Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

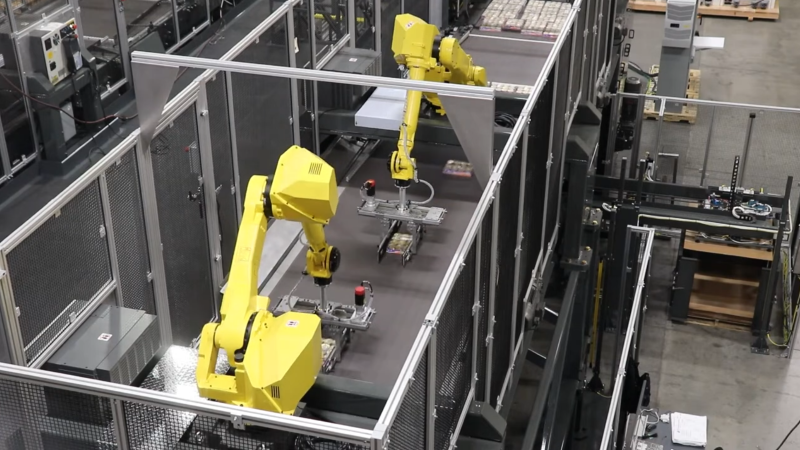

Stact Robomax High Speed Case Palletizer

Discover the future of case palletizing with the Stact RoboMax Automatic High-Speed Case Palletizers. Designed to modernize your palletizing operations, our advanced robotic system replaces outdated lane dividers, case-turning conveyors, and bumpers. Enjoy a low-maintenance, high-efficiency solution that guarantees seamless operation on a continuous mat top belt, significantly enhancing your productivity.

With the flexibility to operate one or two robots, the RoboMax ensures precise positioning and turning of each case, bundle, or tray. This innovative design guarantees perfect layer formation every time, making it suitable for a wide array of packaging needs.

Unlock Limitless Possibilities with Robotic Technology

Experience the full potential of robotic automation in your facility! The RoboMax offers virtually limitless palletizing pattern combinations, allowing you to customize the process to fit your specific requirements. Designed to handle a diverse range of products—from cases and shrink-wrapped trays to plastic shells and bundles—our robots provide a notable reduction in maintenance compared to traditional inline case palletizers.

Boost Efficiency and Maintain Quality

The Stact RoboMax operates at impressive speeds of up to 35 cases per minute per robot. Depending on case size, you can even pair robots for increased throughput, amplifying your efficiency without compromising on quality.

Transform your packaging line with the Stact RoboMax Automatic High-Speed Case Palletizers—where cutting-edge technology meets reliability and performance. Optimize your palletizing process and ensure your delicate products are handled with care.

Contact Us Now! For more information on how our innovative solutions can elevate your packaging operations and drive efficiency in your facility.

Key Features

- Proper and consistent product feeding with the help of our brake and metering belt

- Witness the efficiency of our two robots as they position and/or turn each case, bundle, or tray into the perfect position for layer formation

- Smooth product handling with our mat top layer forming conveyor

- Perfect layer squaring with our split apron plate with four-sided layer squaring

- Say goodbye to hydraulics with our electric hoist

- Four, RC80 (1” pitch) chains, with 3,300 lb (1,500 kg) capacity

- Our high-cycle brake motor guarantees a reliable and long-lasting performance

- Experience precise control with our VFD-controlled hoist

- Benefit from the convenience of our pivoting empty pallet stops

- Simplify your operations with our empty pallet dispenser

Technical Data

Available Options

- Fork style empty pallet dispenser

- Handle different pallet sizes with our multi-chain pallet conveyors

- Pallet conveyors for additional empty pallet stack staging

- Product Builder software

Packaging Styles

Jump to...

Markets

Contact Us

Jump to...

Markets

Contact Us

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

5605 Goldco Dr

Loveland CO 80538

US -

+1 (970) 663-4770 -

+1 (800) 248-0605 (Customer Service) -

+1 (800) 248-0605 (Field Service)