Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Integrated Systems’ product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

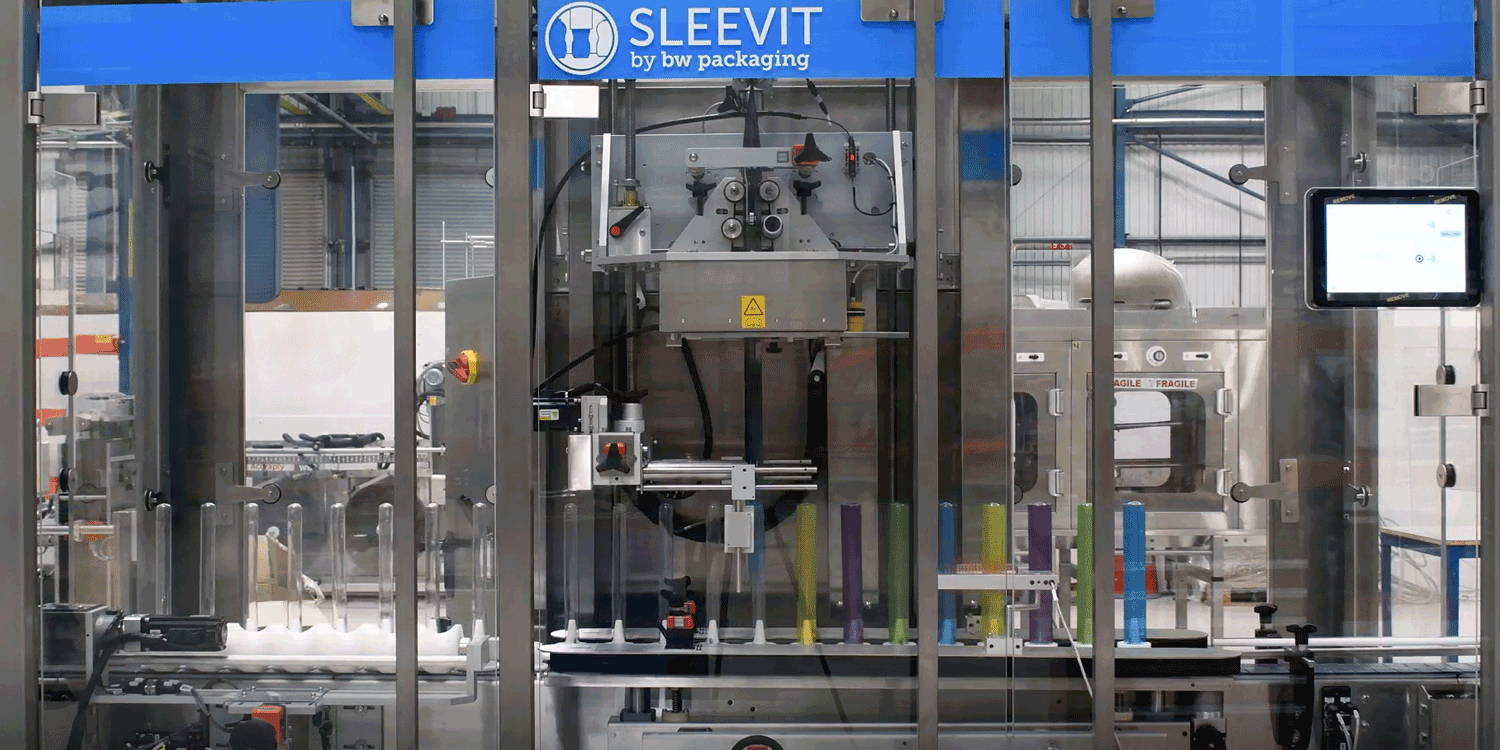

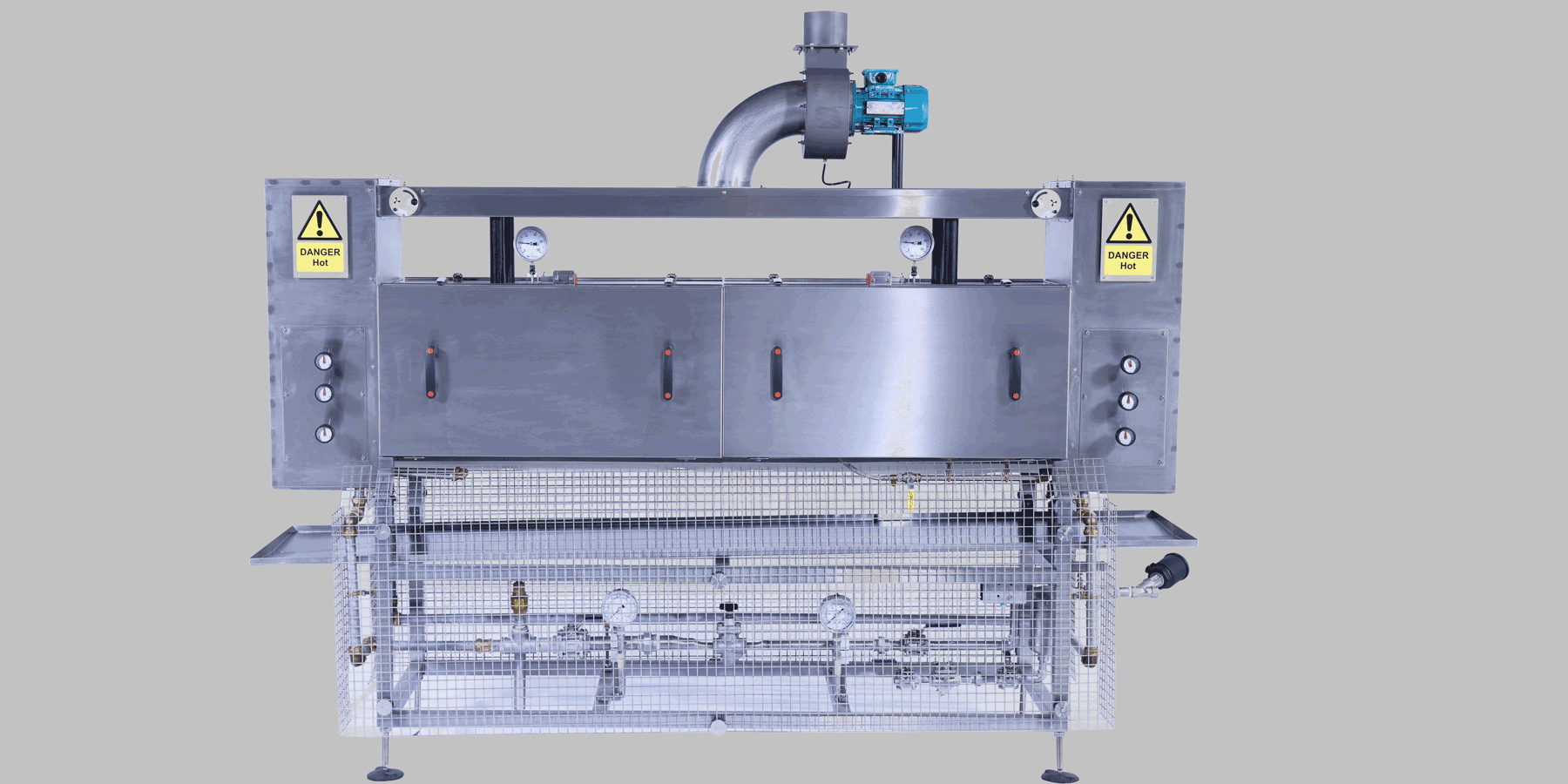

Sleevit ST 100 Stream Shrink Sleeve Tunnel

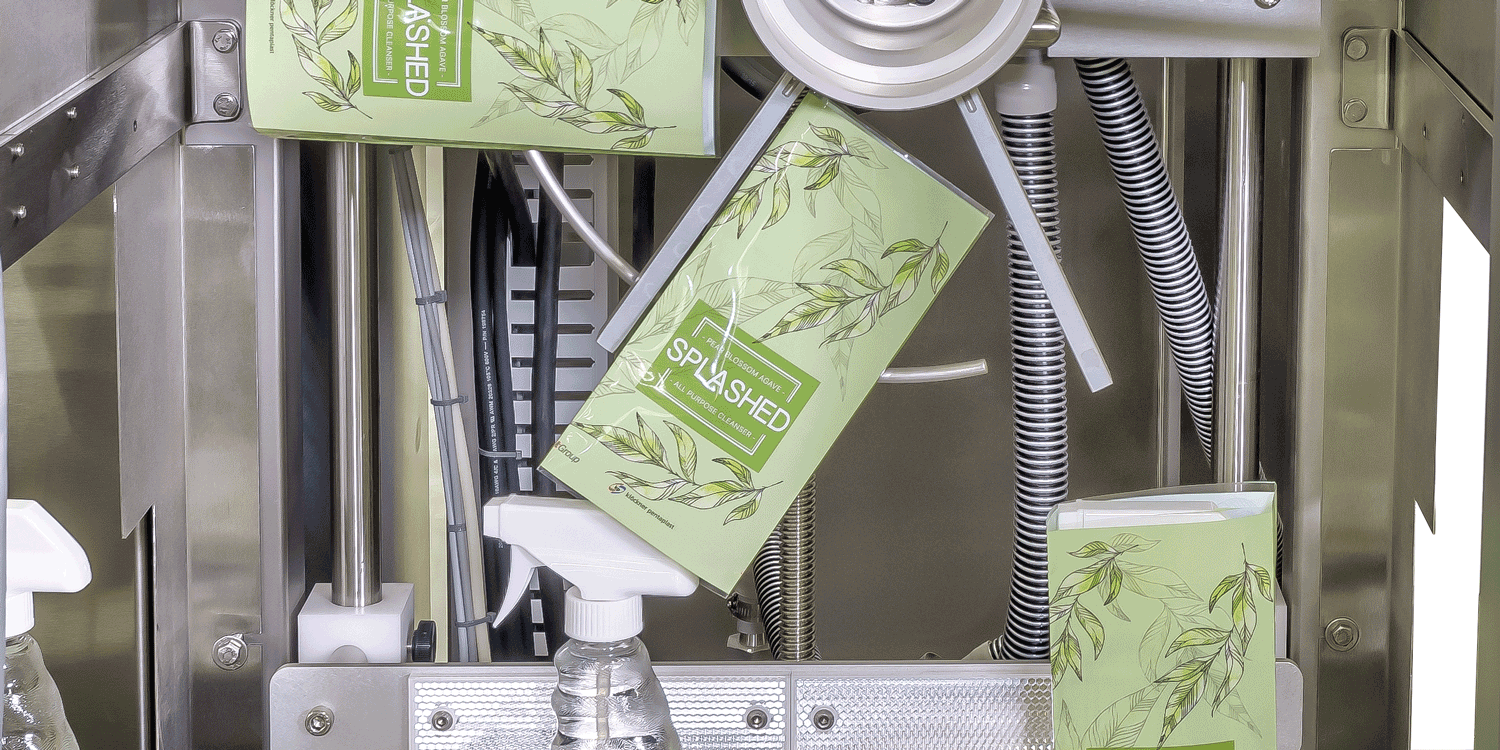

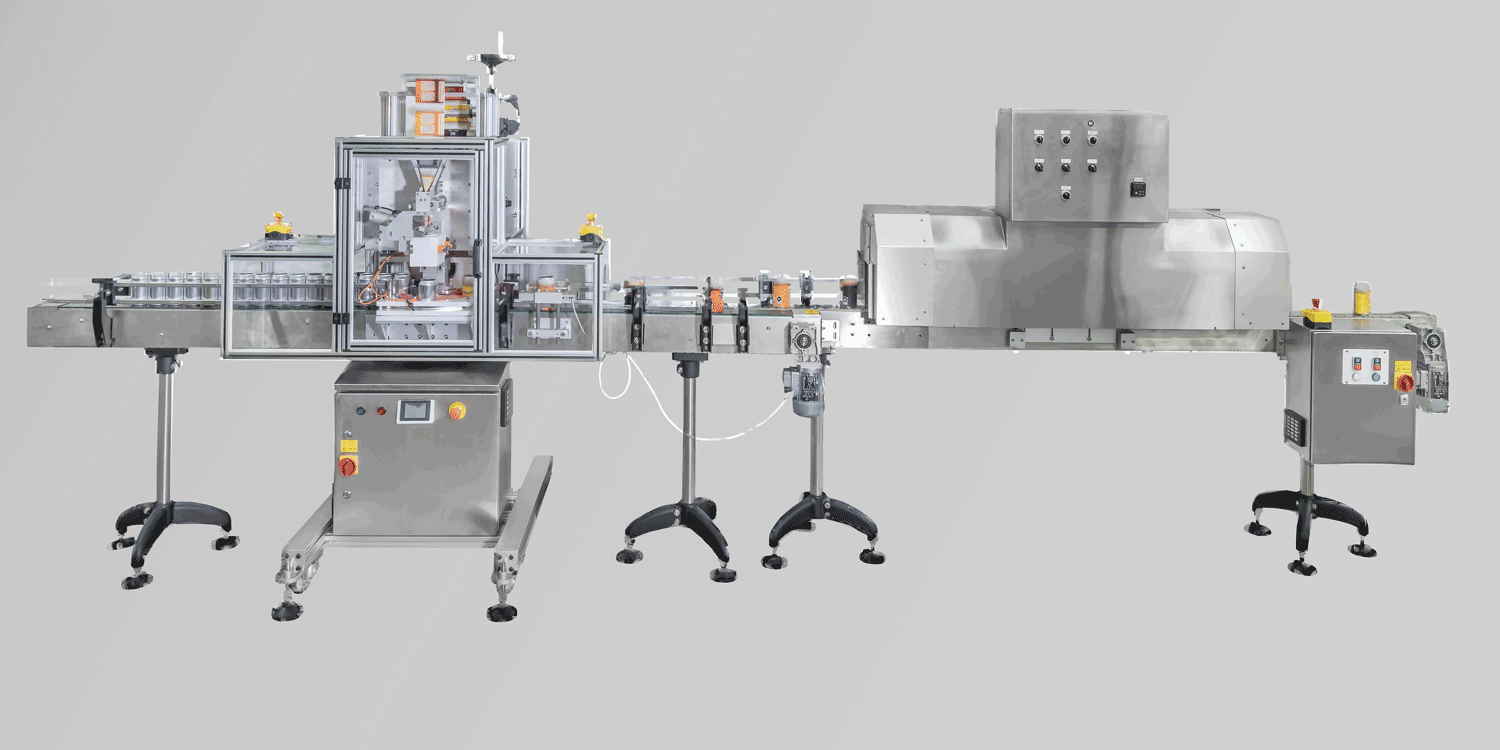

The Sleevit ST 100 steam shrink sleeve tunnel is a high-performance solution designed to handle the most challenging shrink labeling tasks. Engineered from premium stainless steel with a double-skin insulated exterior, this compact steam tunnel excels in shrinking sleeves for containers with unusual shapes, including those that feature heavily waisted sections or require significant changes in shrink rates.

Advantages of Steam Tunnels:

- Versatile Application: Efficiently shrinks PET sleeves to PET bottles and accommodates thinner sleeve materials, making it suitable for diverse packaging needs.

- Customizable Steam Delivery: Equipped with 8 individual steam delivery tubes, each adjustable via needle valves, the ST 100 offers graduated steam flow and precise on/off control for optimal heat application

- Streamlined Maintenance: Designed with practicality in mind, the tunnel includes extraction hoods, a drain tray, and a top-opening inspection door for easy cleaning and container removal.

Innovative Design

The Sleevit ST 100 steam shrink sleeve tunnel boasts a compact design that facilitates simple installation. It can be integrated into existing packaging lines or configured in series for high-speed and zoned applications, enhancing overall efficiency.

To further enhance performance, steam conditioning and pressure reducing kits are available, along with extractor fans suited for 10 meters of ducting. For operations where containers may tip over, optional counting systems ensure accurate tracking in and out of the tunnel.

Advantages of Shrink Sleeve Labeling

- Shrink sleeve labels offer a variety of advantages, particularly for manufacturers working with irregularly shaped containers. Benefits include:

- Full Product Branding: Achieve comprehensive brand visibility with full-body shrink labels.

- Tamper-Evident Packaging: Create secure packaging solutions that enhance consumer safety.

- Seamless Integration: Easily incorporate into your existing packaging operations.

- Scratch Resistance: Ensure durability and longevity of labels, maintaining a pristine appearance.

The ST 100 steam shrink sleeve tunnel is designed to meet the demands of contemporary packaging environments, ensuring reliable and efficient shrink labeling for all container shapes. Experience the perfect blend of functionality and innovation with Sleevit.

Key Features

- Stainless steel construction

- Double skin insulated exterior

- Individually controlled steam delivery tubes

- Accomodates full body decorative sleeve or tamper evident banding

- Easy access for cleaning or container removal

Technical Data

Available Options

- Product counter

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...