Products and Solutions

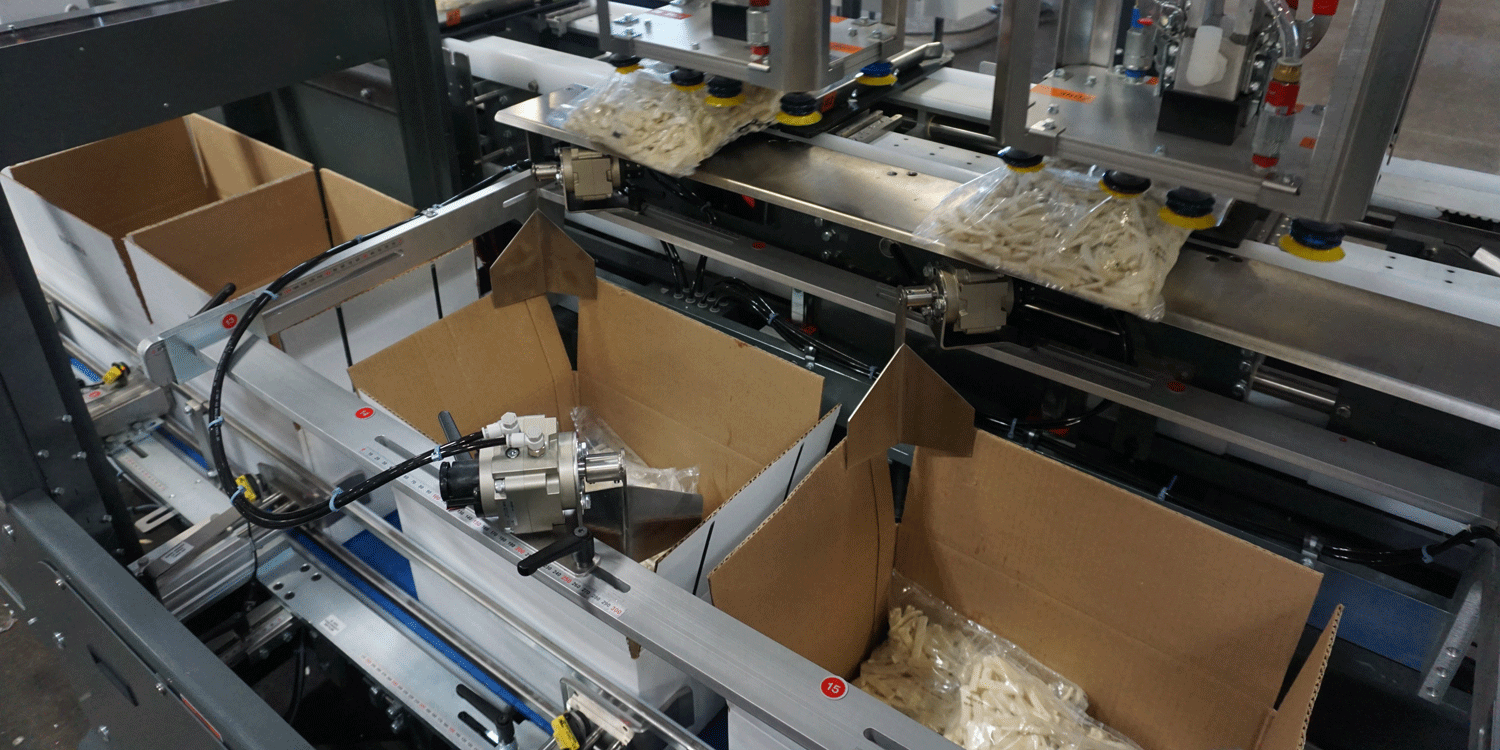

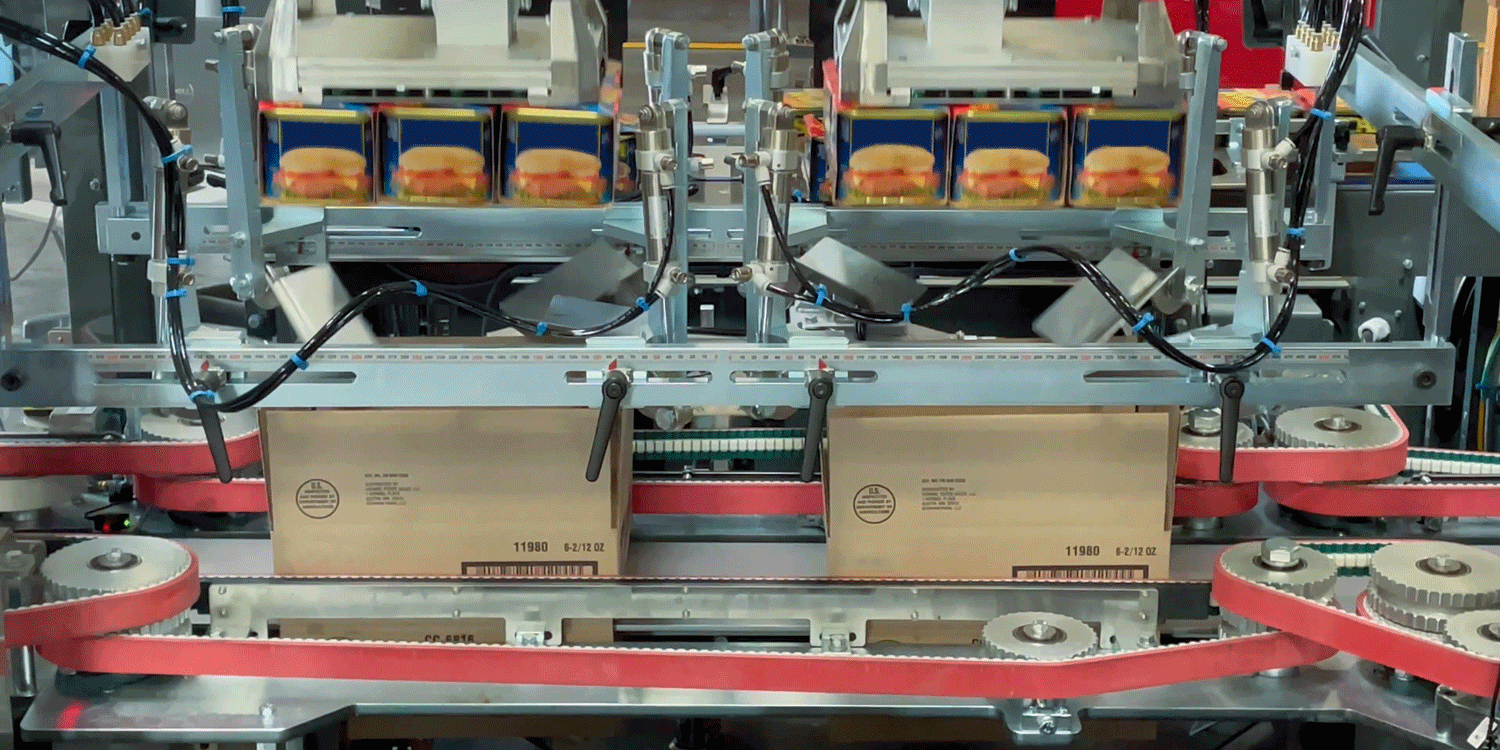

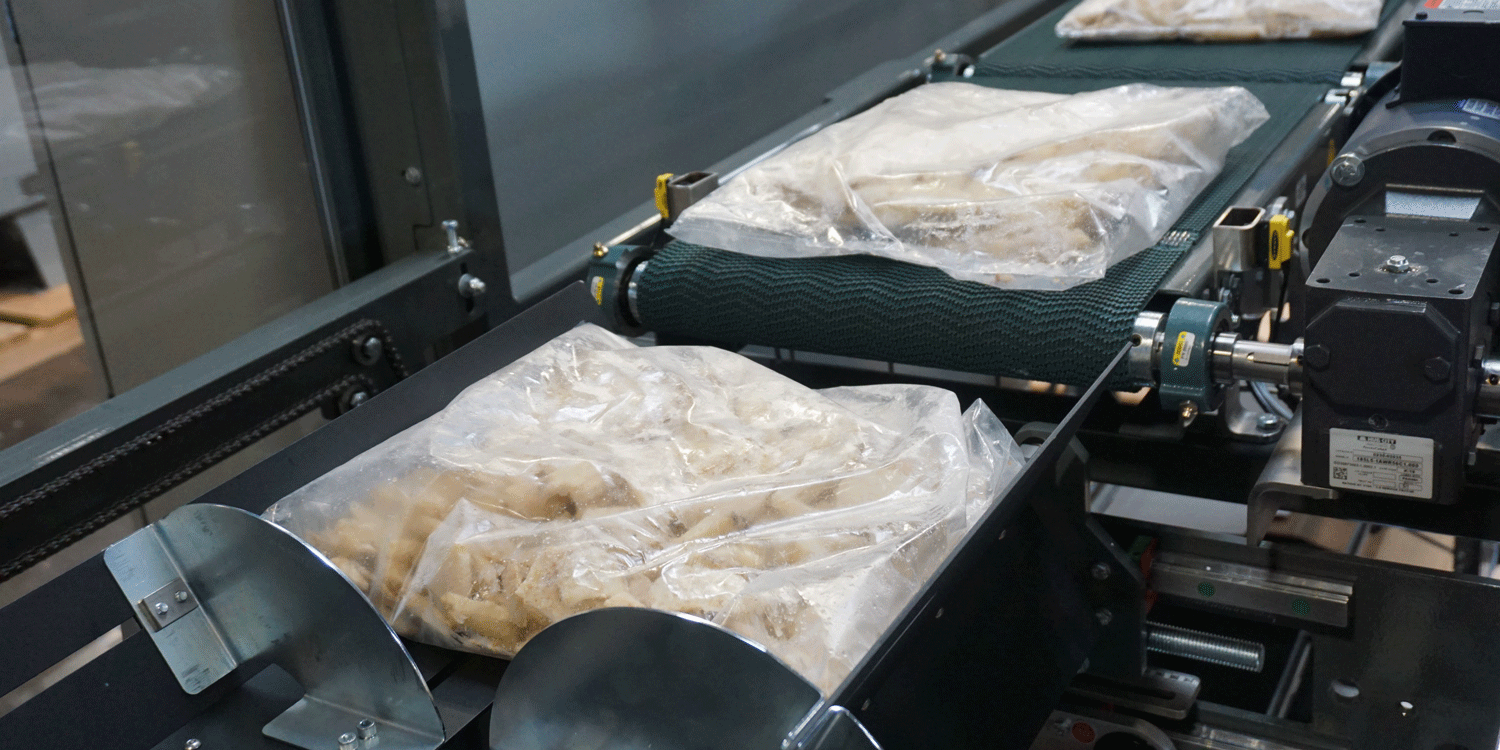

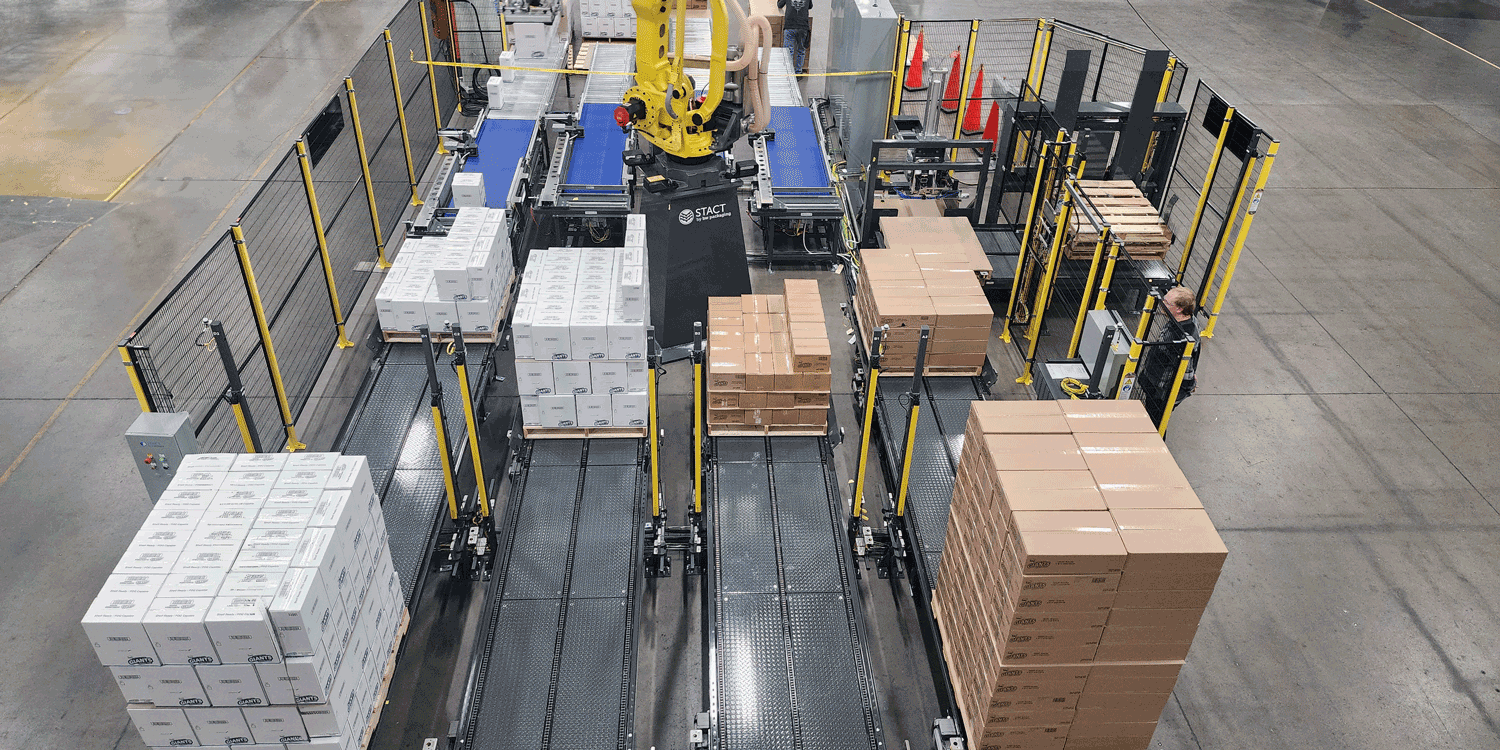

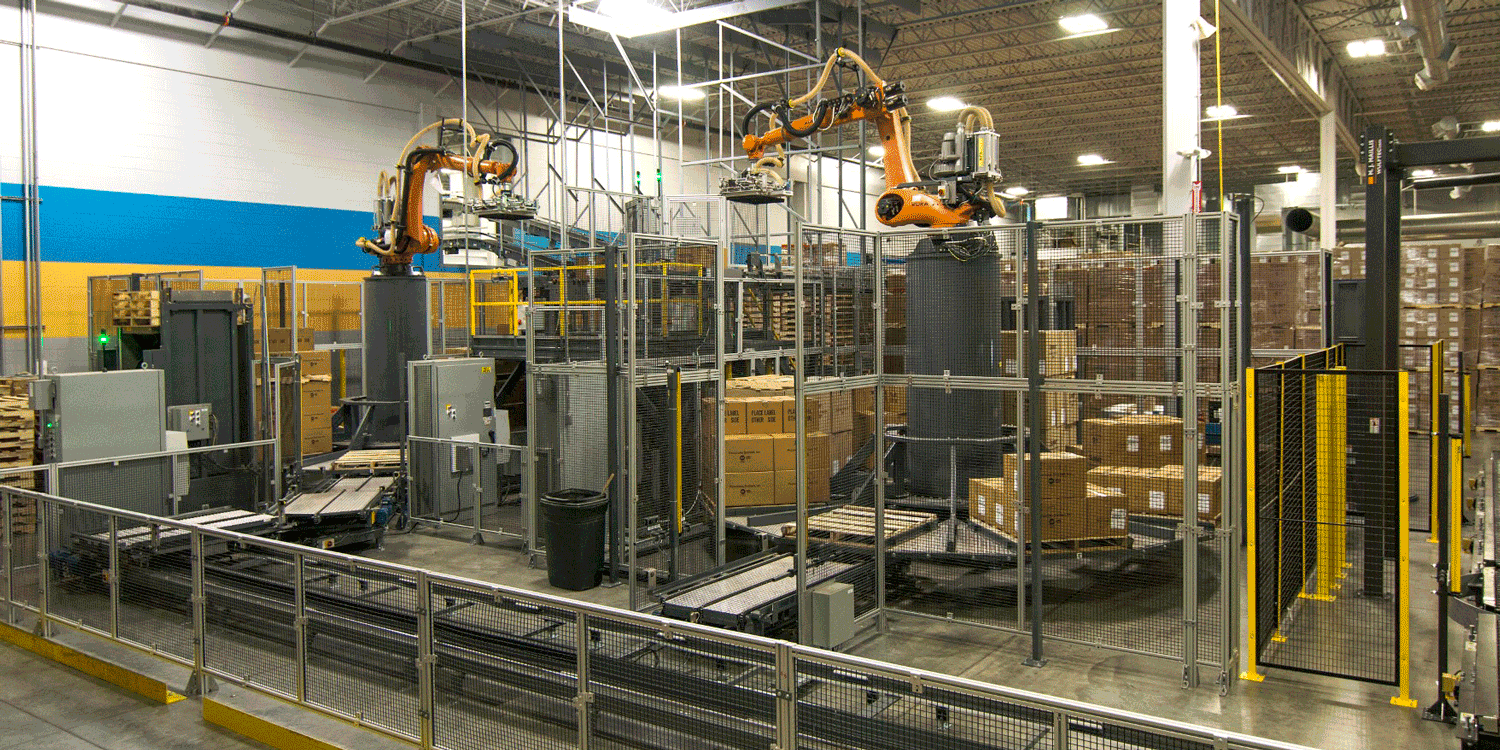

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

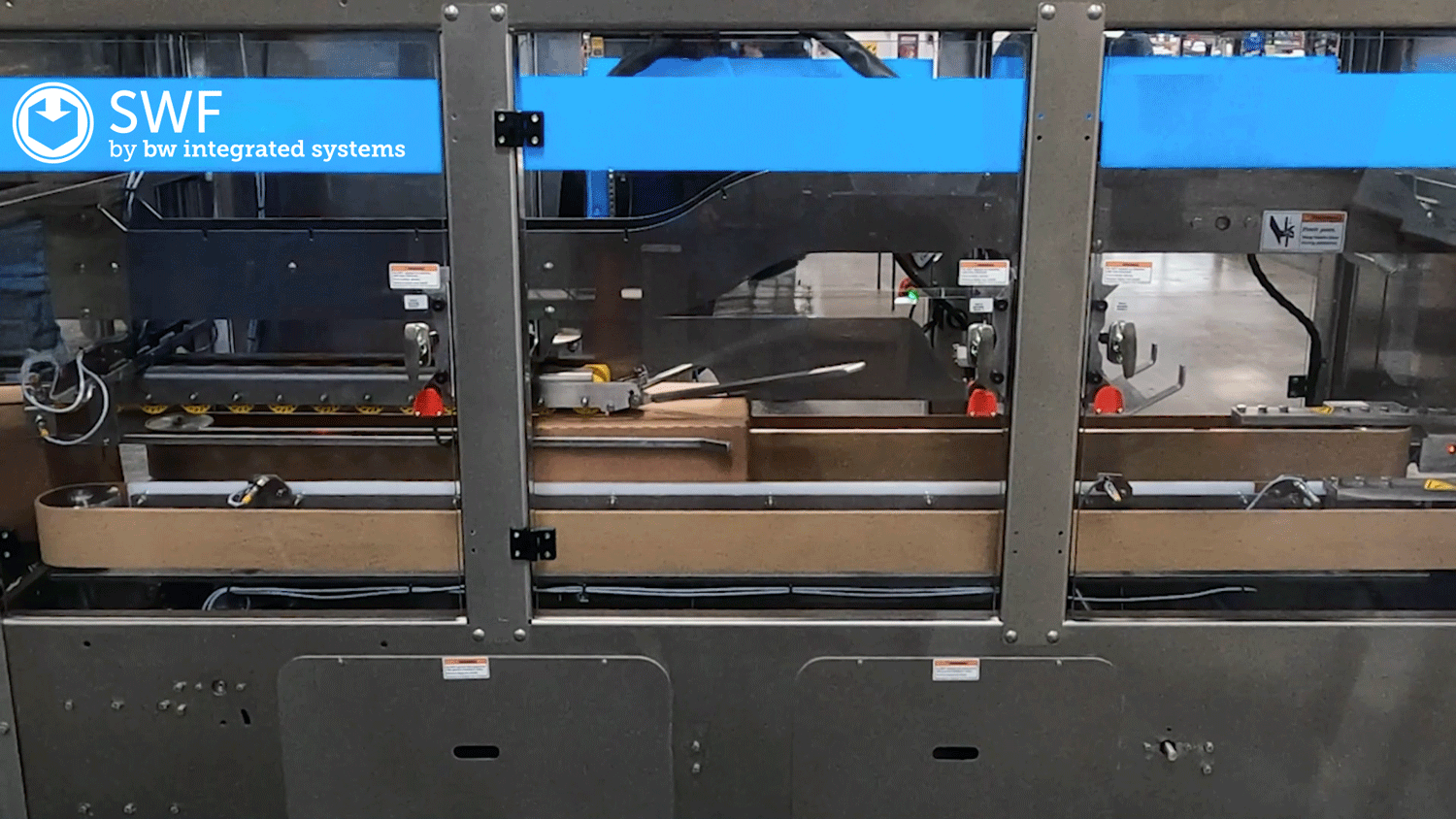

SWF CE 35X Series Case Erector

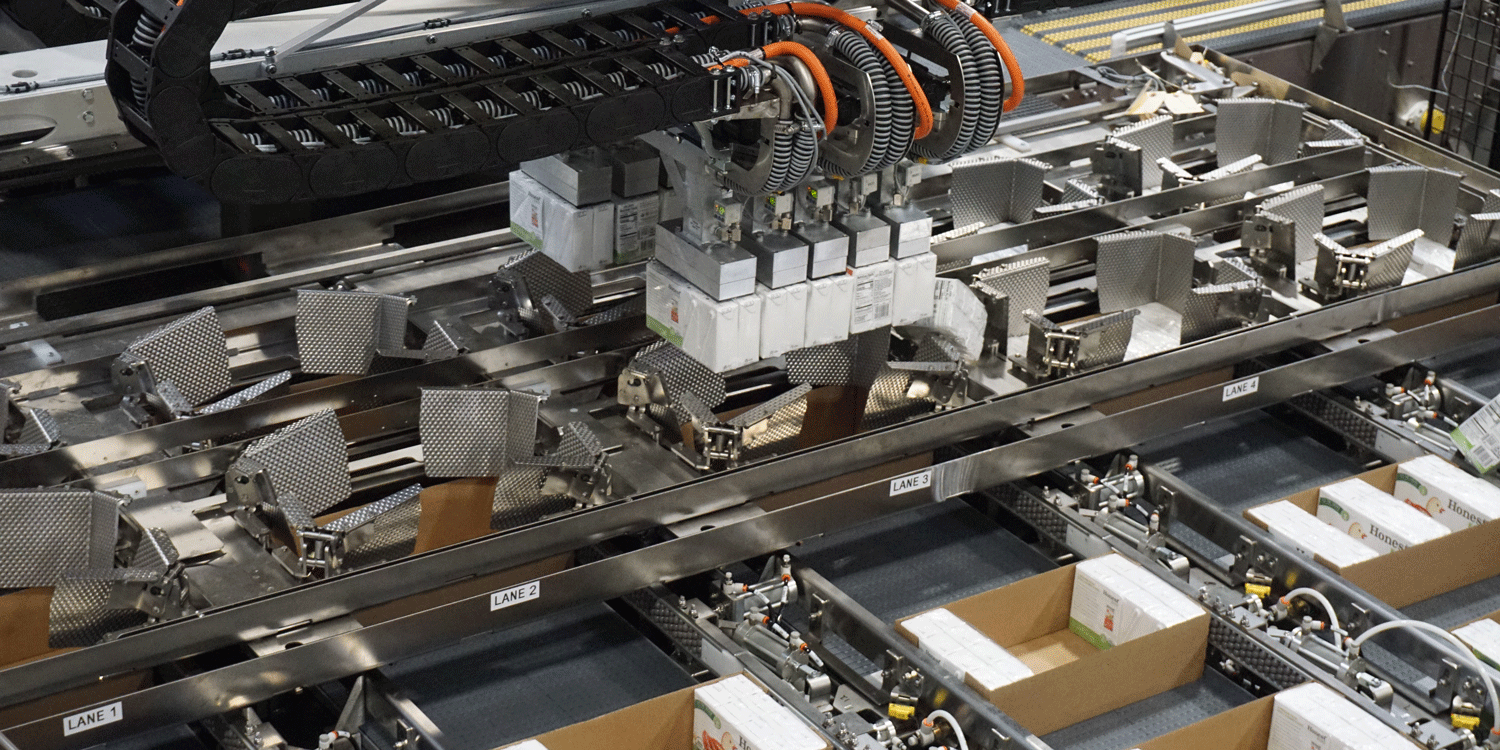

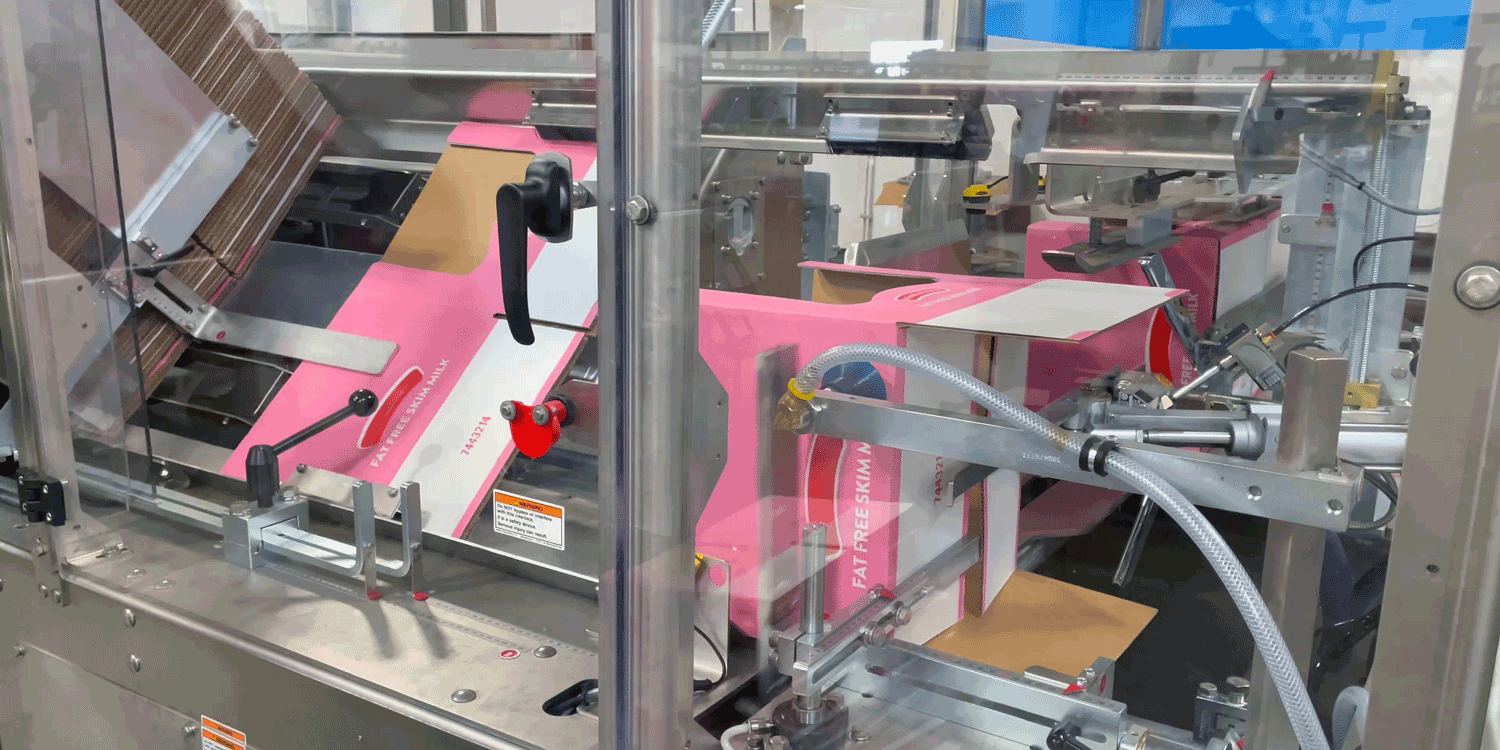

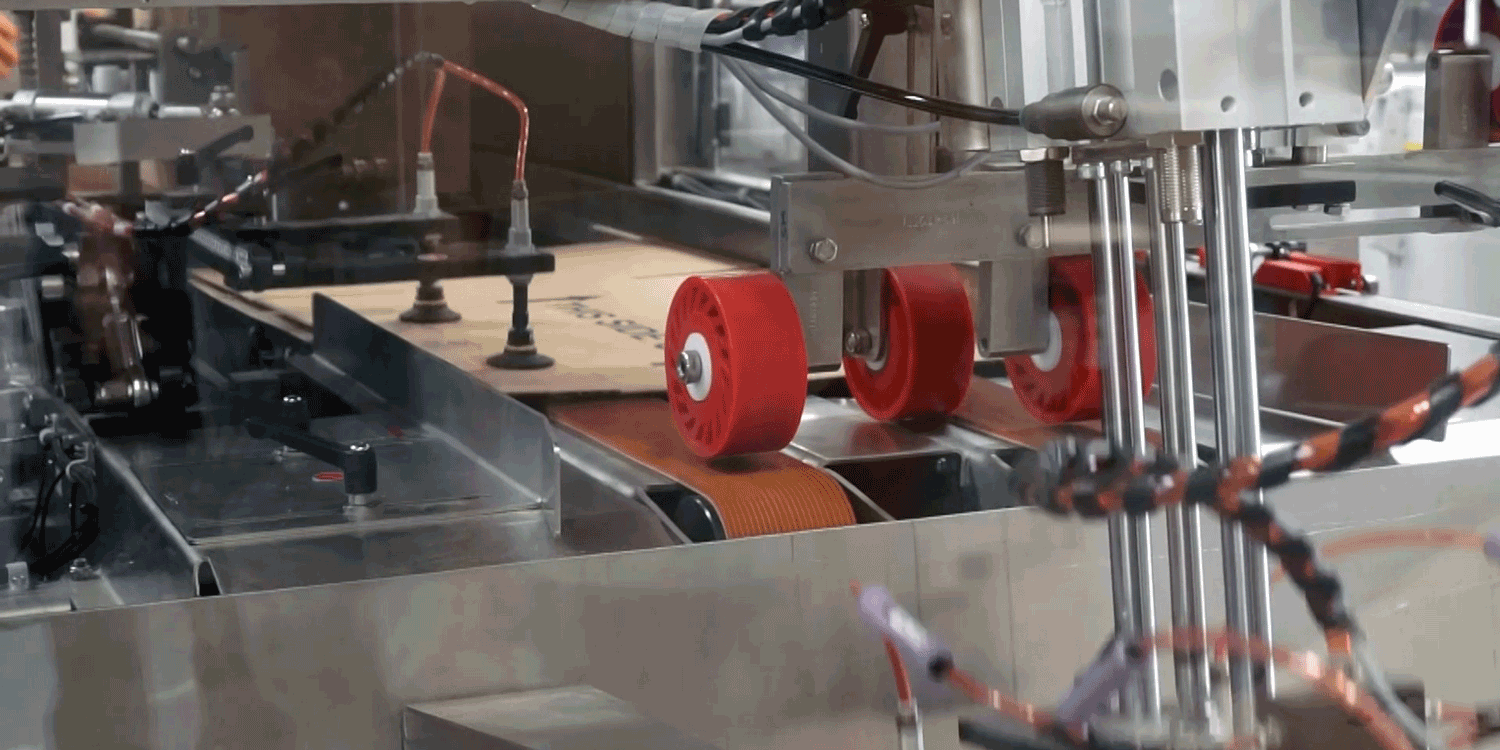

Introducing the SWF CE 35X Series Case Erectors – a revolutionary advancement in the packaging industry! These robust, newly designed, high-speed machines are engineered to effortlessly fold and seal the bottom flaps of RSC (Regular Slotted Containers) and HSC (Half Slotted Containers) cases, making them an essential tool for any business looking to enhance efficiency. You can choose between tape or glue adhesive options to meet your specific needs and witness outstanding performance.

Our standard model features an impressive 37-inch magazine length and operates at a remarkable speed of up to 35 cases per minute. Experience the future of packaging with our cutting-edge continuous rotational-motion technology, designed for high performance and energy efficiency, translating to cost savings for your business.

For over sixty years, SWF has been a leader in the packaging equipment industry, delivering innovative solutions across a variety of sectors. Our extensive lineup—including bliss, tray, and case erecting machinery—has set the standard in the industry, helping businesses like yours discover the most effective packaging designs and machinery solutions.

What sets our equipment apart? Its compact footprint and rugged, 24/7 construction make it suitable for any production environment. An intuitive operator interface simplifies operation, while quick changeover times minimize downtime. Additionally, our advanced features include a high-speed tape head (with an optional pressurized hot-melt glue system), an automatic jam shutdown sensor for added peace of mind, and polycarbonate interlocked guards and doors for enhanced safety.

Key Features

- 2” Dekka high-speed tape head

- Indirect Food Grade design

- Lexan guard package

- 4-color stack light

- Low magazine, broken tape, no tape, low tape, downstream not ready, jam, open flap detection

- 7” Allen Bradley Optix HMI with data collection

- Safety PLC / Ethernet port / Unmanaged Ethernet switch

Technical Data

Available Options

- 3” high-speed tape head

- 3M tape head

- Nordson glue / Nordson glue repository system

- Extended magazine

- LED machine lighting with fault location

- Stainless steel construction

- Stainless steel mesh guards

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...