Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

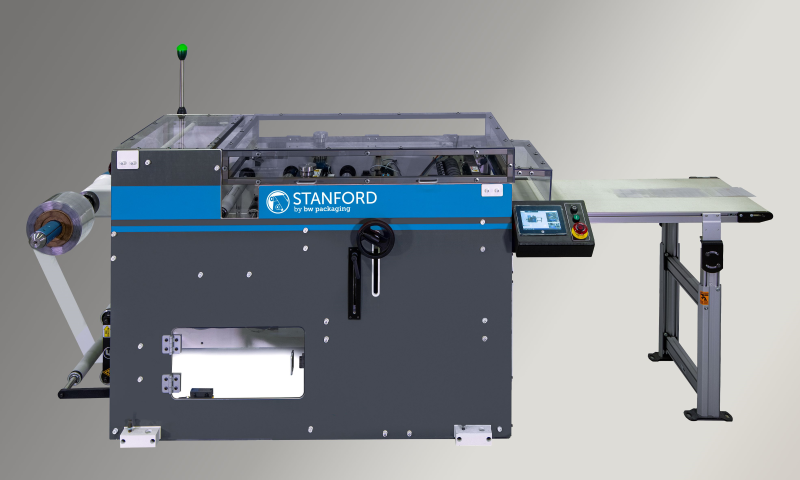

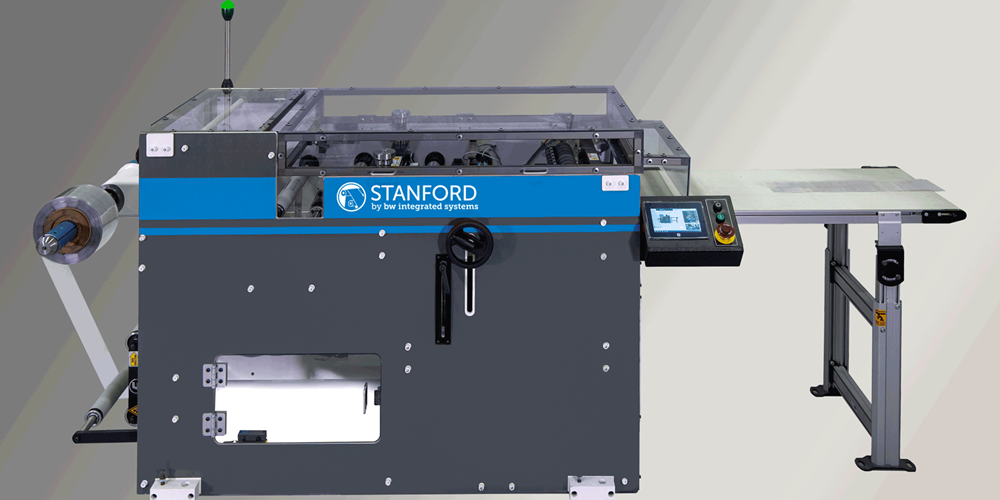

Stanford AC 400 Shrink Sleeve Label Cutter

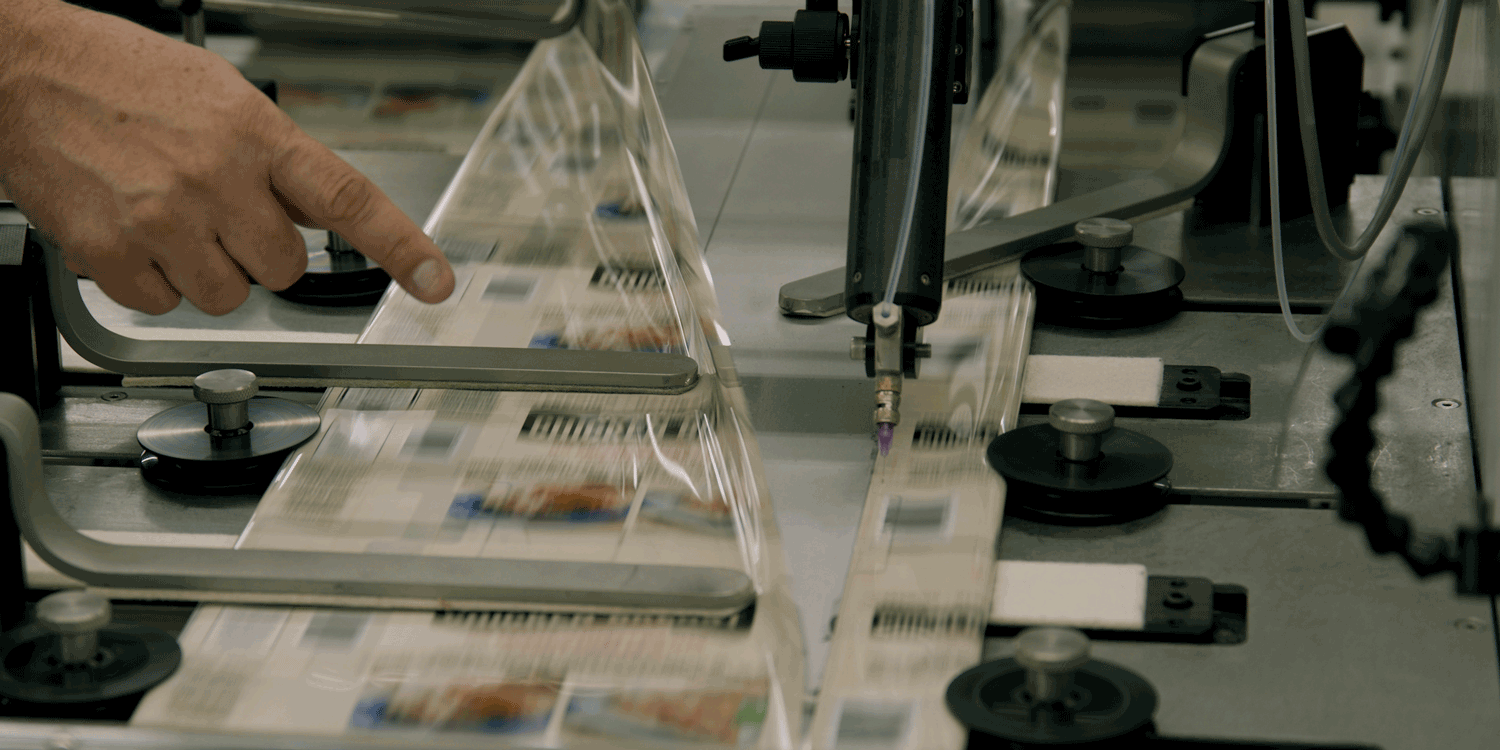

Shrink sleeve labels provide an exceptional opportunity for companies to enhance their branding and marketing efforts. However, the key to successful shrink sleeve packaging lies in the critical steps of the manufacturing process, particularly precision cutting.

In the converting industry, the cutting phase is often a major pain point. Dull or inaccurate cutting machines can lead to significant material waste, negatively impacting efficiency and profitability. To address these challenges, the Stanford AC 400 has been expertly engineered for high-speed and precise cutting of shrink sleeve labels, ensuring optimal performance and minimal waste.

Discover the Advantages of the Stanford AC 400 Shrink Sleeve Cutter

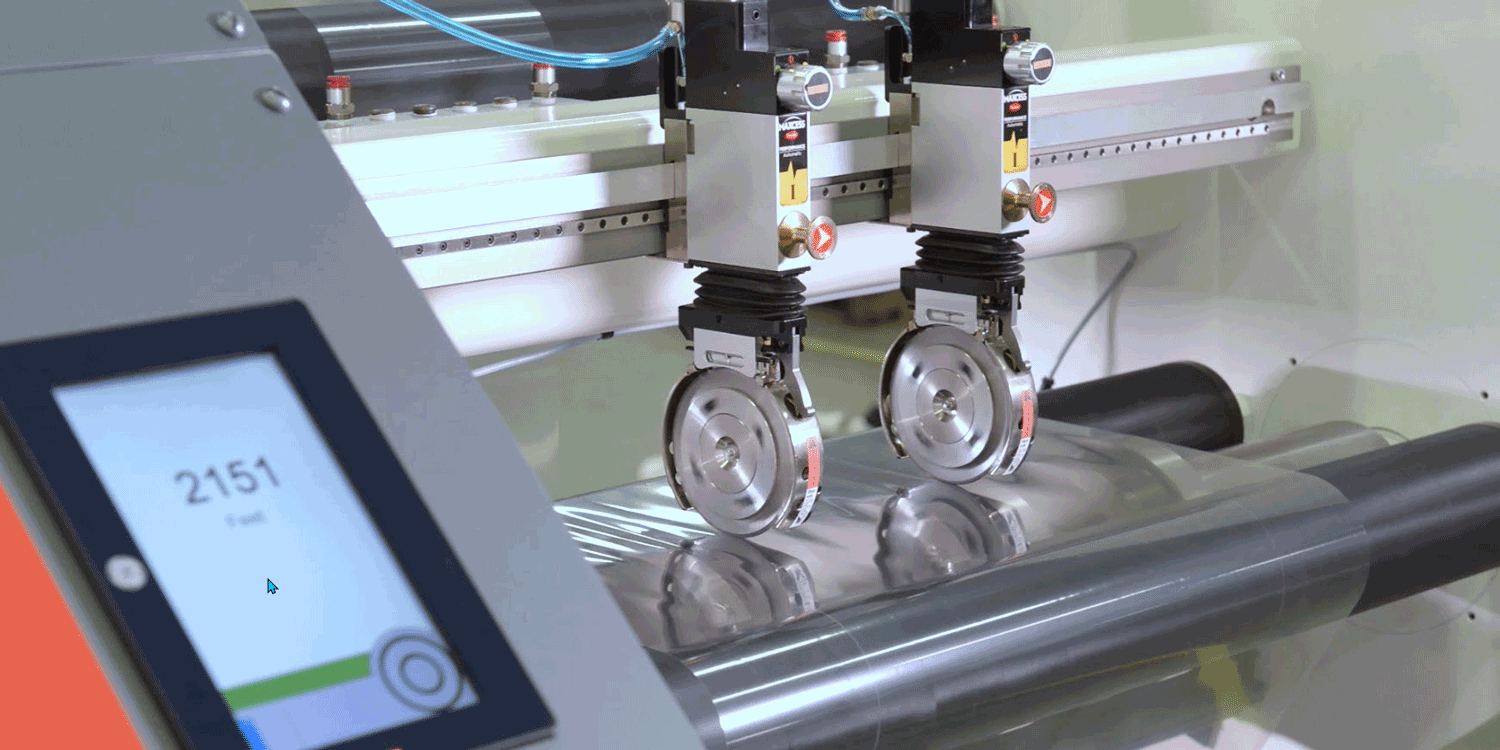

- High-Speed Cutting Performance: With the capability to execute up to 400 cuts per minute at 1.96 inches (50mm), the Stanford AC400 stands out as an industry leader. This exceptional speed combined with a servo-controlled material feed system ensures consistency and efficiency in production.

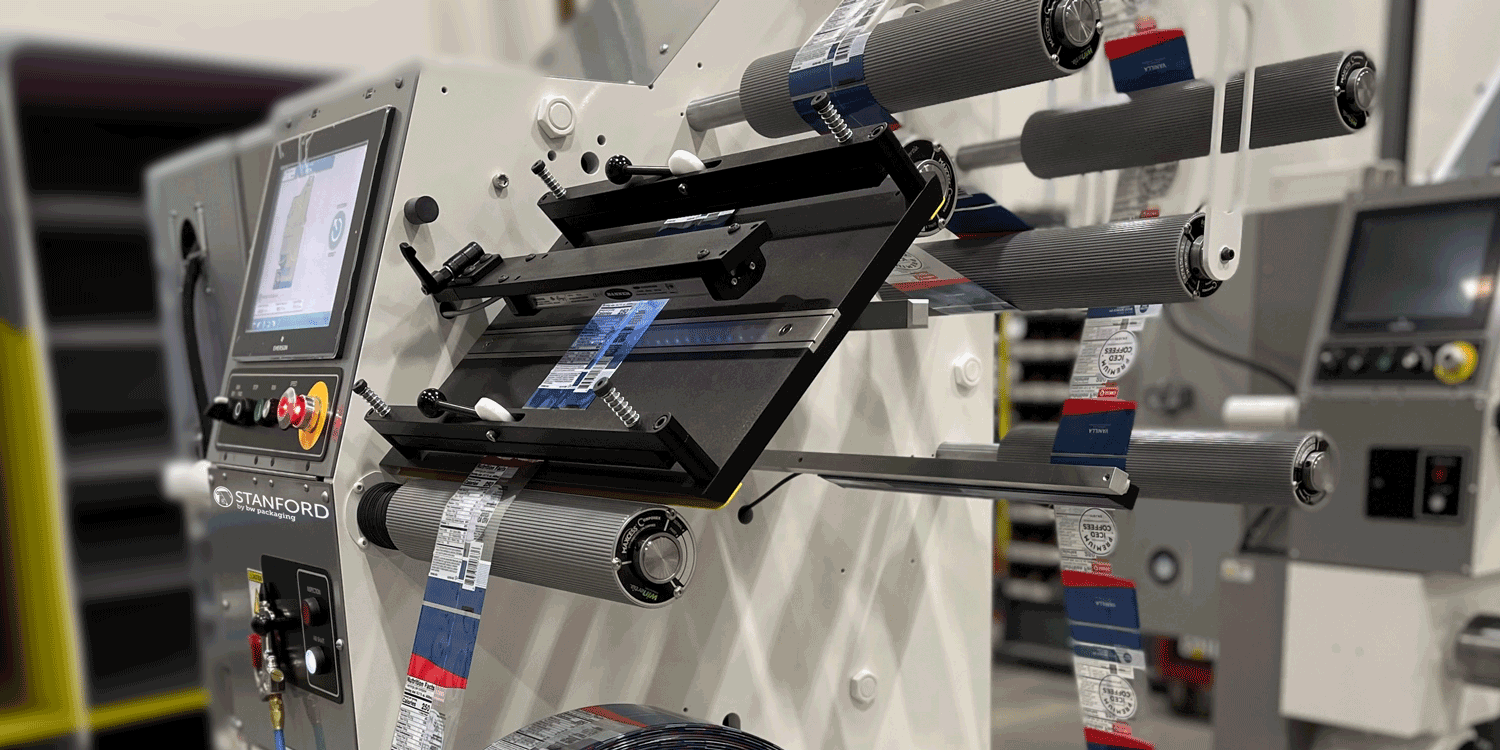

- Innovative Servo-Driven Feed Unit: Our servo-driven feed unit enhances production accuracy by allowing for programmable cut-to-length options and the use of a registration sensor, guaranteeing precision with each cut.

- User-Friendly Technology for Seamless Operation: The Stanford AC400 features intuitive touchscreen controls and remote diagnostics, making operation easy for your team. You can quickly input material “recipes” for efficient product changeovers. Additionally, the internet-based remote diagnostics with Wi-Fi capability significantly reduce machine downtime, boosting overall production rates.

Flexible Enhancements for Customized Solutions

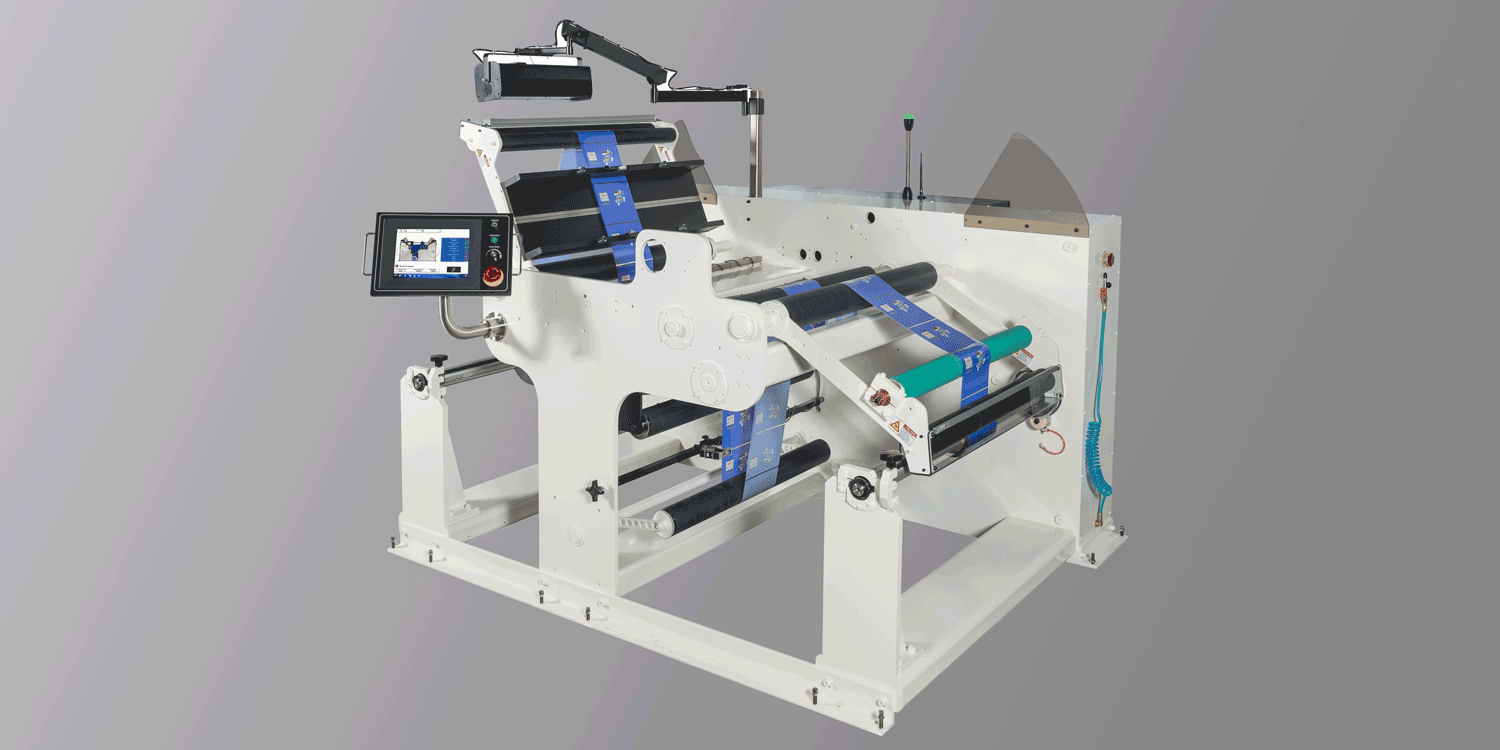

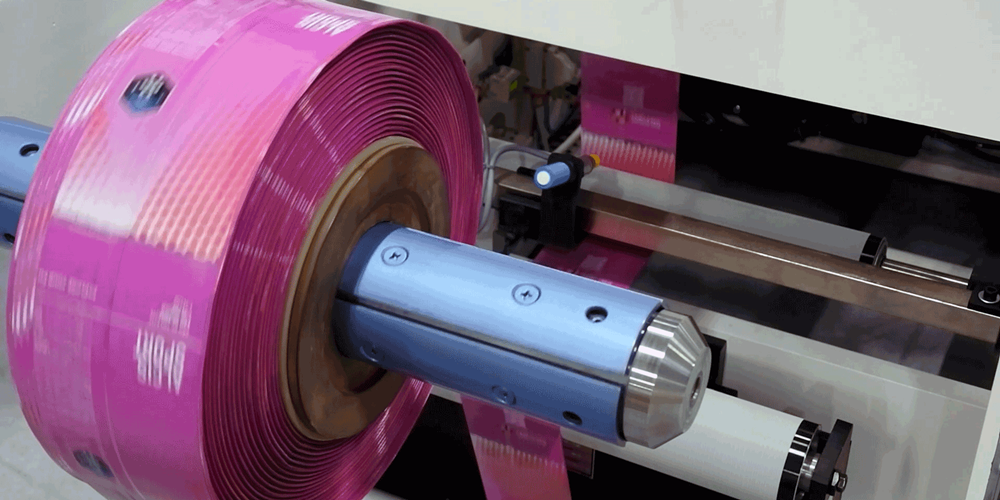

Customize your Stanford AC400 Shrink Sleeve Cutting Machine with optional enhancements tailored to meet your specific operational needs, including:

- Rewinding

- Linear Perforation

- Air Relief Punch

Maximize the potential of your shrink sleeve packaging with Stanford's innovative cutting solutions. Contact us today to learn more about the Stanford AC 400 and discover how it can streamline your production process, reduce waste, and ultimately improve your profitability. Take the next step in enhancing your brand’s impact in the marketplace.

Key Features

Technical Data

Available Options

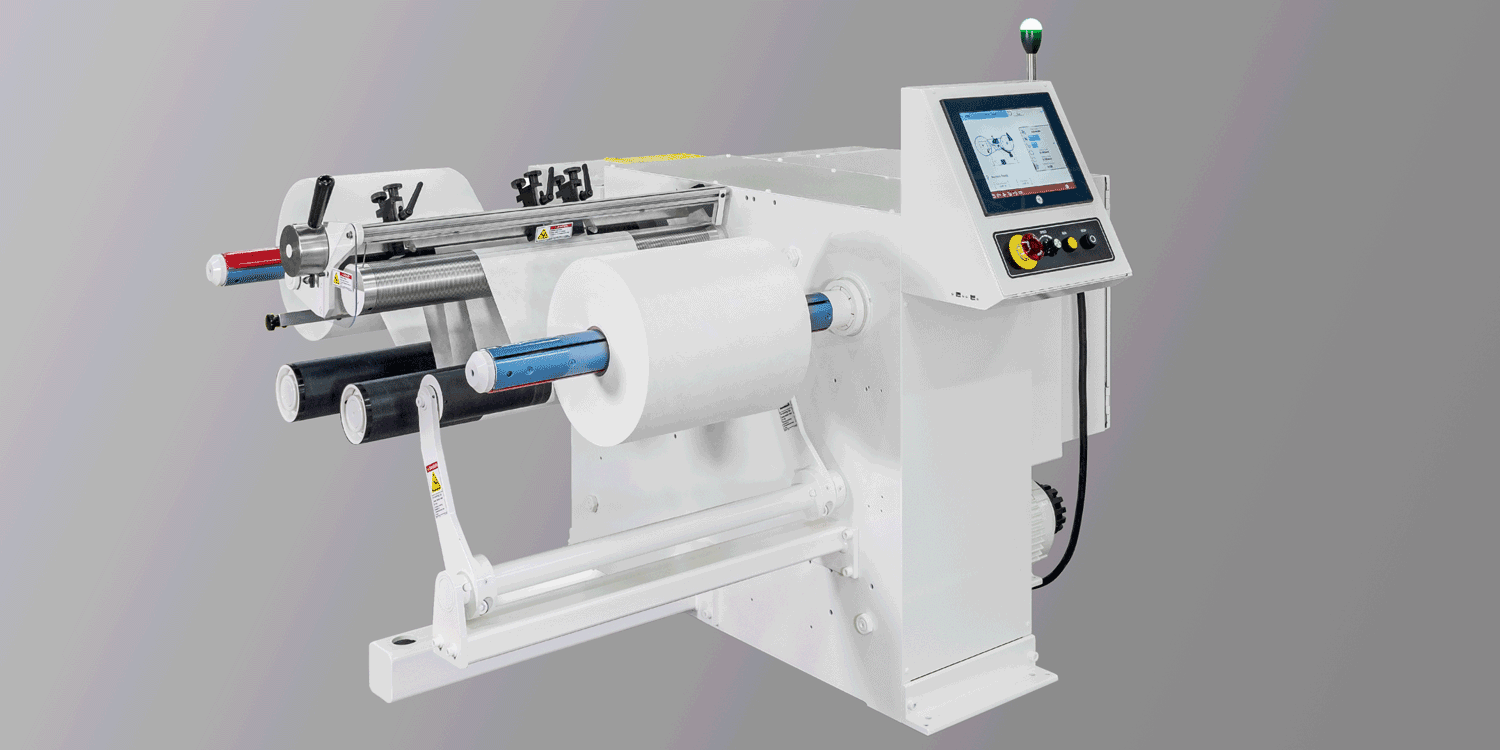

- Rewinding Unit

- Linear Perforation

- Air Relief Punch

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)