Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

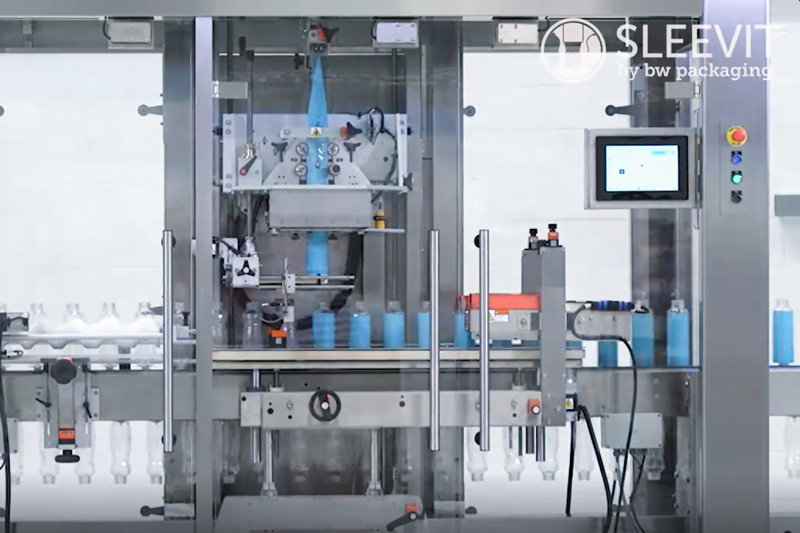

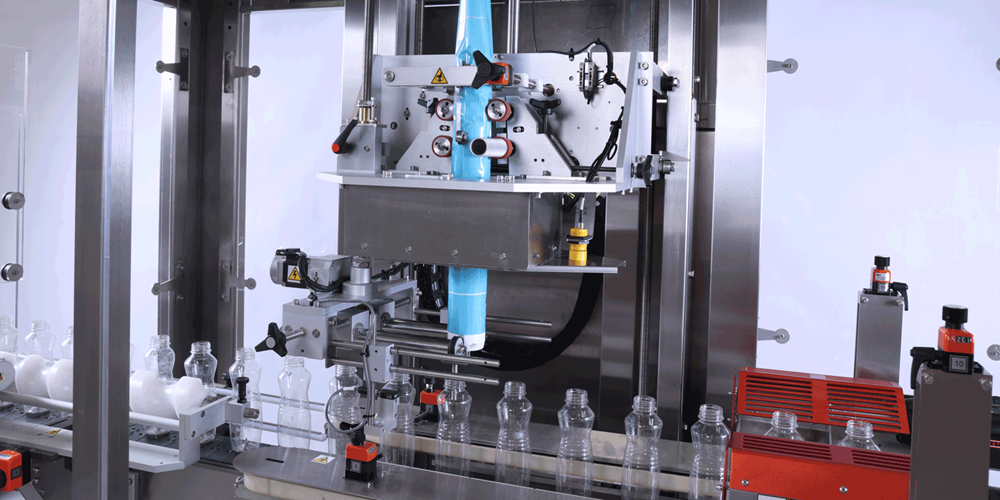

Sleevit Vertical Feed (VF) Series Shrink Sleeve Applicators

As the shrink sleeve marketplace evolves with a growing emphasis on sustainability and streamlined labeling processes, the Sleevit VF Shrink Sleeve Applicator stands out as a cutting-edge solution tailored for modern businesses. Its modular design offers the scalability needed to adapt to your growing demands, making it an ideal investment for enhancing productivity and efficiency in your operations.

The VF Shrink Sleeve Applicator is engineered with an ergonomic design that prioritizes safety, ease of use, and performance while maintaining a compact footprint. This innovative machine not only increases output and simplifies changeovers but also streamlines your operations and lowers maintenance costs—all while improving the visual appeal of your shrink sleeve labels.

When it comes to high-volume production, the Accraply Mandrel Shrink Sleeve Applicator models VF350 and VF650 provide unparalleled performance. These vertical applicators are specifically designed for demanding operations, accommodating a range of container shapes and materials—including glass, plastic, and metal. Whether you're working with filled or empty containers, these models are among the most cost-effective solutions on the market.

Advantages of Shrink Sleeve Applicators:

- Compatibility with various container shapes: round, square, and oval

- Ability to work with materials like PVC, PET/PETG, OPS, hybrid, or PLA

- Application speeds of up to 350 bottles per minute for Model VF350 and 650 bottles per minute for Model VF650

Our state-of-the-art machines also handle a variety of sleeving types, including:

- Full-body sleeves

- Over-the-cap sleeves

- Partial body sleeves

- Tamper-evident packaging

- Multi-pack packaging solutions

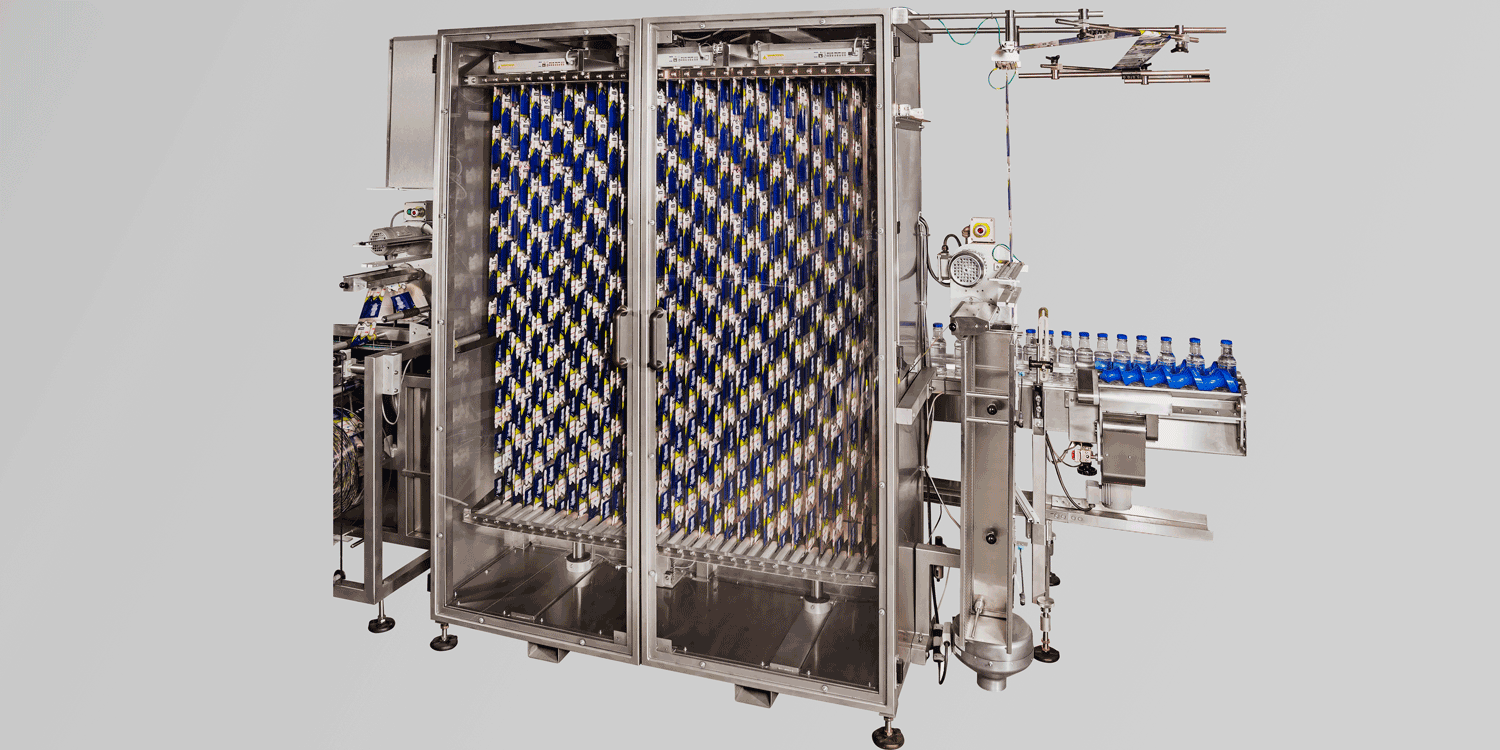

The VF Shrink Sleeve Applicator boasts the versatility to apply full-body, part-body, and tamper-evident sleeves to both filled and empty containers made from sustainable materials. With its capabilities to work with PETG, PETC, RPET, PO, OPS, Hybrid, PVC, and PLA materials, thicknesses between 40 and 70 microns can be efficiently managed. It features two modular guillotine cutting units for products ranging from 30mm to 170mm, with toolless mechanical adjustment and advanced OpView™ HMI for user-friendly operation. Achieving speeds of up to 350ppm or 650ppm at 30mm cut length, this machine can be seamlessly integrated with Sleevit ancillary modules and heat tunnels, offering a comprehensive packaging solution.

Upgrade your packaging process today with our innovative shrink sleeve applicators designed to meet the demands of a fast-evolving market while prioritizing sustainability!

Key Features

- Shrink sleeve labels applied to round, oval or square containers

- Shrink sleeve labels applied to either empty or filled containers made of glass, plastic, metal, or paperboard

- Quick “no-tools” adjustment for fast and easy product changeovers

- Compact design minimizes footprint

- Color touch screen operator interface with recipe storage for container and sleeve material combinations

- For use with PVC, PET/PETG, OPS or PLA material from 40 to 70 microns thick

Technical Data

Available Options

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...