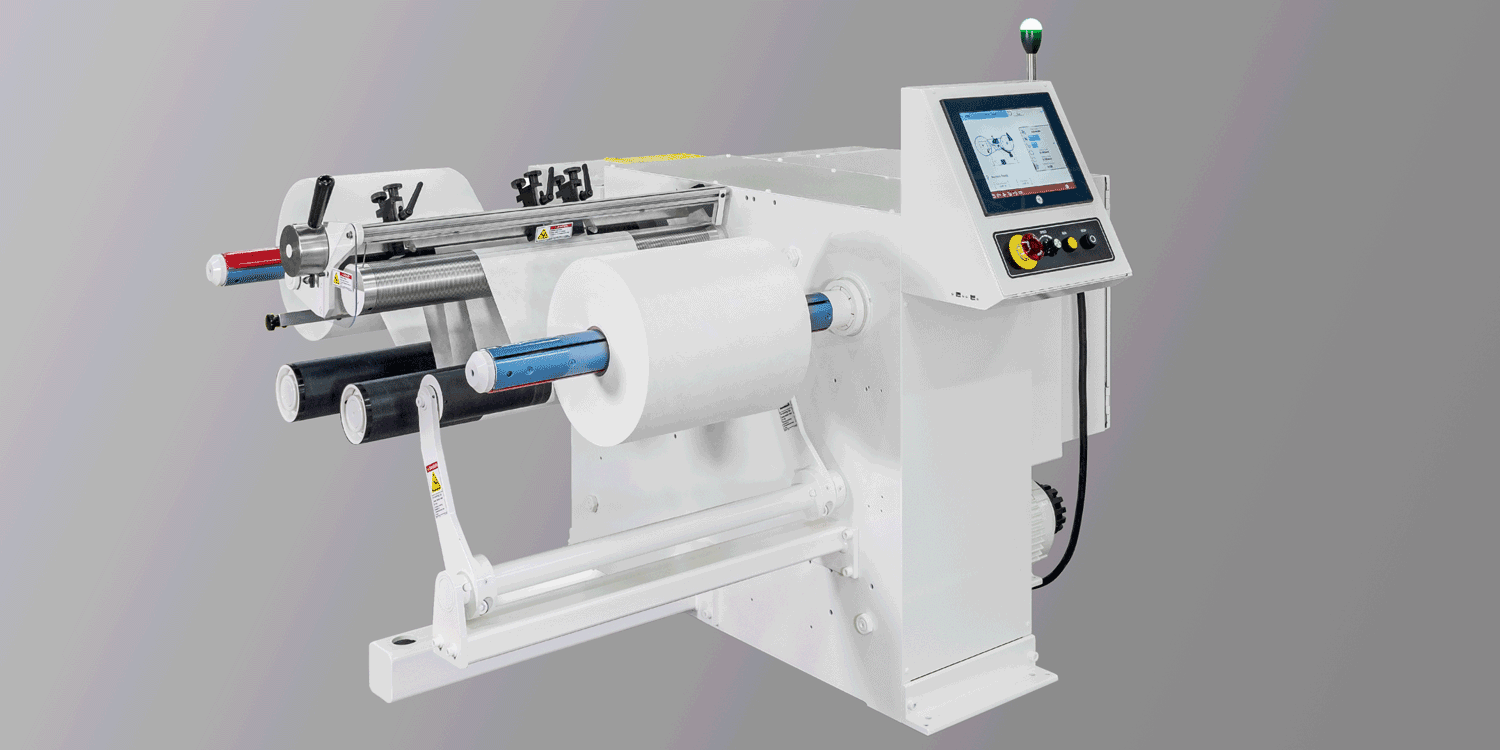

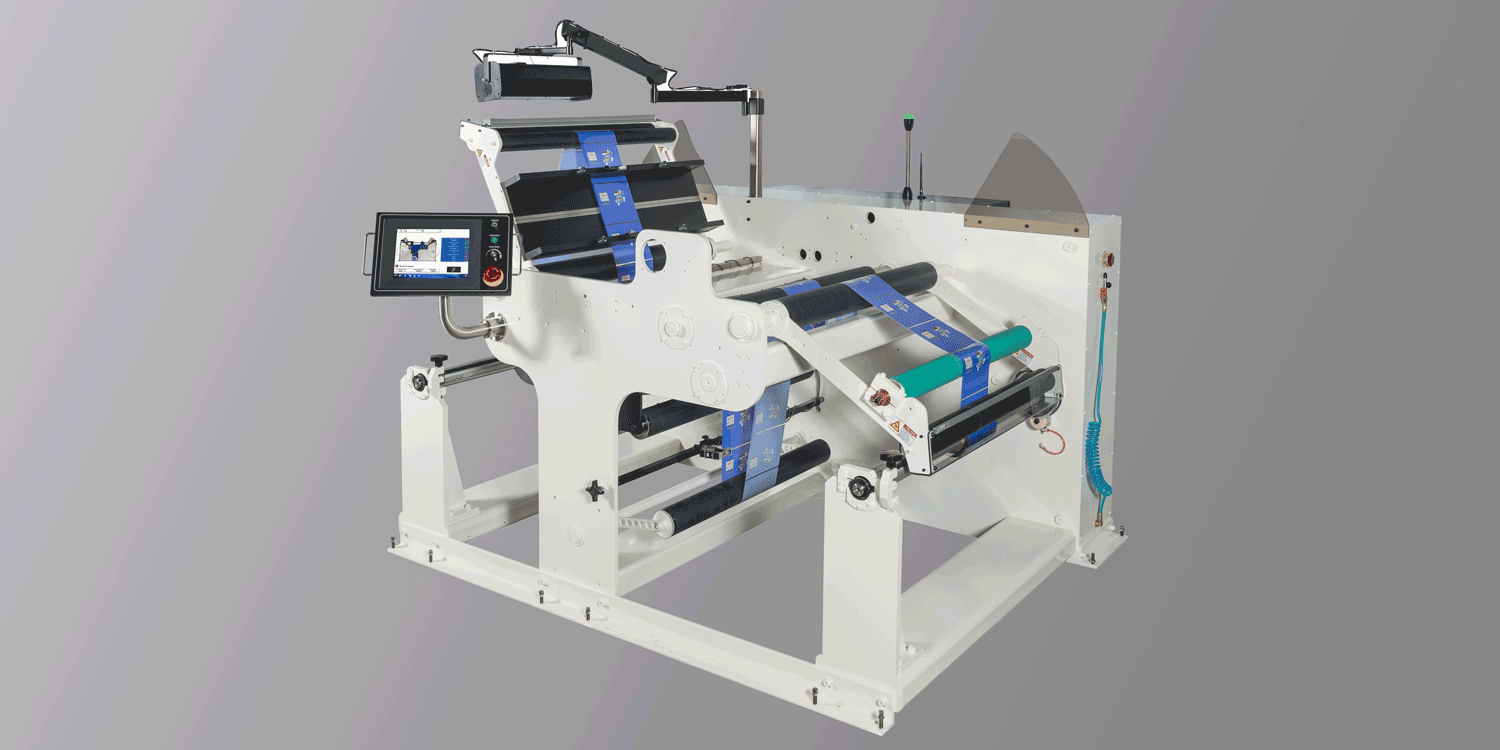

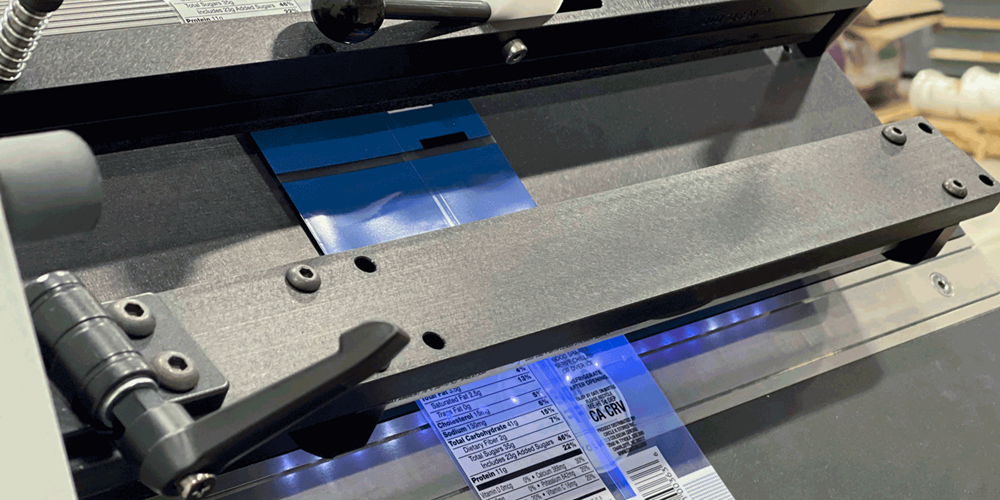

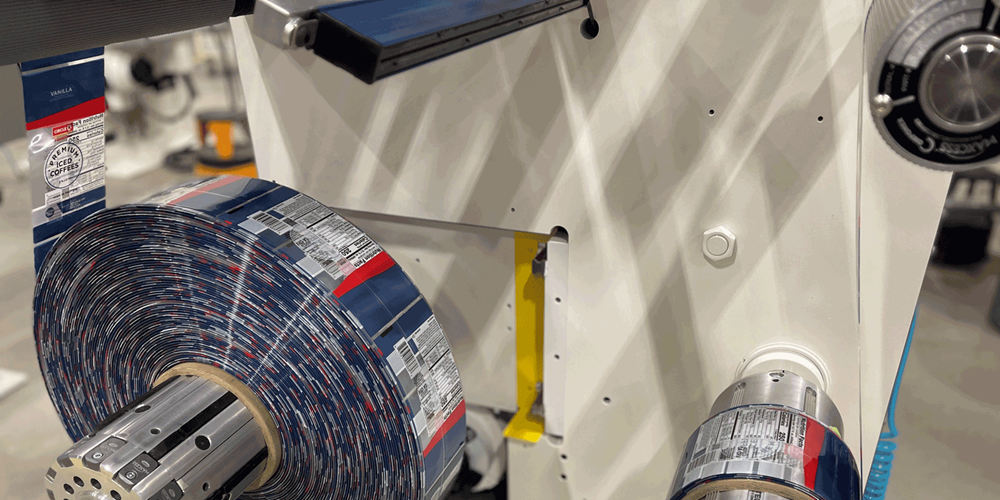

Stanford DM 12 and DM 16 Doctor Machines

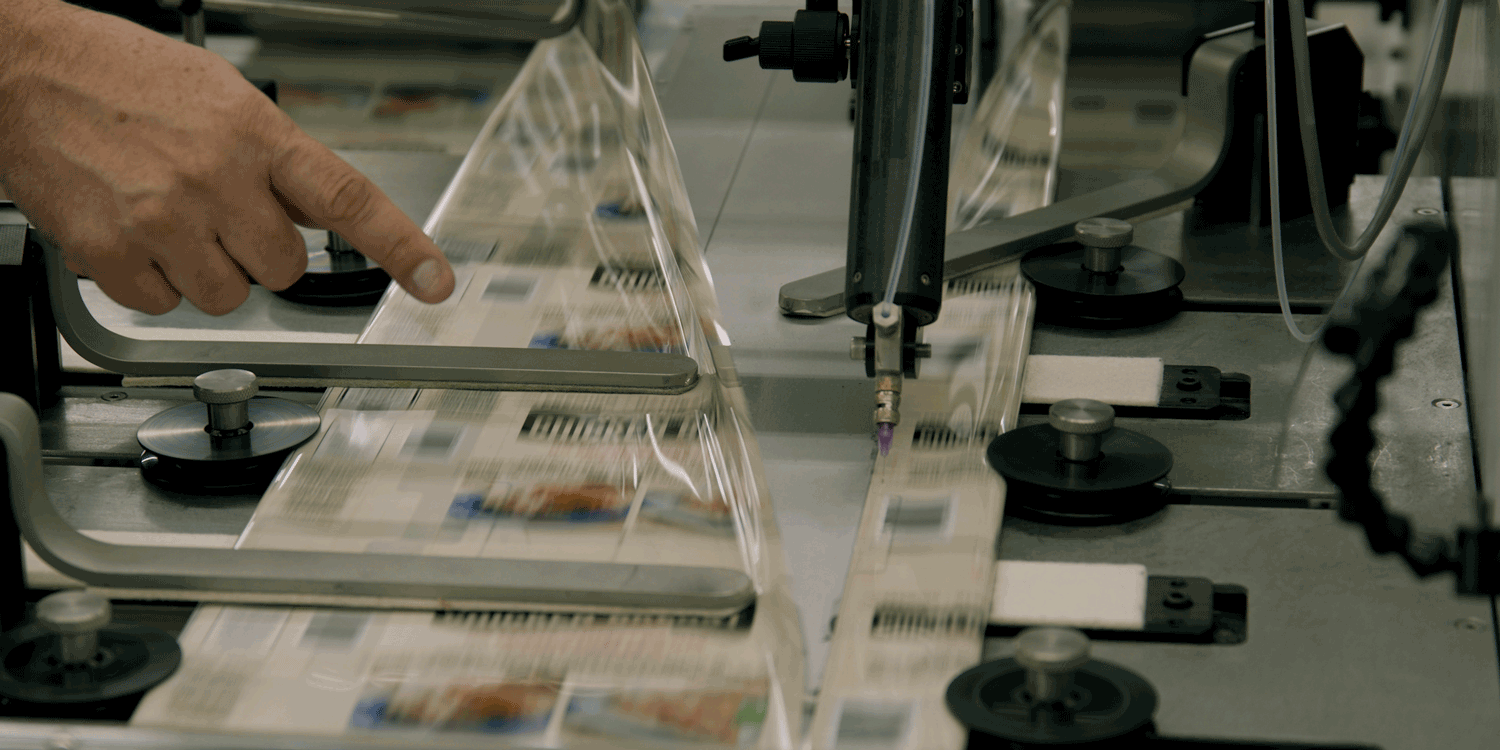

Effective inspection of shrink sleeve labels is critical to maintaining product quality and brand integrity. The Stanford DM12 and DM16 Shrink Sleeve Inspection machines simplify this process, ensuring that every label undergoes thorough examination to detect potential defects.

Key Advantages of the Stanford DM12 and DM16

Both models have been engineered for optimal production efficiency, featuring advanced capabilities that enhance your inspection process:

- Manual Inspection Button: Easily return detected defects to the splice table with just a touch of a button, streamlining the inspection workflow

- High-Speed Performance: Both machines operate at impressive web speeds of up to 500 meters per minute (1,640 feet per minute), making them ideal for high-volume production

- User-Friendly Touchscreen Controls: Intuitive touchscreen interfaces allow operators to manage inspections effortlessly, including the ability to save unlimited product recipes for quick changeovers

- Remote Diagnostics: Minimize downtime with Wi-Fi-enabled internet-based remote diagnostics that offer real-time monitoring and support

- Compact Footprint: Designed to fit seamlessly into existing production lines, the DM12 and DM16 require only two square feet of floor space thanks to their cantilevered, compact design

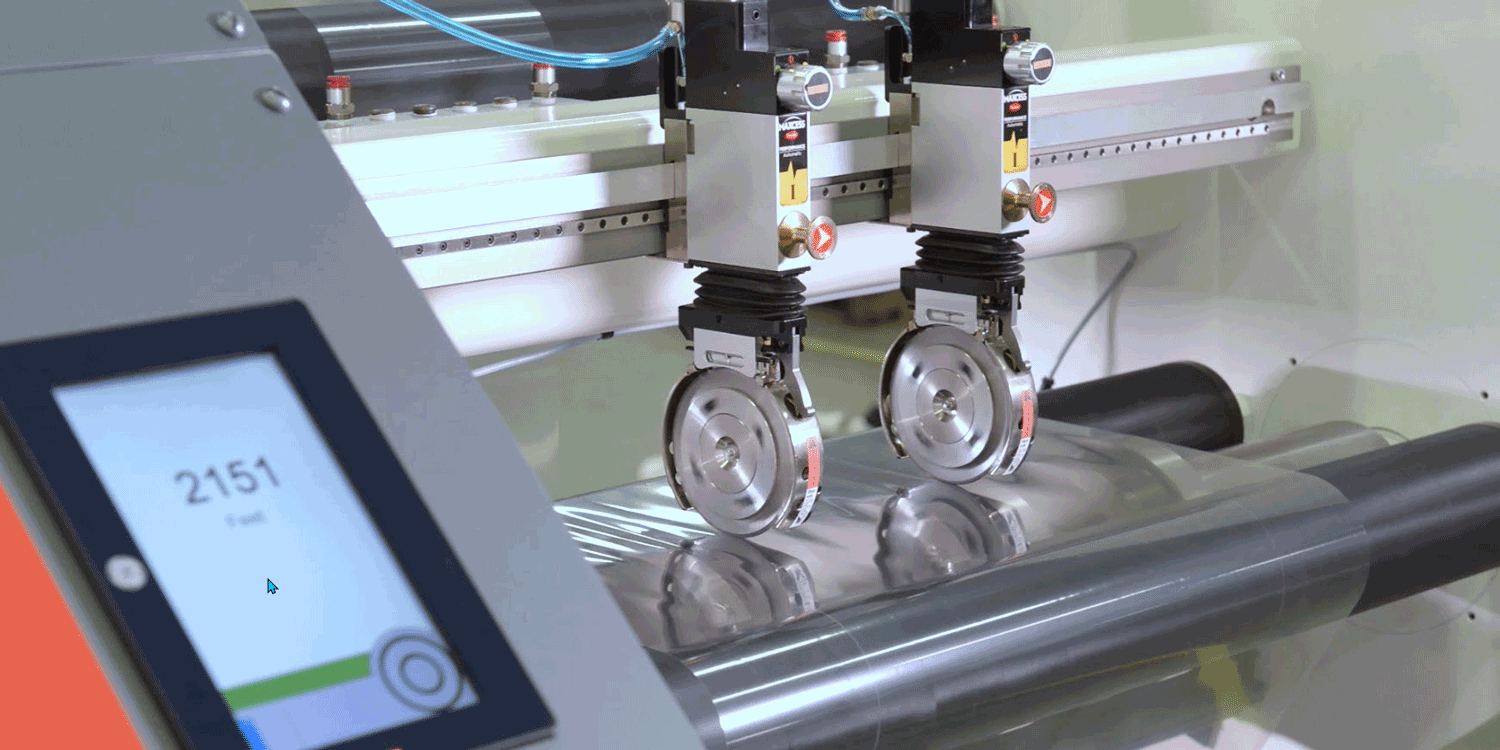

Advanced Detection Features

The DM12 and DM16 are equipped with various options to identify and correct issues, including:

- UV Detection

- Seam Integrity Checks

- Flag Detection

- Bubble Detection

- Splice Detection

This versatility ensures you can address a wide range of label defects and maintain high quality.

The Importance of Quality Inspection

In the converting industry, having effective machinery is crucial for ensuring that each label accurately represents your brand and product. Defective labels not only misrepresent your brand but can also diminish product value. Shrink sleeve inspection machines like the DM12 and DM16 are engineered to pinpoint application issues, from seam integrity to solvent presence, helping you uphold your quality standards.

Don't discard defective labels—correct them with our advanced inspection technology. Explore how the Stanford DM12 and DM16 can enhance your production process by contacting us today. Together, we can ensure your shrink sleeve applications meet the highest standards of quality and efficiency.

Key Features

- Electronic rewind oscillation up to 20 mm [0.75”]

- Cantilevered compact design

- Reversible over/under winding

- Automatic inspections for seam integrity, solvent presence and splice/flag detection

- Two-motor smart AC Vector drive system

- On-board drive-based PAC Control

- Internet-based remote diagnostic with Wi-Fi capability

Technical Data

Available Options

SHAFT OPTIONS

- 3” (76.2mm) base shaft (standard)

- Shaft adapters: 3” (76.2mm) 5” (127mm), 6” (152.4mm) 10” (254mm)

MACHINE OPTIONS

- UV Detection

- Bubble Detection

- Flag Detection

- Splice Detection

- Strobe Light

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...