Products and Solutions

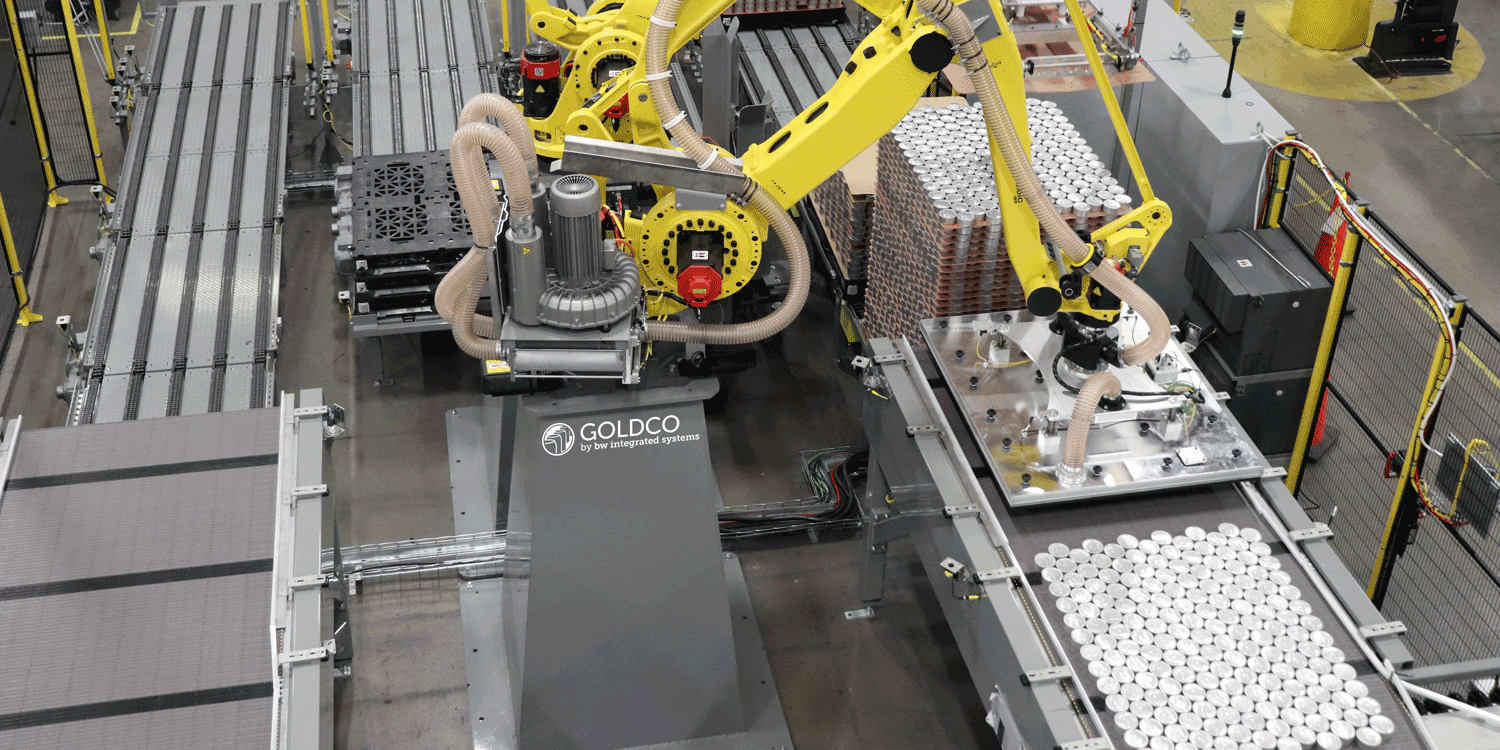

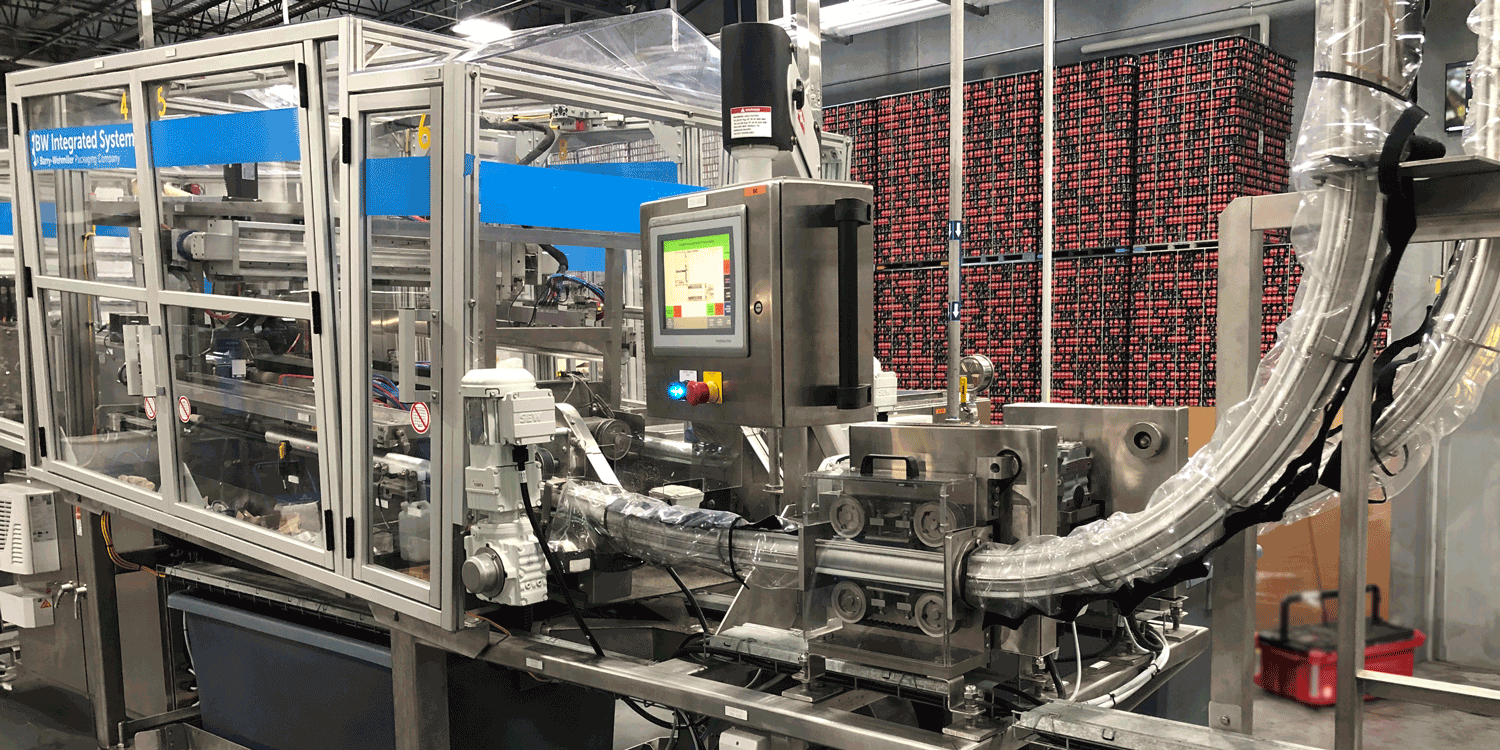

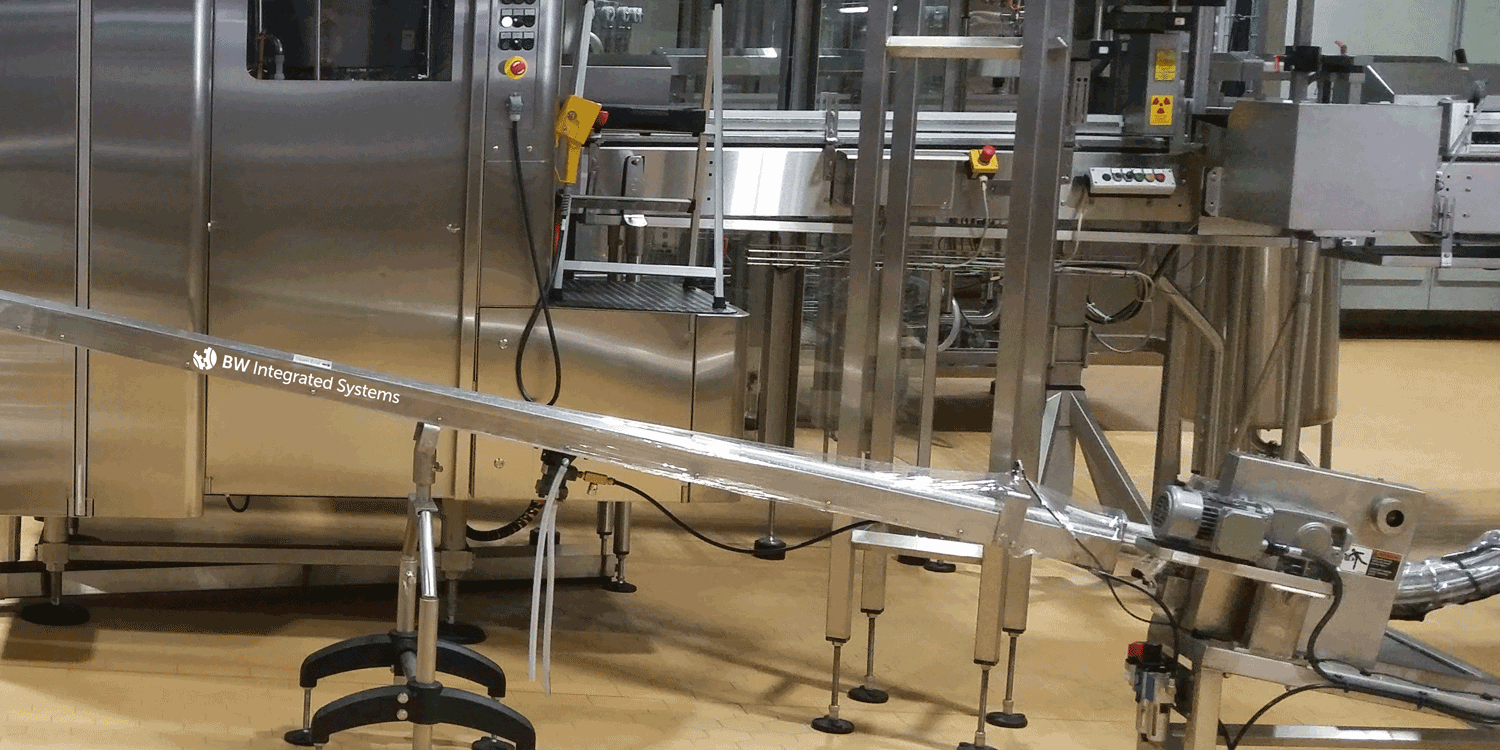

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

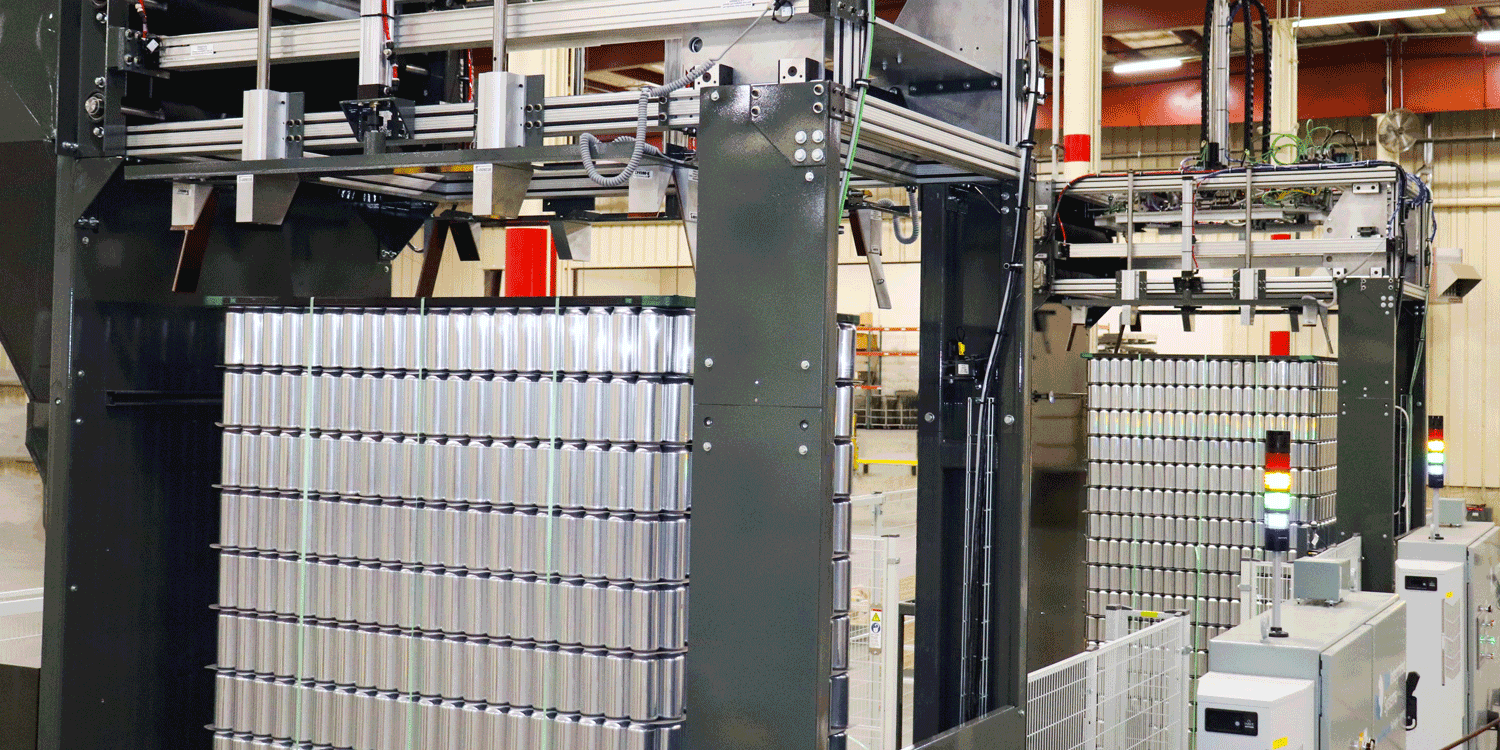

Fleetwood Rotofeeder Semi-Automatic Lid Feeder

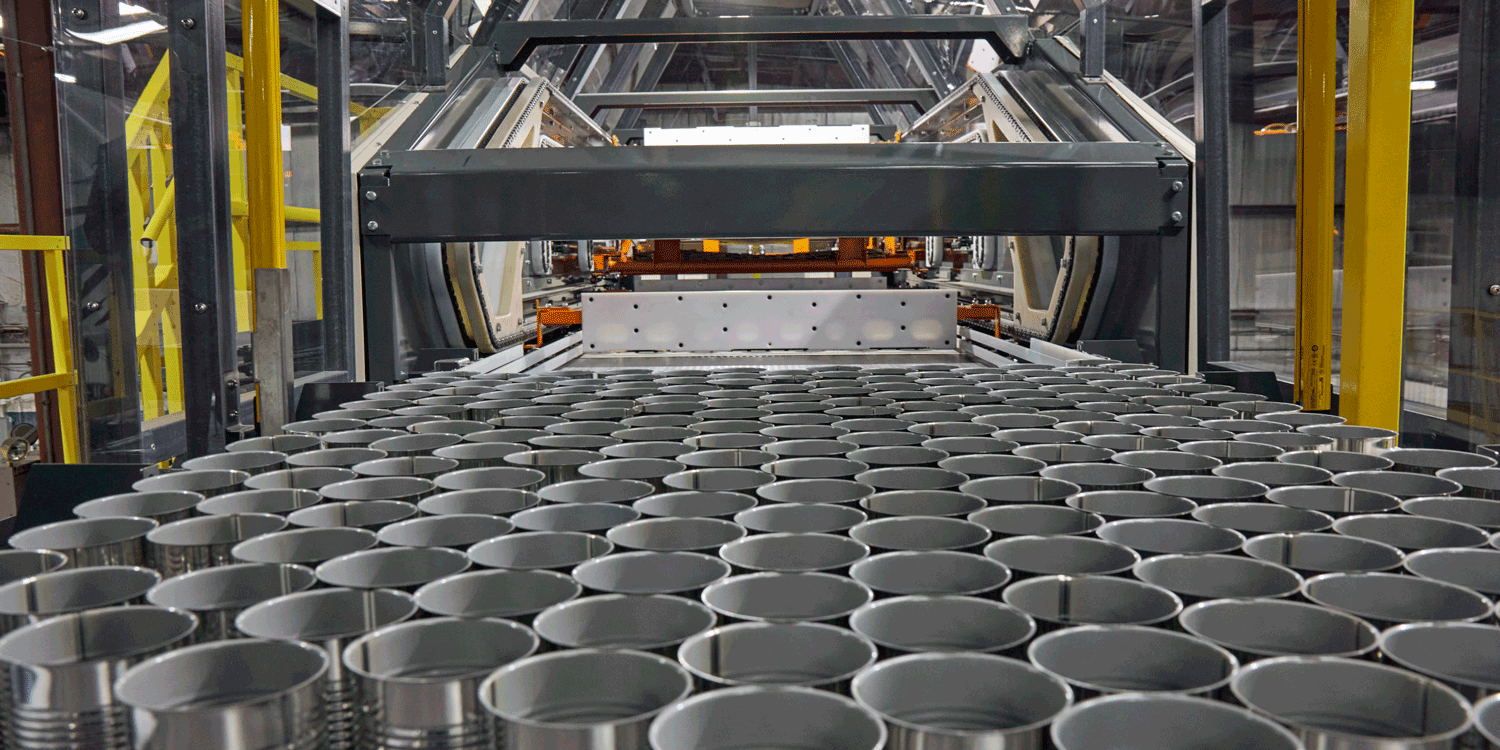

Boost your manufacturing efficiency with our Fleetwood line of Rotofeeder Semi-Automatic Lid Feeders, designed specifically for feeding lids and non-nesting ends. Whether you are working with round, square, rectangular, or oval lids, our feeders offer the perfect solution.

With a robust inventory of lids and automatic on-demand feeding capabilities for one or multiple production lines, you can streamline your lid and can end production like never before. Our Rotofeeder systems are user-friendly and require minimal maintenance, ensuring a seamless transition in your filling or can-making operations while significantly reducing feeding costs.

Versatile Solutions for All Production Needs

Our Rotofeeder systems provide unmatched versatility, featuring high-capacity units that support greater volume and extended feed time. We offer a range of units compatible with large can ends, as well as dual discharge models for feeding dual seamers or separate machines.

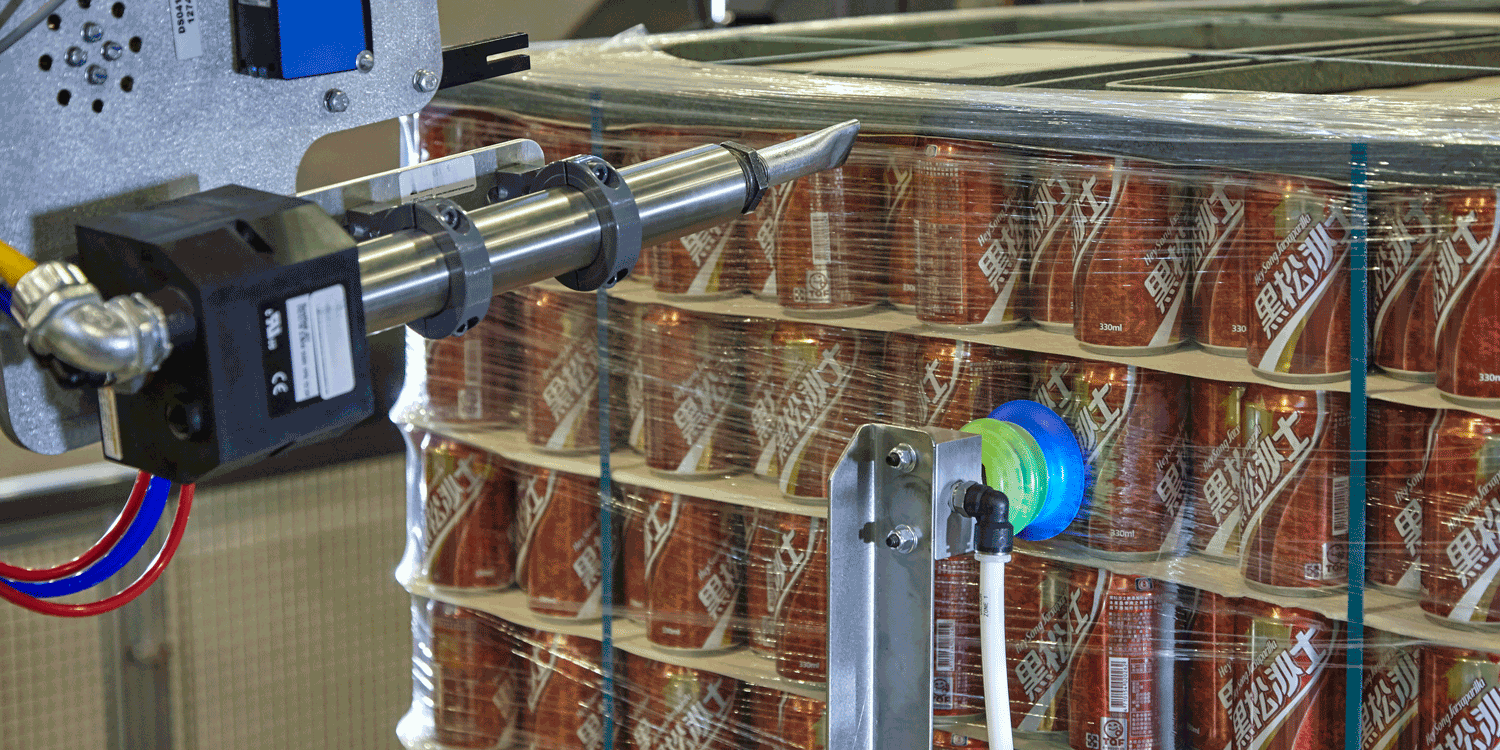

Fleetwood’s industry-leading conveyors are an integral part of the Rotofeeder system, boasting hundreds of configurations tailored to handle all types of lids. Our conveyors can be closely coupled or positioned at various distances from processing equipment for added convenience.

Efficient Lid Conveying for Craft Beverages

For aluminum beer and beverage lids, we utilize low-level belt pushers and high-level roll pushers to efficiently convey lids through customized trackwork configurations. Our conveyor designs, such as the Motorized End Feeder (MEF) with a pivoting downstacker discharge, are ideal for closing machines with restricted access at infeed points, as well as machines adjustable for various can heights.

Join Thousands of Successful Installations

With thousands of installations worldwide, BW Packaging offers the perfect Rotofeeder System for any application. Since 1956, all Fleetwood equipment has been engineered with a customer-focused, reliable, and innovative approach, establishing us as a leader in the can end market. Optimize your production today with our cutting-edge lid feeders.

Key Features

- Product sizes from 200 to 610 diameter

- Product material: Aluminum, Steel, or Foil

- Types of lids: beverage, EZO, sanitary, aerosol, specialty

- Automatically feed seamers and other production machines

- Easy loading and delivers product on demand

- Feeds round, square, rectangular or oval products

- Low maintenance requirements

- Carbon steel painted construction

- Open pockets enable quick visual inspection of product

- User-friendly Allen-Bradley or Siemens controls

Technical Data

Available Options

- Custom conveyor solutions and layouts

- Stainless-steel construction

- Slinky packages for priming and purging lids from trackwork

- Changeover Marker Plugs for clear product change identification

- Pocket opening system for better control of non-nesting ends

- Automatic reversed end detection and ejection systems

- Product size change parts

- Pocket side splash covers

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1305 Lakeview Dr

Romeoville IL 60446

US -

+1 (630) 759-6800 -

+1 (800) 527-0494 (Customer Service) -

+1 (800) 527-0494 (Field Service)

-

Plumtree Farm Industrial Estate, Bircotes

Doncaster DN11 8EW

GB -

+44 (0) 1302 711056 -

+44 (0) 1302 718335 (Customer Service) -

+44 (0) 1302 711056 (Field Service)

Jump to...

Jump to...