Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

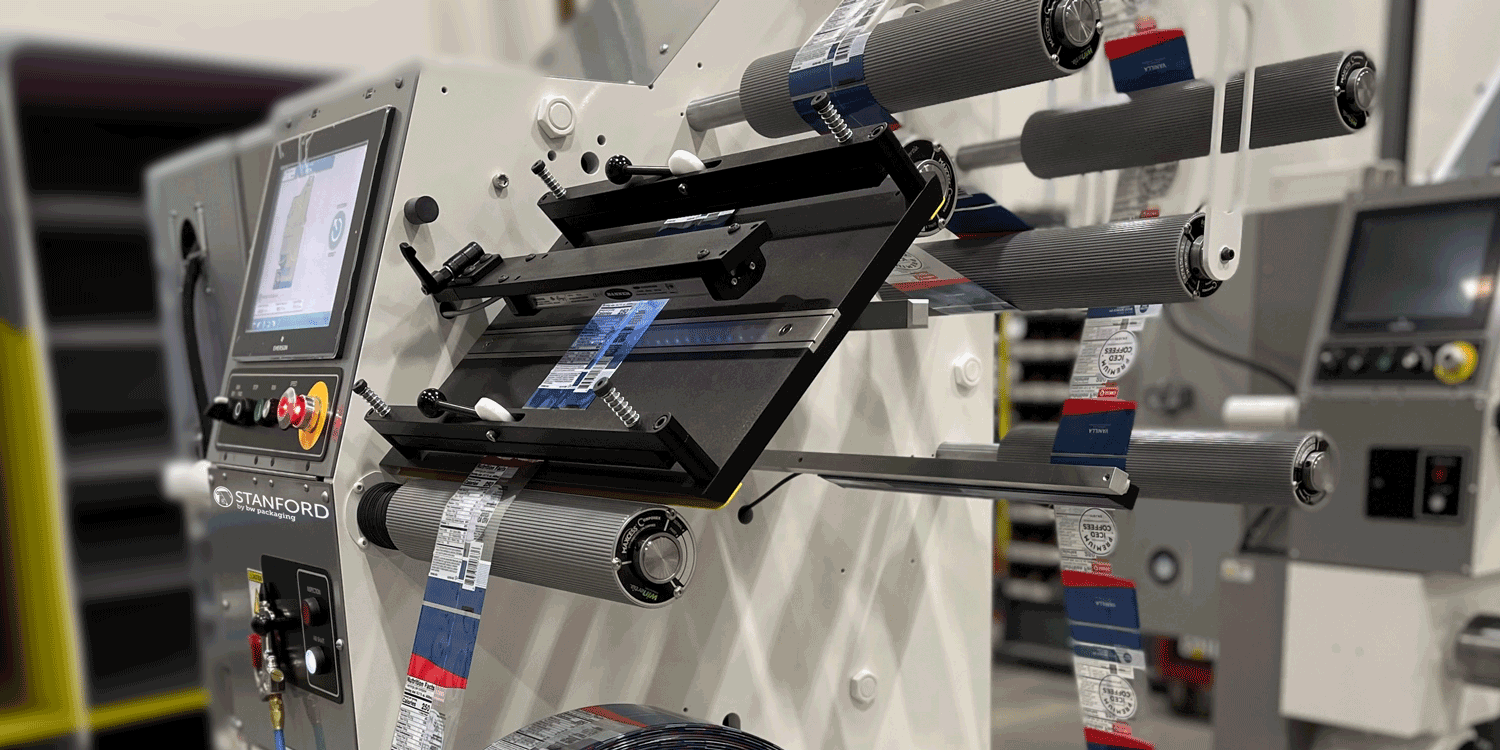

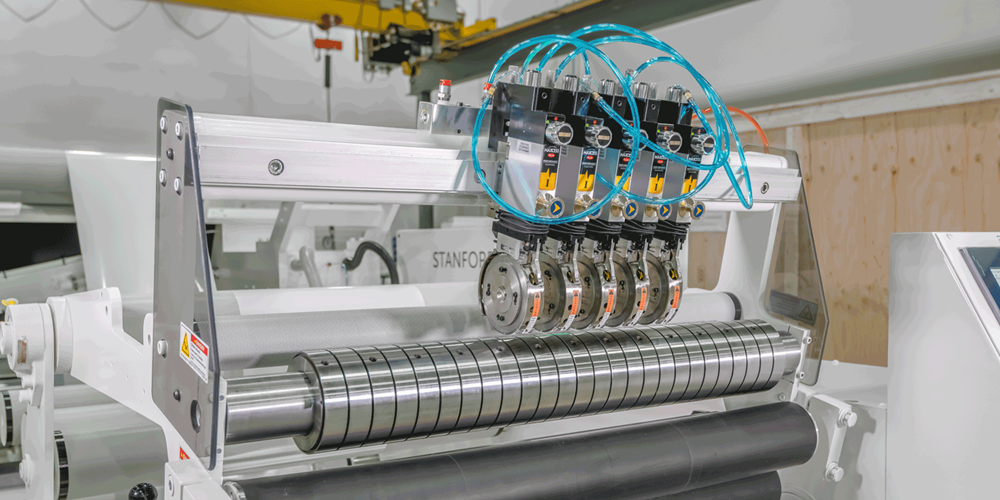

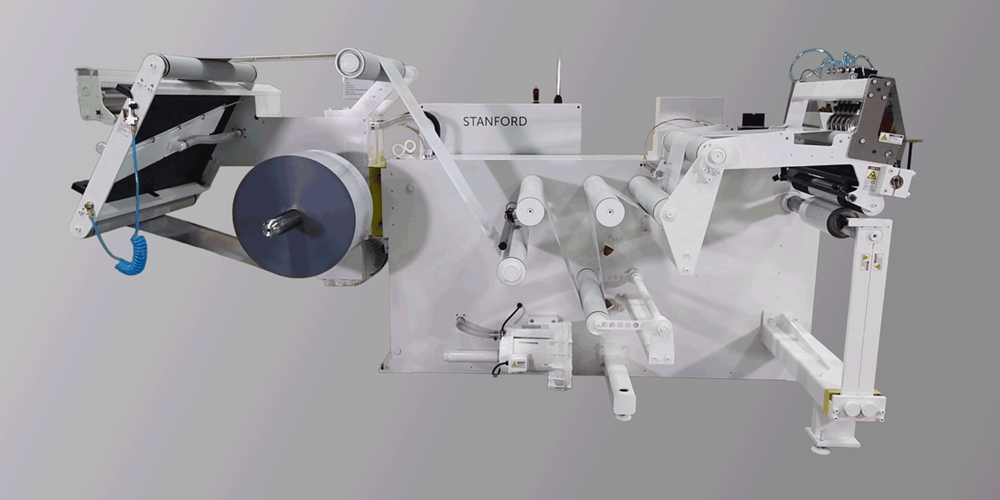

Stanford DM 142 Series Doctor Machines

Defective labels pose significant challenges for manufacturers, leading to unanticipated production costs and wasted materials. However, with the Stanford Doctor Machine, you can effectively salvage these labels and significantly reduce your operating expenses. The Stanford DM 142 series is designed specifically for the converting industry, providing an efficient and cost-effective solution to various production issues.

Salvage Defective Labels with the Stanford DM 142 Series

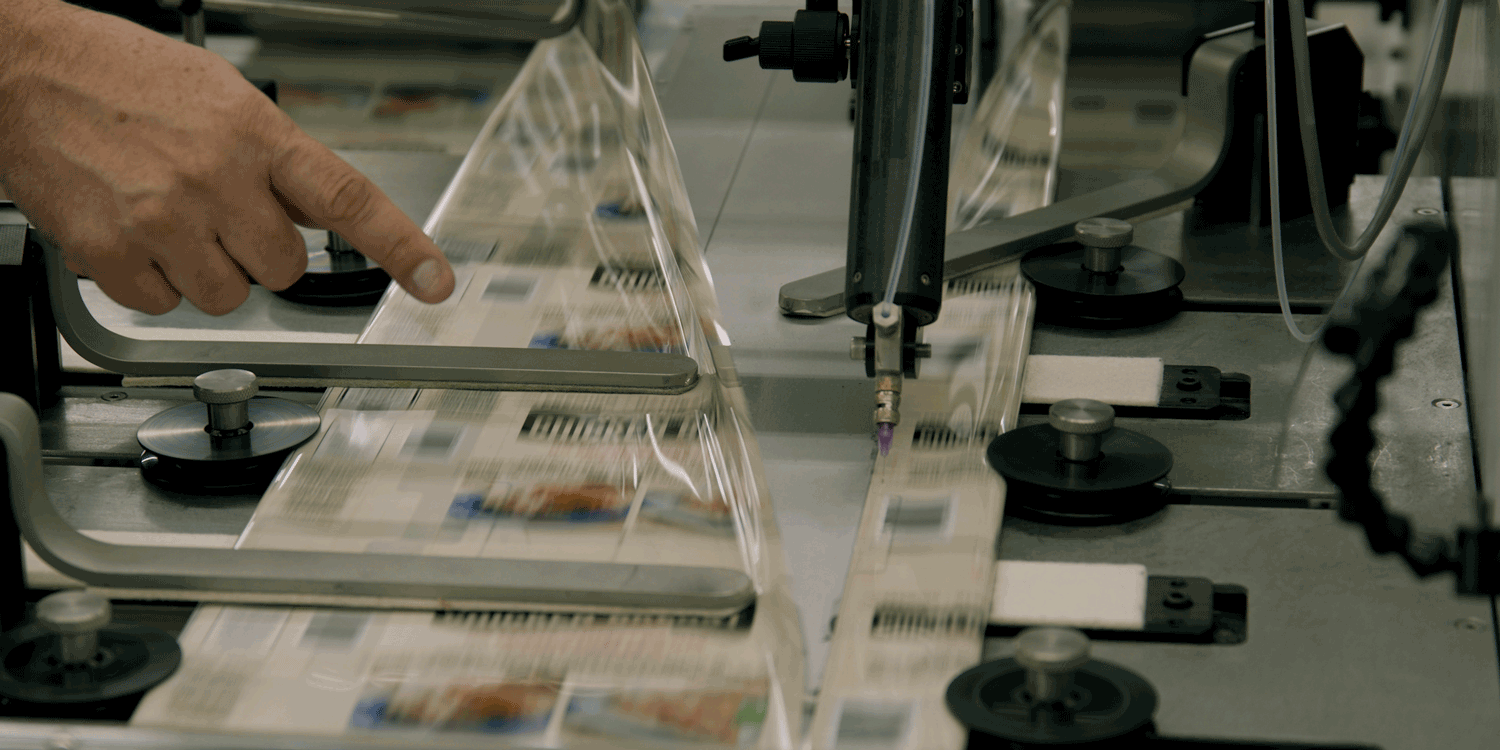

The Stanford Doctor Machines are engineered to tackle a range of problems associated with defective labels, including:

- Removal of defective stock

- Repair of splices

- Re-tensioning of loose rolls

- Edge trimming

- Butt roll rewinding

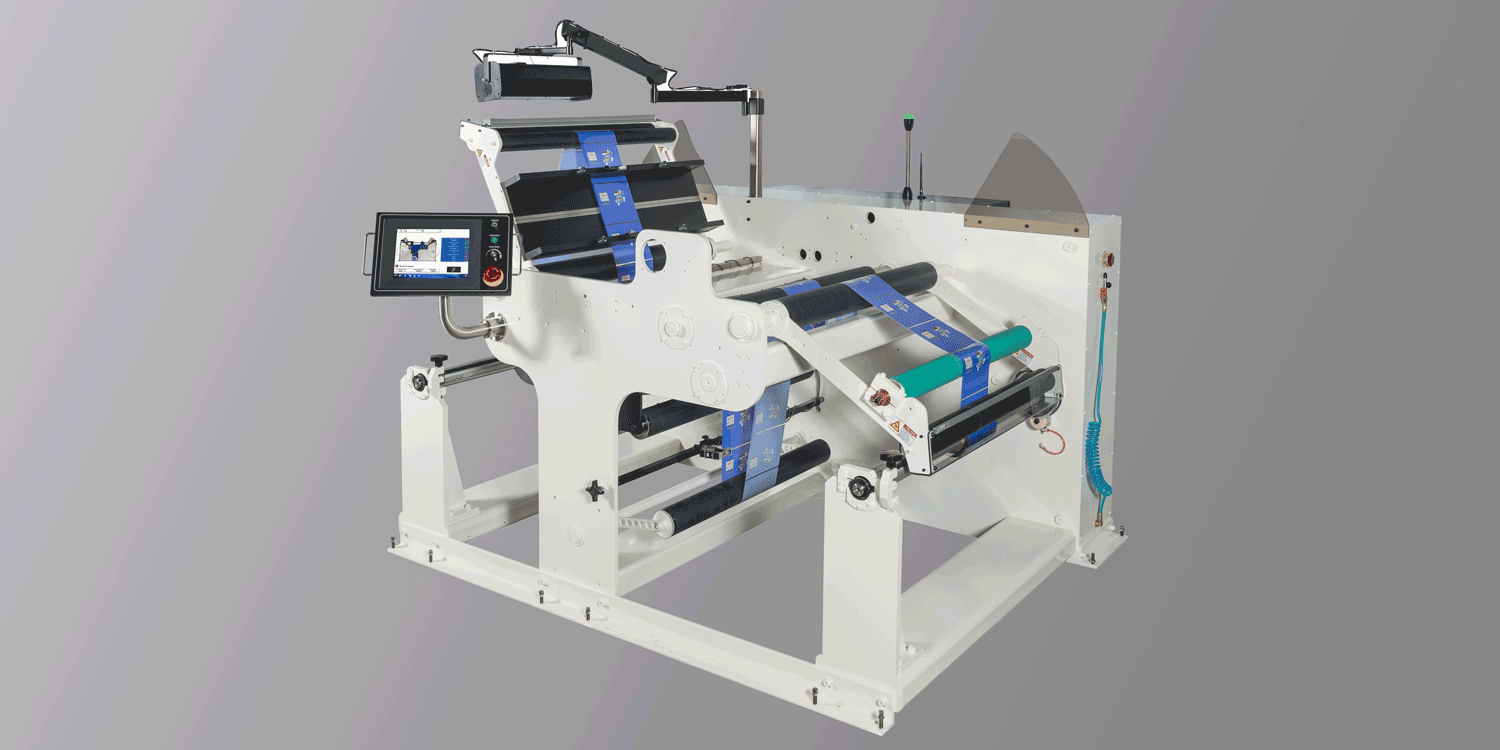

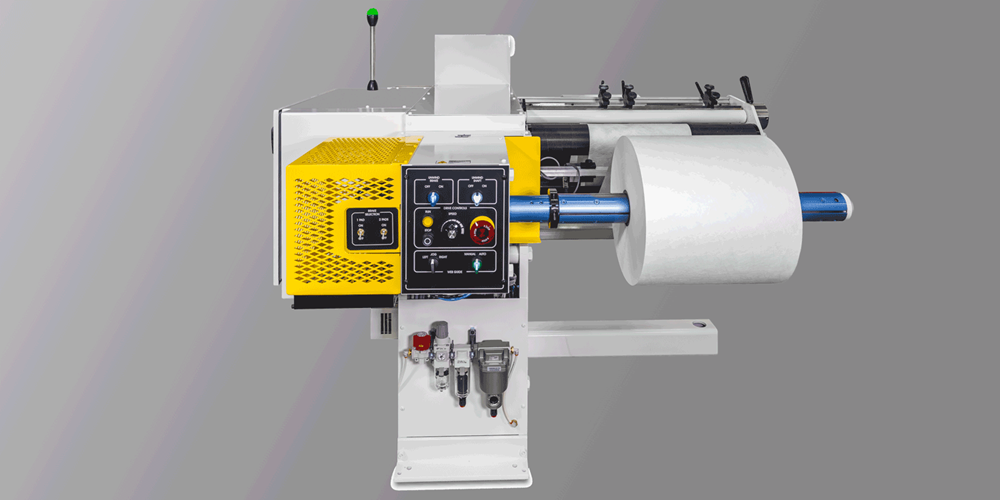

Stanford DM 142 LT

The Stanford DM 142 LT Doctor Machine excels in handling a diverse array of materials that require light tension winding, such as polyethylene, polyester, polypropylene, film laminates, metallized films, and light papers. With a maximum web speed of up to 1,000 fpm (300 mpm), this model efficiently identifies and rectifies defective labels while performing essential tasks such as edge-trimming, web-guiding, and re-tensioning rolls of non-extensible materials including paper, film, foil, and laminates.

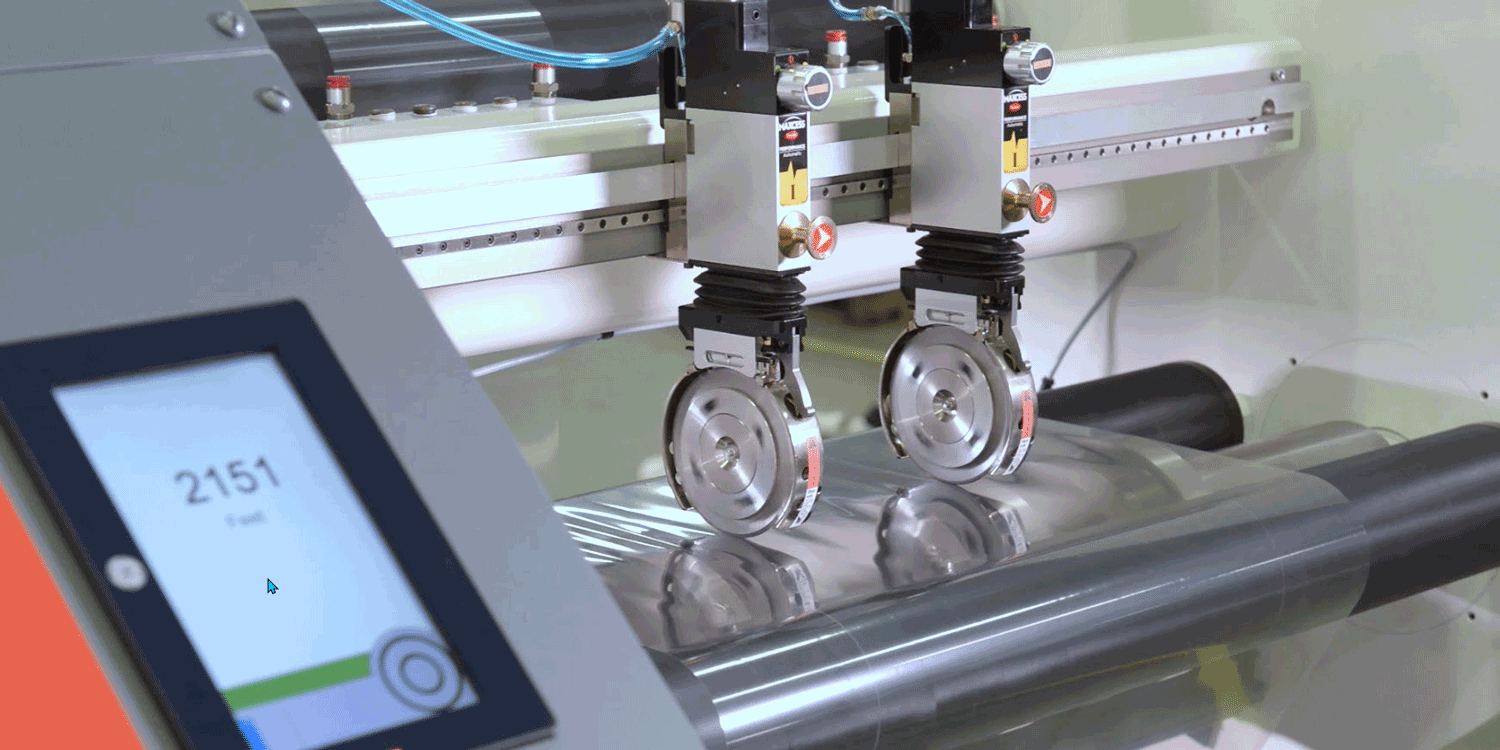

Stanford DM 142 HD

For those needing a robust solution, the Stanford DM 142 HD model accommodates a broader range of materials, including papers, self-adhesive label stock, polystyrene, and stable film laminates. This machine provides effective methods for salvaging defective materials while ensuring high operational efficiency.

Enhanced Features for Optimal Performance

Stanford engineers have meticulously designed each Doctor Machine to boost efficiency and usability. Key features include a cantilevered design that eliminates the need for shaft handling, automatic tension control, and advanced web guides for high-quality output. Additional enhancements such as a rider roll for density control and web break detection minimize downtime, ensuring smooth operations.

Both models are programmable, allowing for precise control over stopping lengths. The dancer lock feature provides a soft tension start, and the unwind control station capabilities facilitate seamless operation. The DM 142 HD also offers advanced features like a bowed roll for improved web separation after slitting, an AC vector drive system, and pneumatic trimming to elevate performance even further.

Key Features

- Cantilevered design eases operation without the need to handle shafts

- Automatic tension control

- Automatic web guide

- Rider roll for density control

- AC Vector Drive System

- Web break detection

- Dancer lock

- Soft tension start

- Programmable stop and early stop length

- Unwind control station

- Rider roll for density control – 142 HD

- Bowed roll for web separation after slitting – 142 HD

- AC Vector drive system – 142 HD

- Pneumatic trimming – 142 HD

Technical Data

Available Options

TRIMMING OPTIONS

- Razor

- Score Shear

SLITTING OPTIONS

- Up-front Shear

MACHINE OPTIONS

- Static elimination

- Strobe

- HMI: 142 / 142 LT (optional), 142 HD (standard)

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...