Products and Solutions

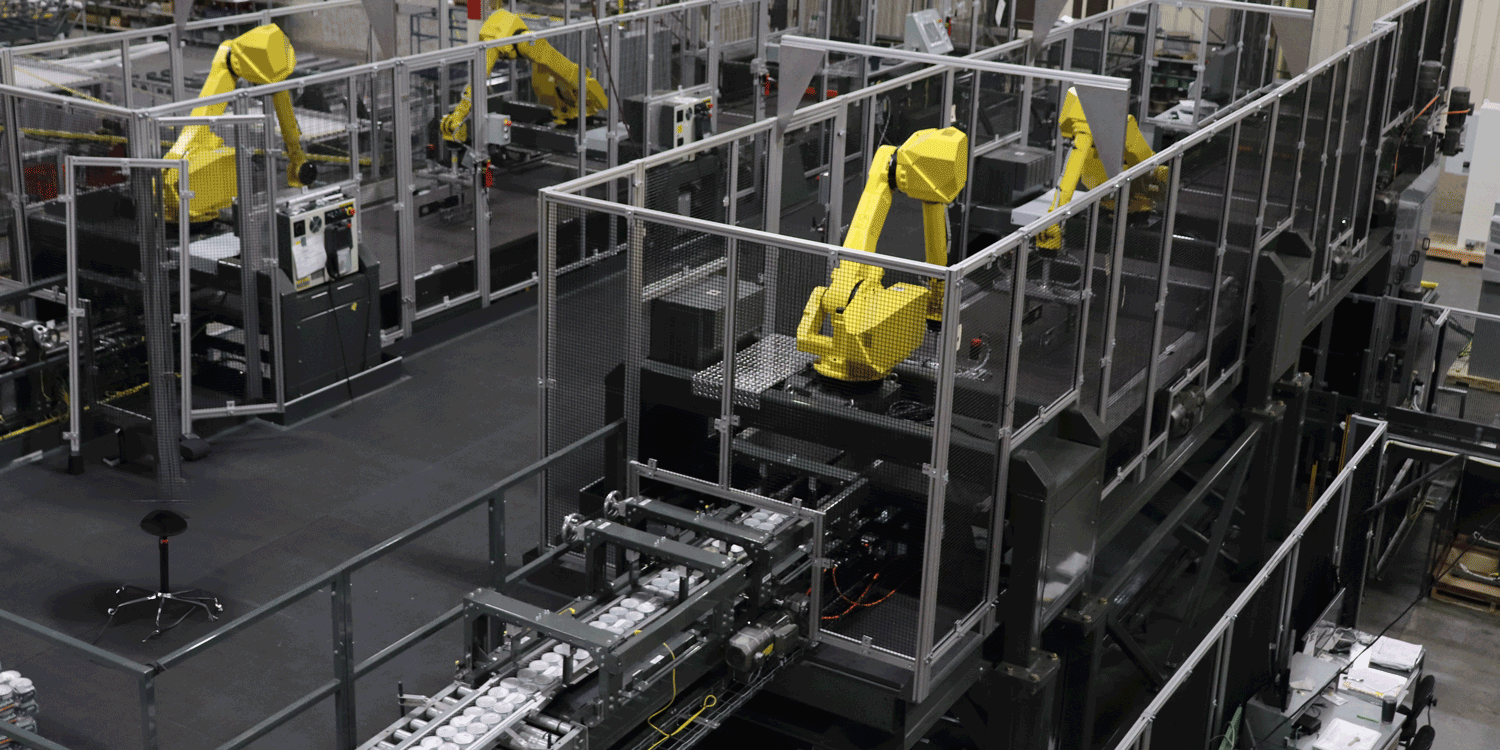

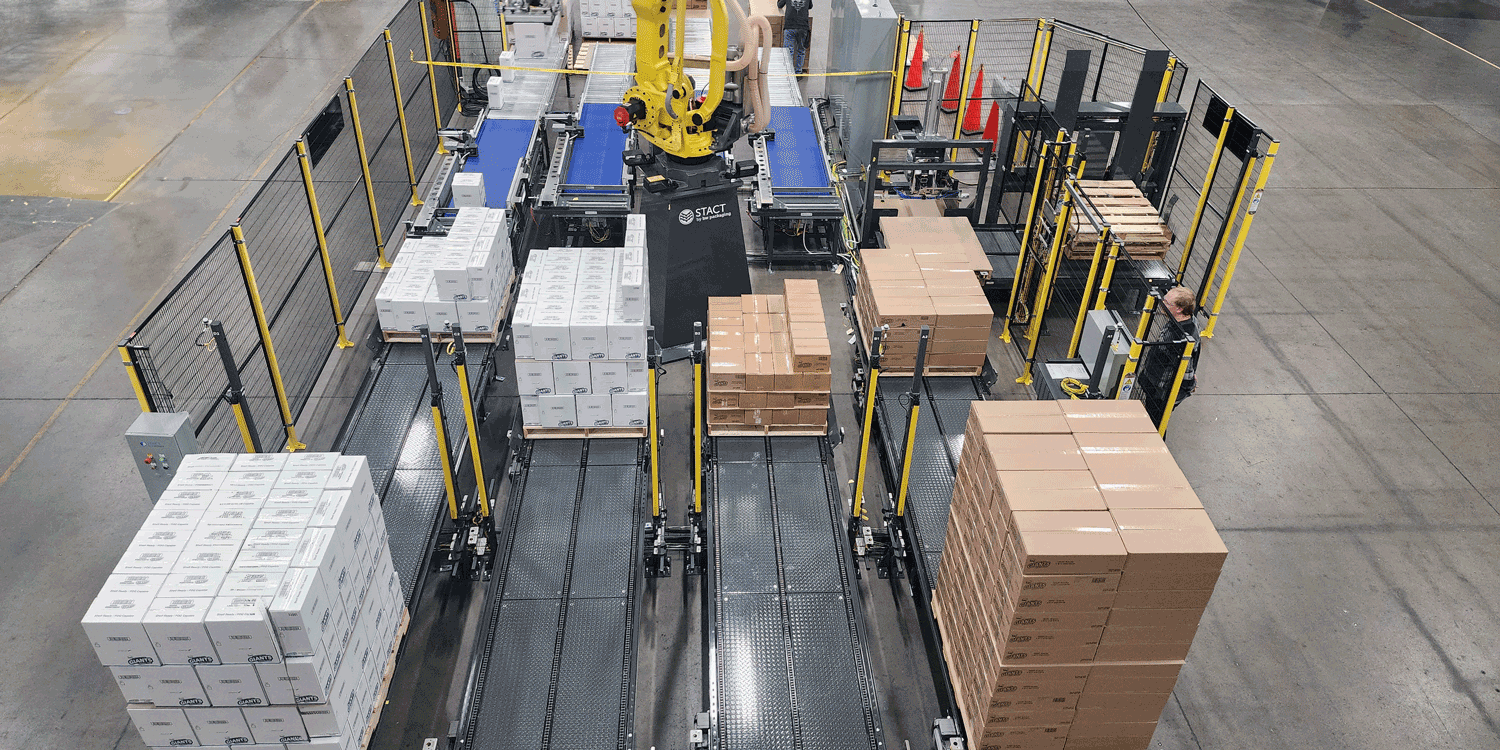

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

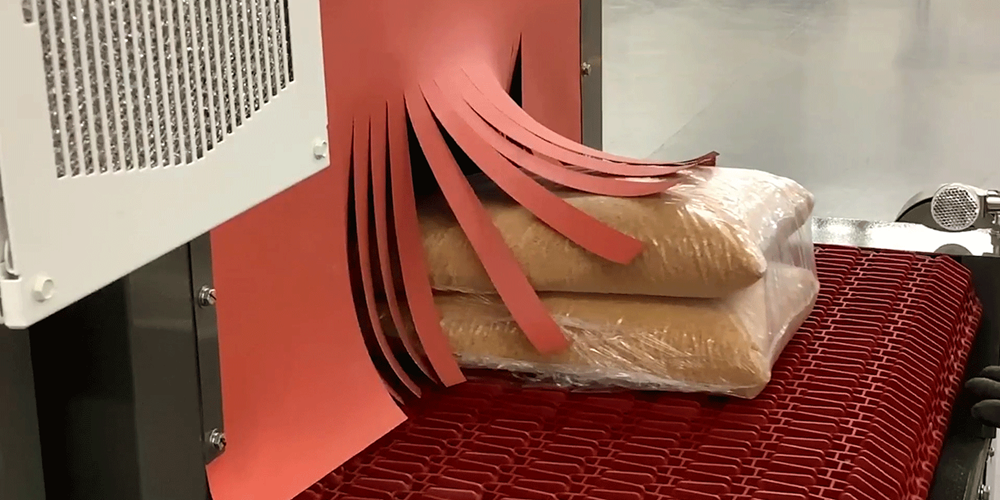

Nigrelli FlexWrap Shrink Bundlers

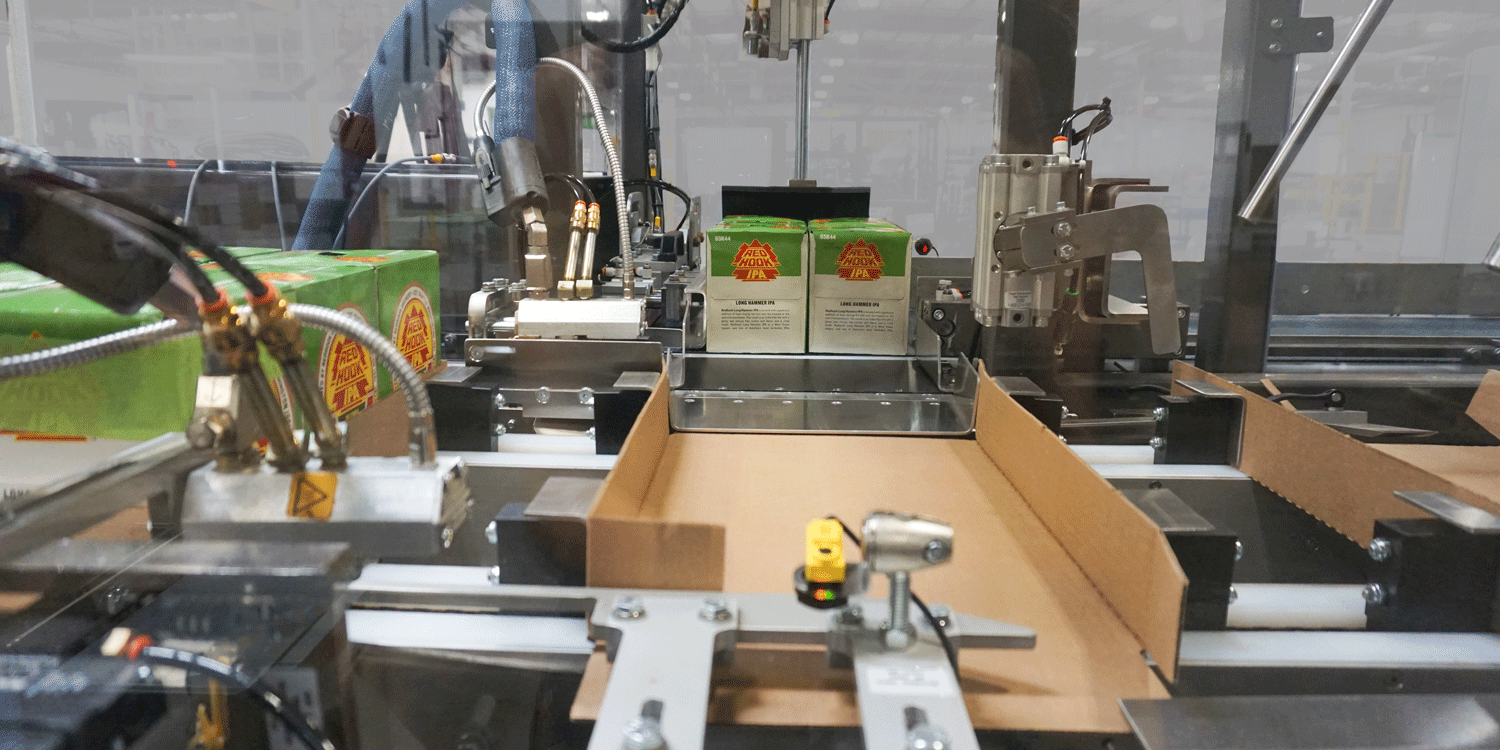

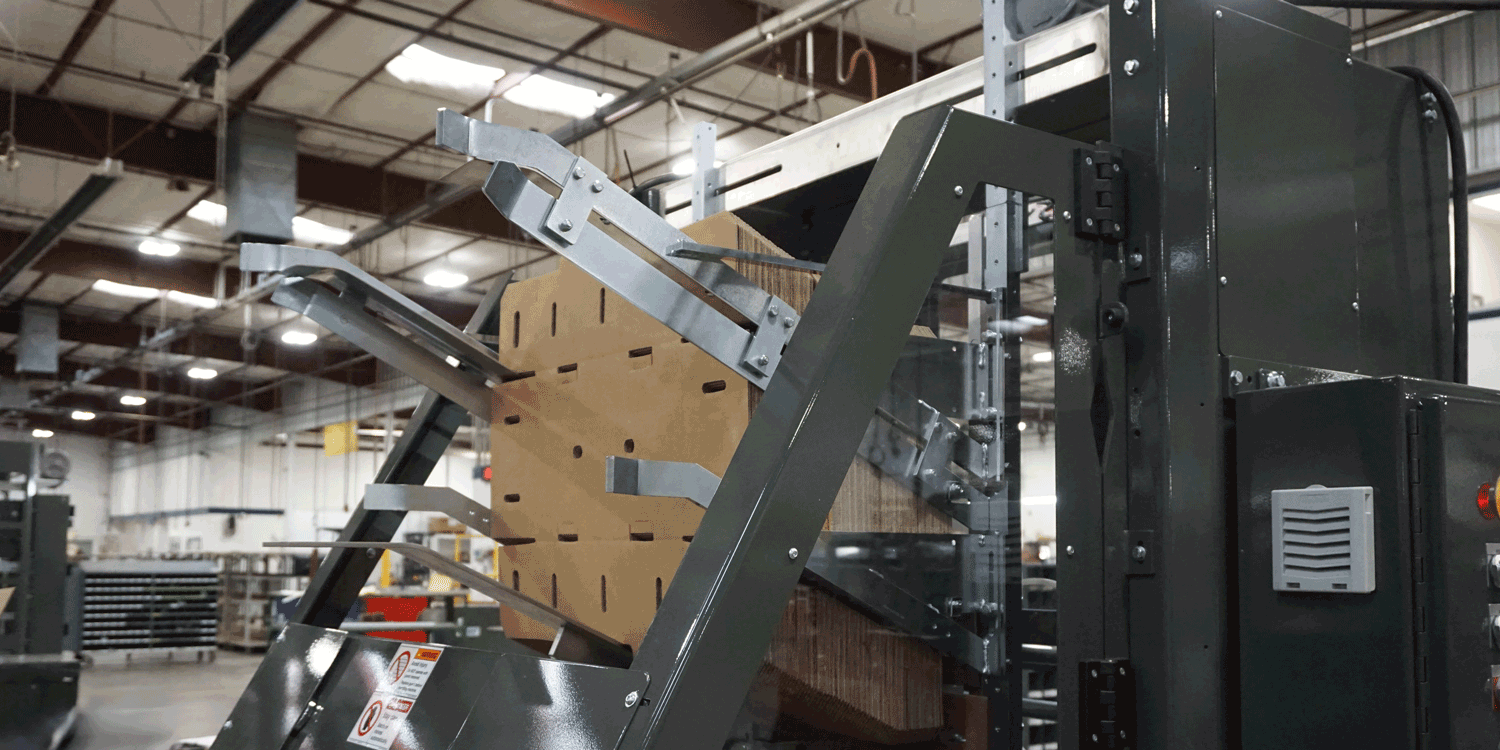

Shrink bundling is an incredibly effective process for packaging that combines multiple products and shrink-wraps them, providing an enhanced layer of protection. At Nigrelli, we offer two cutting-edge solutions: the FlexWrap IM Intermittent Motion and FlexWrap CM Continuous Motion Shrink Bundlers, designed to elevate your packaging operations and streamline production.

FlexWrap IM Shrink Bundlers

Our FlexWrap IM Shrink Bundlers are equipped with the most versatile technologies in the packaging industry. These systems feature customized infeed and collating solutions tailored to meet your unique requirements, ensuring efficient product handling and packaging. The integrated shrink tunnel is engineered to minimize heat loss and maximize oven efficiency, featuring 6” high-temperature insulation and a bank of nine heaters, six of which utilize automatic thermocouple control for intelligent heat regulation. Our exclusive free-air-flow feature allows hot air to circulate uniformly around each bundle, resulting in a tighter, more consistent shrink while conserving energy.

FlexWrap CM Shrink Bundlers

Our FlexWrap CM Continuous Motion Shrink Bundlers offer innovative features designed to boost production rates and simplify machine operation for those looking to optimize continuous operations. These bundlers, when paired with sturdy corrugated trays, provide exceptional stability for heavier items like canned goods, making them perfect for efficient stacking, palletizing, and distribution to consumer outlets.

Revolutionize Your Operations

Experience cutting-edge control with our “Plus” Control System, featuring a state-of-the-art Programmable Logic Controller (PLC) and an intuitive Human-Machine Interface (HMI). This system allows you to monitor production rates in real-time, receive updates on machine faults, and maintain complete control over your operations. The side-mounted dual film cradle with a tool-less centering device simplifies film loading and adjustments, ensuring precise film positioning for flawless results.

Our servo-driven seal bar carriage achieves optimal speed with adjustable precision via the user-friendly HMI, which minimizes downtime due to damaged seal bars. The innovative “quick-change” seal bar design allows for hassle-free removal and replacement in under three minutes, ensuring your operations run smoothly.

Efficiency is further enhanced with our energy-efficient shrink tunnel. Featuring 6” high-temperature insulation, external adjustment knobs for airflow baffles, and variable-speed oven fans, our shrink tunnel guarantees tight bundles with a uniform shrink every time.

Choose Nigrelli’s shrink bundling solutions to enhance your packaging process, reduce waste, and improve overall productivity. Contact us today to learn more about how our advanced technologies can transform your manufacturing operations!

Key Features

FlexWrap IM

- Hot knife sealing bar system

- Positive film feed with dual roll holders for easy film changeover

- Allen-Bradley Logix Series PLC

- Watlow electronic temperature control

- Allen-Bradley PanelView HMI

- Energy saving heat tunnel

- Available with inline or perpendicular infeed

FlexWrap CM

- CM (Continuous Motion) overwrap system provides maximum production speed

- Automatic degrouping system includes tool-less adjustable flight lug spacing

- Servo-driven seal bar carriage with quick-change, adjustable height seal bar

- On-the-fly adjustments through workstation touchscreen

- PLC control system with diagnostic display panel

- Positive film feed with dual rollers for easy film changeover

Technical Data

Available Options

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...