Products and Solutions

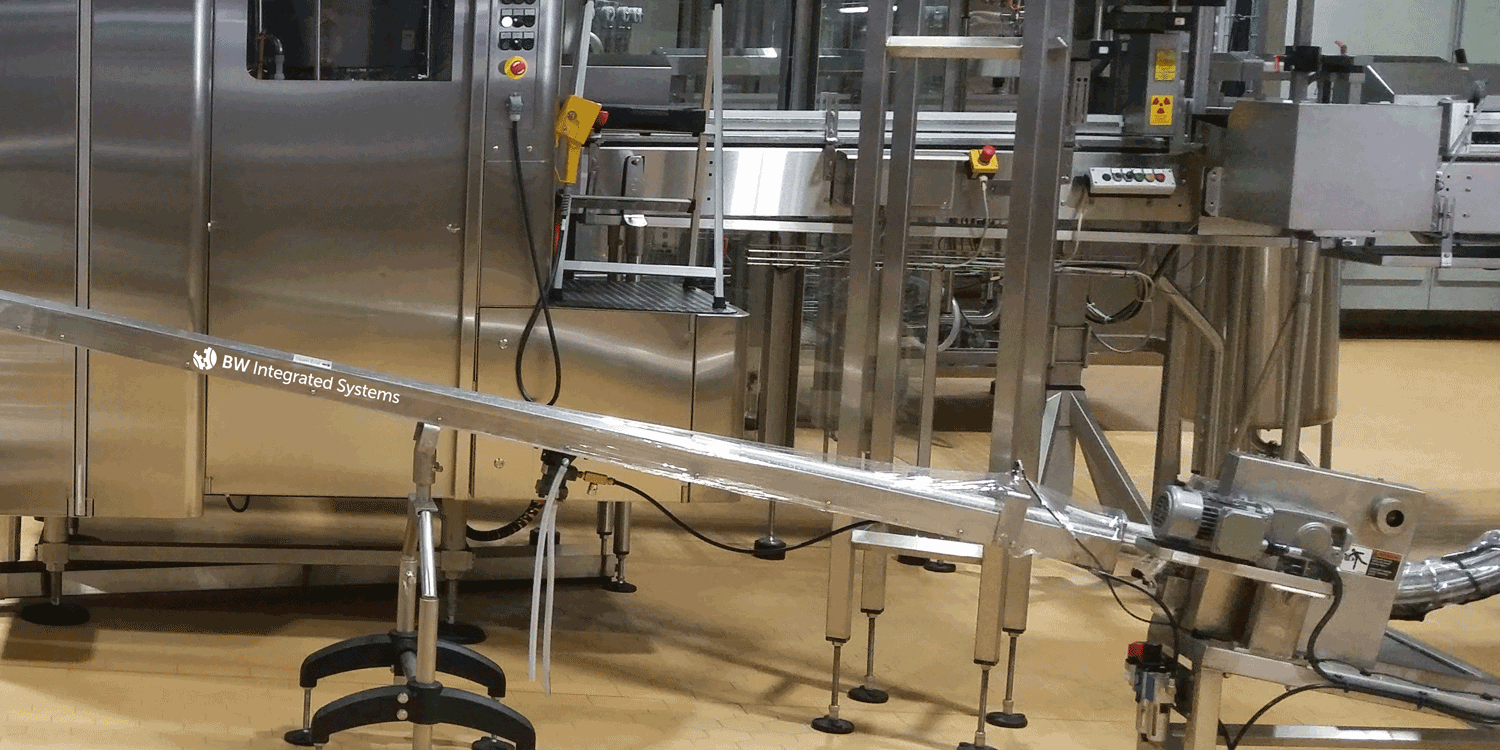

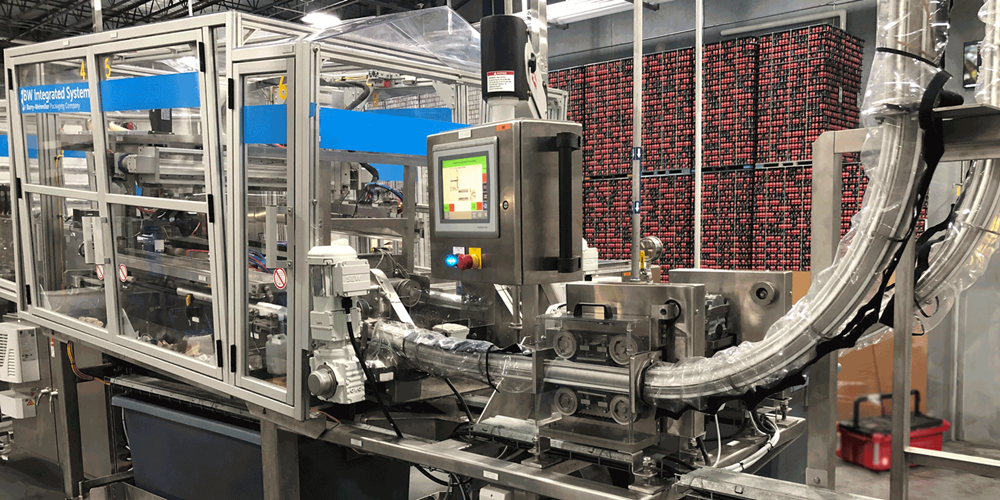

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

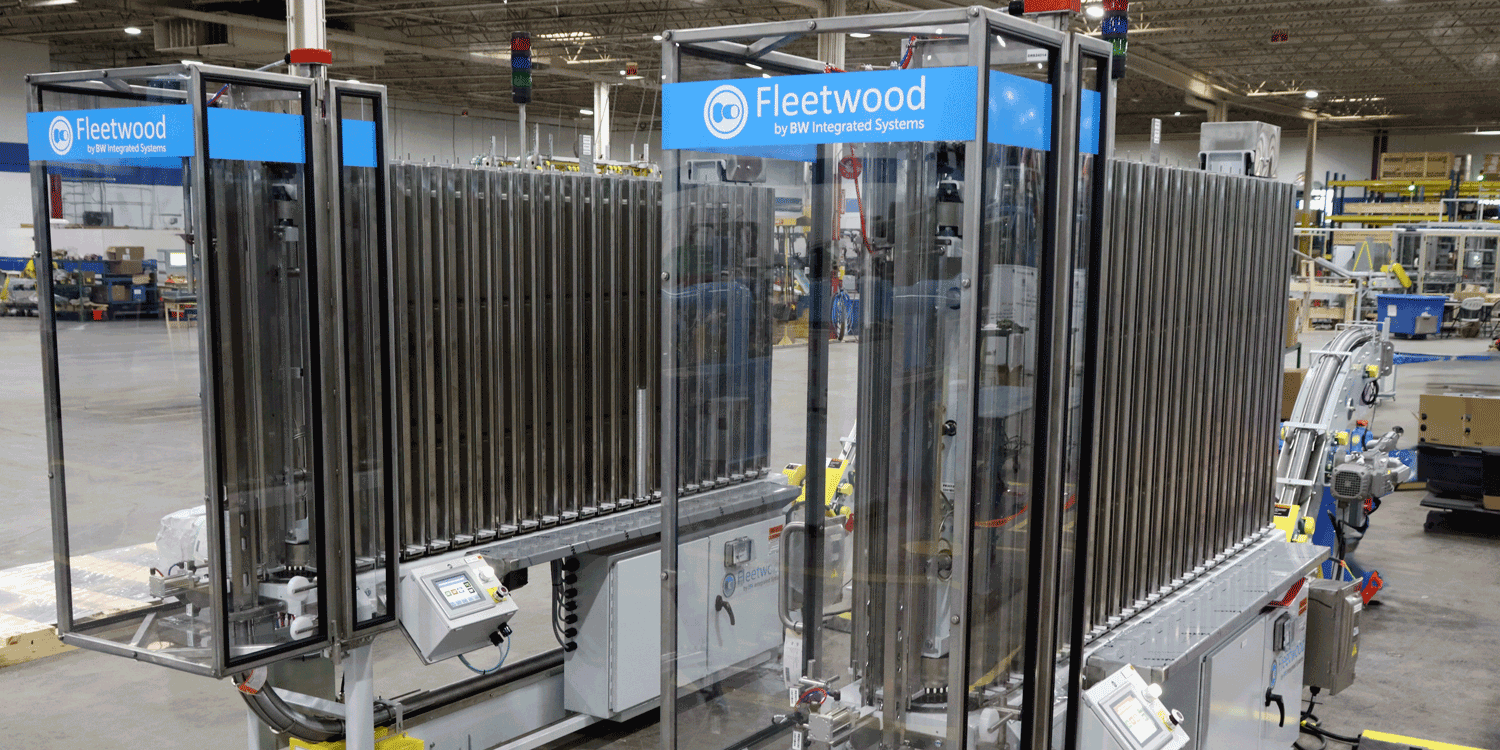

Fleetwood Automatic Lid Feeders (ALF)

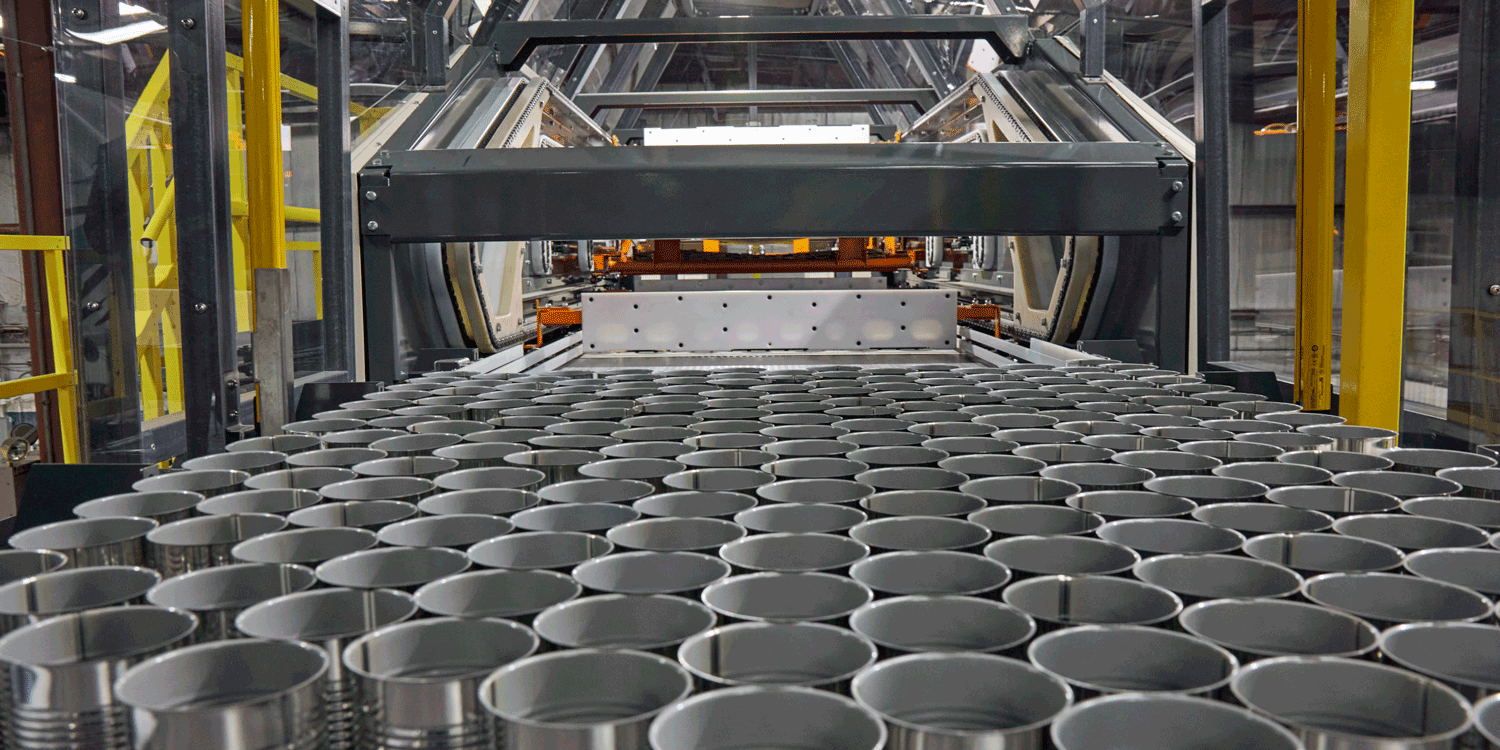

Introducing Fleetwood’s Automatic Lid Feeders—your ultimate solution for efficient lid handling. In today’s fast-paced production environment, say goodbye to the tedious and time-consuming task of manually unloading and feeding bagged lids. Our cutting-edge technology is designed to streamline your operations, allowing your team to focus on optimizing filling processes.

Effortless Lid Loading and Handling

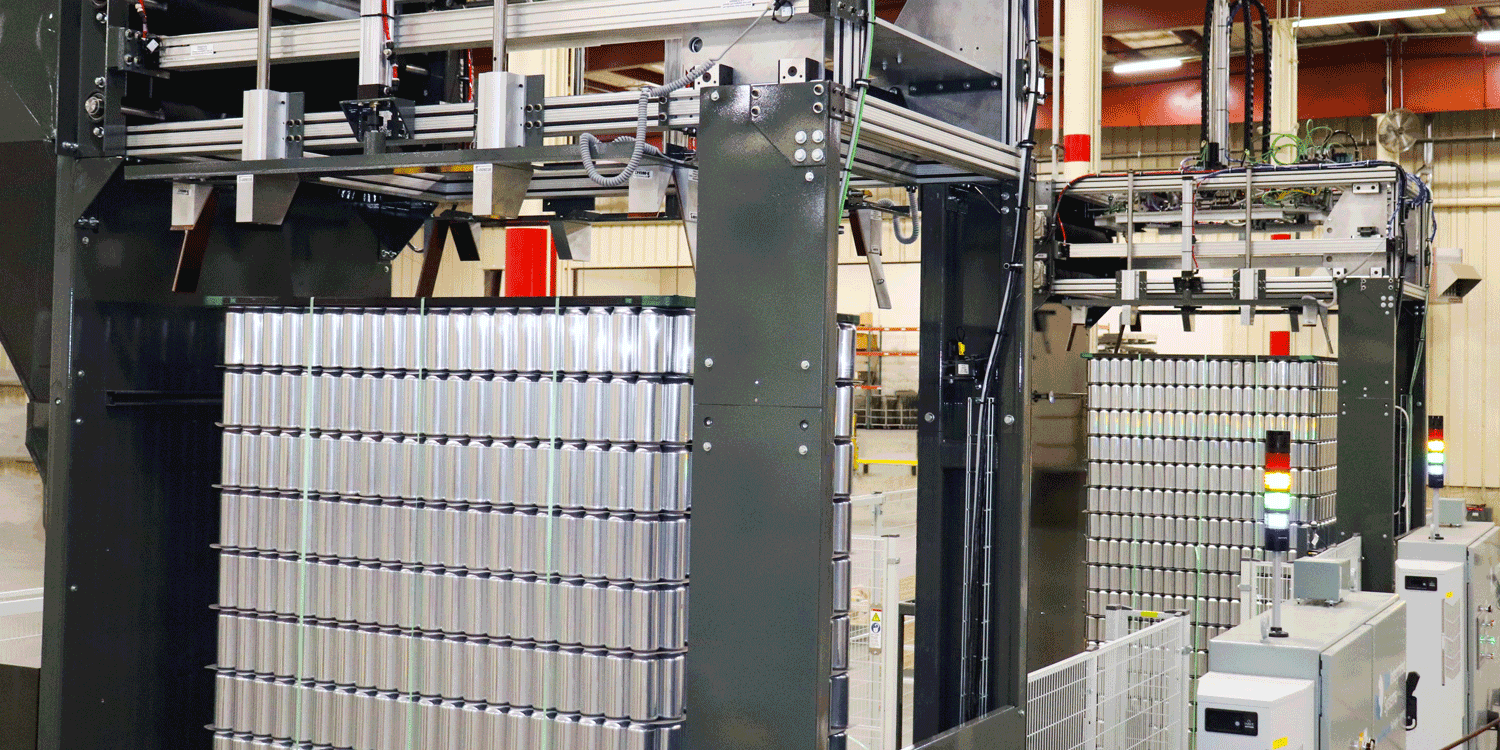

With Fleetwood’s ALF 130 and ALF 240 Automatic Lid Feeders, loading bags of lids is a breeze. Simply place the bagged sleeves of can lids onto the feeder’s table, and our system takes care of the rest. The feeders automatically index on-demand, supplying individual sleeves to the ALF for continuous, efficient production with minimal operator interaction.

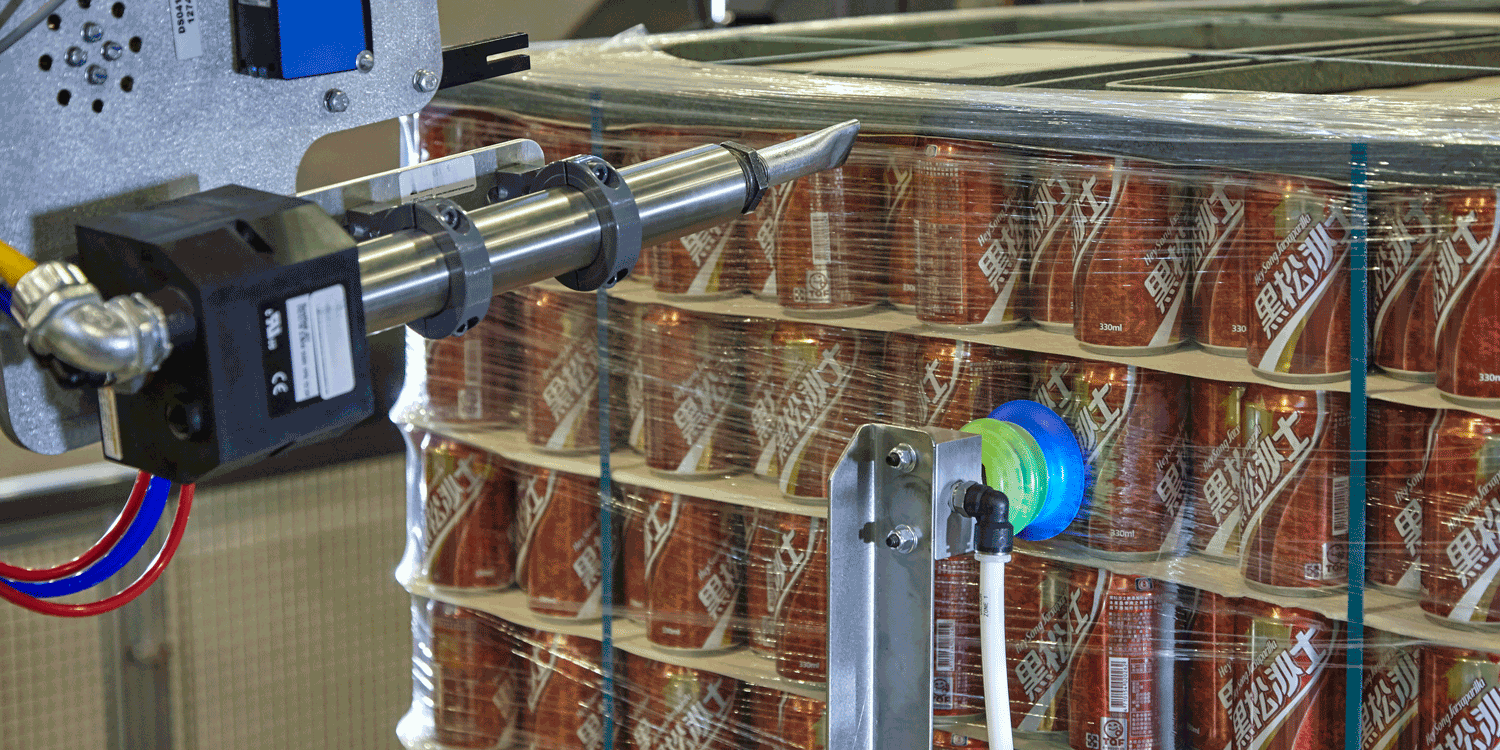

Experience smooth and worry-free operation as each sleeve is fed in one-by-one, precisely oriented to achieve optimum cutting positions. Our innovative technology ensures that each bag is cleanly slit along its full length without ever touching the lids. After cutting, the bags are fully removed and gravity-dropped into a scrap bin, creating a tidy workspace and improving overall efficiency.

Enhancing Production Capabilities

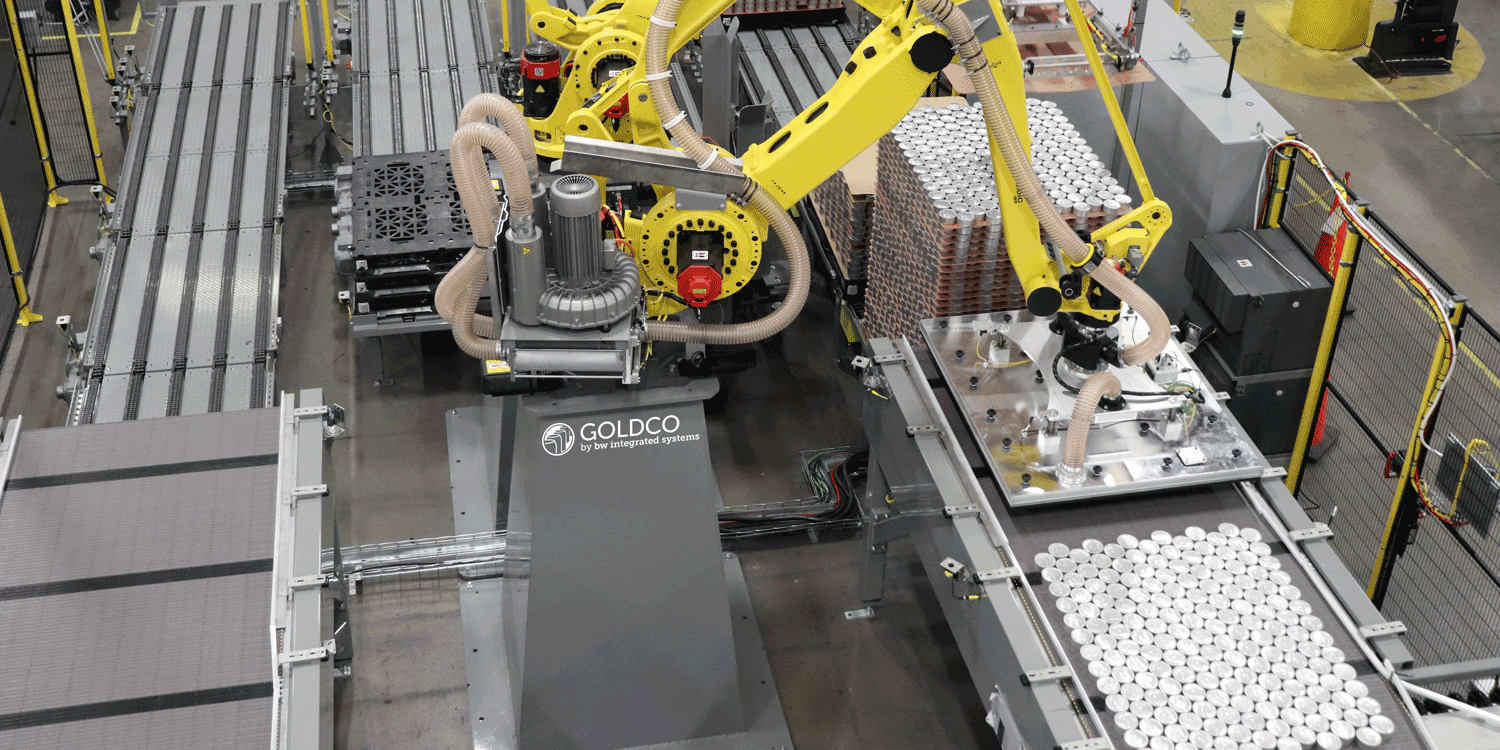

Fleetwood’s ALF 130 Automatic Lid Feeders are specifically engineered to provide a constant and reliable flow of lids to single infeed can seamers, making them a cost-effective solution for beverage and food processors. On the other hand, the ALF 240 model enhances speed and efficiency for high-speed lines, equipped to meet varying layout and capacity requirements with numerous customizable options.

The ALF 240 system allows for easy coupling with bag feed tables of various sizes, or the feed table can be positioned remotely to provide maximum layout flexibility. For facilities needing extra capacity with minimal operator involvement, an optional bag depalletizer can be integrated into the system.

Minimize Maintenance and Maximize Efficiency

Both models are designed for low maintenance and easy cleaning, guaranteeing peak performance and machine efficiency. By choosing Fleetwood, you’re not just investing in equipment; you’re enhancing your overall equipment effectiveness (OEE) and ensuring your production lines run smoothly and efficiently.

Since 1956, Fleetwood has been a trusted leader in the can end market, building equipment that reflects our commitment to customer-focused, reliable, and innovative solutions. Elevate your filling operations with Fleetwood's Automatic Lid Feeders and transform your lid handling processes today!

Key Features

- Small footprint – ALF 130

- Easy loading and delivers product on demand

- Low maintenance requirements

- Reliable 24/7 operation

- Automatic reversed end detection and ejection system

- Designed for easy operator and maintenance access

- Change parts available for product size changes

- User-friendly Allen-Bradley PLC controls

Technical Data

Available Options

- Custom conveyor solutions and layouts

- Stainless-steel construction

- Slinky packages for priming and purging lids from trackwork

- Various bag feed table capacities

- Product size change parts

- Siemens PLC control system

- Semi-automatic or automatic bag depalletizer

- Empty bag remote vacuum collection and bailer systems (ALF 240)

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1305 Lakeview Dr

Romeoville IL 60446

US -

+1 (630) 759-6800 -

+1 (800) 527-0494 (Customer Service) -

+1 (800) 527-0494 (Field Service)

-

Plumtree Farm Industrial Estate, Bircotes

Doncaster DN11 8EW

GB -

+44 (0) 1302 711056 -

+44 (0) 1302 718335 (Customer Service) -

+44 (0) 1302 711056 (Field Service)