Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

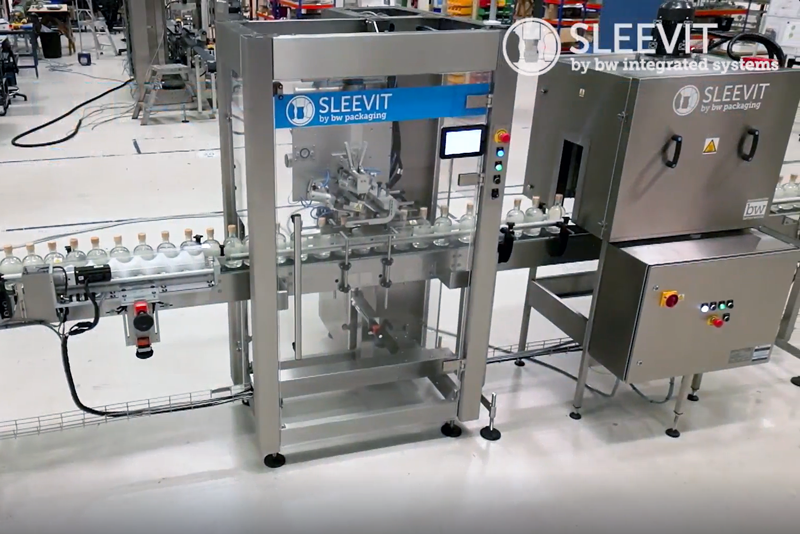

Sleevit Direct Feed (DF) Series Shrink Sleeve Applicators

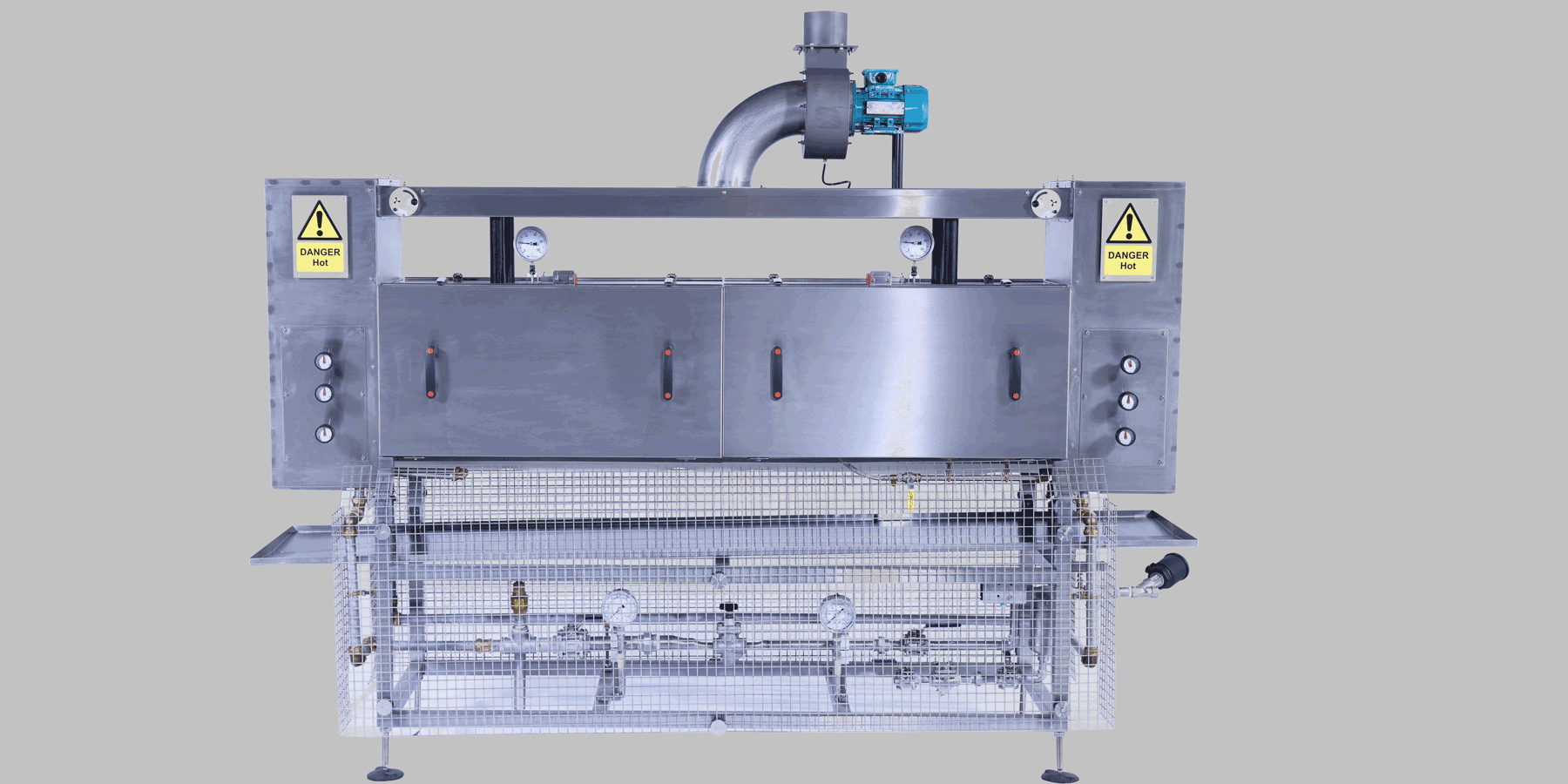

The DF Series of Shrink Sleeve Applicators from Sleevit is the ultimate solution for efficiently applying tamper-evident or partial body sleeves. Its compact and flexible design accommodates various applications, while innovative features like a servo-driven axis and tool-less adjustments ensure effortless product changeovers. With the next-generation OpView™ HMI, you can expect enhanced production efficiency and reduced waste.

The DF Series offers a robust line of tamper-evident label applicators designed for various applications. Engineered for customization, these machines can adapt to your specific requirements, ensuring a seamless integration into your production line. With a focus on easy installation and maintenance, the DF Series helps you efficiently meet your production targets. Capable of achieving impressive speeds of up to 300 products per minute, these applicators work well with a wide range of materials, including PVC, rPET, PETG, OPS, and PLA.

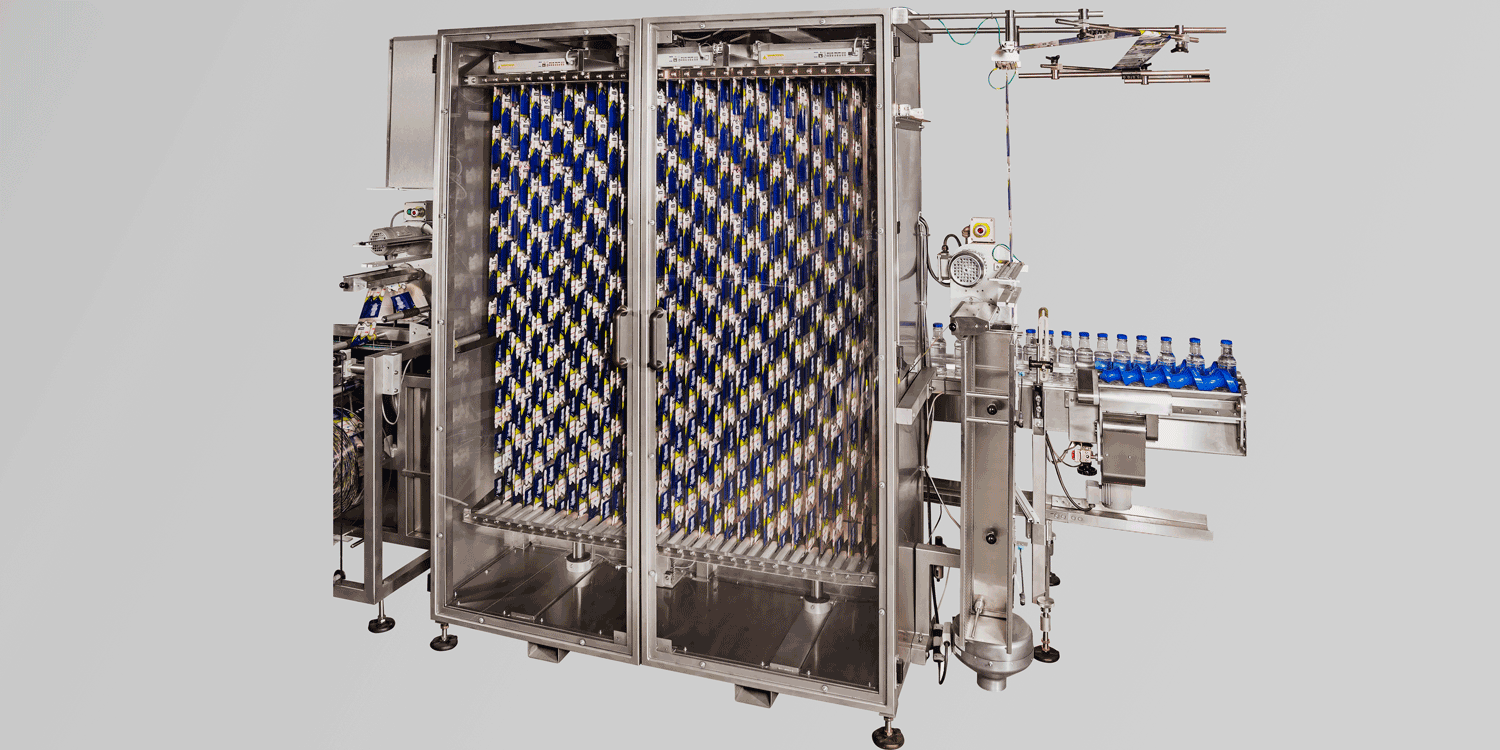

Key Advantages of the Sleevit DF Series

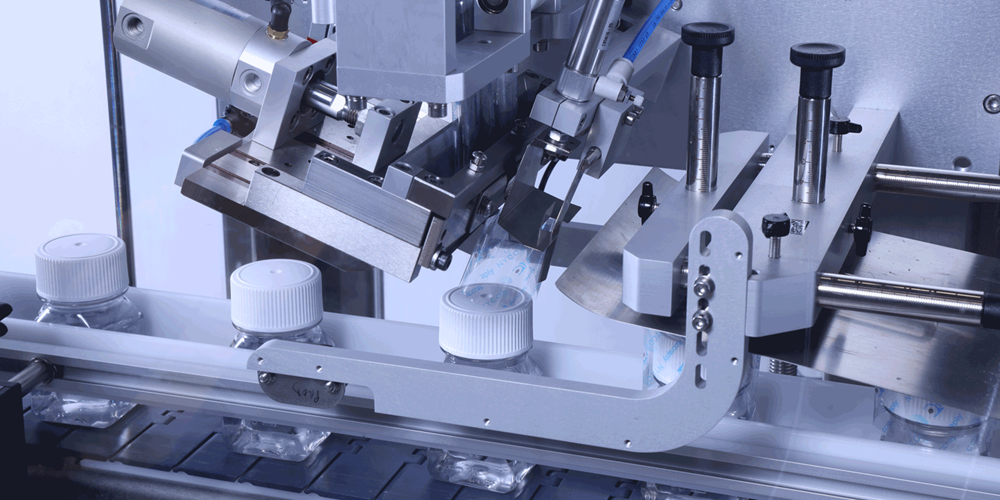

Designed for versatility, the Sleevit DF Series accommodates sleeving for products with diameters ranging from 20 mm to 195 mm and sleeve lengths from 20 mm to 50 mm. The user-friendly Human-Machine Interface (HMI) enhances operational efficiency and provides password-protected product recall to boost throughput. The state-of-the-art servo film feed mechanism simplifies setup and ensures accurate sleeve placement, making our tamper-evident applicators a vital component of your production line.

The Benefits of Tamper-Evident Labels

Tamper-evident labels not only provide peace of mind to consumers but also offer significant advantages for manufacturers. These labels help minimize the risk of contamination after manufacturing, reducing the likelihood of costly recalls. Additionally, they enhance quality control within your supply chain, allowing you to clearly detect and assess damage incurred during shipping and distribution. If a product is found to be damaged, tamper-evident labels enable you to trace back to the specific point in the supply chain where the issue occurred.

Revolutionize Your Sleeving Process Today

At Sleevit, we specialize in innovative sleeving solutions that empower your business. With our advanced equipment, you’ll experience seamless repeatability, minimal downtime, and enhanced product appeal. Ready to transform your packaging operations? Contact BW Packaging today to learn more about the DF Shrink Sleeve Applicator and our comprehensive range of solutions tailored to meet your needs.

Key Features

- Fully enclosed and interlocked guarding as standard

- OpViewTM HMI features an intuitive and scalable design with a smartphone-like interface, and creates a clear path for operators to easily set up, operate, and troubleshoot any machine

- Can be fully customized to meet exact customer requirements

- Fully interchangeable change parts and assemblies

- Flexibility of sleeve length

- Easy to install, set up, and can be converted to apply low-speed full-body application

Technical Data

Available Options

- Larger, front or rear column mounted reel holders for ease of reel change

- PackML

- Safety PLC’s

- Industry 4.0

- Pharmaceutical: 21 CFR part 11 & validation packages

- Siemens or Allen-Bradley/Rockwell controls

- Label overprint by TTO, CIJ, laser or hot foil

- Vision inspection system - sensor, scanner or camera

- Fail safe, track-and-reject systems with verification

- Queue control

- Fallen bottle detection

- Infeed & outfeed container transfer via side belts, conveyor flush sides

- Product pitching via servo scroll, gapping wheel or gatting unit

- Product orientation via chain aligners, centering units, or tri-roller

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

9350 W Broadway Ave

Brooklyn Park MN 55445

US -

+1 (763) 557-1313 -

(Customer Service) -

(Field Service)

-

Gilchrist Rd

Manchester M44 5AY

GB -

+44 (0) 161 848 4800 -

+44 (0) 161 848 4858 (Customer Service) -

+44 (0) 161 848 4855 (Field Service)

Jump to...

Jump to...