Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

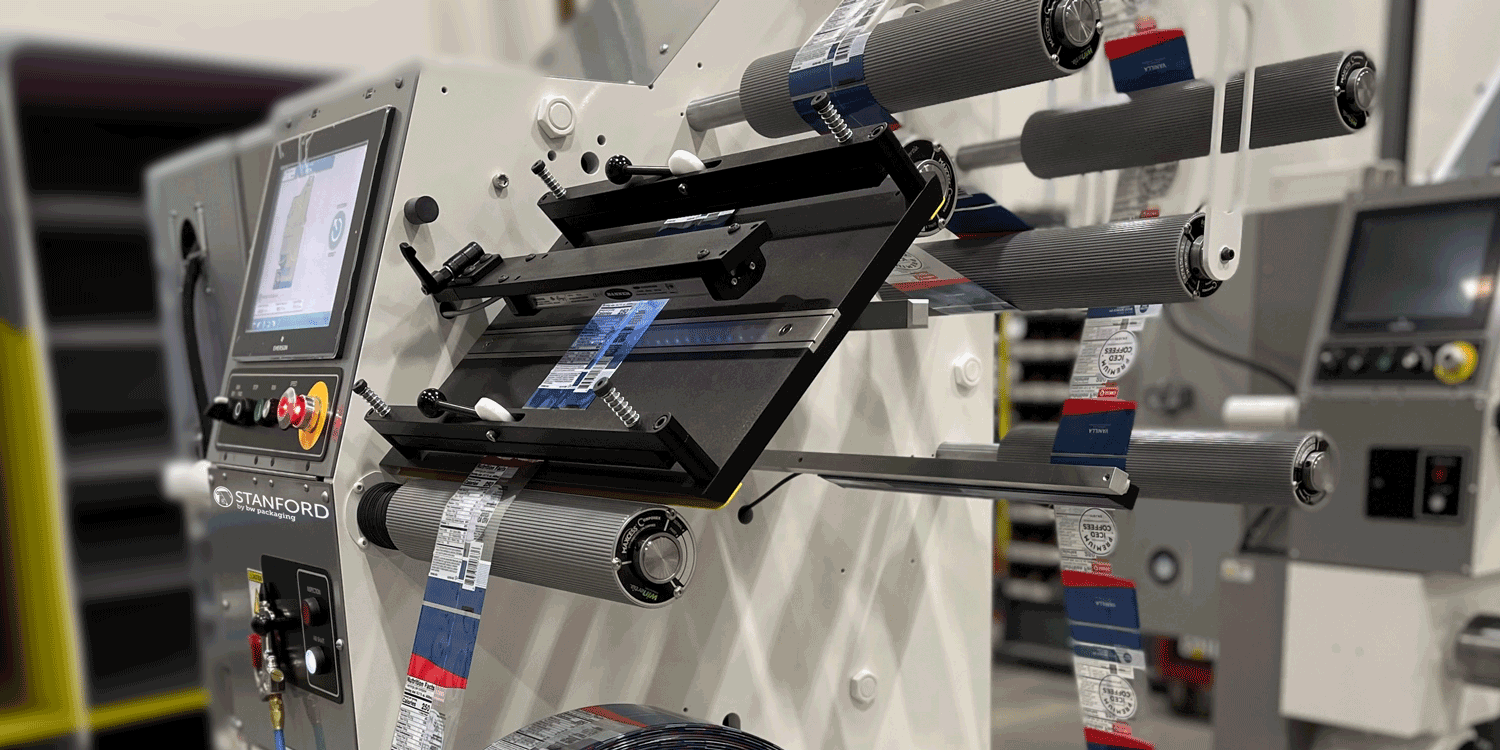

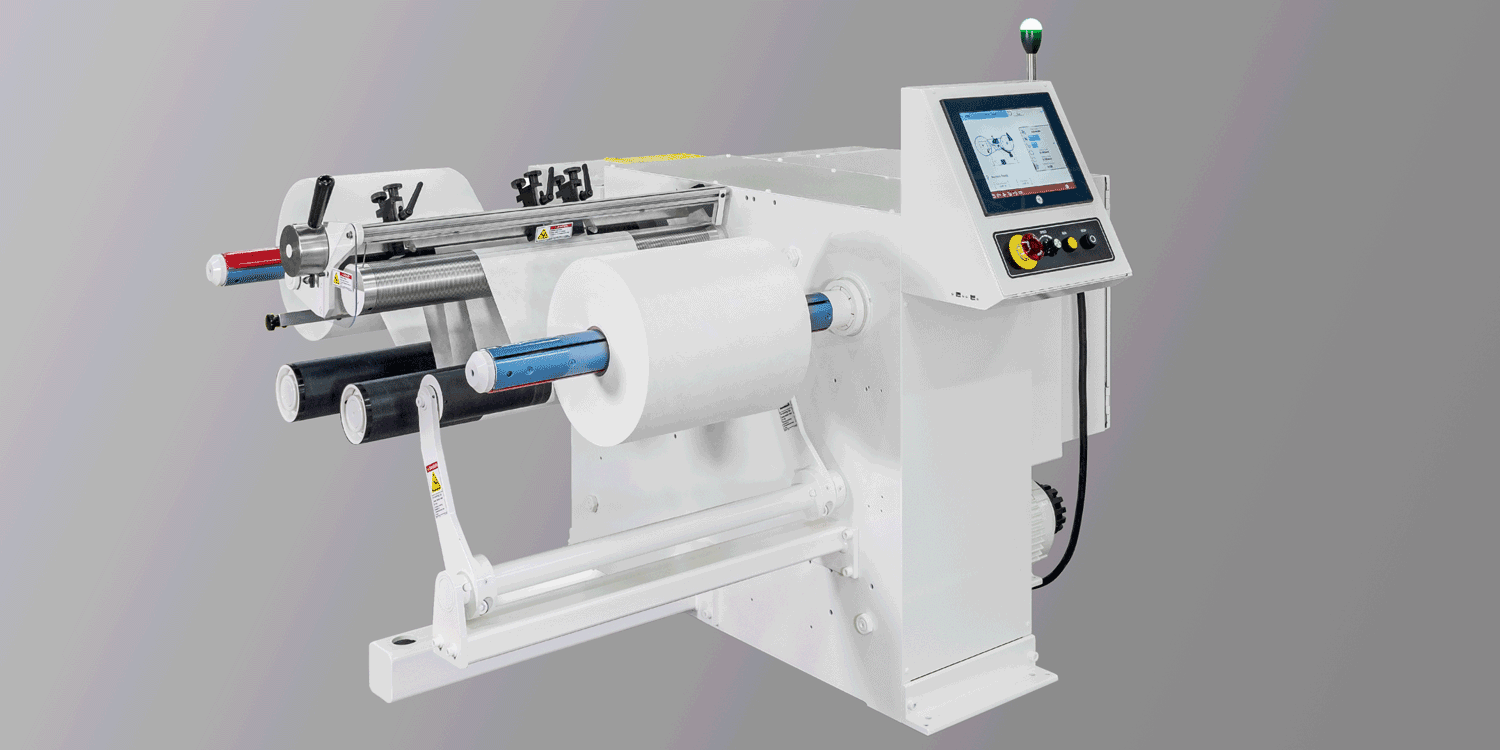

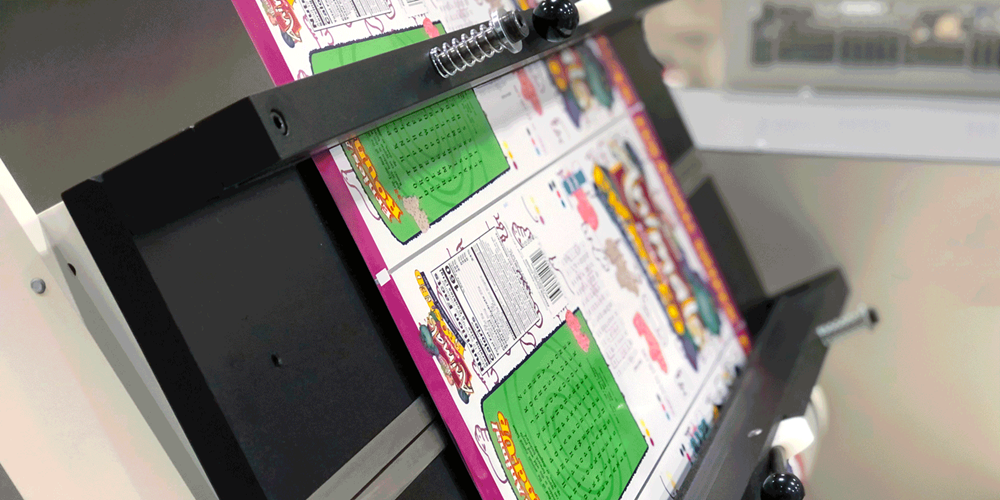

Stanford DM 152 LT Doctor Machine

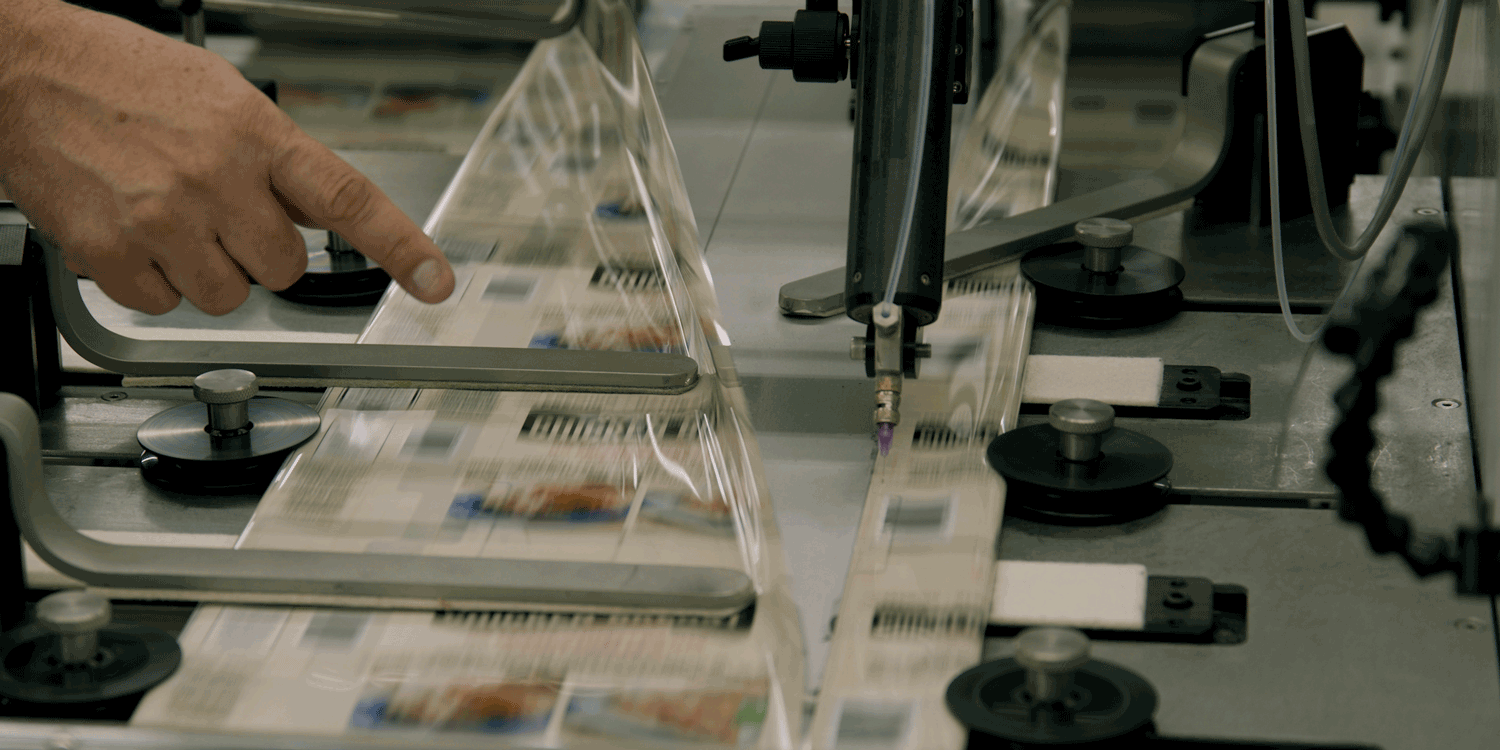

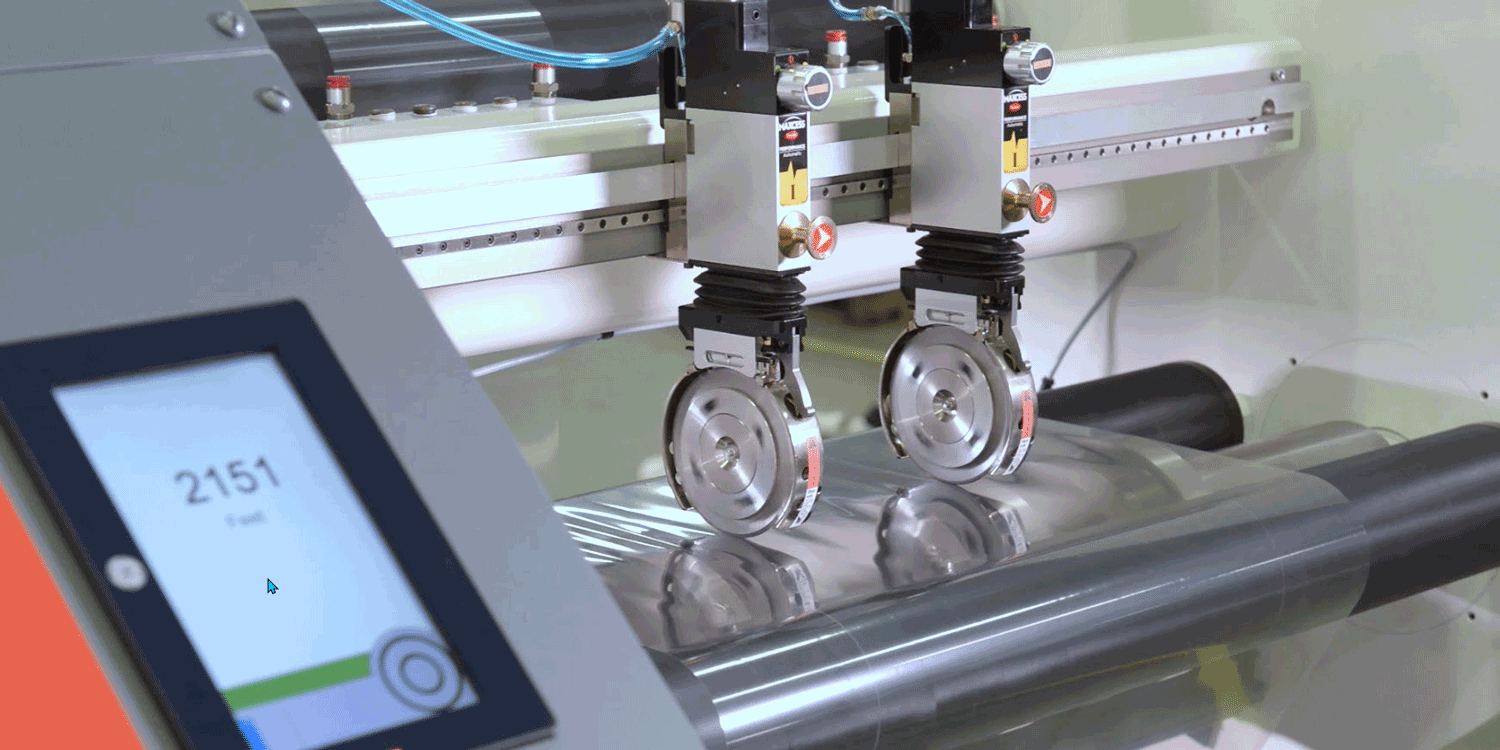

The reversible Doctor Machine® 152 LT is a highly versatile device designed for removing defective printing, repairing splices, re-tensioning, and edge-guiding rolls of damaged material. It is suitable for a wide range of materials, including light films, film laminates, non-wovens, and lightweight papers. Thanks to its dual motor AC Vector drive system, the machine operates efficiently at high speeds. The user-friendly touchscreen control panel clearly displays all running parameters during operation, and operators can easily return any detected defects to the splice table by pressing the manual inspection button.

The 152 LT is equipped with a variety of advanced features that enhance its versatility and ease of use. Its intuitive touchscreen controls allow for unlimited recipes, making it simple to adjust and fine-tune the machine to meet specific needs. Additionally, the machine features pneumatically inert rider rolls that ensure precise density control, along with a two-motor smart AC Vector drive system for smooth and efficient operation.

The 152 LT utilizes a compactLogix PAC Control system, which is both powerful and user-friendly, providing operators with a clear view of all operational parameters. Other notable features include a reversible over/under winding system and a cantilevered design that simplifies the loading and unloading of materials.

Operators can swiftly detect defects using the manual inspection button that automatically sends any identified issues back to the splice table. Furthermore, the 152 LT includes taper tension and an optional inspection area for enhanced precision and control. To facilitate maintenance and support, the machine also offers internet-based remote diagnostic capabilities and Wi-Fi connectivity.

Key Features

Technical Data

Available Options

Trimming Options:

- Razor

- Score Shear

Machine Options:

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...