Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

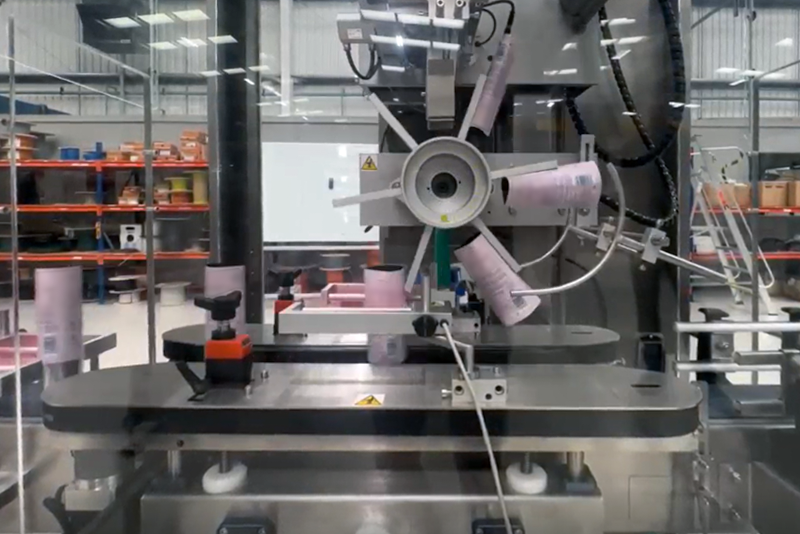

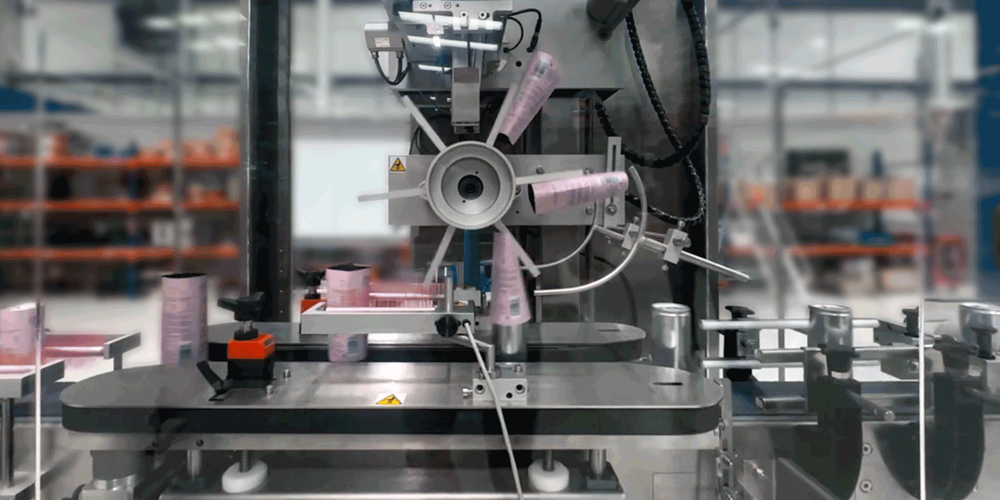

Sleevit Rotary (RF) Series Shrink Sleeve Applicators

Discover the next level of product packaging with the innovative Sleevit Shrink Sleeve Label Applicators, models RF150 and RF250. Designed for efficiency, these compact machines are operator-friendly and easy to maintain, making them ideal for applying full-body or tamper-evident bands to various container shapes and sizes.

Precision Application for All Container Types

Our shrink sleeve applicators can accommodate oval, round, and square containers made from plastic, glass, or metal, all at impressive speeds of up to 150 units per minute for Model RF150 and 250 units per minute for Model RF250. The cutting-edge technology allows for synchronous application of shrinkable materials, ensuring optimal accuracy for a seamless fit on each container.

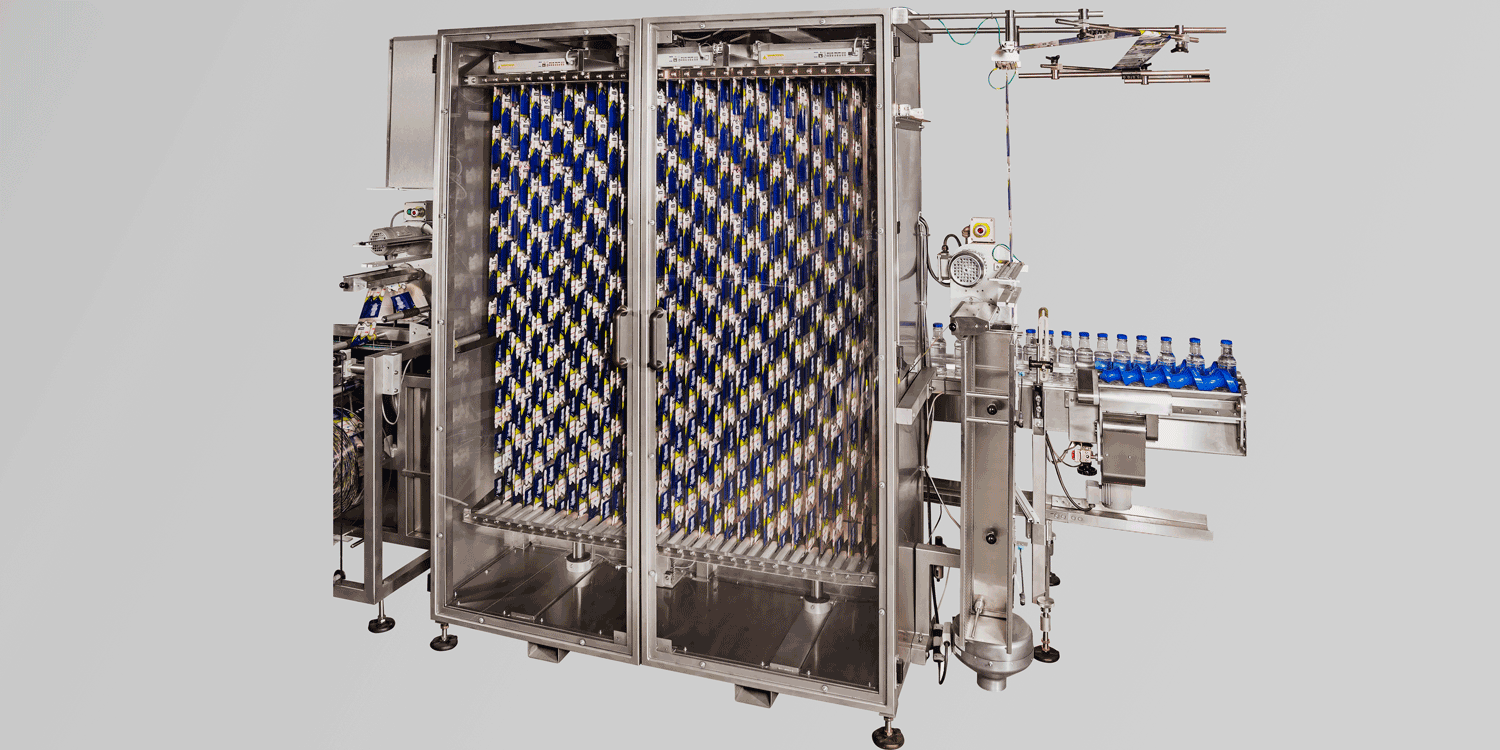

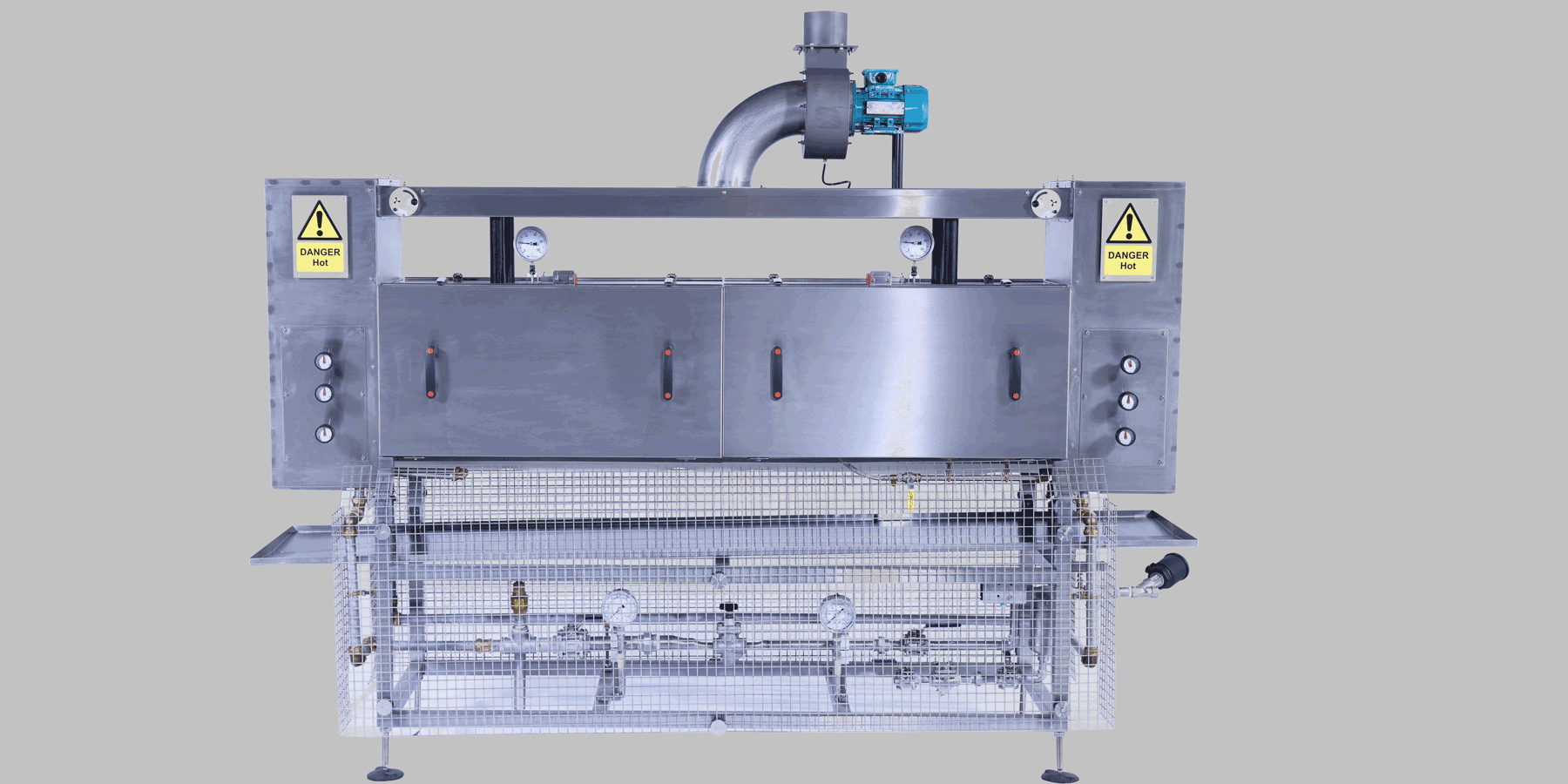

These Shrink Sleeve labelers are designed to integrate effortlessly with your current packaging operations. Our team is ready to assist you in creating a comprehensive system, including conveyors and heat tunnels, tailored to meet your production needs.

Boost Your Product’s Shelf Appeal

Full-body shrink sleeve labels not only enhance the visual appeal of your products but also provide a competitive edge in the market. Customizable shrink sleeves can be designed to attract consumer attention or to support promotional strategies, significantly improving your product's shelf presence.

Advanced Technology for Enhanced Performance

The RF150 and RF250 models utilize a rotary-fed design, employing a rotating arm that skillfully applies full-body shrink sleeves onto containers. Once applied, products are transported through a steam shrink tunnel, where heat causes the sleeves to conform perfectly to each container's shape, ensuring a professional finish.

If you're looking for advanced solutions in shrink sleeve application, we are here to help. Our expert team can assist you in building or expanding your shrink sleeve production line. Contact us today to learn more about our revolutionary shrink sleeve equipment that can enhance efficiency and drive your success.

Transform your packaging game with Sleevit Shrink Sleeve Label Applicators and stand out on the shelves!

Key Features

- Up to 250 products per minute

- Extremely flexible machine, suitable for customers with challenging applications or wide product ranges (contract packers)

- UL, CE, UKCA compliance

- Compliance with demanding customer specifications

- Servo-controlled platform

- Shrink sleeve labels applied to either empty or filled oval, round, square, plastic, glass, metal, or paperboard containers

- Compact design minimizes footprint

- Fully enclosed and interlocked guarding

- Quick “no-tools” adjustment and position indicators for repeatability and rapid changeovers

- Color touchscreen operator interface with recipe storage for container and sleeve material combinations

- OpViewTM HMI features an intuitive and, scalable design with a smartphone-like interface, and creates clear path for operators to easily set-up, operate and troubleshoot any machine

Technical Data

Available Options

- CFR21 part 11 compliant

- Reel changeover system for continuous production

- Container spacing and positioning unit

- Detect/eject system for incorrectly sleeved containers

- Sleeve positioning system

- Various material shrink tunnels

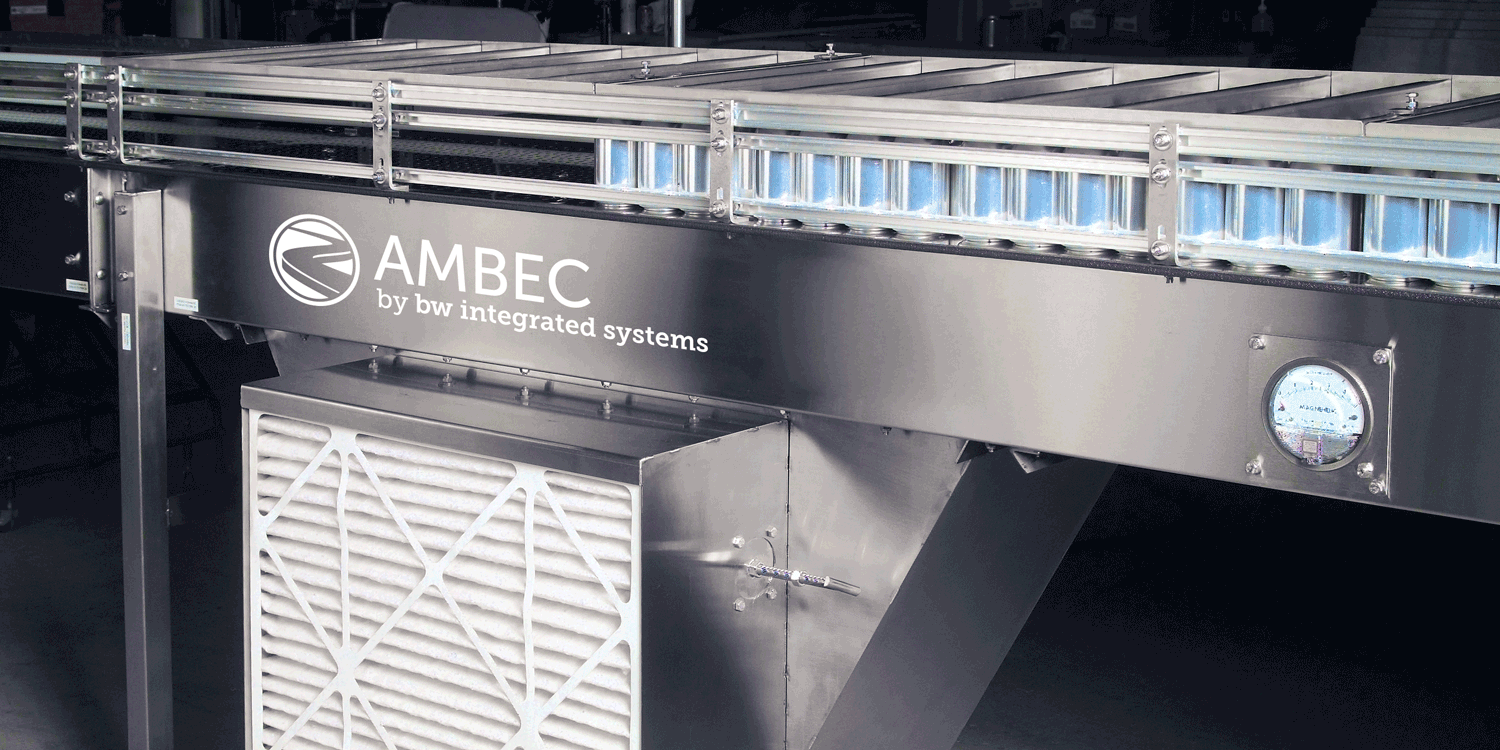

- Conveyor systems

- Standard, compatible modules for customization to exact requirements

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...