Products and Solutions

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

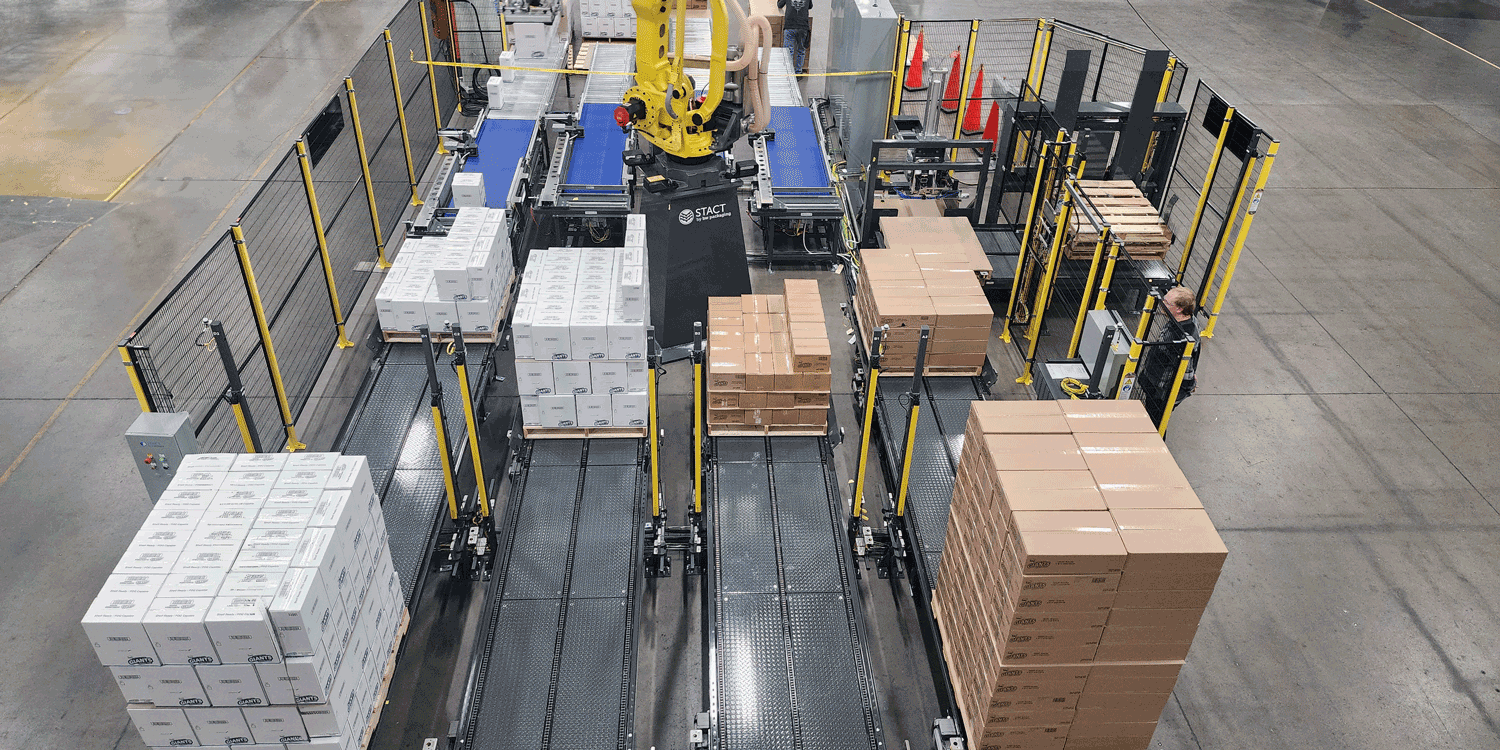

Stact Maximus Case Palletizer

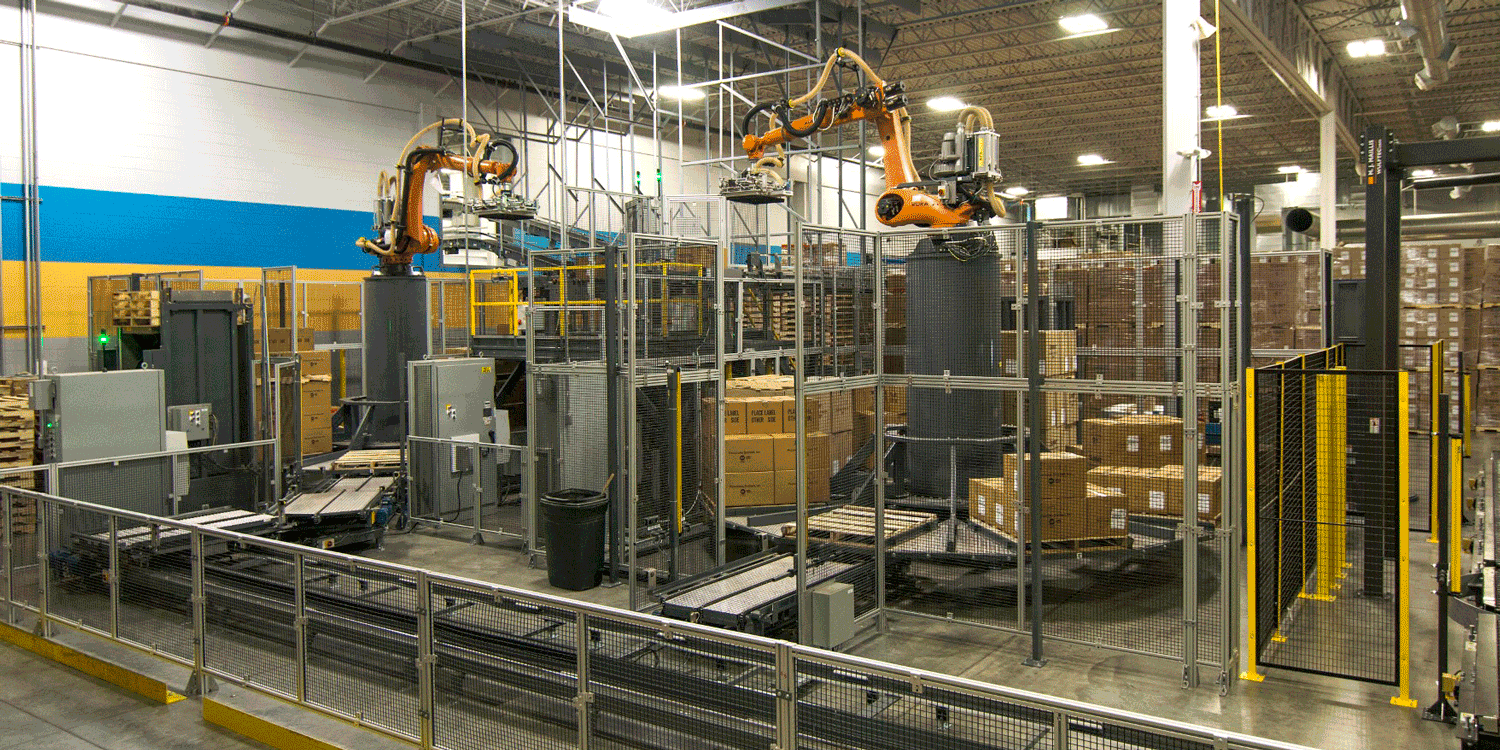

In today's competitive market, efficiency and flexibility are paramount. Introducing the Maximus Series—a revolutionary high-level case palletizer meticulously designed to meet evolving market demands. With its compact design and advanced technology, Maximus stands out as a leader in palletizing solutions.

Engineered by top industry experts and informed by valuable customer feedback, the Maximus Series integrates cutting-edge layer forming technology to optimize your palletizing process. Its compact footprint makes it an ideal choice for various mid-speed palletizing markets, particularly in the food, household, chemical, personal care, and beverage industries.

User-Friendly and Easy to Maintain

At the core of the Maximus design is a commitment to user accessibility. We understand the importance of maintenance, which is why our palletizer features systems that are incredibly easy to access. The quick vertical start-up philosophy allows you to get your operations up and running in no time, minimizing downtime and maximizing productivity.

Designed with convenience in mind, the Maximus palletizer can be easily split for shipping, facilitating passage through standard doorways. Once on your production floor, reassembly is straightforward—simply place the top frame onto the base frame using our innovative bolt-together construction and quick disconnect controls.

Efficient and Accurate Palletizing Process

The operational efficiency of Maximus begins when cases enter through the infeed conveyor. From there, cases are expertly routed to the layer forming section, where they're compacted to create tight product patterns. Our advanced system levels pallets under the apron, ensuring precise load building while pre-positioning empty pallets. This significantly reduces pallet exchange time, enhancing your overall productivity. The palletized loads then exit seamlessly via the discharge conveyor, completing a highly efficient product handling cycle.

Transform your palletizing process with the Maximus Series. Experience enhanced flexibility, compact design, and unparalleled efficiency—all while enjoying simple maintenance and quick setup. Join the growing number of industries optimizing their palletizing technology with Maximus. Contact us today to learn more!

Key Features

- Quicker vertical start-up with our unique split-for-ship feature

- State-of-the-art operator interface, equipped with pattern building software and visually guided fault recovery

- Versatile pattern forming capabilities for a wide range of products or SKUs

- Monitor machine operations with ease, thanks to our clean and open design that offers greater visibility

- Easily accommodates most end-of-line layouts

- Fully automated integrated pallet dispenser

- Pack ML enabled

Technical Data

Available Options

- Layer table

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1305 Lakeview Dr

Romeoville IL 60446

US -

+1 (630) 759-6800 -

+1 (800) 527-0494 (Customer Service) -

+1 (800) 527-0494 (Field Service)

-

5605 Goldco Dr

Loveland CO 80538

US -

+1 (970) 663-4770 -

+1 (800) 248-0605 (Customer Service) -

+1 (800) 248-0605 (Field Service)

-

Plumtree Farm Industrial Estate, Bircotes

Doncaster DN11 8EW

GB -

+44 (0) 1302 711056 -

+44 (0) 1302 718335 (Customer Service) -

+44 (0) 1302 711056 (Field Service)

Jump to...

Jump to...