Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Integrated Systems’ product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

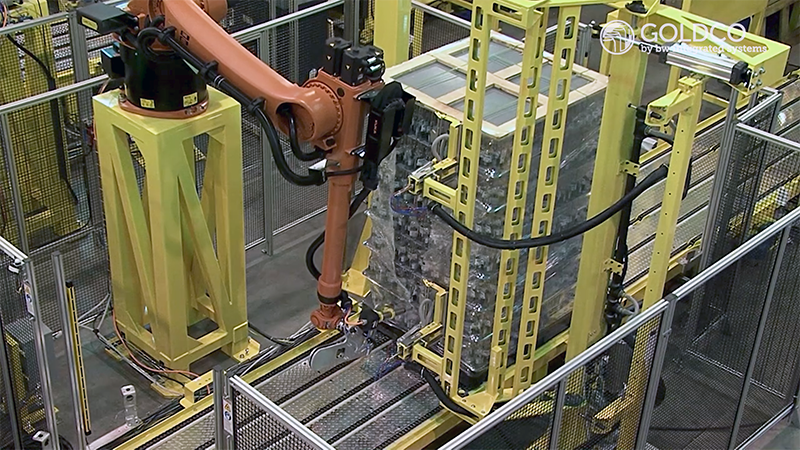

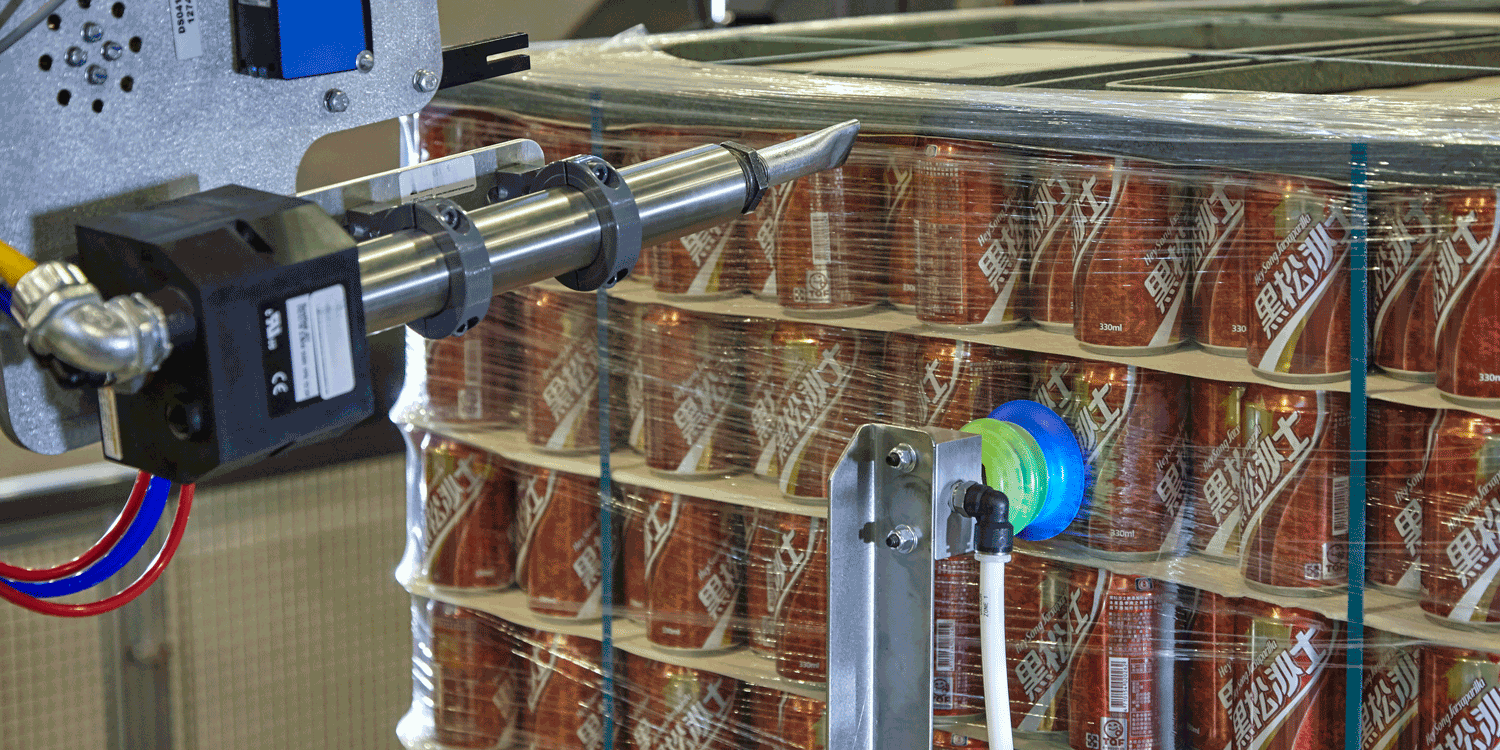

Goldco Robotic Unwrapper

Goldco Robotic Unwrappers, your ultimate solution for efficiently removing stretch and shrink wrap from pallet loads before depalletizing. Engineered for versatility, our Unwrapper can handle a wide range of loads, including bulk glass or plastic bottles, aluminum or steel cans, and stacked cases or stretch-wrapped bundles.

Tailored Wrap Removal Solutions

We understand that not all types of wrap can be treated the same way. That's why we offer two specialized applications to meet your unique wrap removal needs:

- Standard Stretch Wrap Unwrapper: Ideal for handling stretch wrap with ease

- Fully Featured Unwrapper: Capable of removing both stretch and shrink wrap from pallet loads, providing greater flexibility for different packaging types

Advanced Technology for Efficient Unwrapping

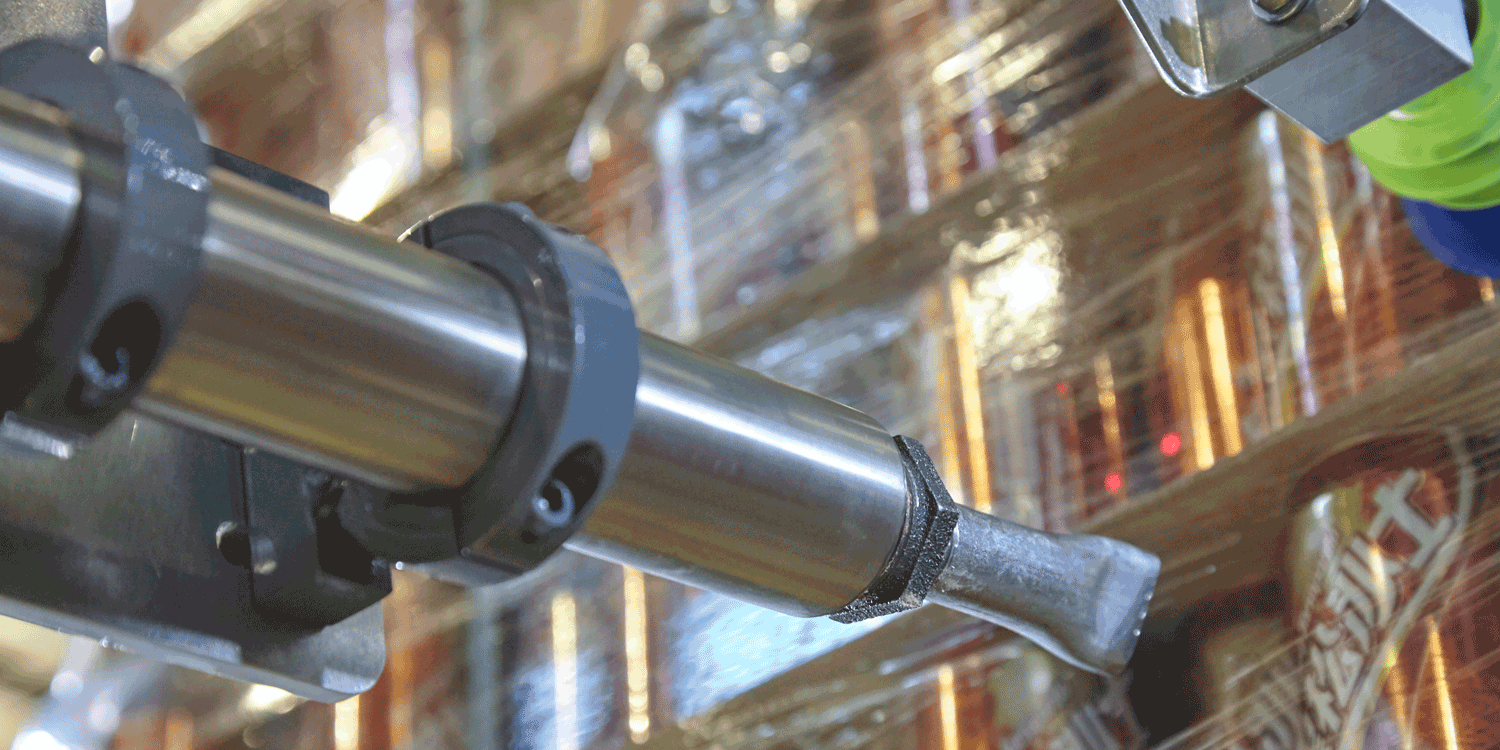

Our Unwrapper employs a focused hot air gun, also known as a heat gun, to direct a stream of hot air onto the wrap, facilitating quick and efficient removal. Once the wrap is detached, it is funneled into a pinch roller assembly that pulls the material through to one of several post-unwrapping disposal options. Choose from simple bins, integrated vacuum pipe systems, or bailers for effective wrap disposal.

For high-volume operations, multiple Unwrappers can efficiently feed into a common bailer, making it easy to streamline processes across multiple lines.

Upgrade your packaging operations with the Goldco Robotic Unwrapper – where efficiency meets reliability in pallet unwinding. Contact us today to find out how we can help enhance your production line!

Key Features

- Manual unwrapping of loads is eliminated which removes the need for ladders, the risk of static electric shock from handling the wrap and physical straining

- Minimal floor space required

- Reduced maintenance due to fewer moving parts versus traditional fixed automation unwrapping systems\

- Robotic solutions allow for greater flexibility with incoming pallet quality

Technical Data

STRETCH-WRAPPED BULK AND CASE PRODUCT QUALIFIERS

- Pallet orientation into machine: narrow or wide-way leading (must be specified)

- Load height: 120” [3048mm] max

- Load not to exceed 1.5” [38.10mm] for bulk product and 5” [127mm] for case or bundled product - out of plumb in any direction

- Shrink bag nominal thickness to be 4 mils

- Layer to layer offset for case/bundled loads not to exceed 0.75” [19.05mm]

- Total accumulative wrap thickness with 80 gauge film (0.80 mils) - 2 wraps min 0.0012” [0.03048mm] - 4 wraps max 0.0024 [0.06096mm]

- Wrap must be uniform; no gaps, holes, or bunching

Available Options

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

5605 Goldco Dr

Loveland CO 80538

US -

+1 (970) 663-4770 -

+1 (800) 248-0605 (Customer Service) -

+1 (800) 248-0605 (Field Service)

Jump to...

Jump to...