Products and Solutions

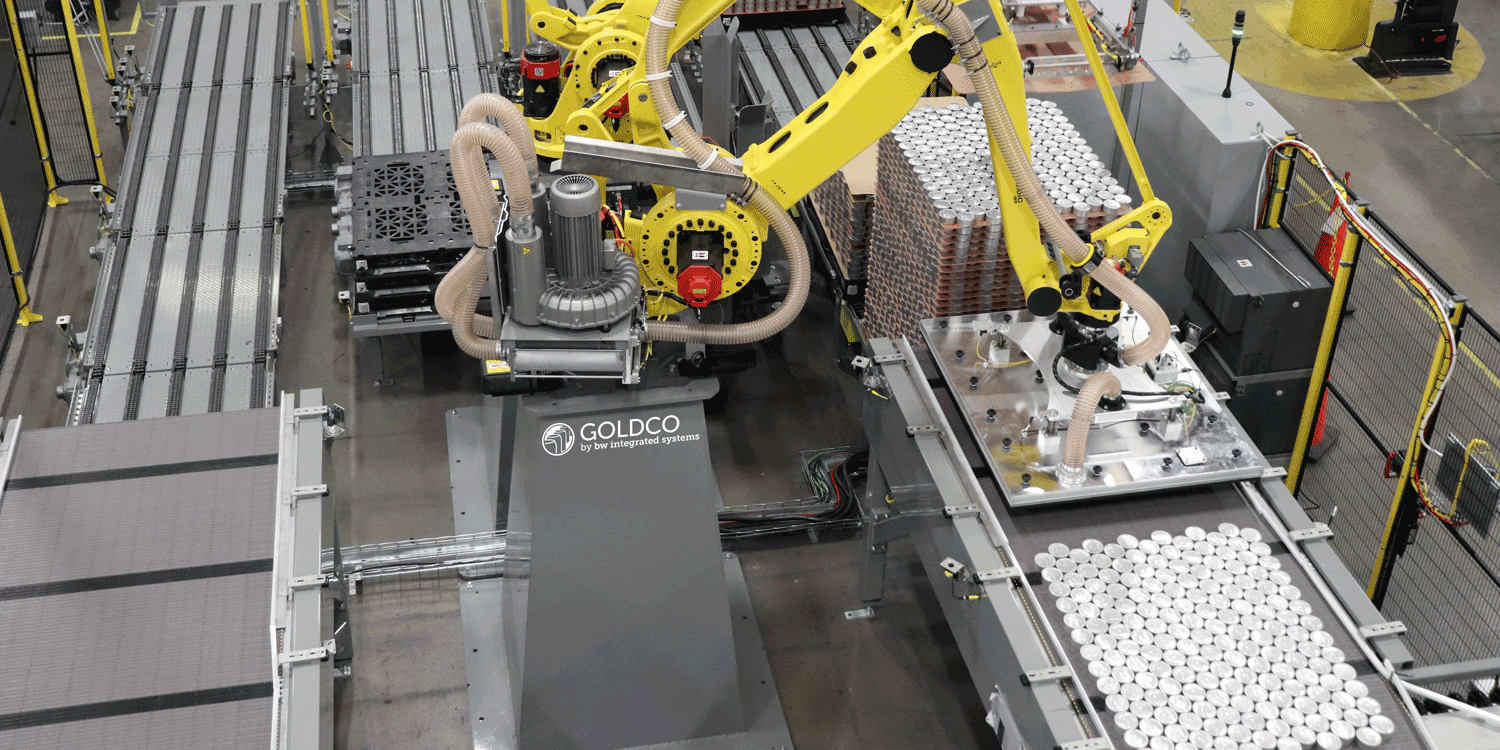

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

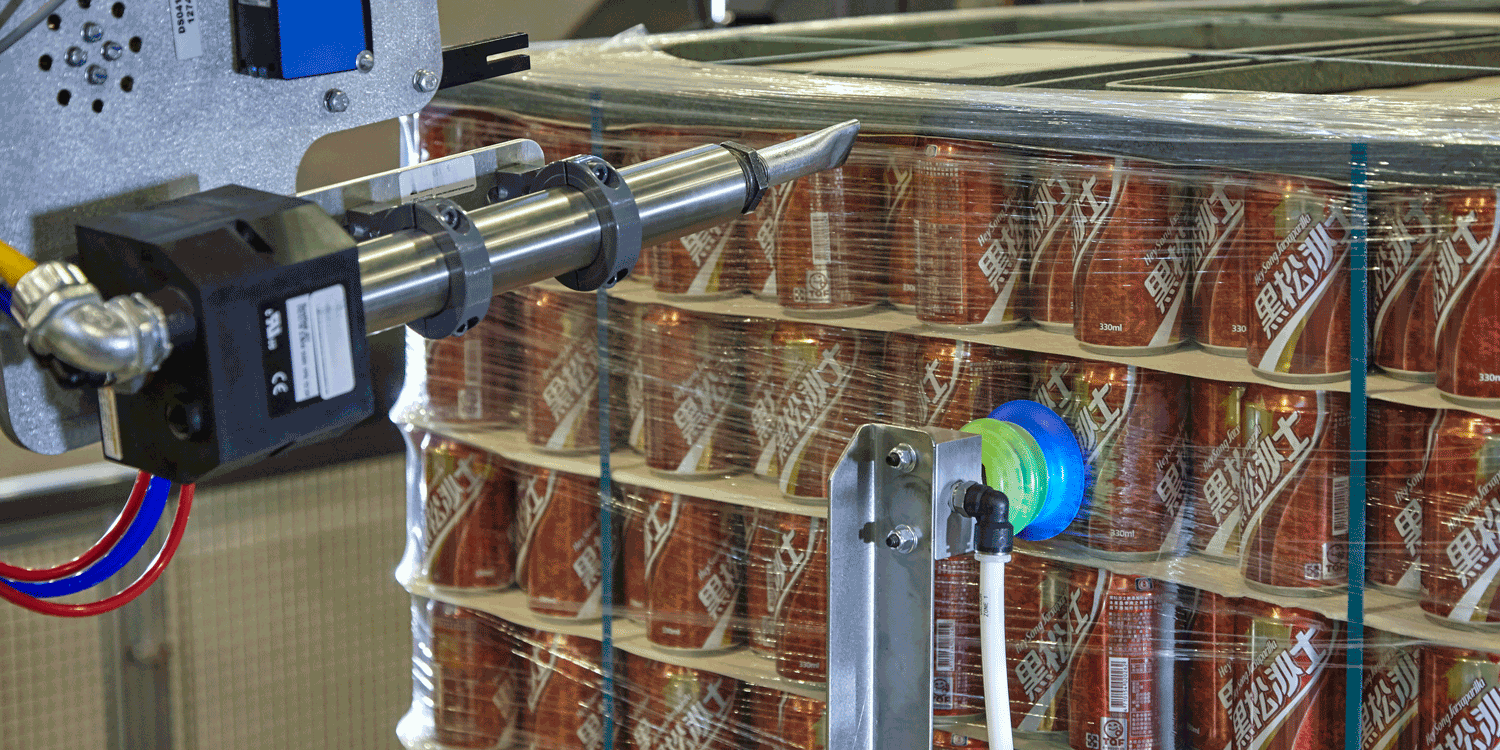

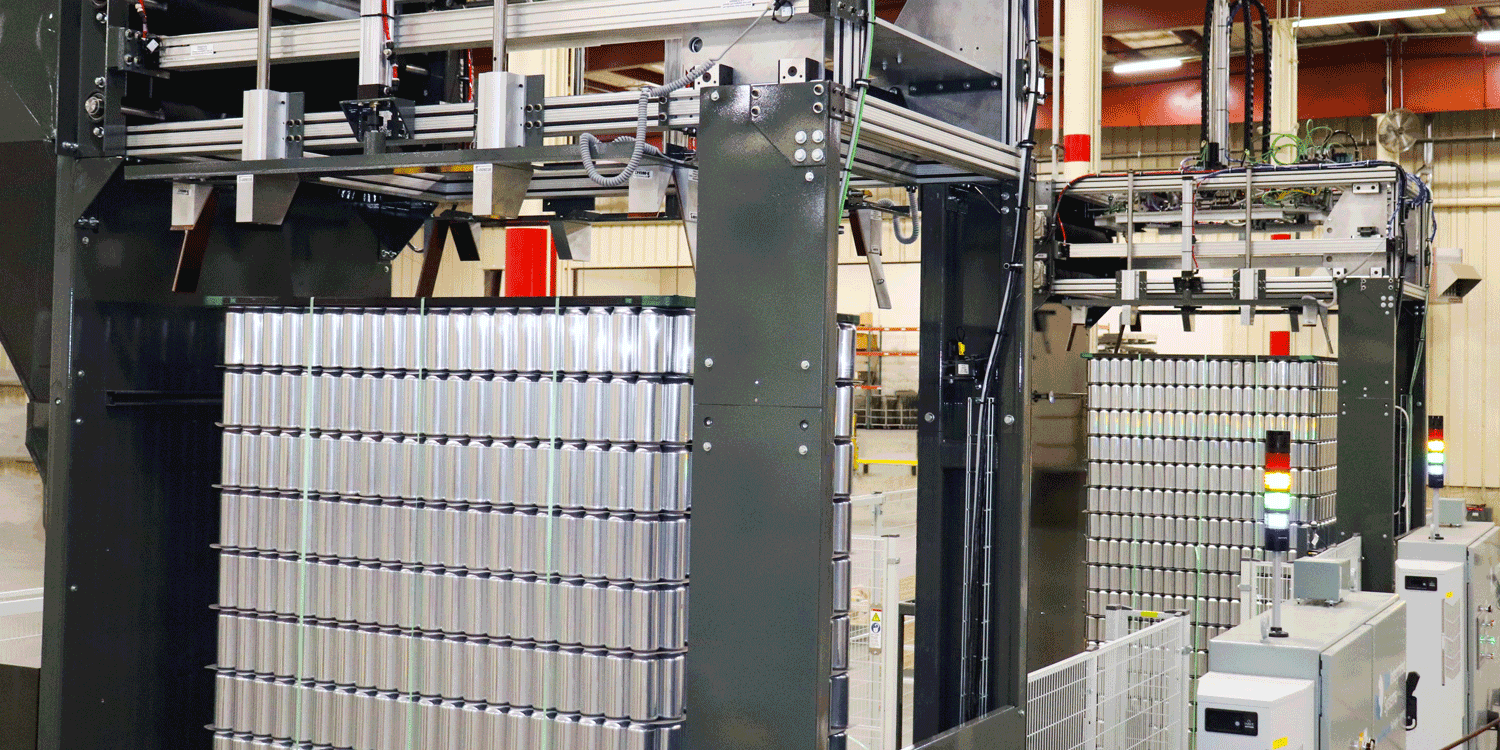

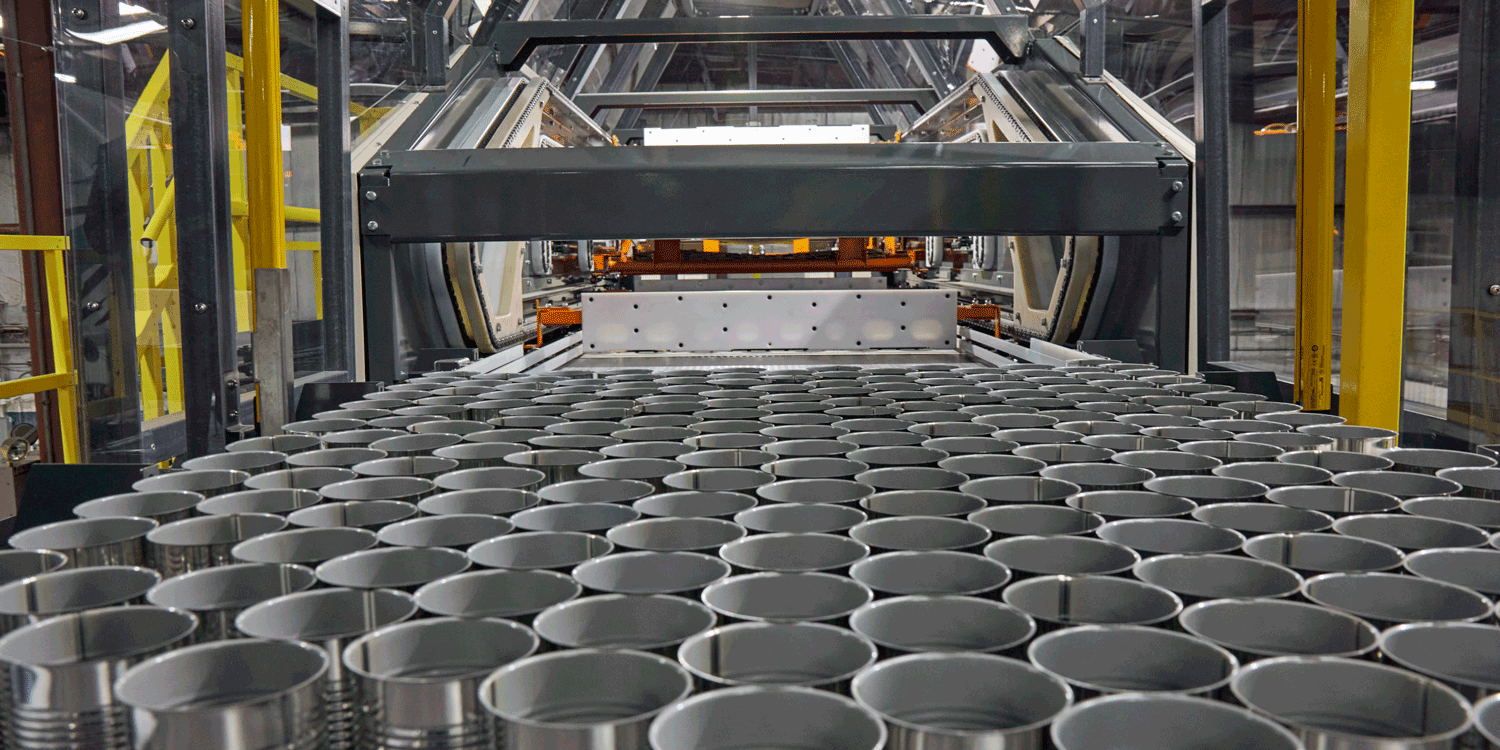

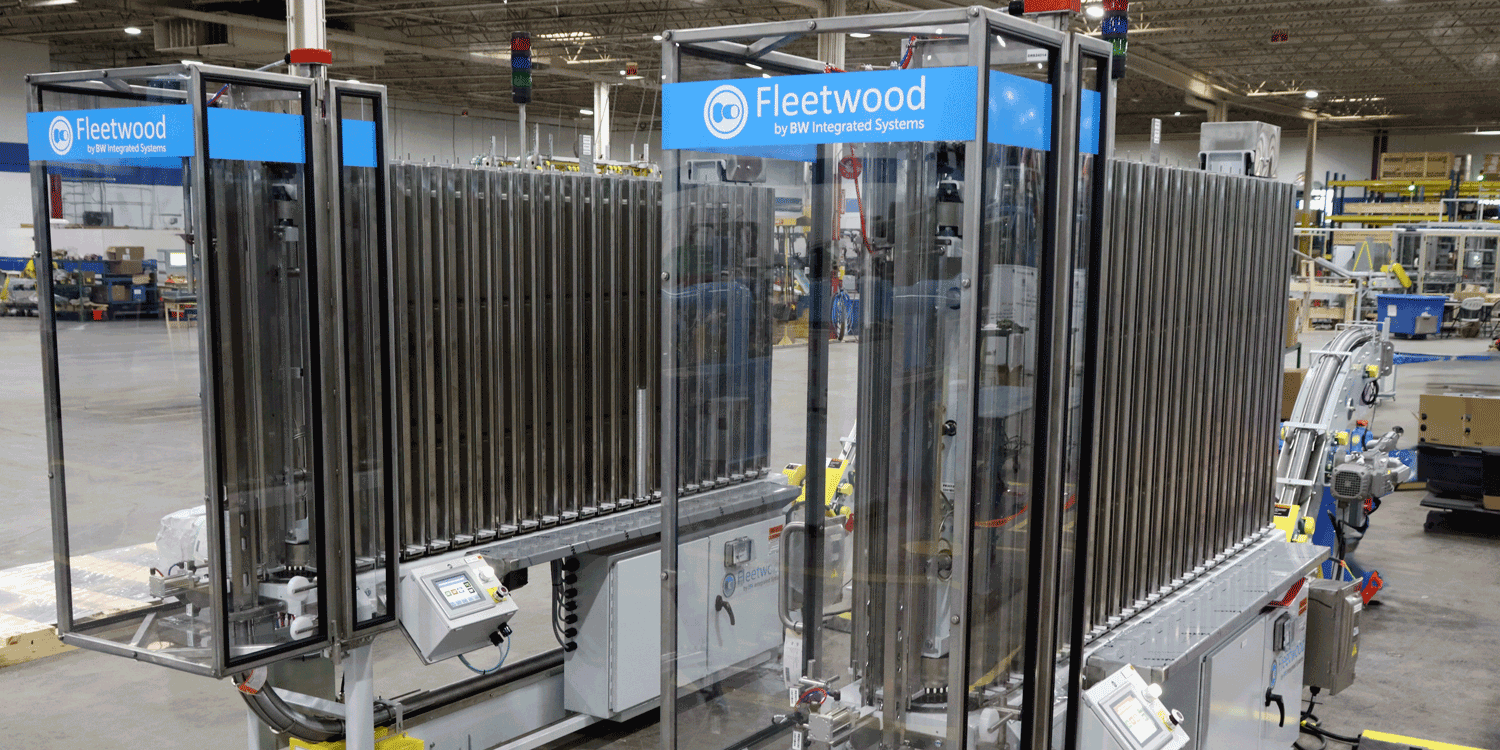

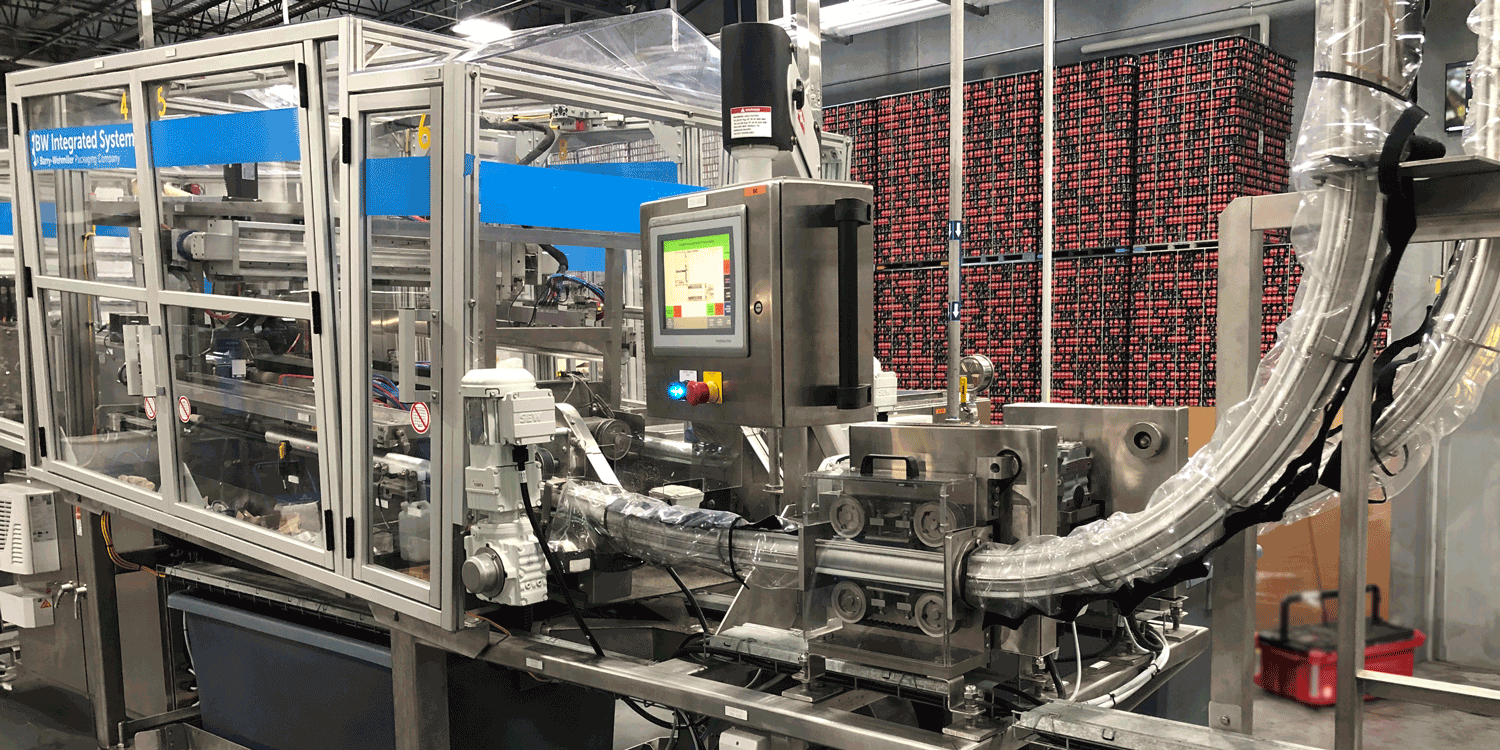

Fleetwood Low Level V-Tray Can Lid Feeder

The Fleetwood LLV Low Level V-Tray is the ultimate solution for enhancing your can lid feeding process by bringing it down to ground level. This innovative system significantly improves safety and ergonomics for operators, creating a more efficient workspace. One of its key advantages is the flexible can lid trackwork layouts, allowing for easy positioning of the LLV V-Tray system to fit seamlessly within your plant layout, whether you are filling cans at a speed of 100 or 600 per minute. Additionally, the system is designed to be both economical and reliable, making it a cost-effective manual lid feed solution that can be configured for installation close to your seamer or at a short distance away, providing versatility in your production line.

Operator safety is greatly enhanced with the LLV Low Level V-Tray, as it allows operators to handle lid bags comfortably at floor level, eliminating the need for hazardous rolling platforms or ladders. Furthermore, the system offers improved storage options, with additional lid storage capacities available to increase operational flexibility and efficiency. Upgrade to the Fleetwood LLV Low Level V-Tray today for a safer, more ergonomic, and efficient lid feeding solution that aligns with your production goals!

Key Features

- 3 - 5 bag storage capacity available

- Stainless steel construction

- IP66/NEMA4 electric vibrator

- Low-level end detection

- Discharge end conveyor with gap control unit at seamer

- Custom lid feed conveying to meet your specific needs

- Hardwired controls

- IP66/NEMA4X stainless steel control enclosure

- Power requirements: 3-Phase AC power, 5FLA

Technical Data

Available Options

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1305 Lakeview Dr

Romeoville IL 60446

US -

+1 (630) 759-6800 -

+1 (800) 527-0494 (Customer Service) -

+1 (800) 527-0494 (Field Service)

-

Plumtree Farm Industrial Estate, Bircotes

Doncaster DN11 8EW

GB -

+44 (0) 1302 711056 -

+44 (0) 1302 718335 (Customer Service) -

+44 (0) 1302 711056 (Field Service)