Products and Solutions

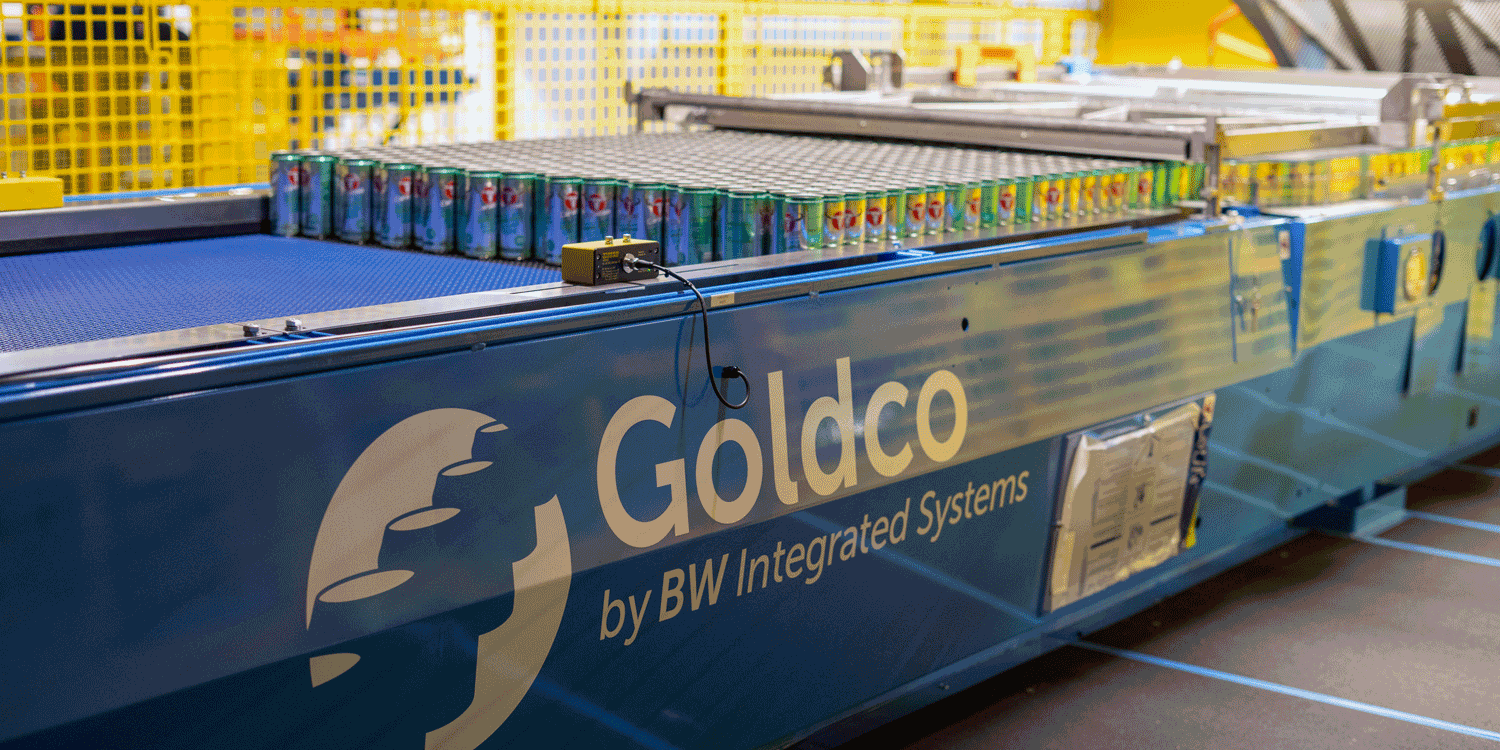

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

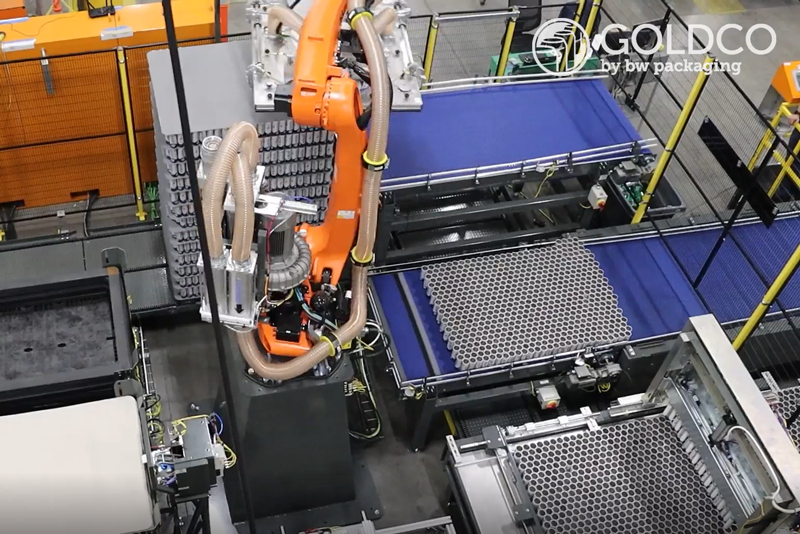

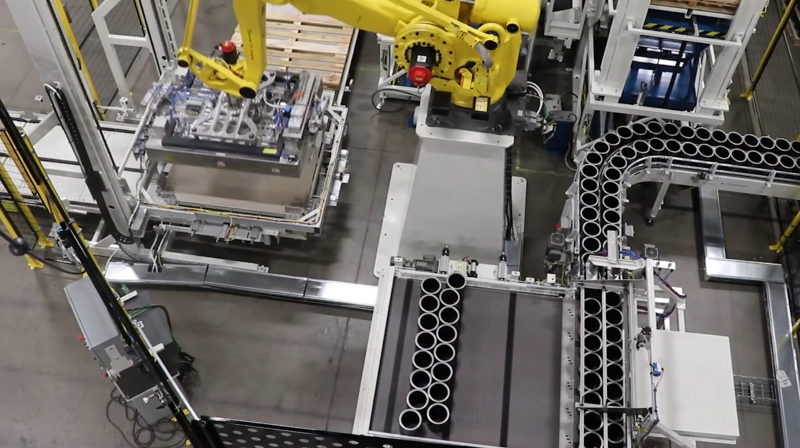

Goldco Robotic Bulk Palletizer

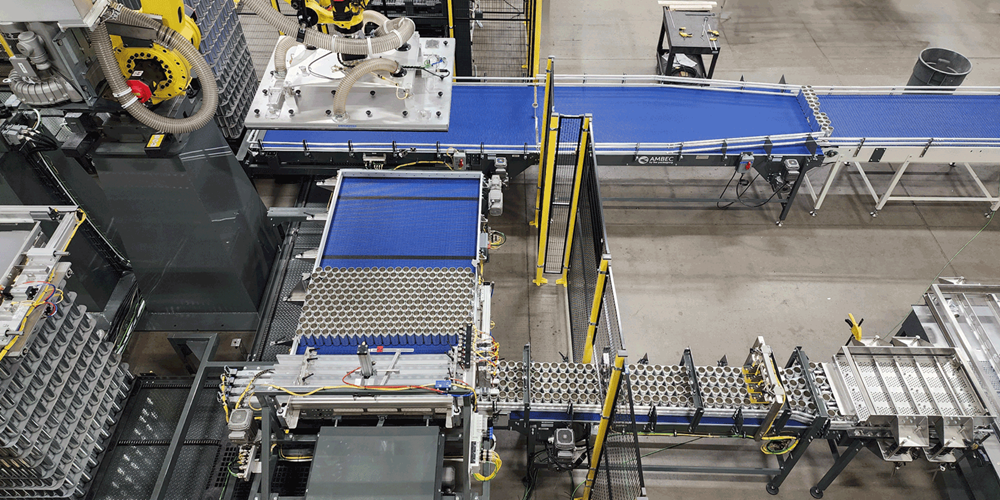

Goldco’s innovative Robotic Bulk Palletizers are designed to transform the perception of traditional high-level fixed automation in the packaging industry. By integrating cutting-edge technology at floor level, we are ushering in a new era of operational efficiency.

Streamlined Sequence of Operation

Our robotic bulk palletizer specializes in automating pallet loading processes. The operation begins with the robot picking up a layer pad, followed by an empty pallet, which is then carefully positioned on top of the layer pad. With unmatched precision, the robot places the empty pallet onto the load-building conveyor, ensuring proper alignment.

Next, the robot picks up another layer pad and initiates the stacking process, lifting the first layer of products and placing them onto the pallet, all while maintaining squareness for an optimal load. This meticulous layering process continues until the complete load is assembled. Upon completion, the squaring mechanism is activated, and the finished load is discharged seamlessly.

Optimize your production line with Goldco’s Robotic Bulk Palletizers, engineered to handle a diverse range of specialty, general purpose, and food container products. Elevate your efficiency and productivity today!

Key Features

- Flexible palletizing cell - quick resulting in reliable can size changeovers

- Stationary load building - pallet does not lower for each layer eliminating disruption to previously palletized layers

- Cost-effective alternative over conventional “high-level” palletizers

- Our can infeed locations offer flexibility, allowing you to have them at floor level for easy access and visibility to palletizing functions, or raised to accommodate foot traffic under the can line

Technical Data

Available Options

- Capable of accommodating multiple pallet sizes

- Filled steel can capability

- Separate handling for pallets, layer pads, and top frames for higher output lines

- Indexing layer centering assembly for straight square pallet loads - holds existing layer while next layer is placed on layer pad

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

5605 Goldco Dr

Loveland CO 80538

US -

+1 (970) 663-4770 -

+1 (800) 248-0605 (Customer Service) -

+1 (800) 248-0605 (Field Service)

-

Plumtree Farm Industrial Estate, Bircotes

Doncaster DN11 8EW

GB -

+44 (0) 1302 711056 -

+44 (0) 1302 718335 (Customer Service) -

+44 (0) 1302 711056 (Field Service)

Jump to...

Jump to...