Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

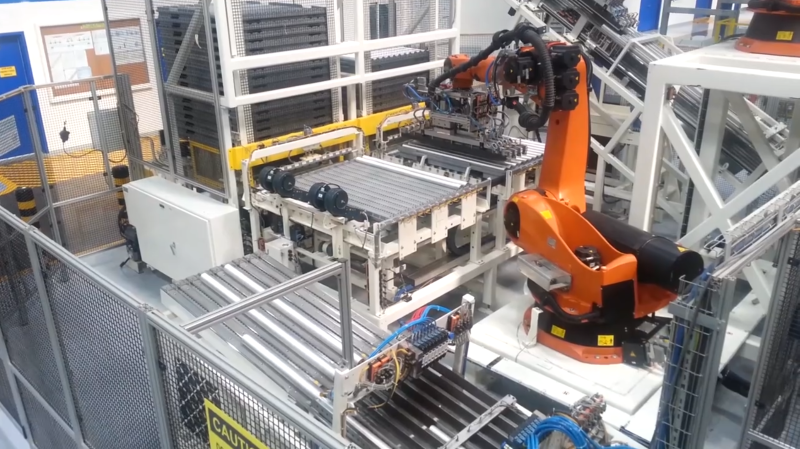

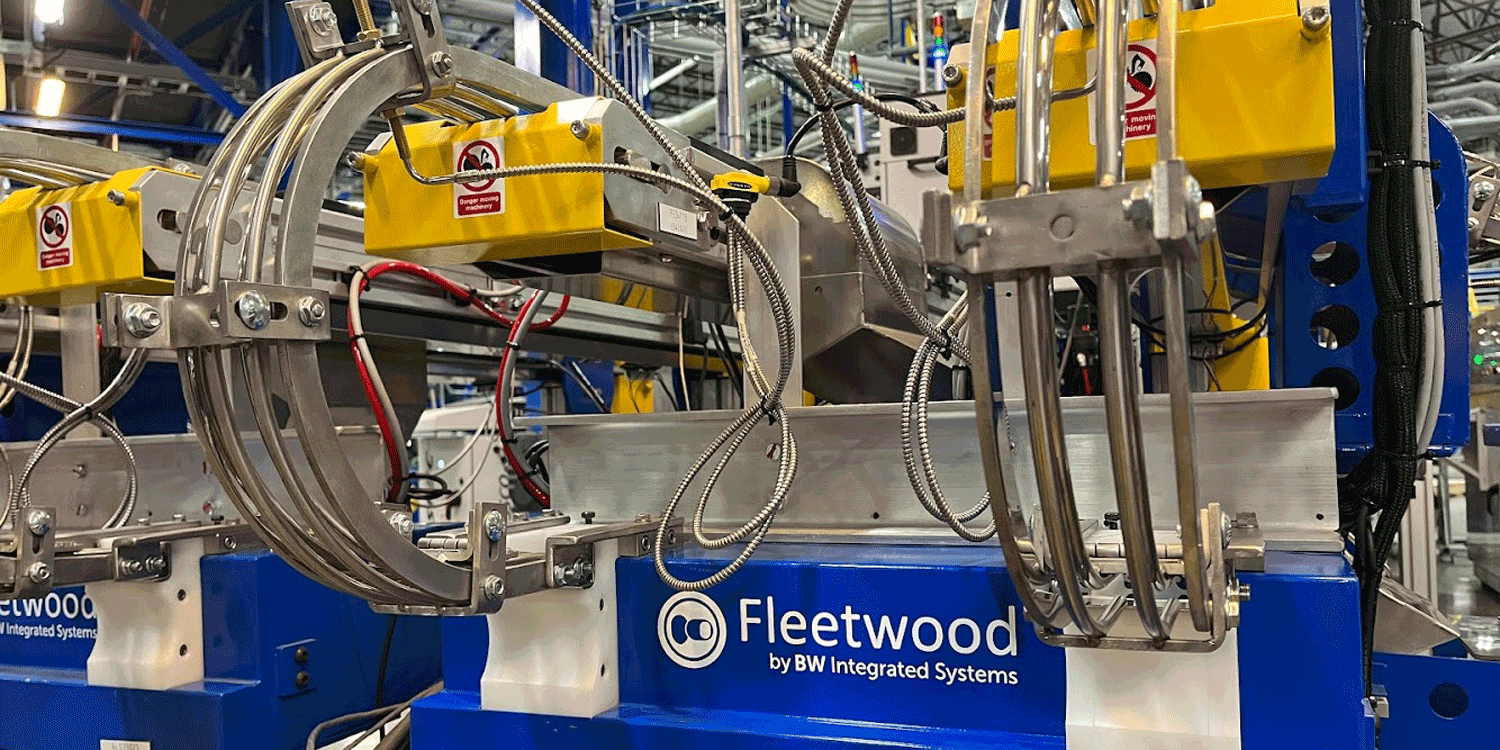

Fleetwood Robotic Tray Storage (RTS)

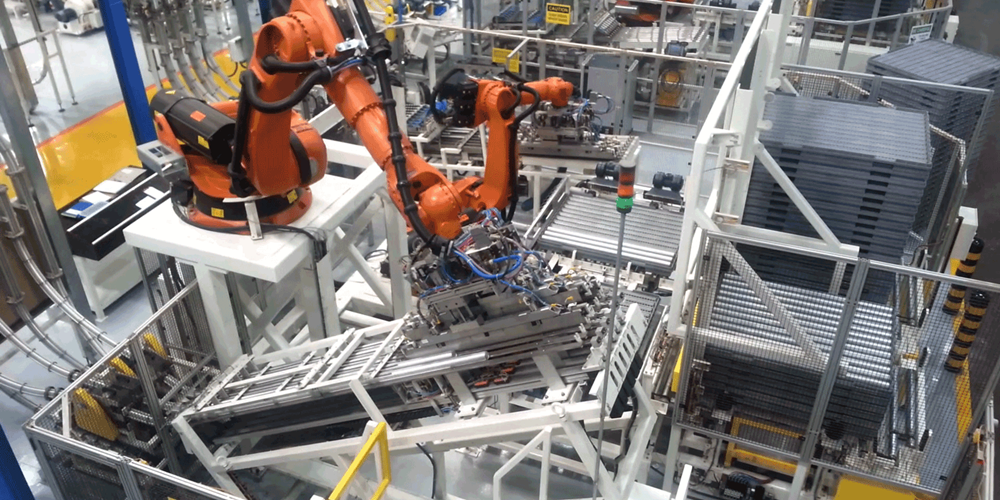

Boost your can end manufacturing process with Fleetwood's advanced Robotic Tray Storage (RTS) Systems. Our cutting-edge technology enhances line efficiency by optimizing the distribution and accumulation of shells. The RTS intelligently balances infeed and discharge rates along with the number of lanes, ensuring that your production line meets its exact demands.

Our innovative removal trays allow for the storage of excess production, facilitating a seamless supply of materials even during underproduction periods. With the RTS, you can expect top-tier handling of the highest line speeds and efficiency standards in the industry.

Streamlined Shell Distribution and Production Isolation

Fleetwood’s Robotic Tray Storage Balancing Systems are designed for effortless handling of shell distribution, effectively isolating upstream and downstream production processes. Infeed lanes are adept at separating sticks of ends by length, while our robotic arm directs these sticks to either storage trays or discharge lanes based on real-time product demand. As trays fill, they are stacked and can be stored outside of the RTS, allowing for the build-up of product inventory that is seamlessly reintroduced to maintain continuous production flow.

User-Friendly Operation and 24/7 Reliability

With optional automatic product change marker detection, our operators can concentrate on facilitating changeovers in other areas of the production line. The RTS system is engineered for robust 24/7 operation and is powered by Fleetwood’s intuitive control system. Since 1956, Fleetwood has maintained a customer-focused, reliable, and innovative approach that has established us as a leader in the can-end market.

Enhanced Visibility and Accessibility

Our floor-level design ensures open visibility of the production process and easy access without the need for elevated platforms. The RTS 1812M model offers flexible tray handling configurations, capable of managing new or existing metal trays in your inventory. This system efficiently handles product type and color changeovers, effectively isolating primary from secondary products to ensure uninterrupted production.

Cost-Effective Solutions with Robust Plastic Trays

Choose Fleetwood's economical RTS 1408P or 2812P plastic trays to maintain your product inventory with minimal capital investment year after year. Our system reliably accommodates product type or color transitions, allowing you to isolate primary products from secondary ones, thus optimizing production reliability.

By choosing Fleetwood’s Robotic Tray Storage Systems, you're not just investing in technology; you're investing in the future of your production line efficiency and reliability. Contact us today to learn more about how we can help elevate your manufacturing processes!

Key Features

- Production capacities up to 14,000 spm

- Capability for ends from 200 to 206 diameter

- Infeed configurations up to 8 lanes

- Discharge configurations up to 12 lanes

- Low maintenance requirements

- Floor-level design for superior product visibility

- Full system accessibility without platforms

- Air hold-ups and servo-controlled stick handling of shells with minimal pressure and product contact

- Reliable product/color change and isolation functionality

- User-friendly Allen-Bradley PLC control system

- Metal Trays (1812M)

- Tray stack capacity of 180,000 shells (1408P/2812P)

- Robust low-cost HDPE plastic stackable product trays for customer inventory (1408P/2812P)

- Easy product visibility and accessibility (1408P/2812P)

Technical Data

Available Options

- Custom lane quantity configurations and system layouts

- Automatic product/color change marker detection

- Color change QC sample drawer for product inspection/ reintroduction

- Indexing table for dual-product production on separate machines

- Counting & tracking systems for tray stack shell counts and daily production information

- Siemens PLC control system

- Secondary tray handling system for single system dual color operation (1408P/2812P)

- Tray handling configurations for any metal storage trays from any manufacturer (1812M)

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1305 Lakeview Dr

Romeoville IL 60446

US -

+1 (630) 759-6800 -

+1 (800) 527-0494 (Customer Service) -

+1 (800) 527-0494 (Field Service)

-

Plumtree Farm Industrial Estate, Bircotes

Doncaster DN11 8EW

GB -

+44 (0) 1302 711056 -

+44 (0) 1302 718335 (Customer Service) -

+44 (0) 1302 711056 (Field Service)

Jump to...

Jump to...