Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

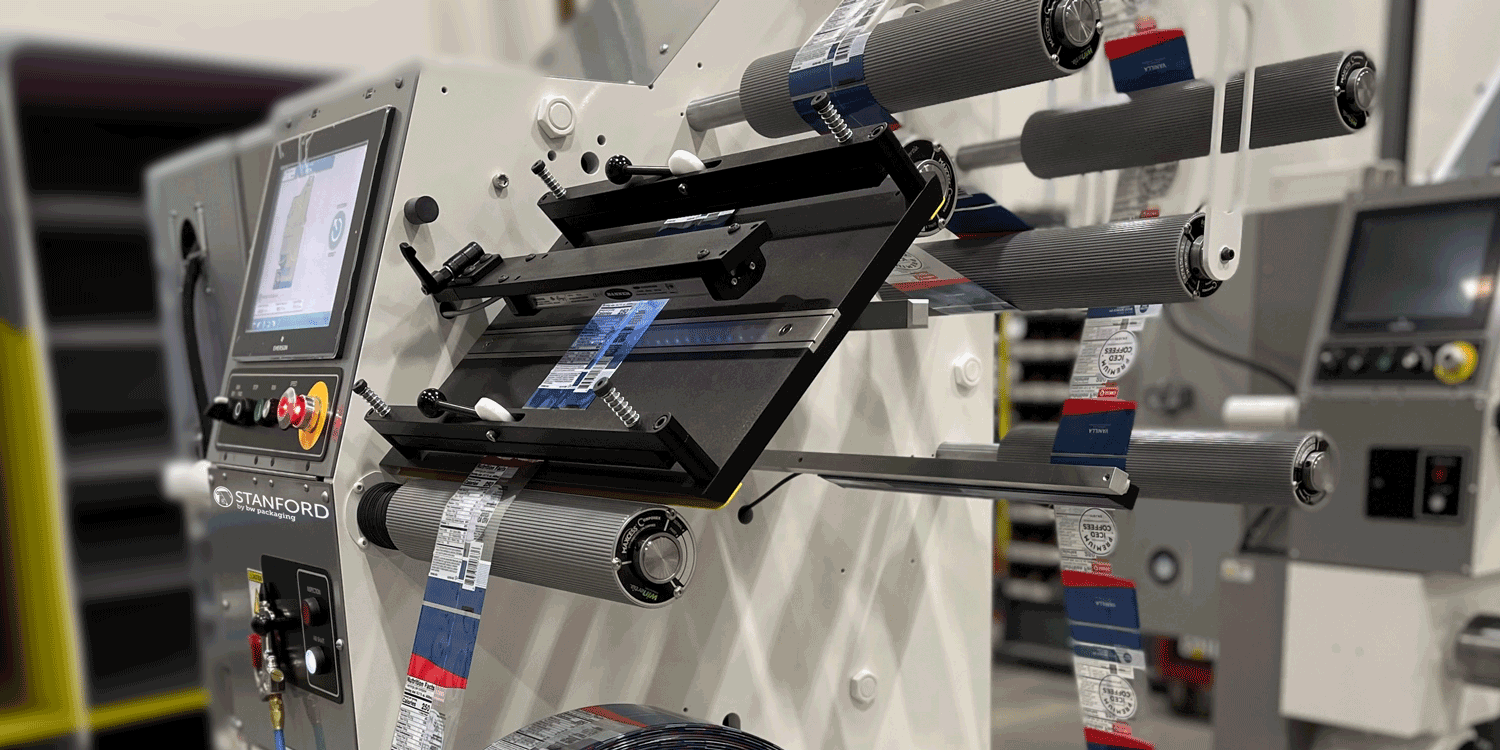

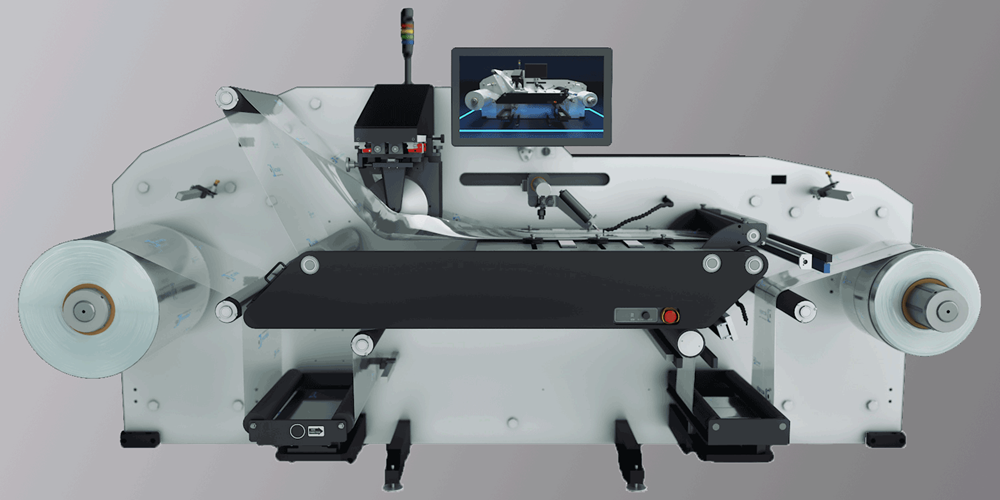

Stanford Revolve™ Platform

Smarter by Design. Built from Experience.

The Stanford Revolve™ Platform isn't just the fastest shrink sleeve seamer on the market; it's the smartest. Unlike other solutions, the Revolve is engineered by BW Packaging, a leader not only in shrink sleeve seaming but also in shrink sleeve application. This dual expertise gives us unmatched insight into the full shrink sleeve lifecycle, and it shows.

From reduced material waste to smarter solvent control, every detail of the Revolve is designed to deliver a superior roll that performs better in the field. That means greater efficiency for you and greater reliability for your customers.

Engineered for Industry-Leading Setups

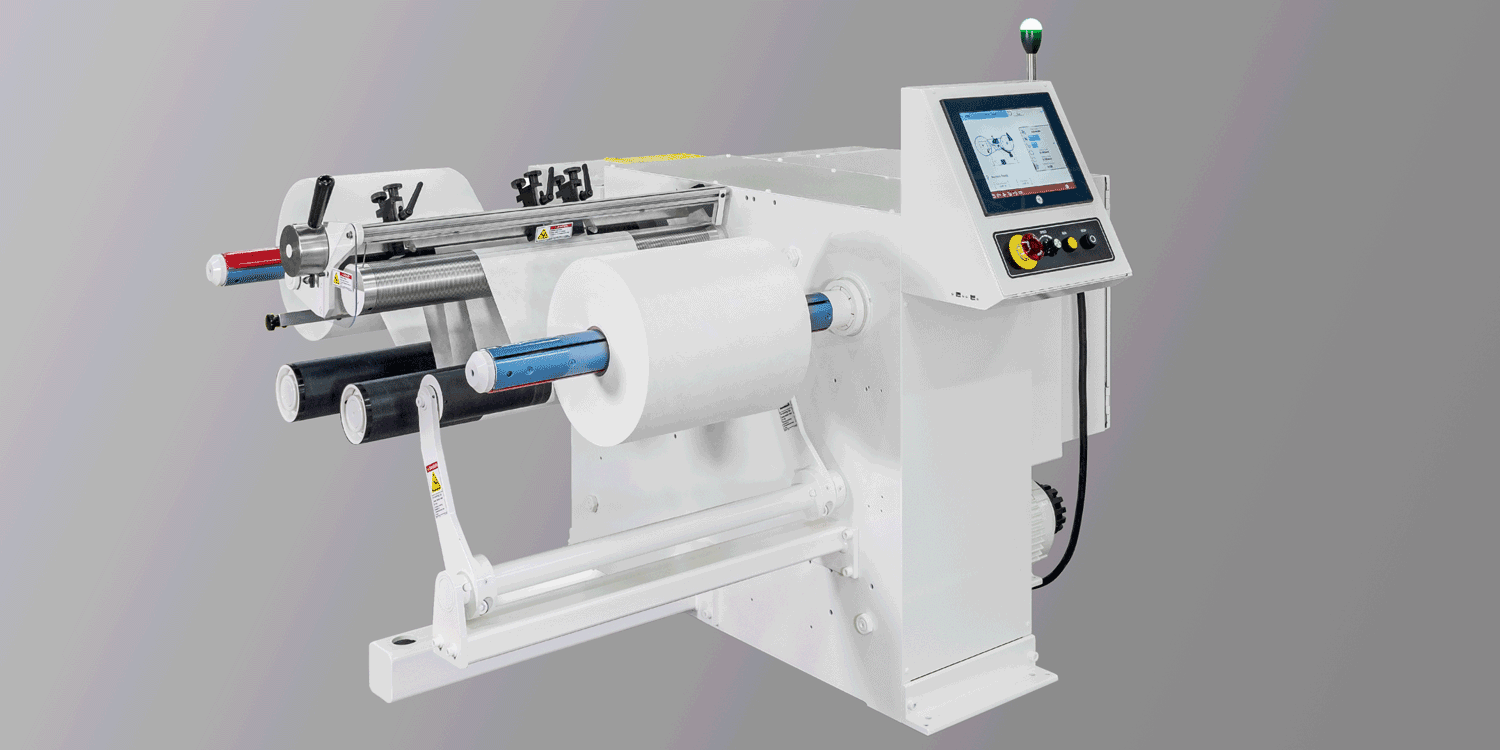

Fast Setup, Minimal Waste

Traditional seamers can waste hundreds of feet of film during lengthy 30-minute setups. The Revolve™ changes that with automated servo controls that reduce setup time to just five minutes with repeatable recipes and minimal material waste, giving you faster changeovers and a rapid return on investment.

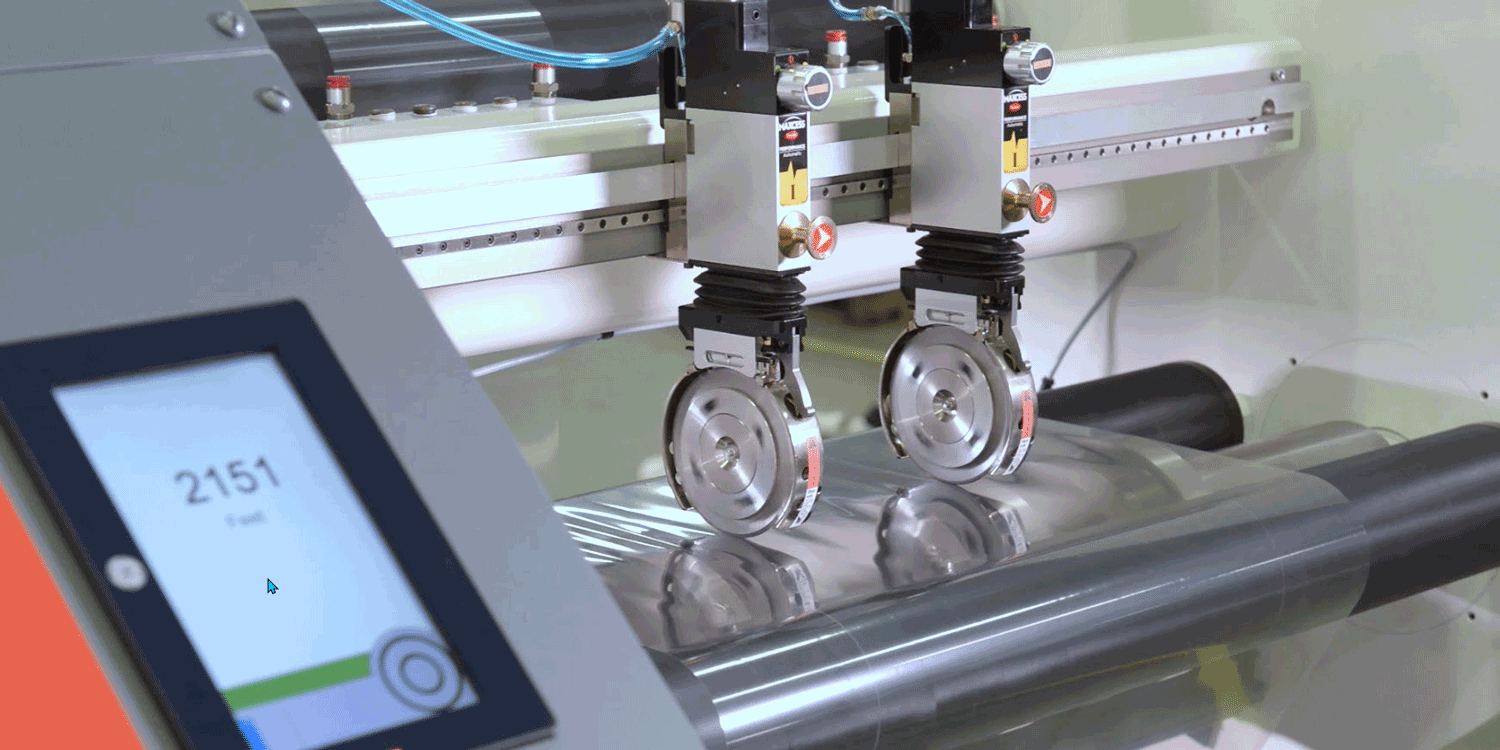

Intelligent Tracking & Seam Validation

An advanced layflat monitoring system checks seam positioning every 1.3 seconds throughout the run, offering real-time validation of seam integrity and roll quality, so you can run with confidence from start to finish.

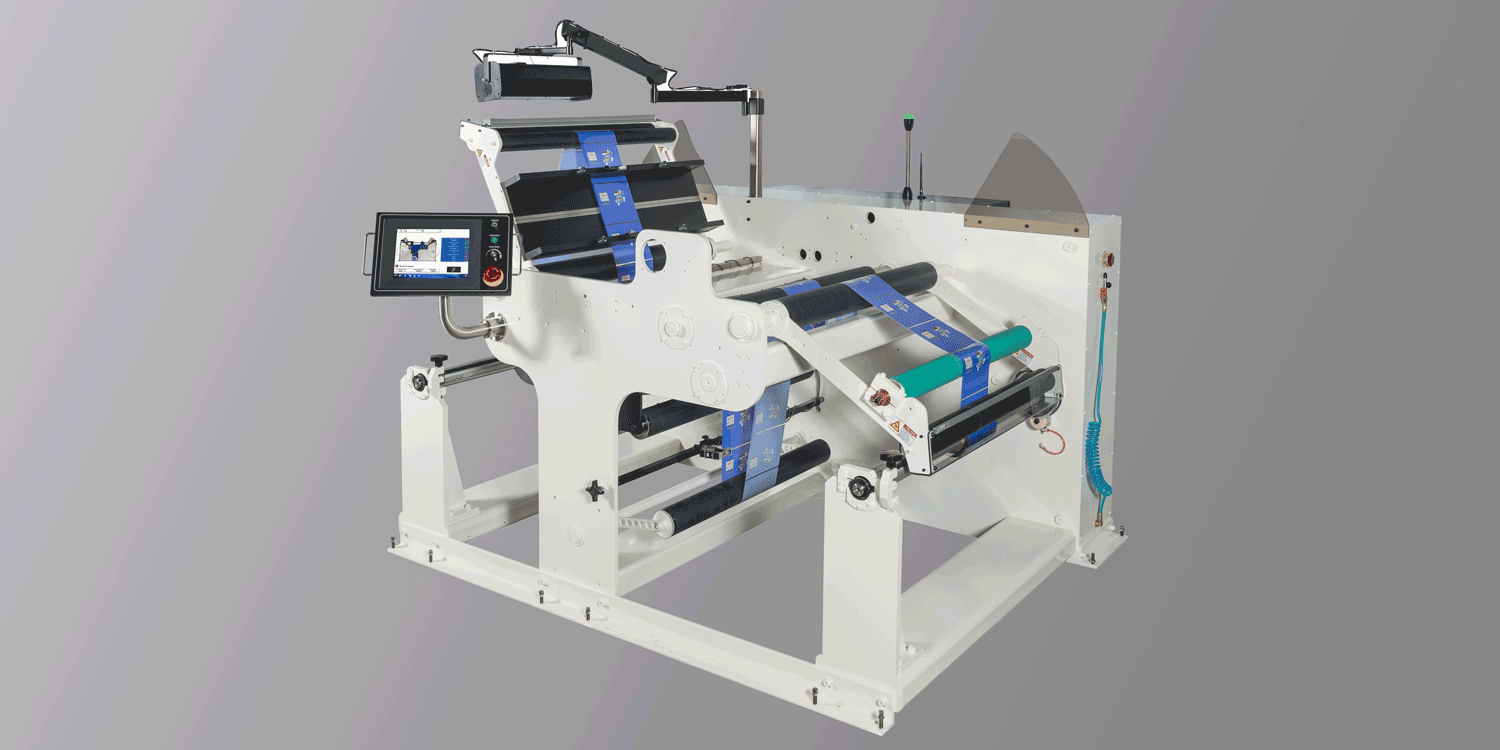

Smarter Oscillation Control

The Revolve™ maintains consistent layer distribution from core to edge, avoiding buildup issues that disrupt application. With precise oscillation control, you get tightly wound, high-performance rolls every time.

Precision Solvent Delivery

Unlike gravity-fed or pneumatic systems, Revolve’s medical-grade pump ensures consistent solvent flow at any speed, delivering clean, reliable seams with no over- or under-application.

Scalable Solution for Growing Businesses

As your business evolves, the Revolve’s intuitive modular design allows for easy field upgrades to increase throughput and seaming capabilities without hassle

Elevate your operations and maintain high-quality standards with the Stanford Revolve™—the industry leader in shrink sleeve seaming solutions. Get in touch today to learn how you can improve productivity, reduce downtime, and enhance output with this next-generation seaming solution.

Key Features

Technical Data

Available Options

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)