Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

Fleetwood Conveyance, Can End Manufacturing

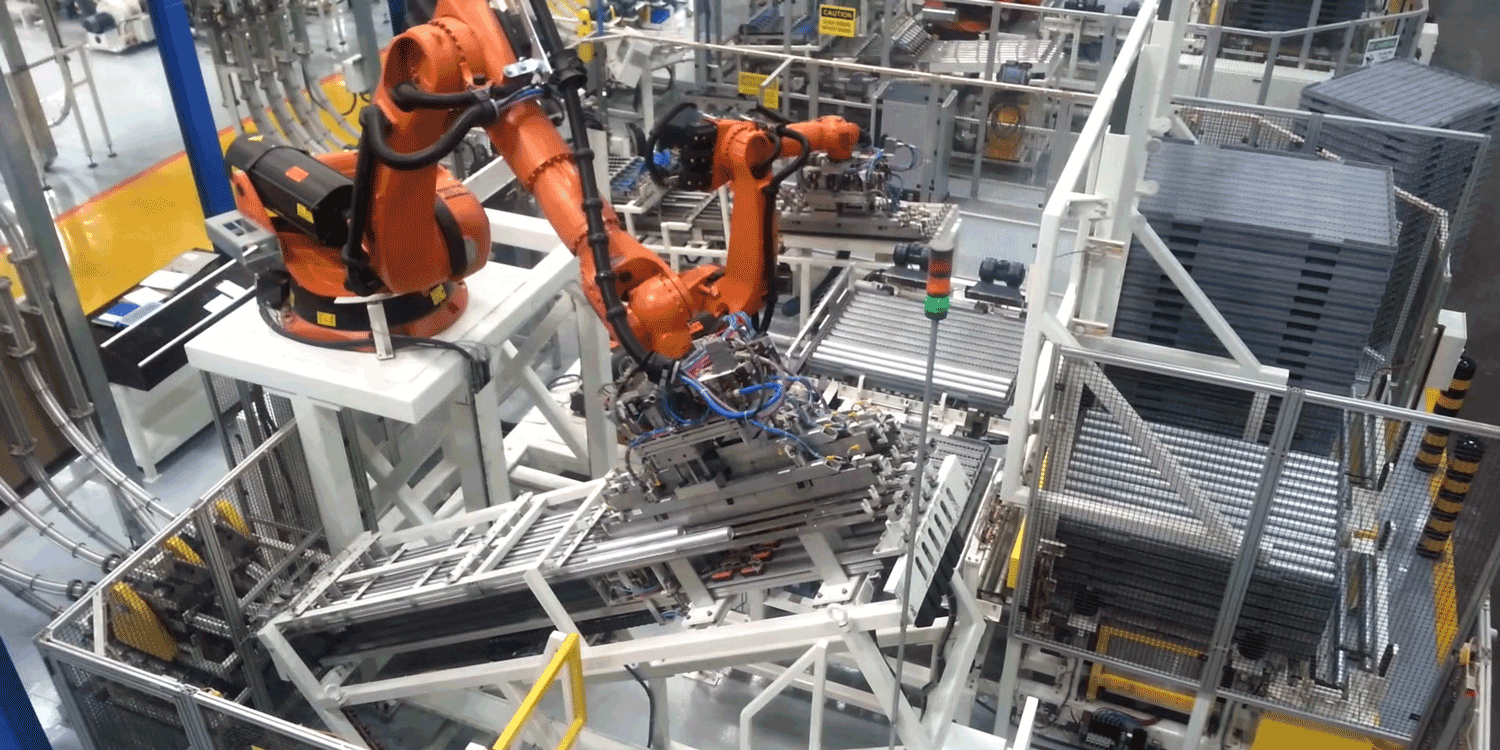

Fleetwood’s innovative line of Conveyance Solutions is designed specifically for can end manufacturing companies, offering state-of-the-art products tailored to meet diverse production line needs. Our systems begin at the shell press, where we pioneered synchronizer technology to effectively address end spacing challenges as industry speeds continue to rise.

Customizable Trackwork and Pusher Configurations

We provide an extensive range of trackwork and pusher configurations that seamlessly integrate with any customer-selected equipment, allowing for adaptability in even the most constrained plant spaces. Our conveyors feature multiple product sampling and camera inspection locations to fulfill the testing requirements of any client.

Versatile Conveyor Options

Our liner conveyor solutions support all liner types, speeds, and compound formulations, ensuring optimal performance for your specific application. Additionally, we offer conversion solutions suitable for both four-lane and six-lane press systems. All systems are backed by Fleetwood's user-friendly control technology, designed to enhance production efficiency.

Global Expertise in Conveyor Solutions

With over 65 years of experience, Fleetwood has established itself as a trusted provider in the can end manufacturing industry, boasting thousands of installations across more than 60 countries worldwide. Our customers rely on us for complete conveyor lines that handle the highest speeds and the most delicate shells, ends, and lids.

Innovative and Flexible Solutions

We cater to a wide range of materials including aluminum, steel, foil, and plastics. Our configurations support various formats such as SOT, ring pull, EZO, CDL, ISE, aerosol, sanitary, and foil peel, serving industries from beverage and food, to aerosol and consumer goods. In addition, we offer advanced vacuum and magnetic conveyor solutions, leveraging our extensive expertise in aluminum, steel, and specialty end manufacturing.

At Fleetwood, our layouts are crafted with a commitment to innovation and customer-centric solutions, prioritizing quality and attention to detail. As a leader in the can end market since 1956, we are dedicated to providing powerful and reliable conveyance solutions tailored for your unique application.

With thousands of successful installations globally, Fleetwood Integrated Systems is your go-to source for cutting-edge conveyance solutions. Experience the difference with our reliable and innovative systems designed to optimize your production capabilities today!

Key Features

- Line speed: up to 15,000 ends per minute

- Lid size: 200 - 603 diameter

- Innovative, efficient, and flexible line layouts

- Short delivery times and low maintenance requirements

- Extensive technical knowledge and a global service team

- Full lines, small projects, individual conveyors, and repair parts

- Installations with all major global manufacturers, system integrators as well as countless regional manufacturers

- High-quality stainless-steel chutes to transfer ends without air assist requirements

- Integrated user-friendly control systems for seamless installation and vertical start-ups

- Plastic-coated rod cages, hopper tubes, and trackwork for gentle handling throughout the production line

- Purchased components from globally available brands for high reliability and local customer support

Technical Data

Available Options

- Customer specification packages and many other options

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1305 Lakeview Dr

Romeoville IL 60446

US -

+1 (630) 759-6800 -

+1 (800) 527-0494 (Customer Service) -

+1 (800) 527-0494 (Field Service)

-

Plumtree Farm Industrial Estate, Bircotes

Doncaster DN11 8EW

GB -

+44 (0) 1302 711056 -

+44 (0) 1302 718335 (Customer Service) -

+44 (0) 1302 711056 (Field Service)